Machining method of super-austenite stainless steel plate coil

A technology of austenitic stainless steel and processing method, which is applied in the field of metal pressure processing, can solve the problems of poor hot working performance, limited wide application and narrow hot working range, etc., and achieves the effect of improving the quality of the plate surface and the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

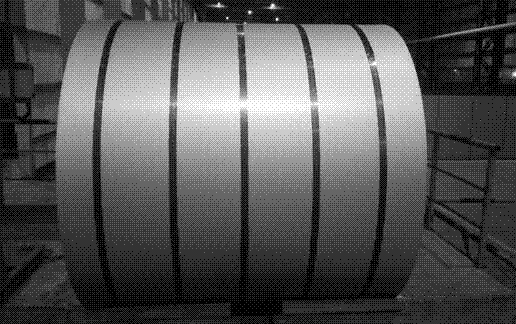

Image

Examples

Embodiment 1

[0026] The super austenitic stainless steel coils used in this example are composed by mass: C: 0.018%; Si: 0.45%; Mn: 1.35%; P: 0.025%; S: 0.0018%; N: 0.085%; Cr: 20.9 %; Cu: 1.35%; Mo: 4.23%; Ni: 24.5%; the balance is iron.

[0027] The rolling process route of the super austenitic stainless steel coil with a thickness of 5.85mm is grinding cast slab→heating→high pressure water dephosphorization→rough rolling→finish rolling→cooling→coiling→solid solution pickling.

[0028] (1) Grind the 180mm-thick billet through 26-mesh and 32-mesh grinding wheels respectively;

[0029] (2) After the slab is ground, it enters the heating furnace. It is heated in the preheating section for 56 minutes, heated to 1250°C in the soaking section, and the holding time in the soaking section is 60 minutes. The temperature of the upper surface of the slab is 10°C lower than that of the lower surface;

[0030] (3) After the cast slab is released from the furnace, it is dephosphorized by high-pressur...

Embodiment 2

[0036] The super austenitic stainless steel plate used in this example is composed by mass: C: 0.019%; Si: 0.48%; Mn: 1.45%; P: 0.029%; S: 0.0015%; N: 0.065%; Cr: 21.1% ; Cu: 1.36%; Mo: 4.25%; Ni: 24.3%; the balance is Fe.

[0037] The rolling process route of the super austenitic stainless steel coil with a thickness of 12mm is grinding cast slab→heating→high pressure water dephosphorization→rough rolling→finish rolling→cooling→coiling→solid solution pickling.

[0038] (1) Grind the 200mm-thick billet through 26-mesh and 32-mesh grinding wheels respectively;

[0039] (2) After the slab is ground, it enters the heating furnace. The heating time in the preheating section is 52 minutes, the soaking section is heated to 1220°C, and the soaking section is kept warm for 54 minutes. The temperature of the upper surface of the slab is 11°C lower than that of the lower surface;

[0040](3) After the cast slab is released from the furnace, it is dephosphorized by high-pressure water. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com