Patents

Literature

40 results about "Cabin pressurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cabin pressurization is a process in which conditioned air is pumped into the cabin of an aircraft or spacecraft, in order to create a safe and comfortable environment for passengers and crew flying at high altitudes. For aircraft, this air is usually bled off from the gas turbine engines at the compressor stage, and for spacecraft, it is carried in high-pressure, often cryogenic tanks. The air is cooled, humidified, and mixed with recirculated air if necessary, before it is distributed to the cabin by one or more environmental control systems. The cabin pressure is regulated by the outflow valve.

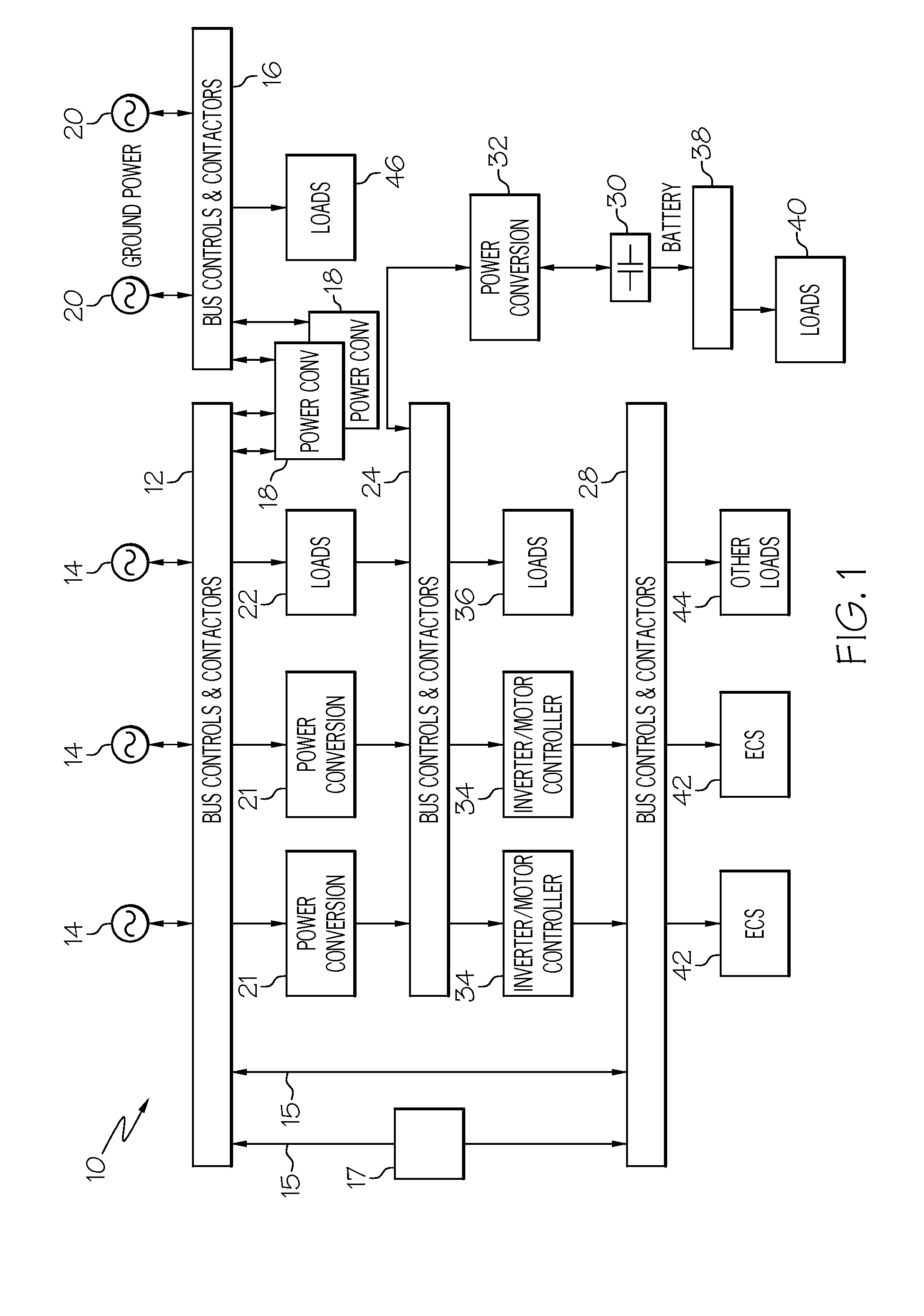

Integrated power and pressurization system

InactiveUS7578136B2Air-treatment apparatus arrangementsEnergy efficient board measuresNacelleEngineering

