High temperature thermal energy storage system

a technology of thermal energy storage and high temperature, which is applied in the direction of indirect heat exchangers, machines/engines, light and heating equipment, etc., can solve the problems of fracture and gravelization of the pcm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

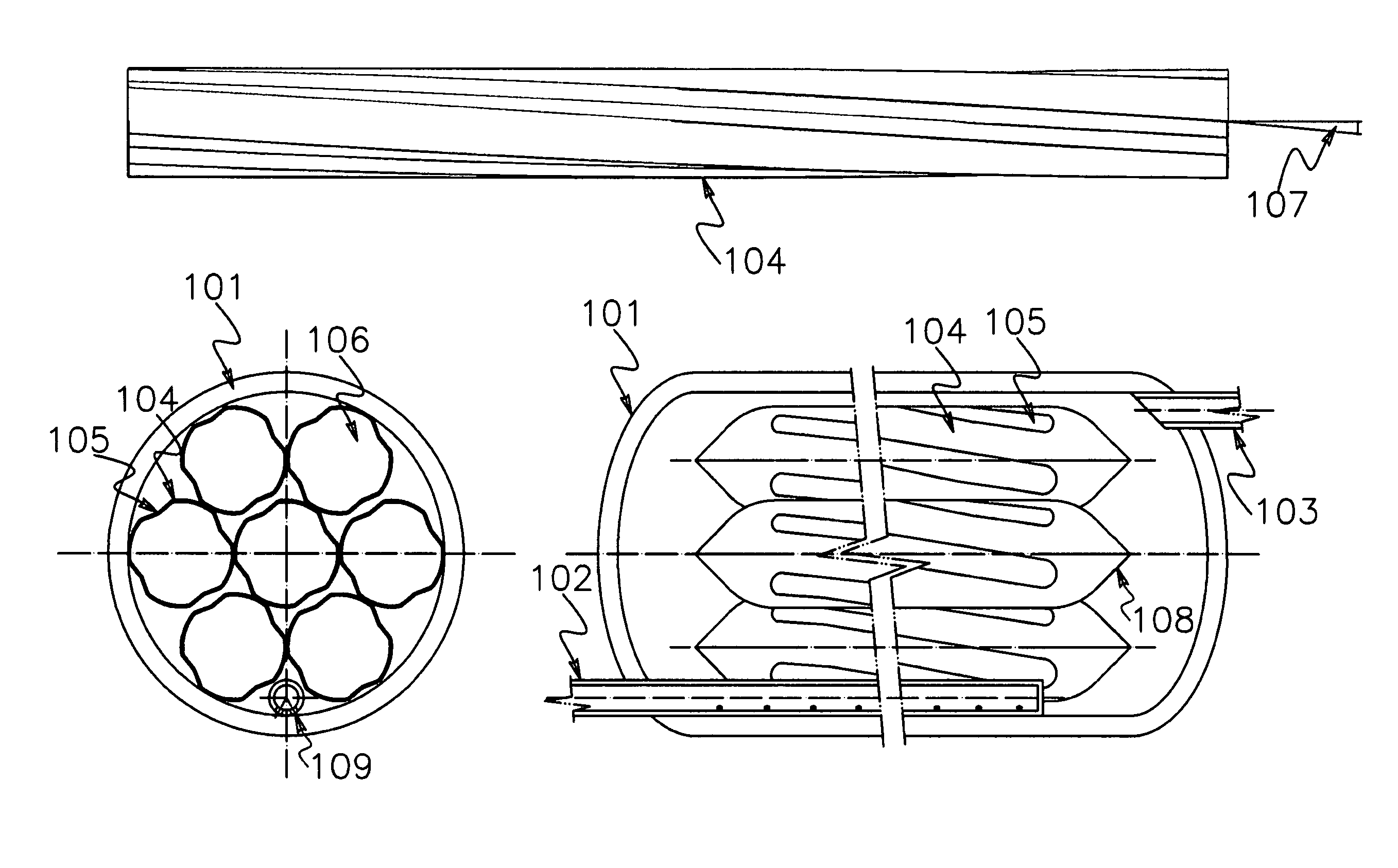

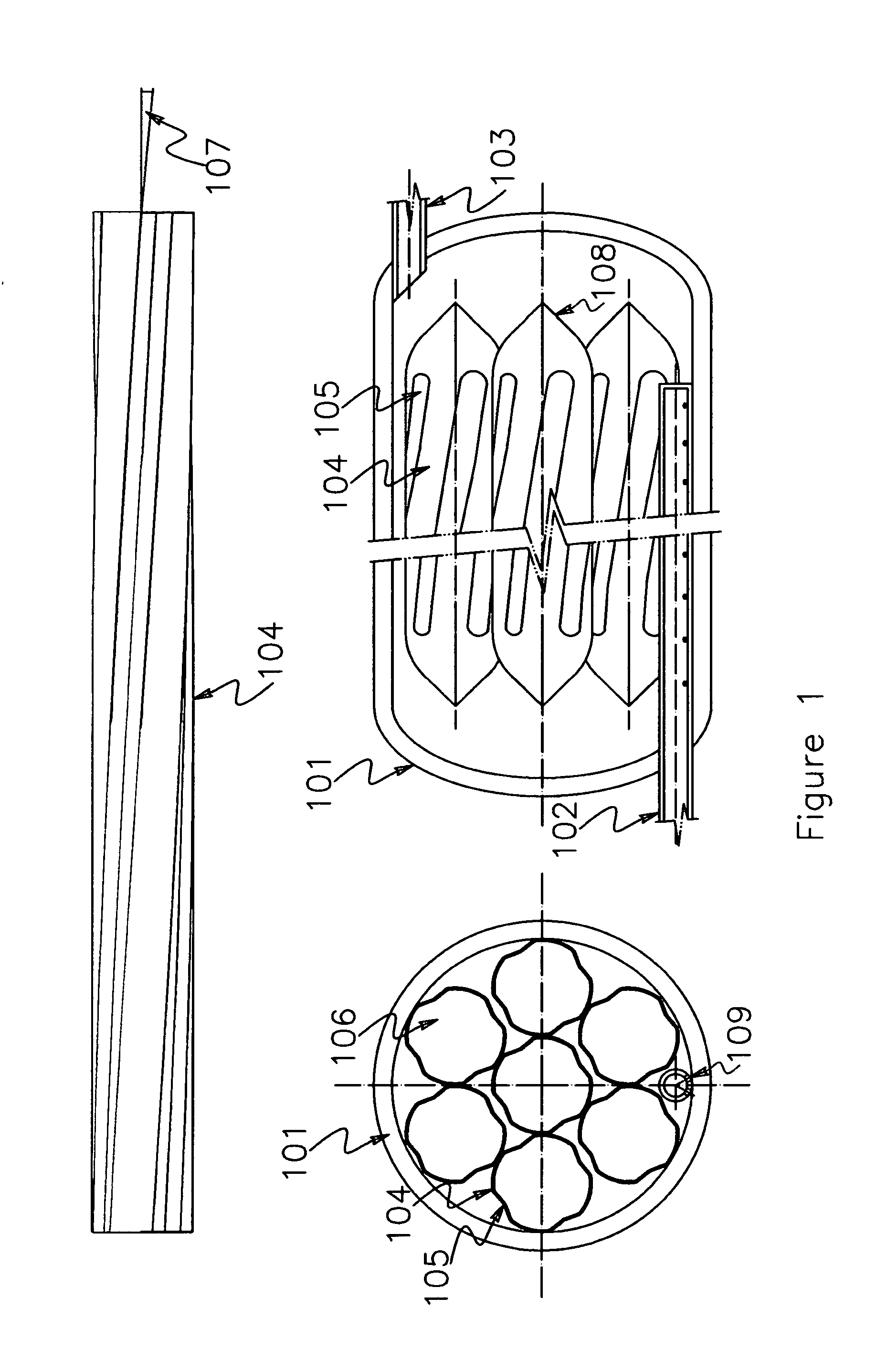

[0018]Referring now to the drawings, in which like numerals indicate like elements throughout the several views, FIG. 1 depicts one embodiment of the helically grooved tube-capsules 104. The capsules may be formed from a thin wall metal tube by enrolling helical grooves along the length of the tubes or by extrusion or other metal forming procedure. The grooved tubes may resemble the rifled barrel of guns. The ratio of the length to the diameter of the tube is from 6 to 300. The angle 107 between the tangent of the helix of the grooves and the axis of the tube may be from 0 to 30 degrees. The shape of the profile of the groove 105 is curved that may be circular or oval. The number of the grooves on the tube may be from 2 to 12. The ratio of the depth of the groove to the diameter of the tube may be from 0.02 to 0.4. The purpose of the grooving is to provide radial and axial flexibility of the tube wall to accommodate the thermal expansion of the encapsulated phase change material. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com