Self-feedback control method of gas dispenser

A control method and gas filling machine technology, applied in the container discharge method, container filling method, mechanical equipment, etc., can solve the problem of insufficient judgment and error correction ability, insufficient fault self-correction and judgment ability, and lack of internal gas filling machine Environmental adaptability of mechanical structure pipelines and other issues to achieve the effect of improving adaptability and realizing self-feedback control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

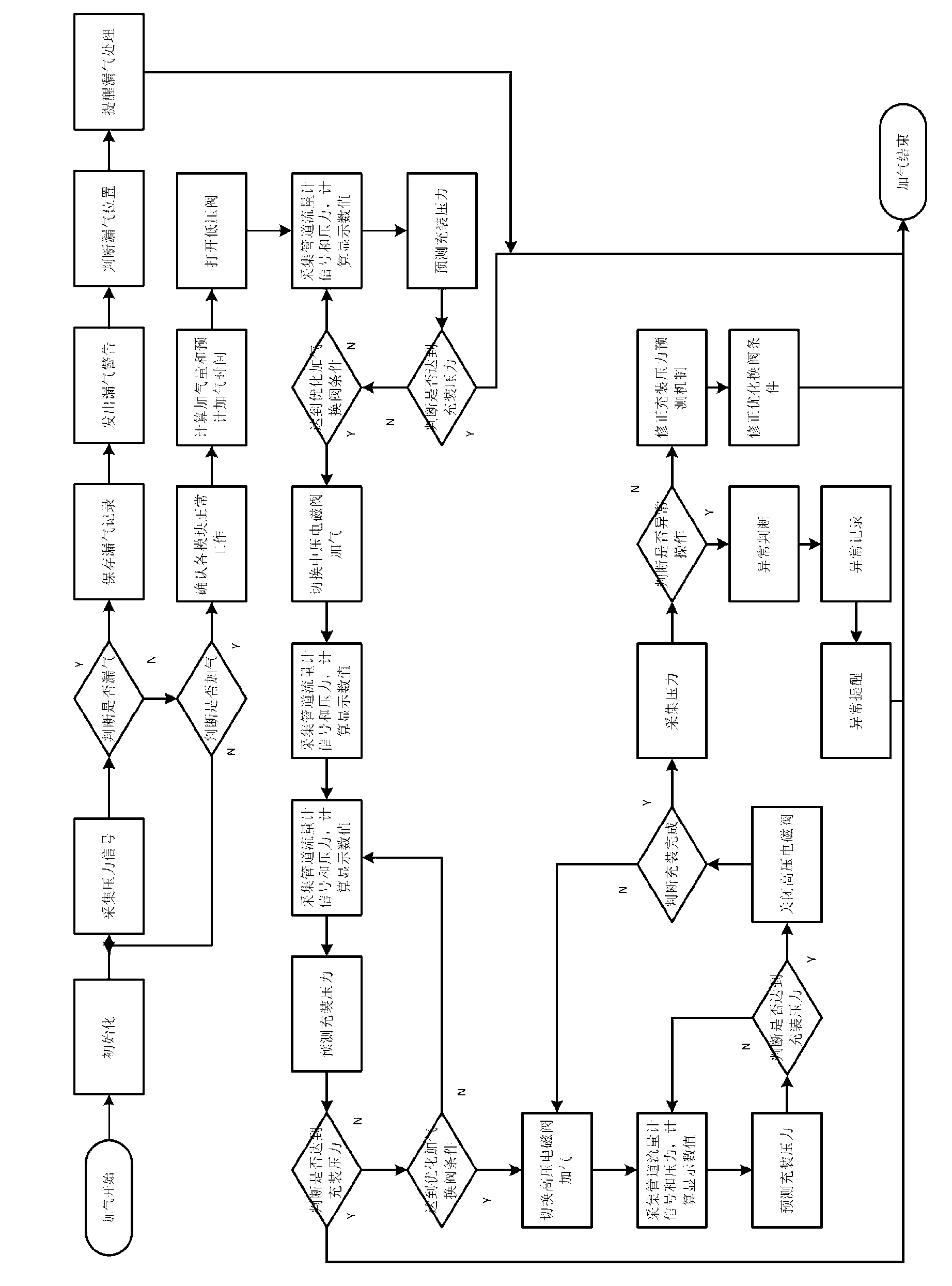

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0018] The present invention provides a kind of self-feedback control method of gas dispenser, comprising:

[0019] Step 1. Initialize the system, collect the pressure data detected by the pressure limiting sensor device every 0.5 minutes, and record them as Q1, Q2, Q3, Q4 respectively, according to the pressure data inside the gas dispenser pipeline detected by the pressure limiting sensor device Calculate the instantaneous pressure change rate Q, Q=(Q4+Ql-Q2-Q3) / 4, at this time, the low-pressure solenoid valve, medium-pressure solenoid valve and high-pressure solenoid valve are all closed, and the pressure inside the pipeline read by the pressure limiting sensor device When the instantaneous pressure change rate is greater than the set value, in order to avoid false alarms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com