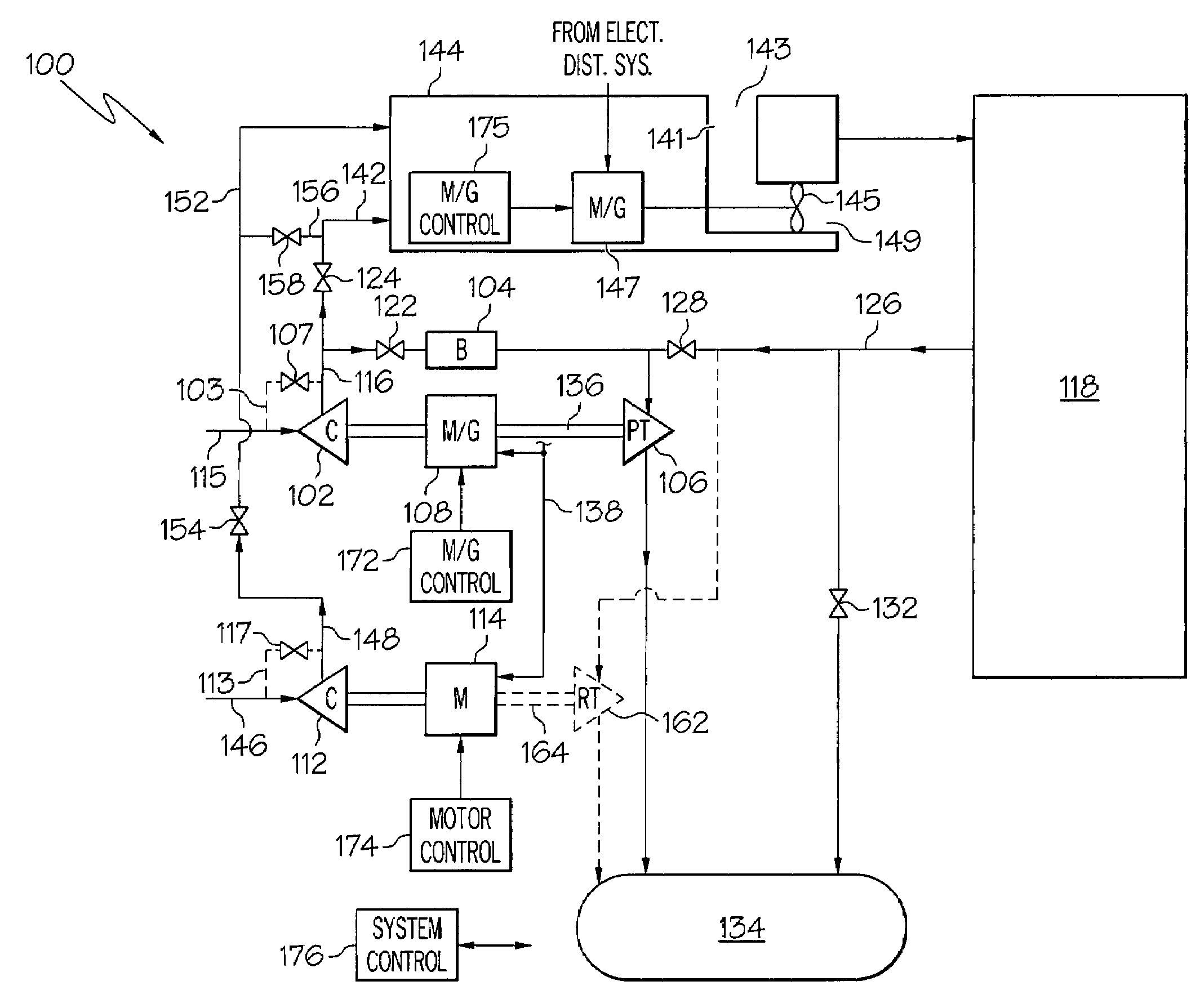

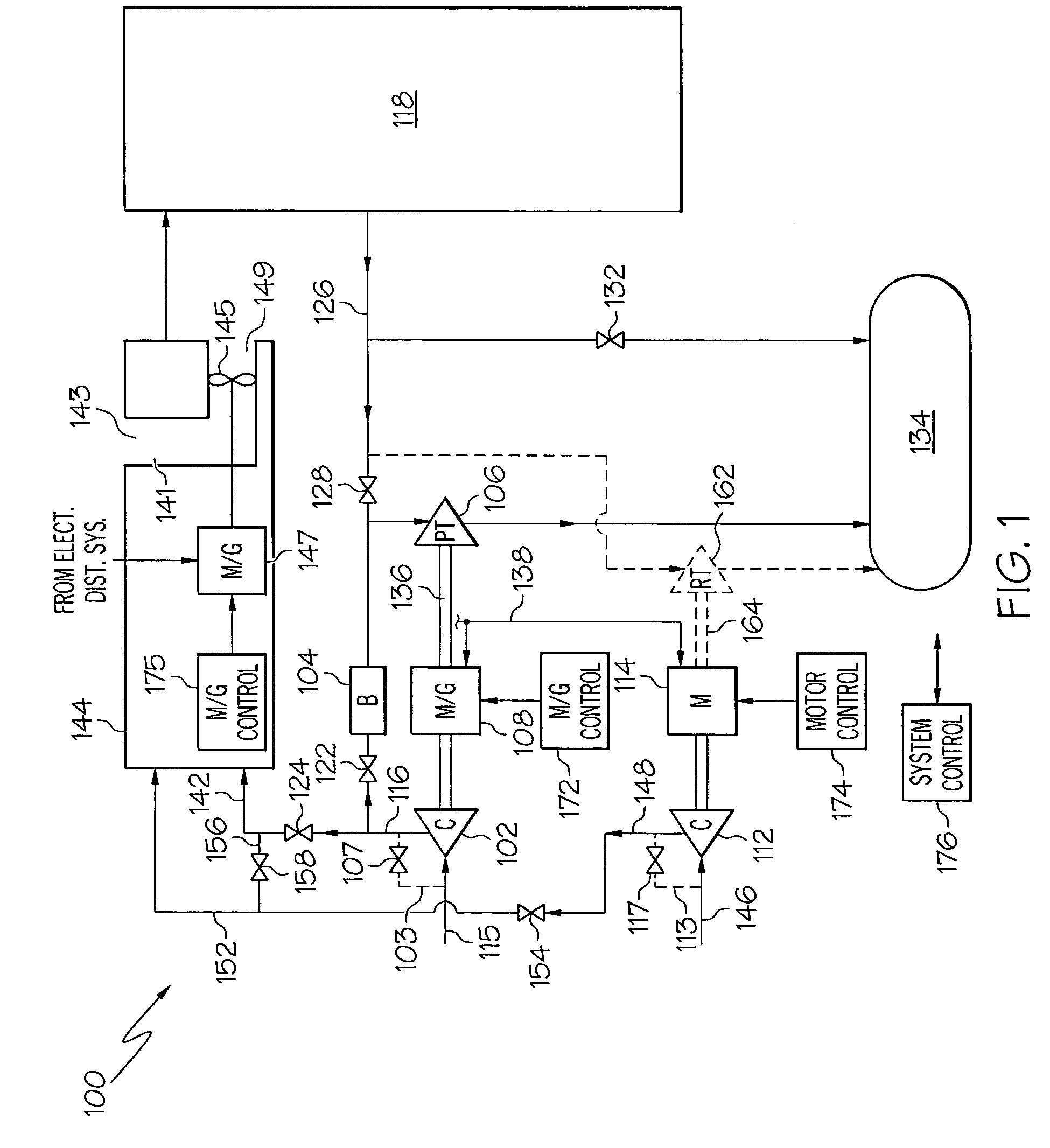

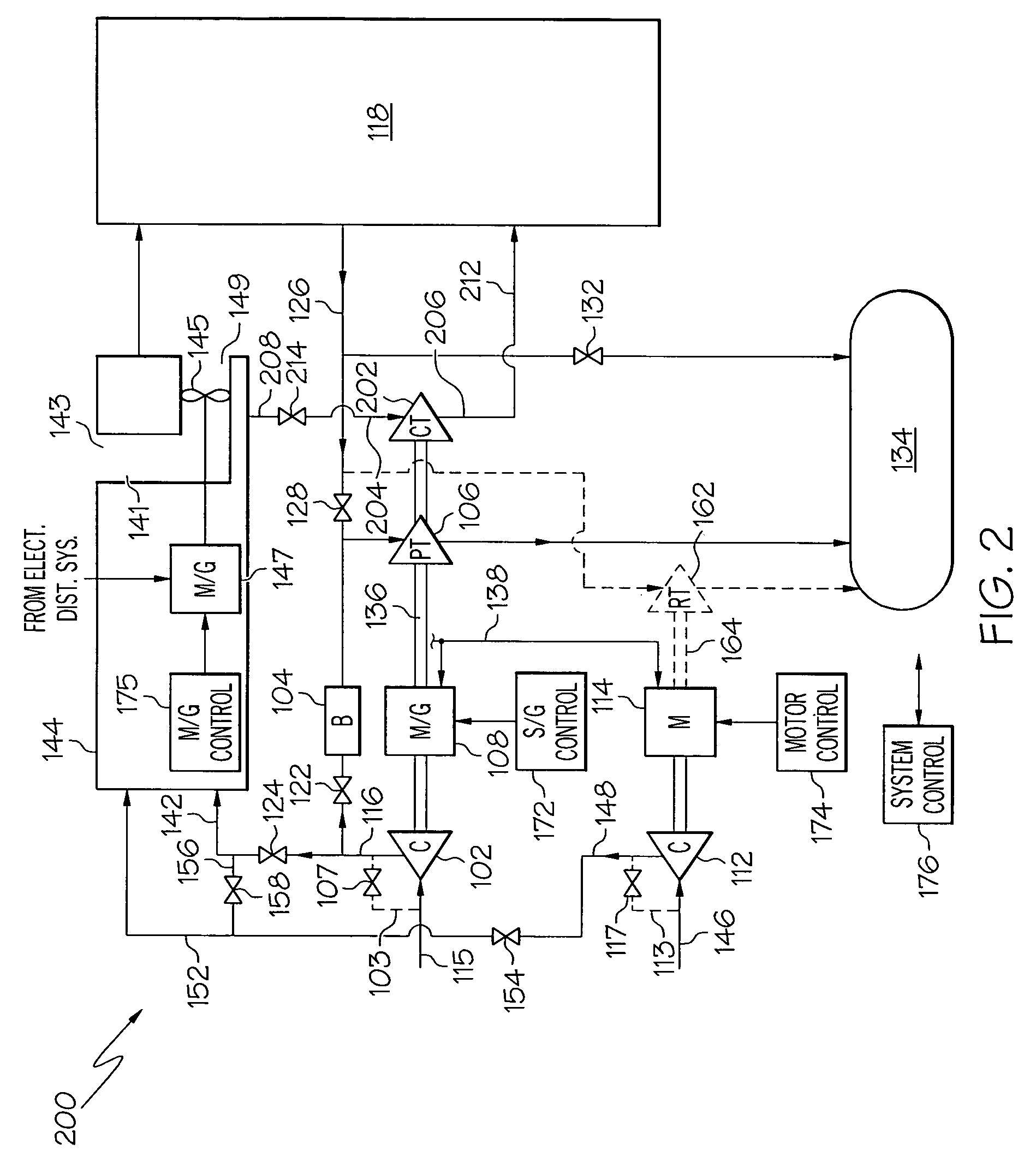

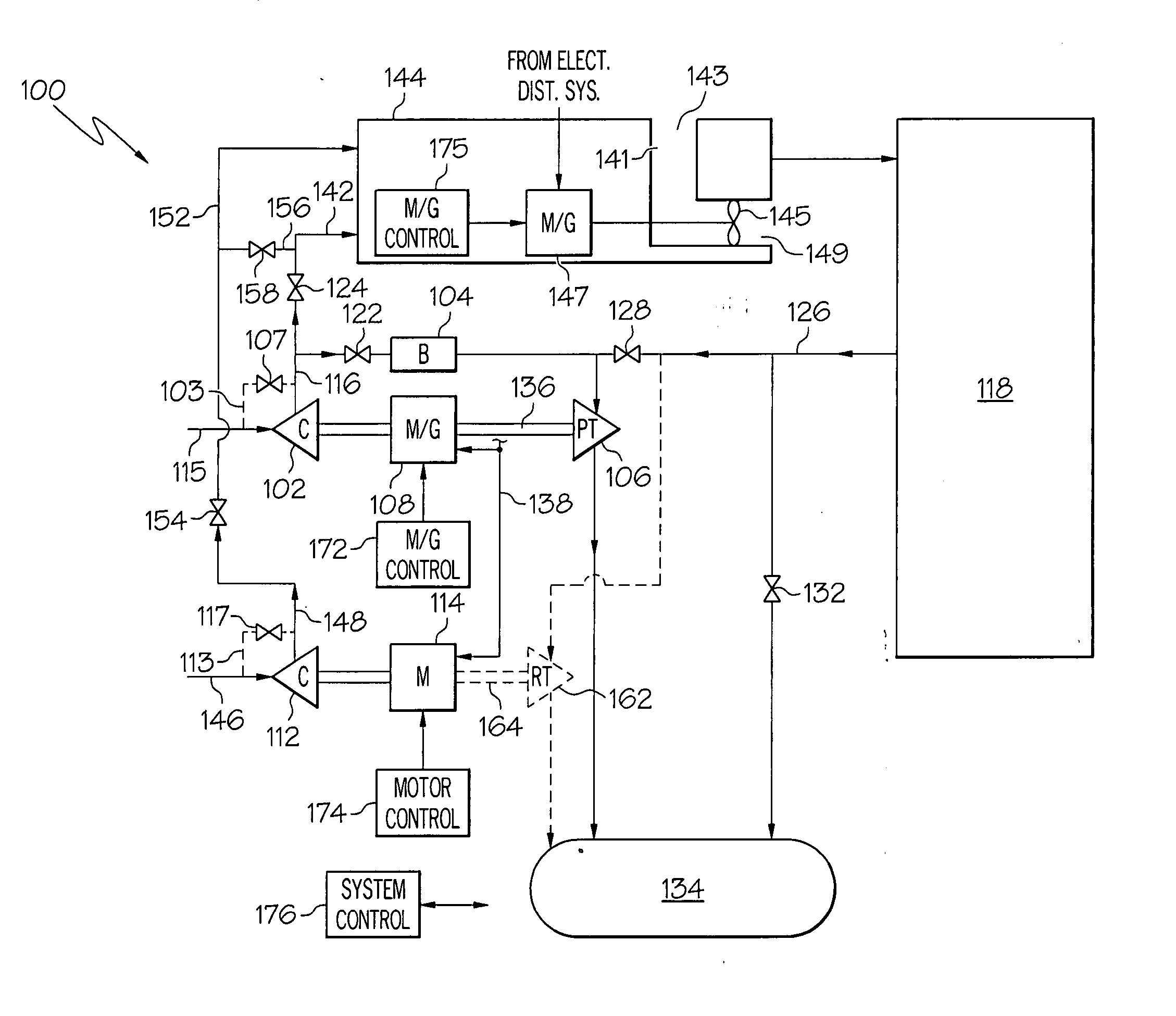

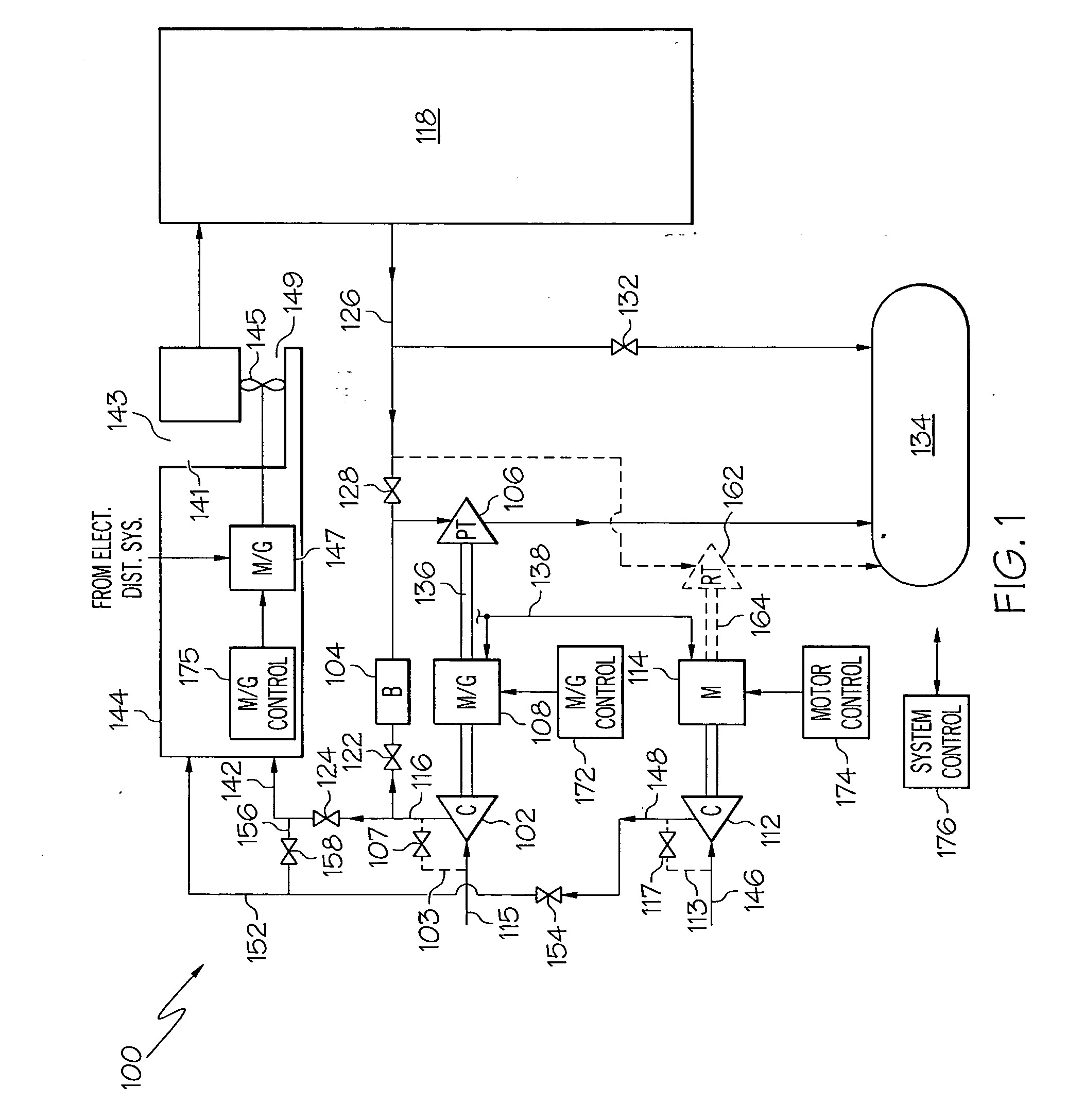

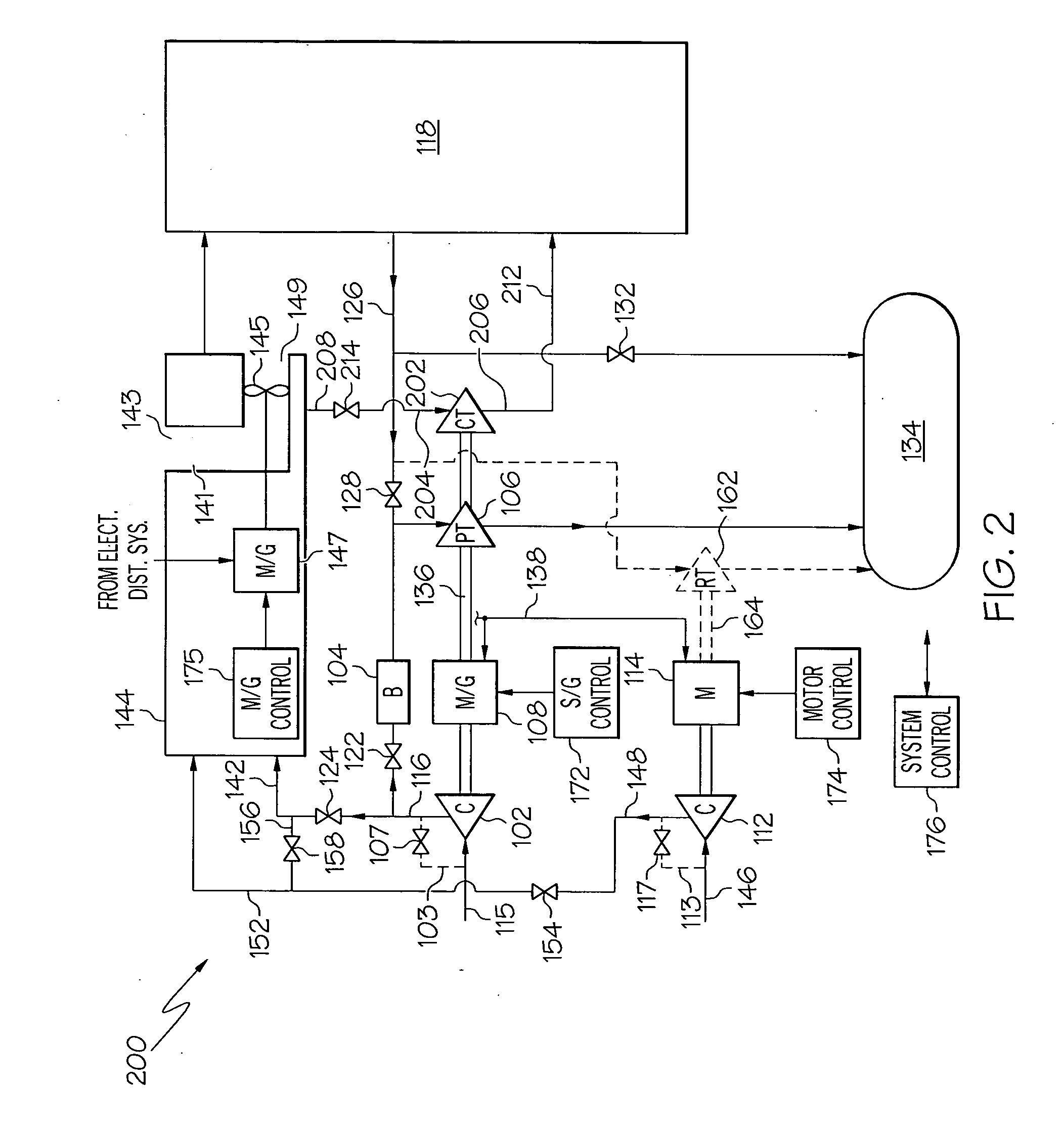

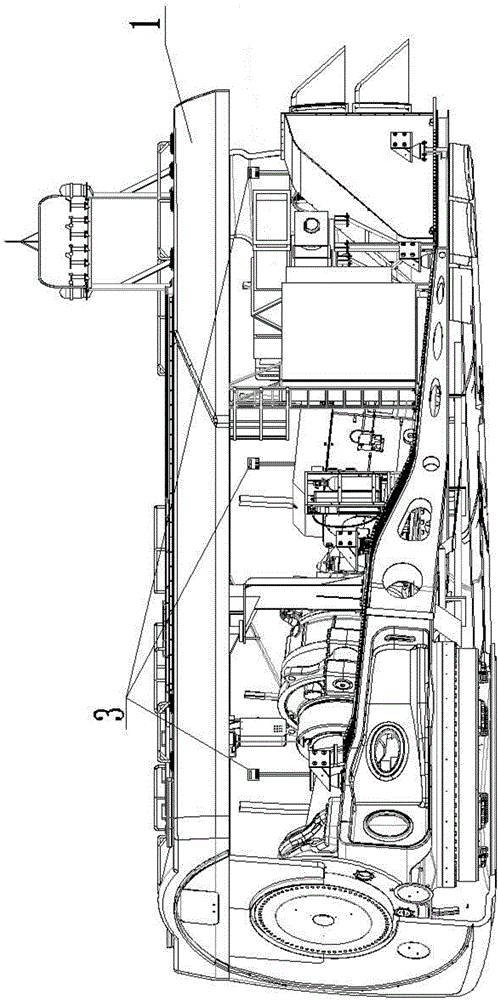

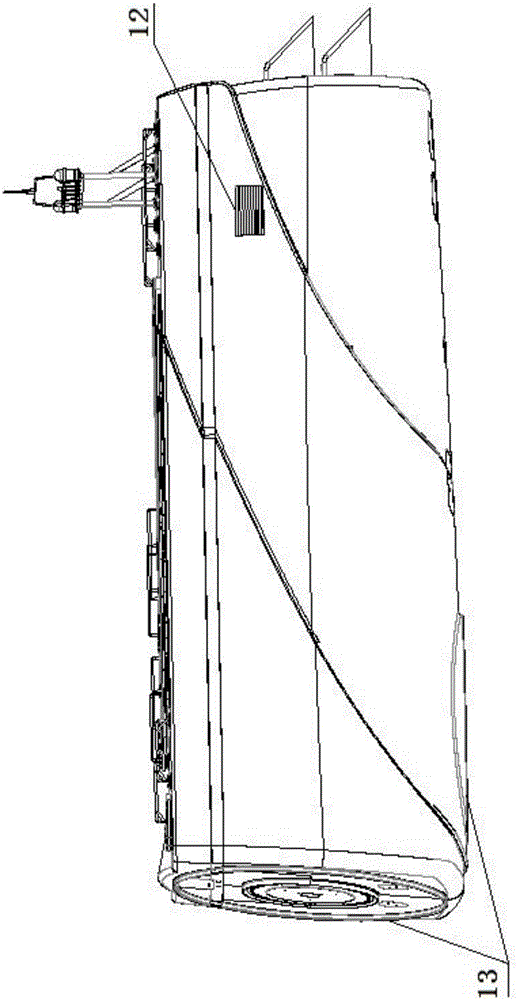

An integrated power and pressurization management system supplies electrical power and cabin pressurization and cooling air during both airborne and ground operations. The system includes an integral auxiliary power unit (APU) that has a compressor, a motor-generator, and a power turbine all mounted on one shaft. The integral APU can supply compressed air for cabin pressurization and environmental cooling functions, and can generate electrical power for various electrical loads. The system further includes one or more electrically driven compressors.

Owner:HONEYWELL INT INC

Integrated power and pressurization system

InactiveUS20060231680A1Air-treatment apparatus arrangementsEnergy efficient board measuresAuxiliary power unitCabin pressurization

An integrated power and pressurization management system supplies electrical power and cabin pressurization and cooling air during both airborne and ground operations. The system includes an integral auxiliary power unit (APU) that has a compressor, a motor-generator, and a power turbine all mounted on one shaft. The integral APU can supply compressed air for cabin pressurization and environmental cooling functions, and can generate electrical power for various electrical loads. The system further includes one or more electrically driven compressors.

Owner:HONEYWELL INT INC

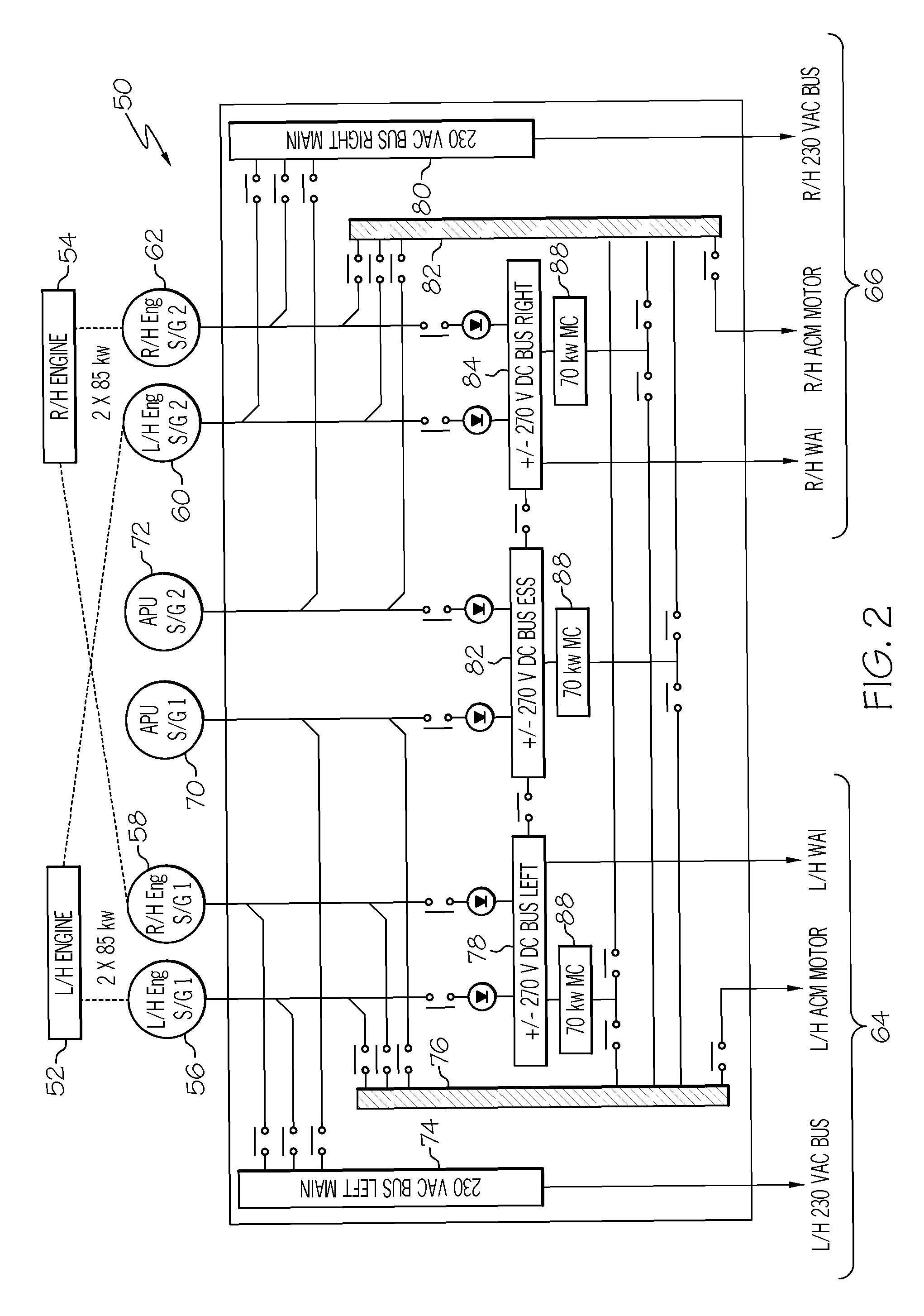

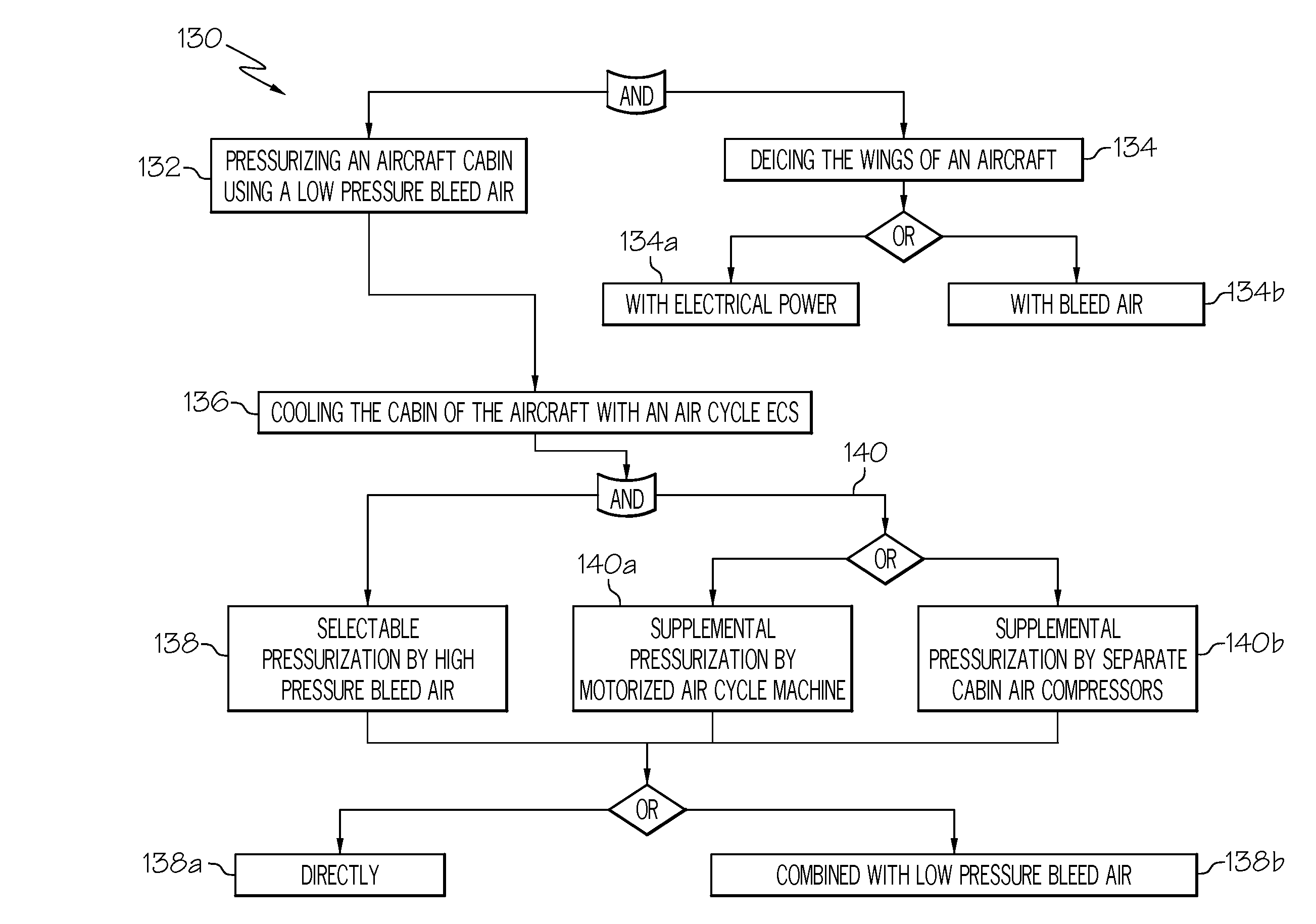

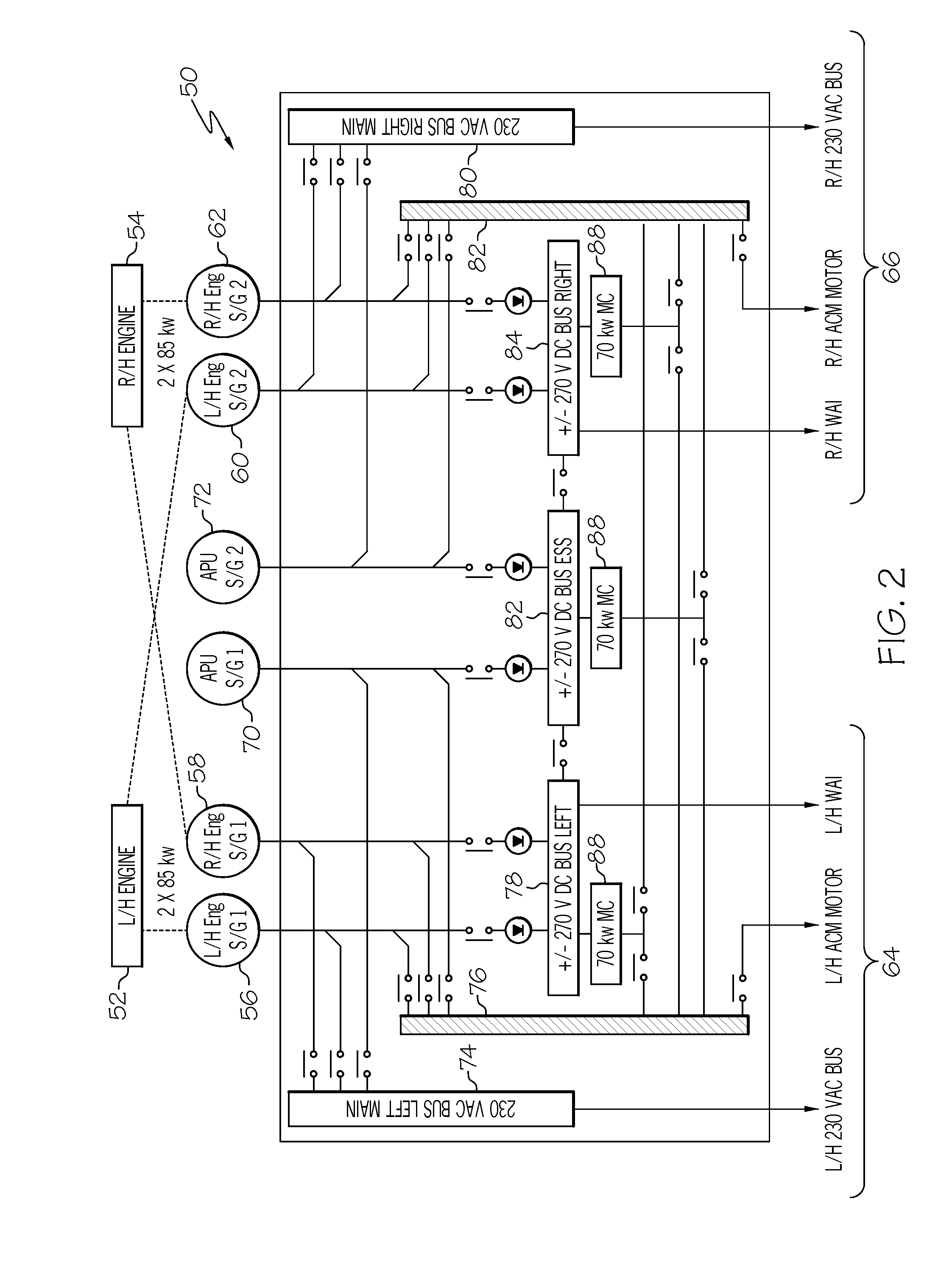

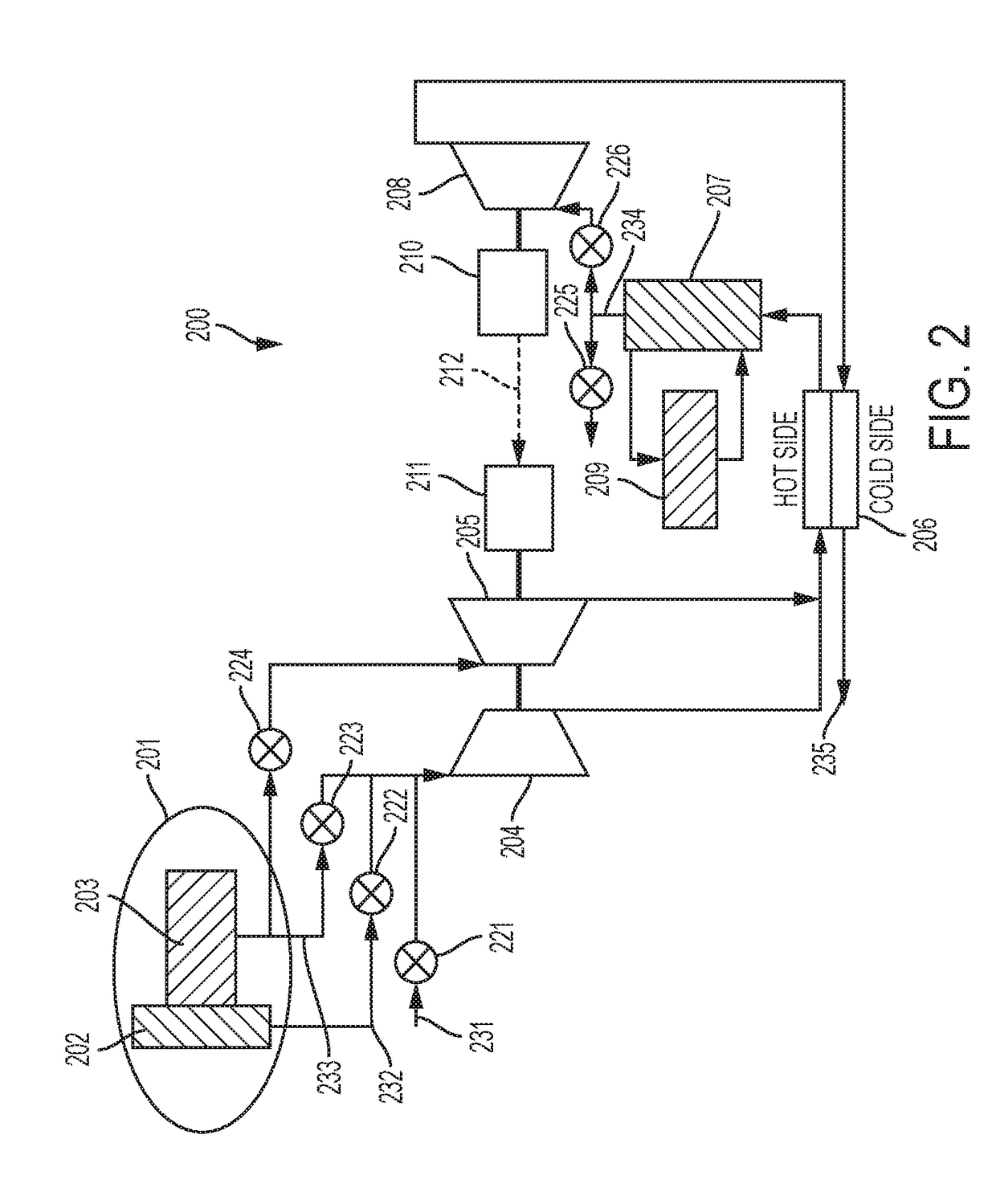

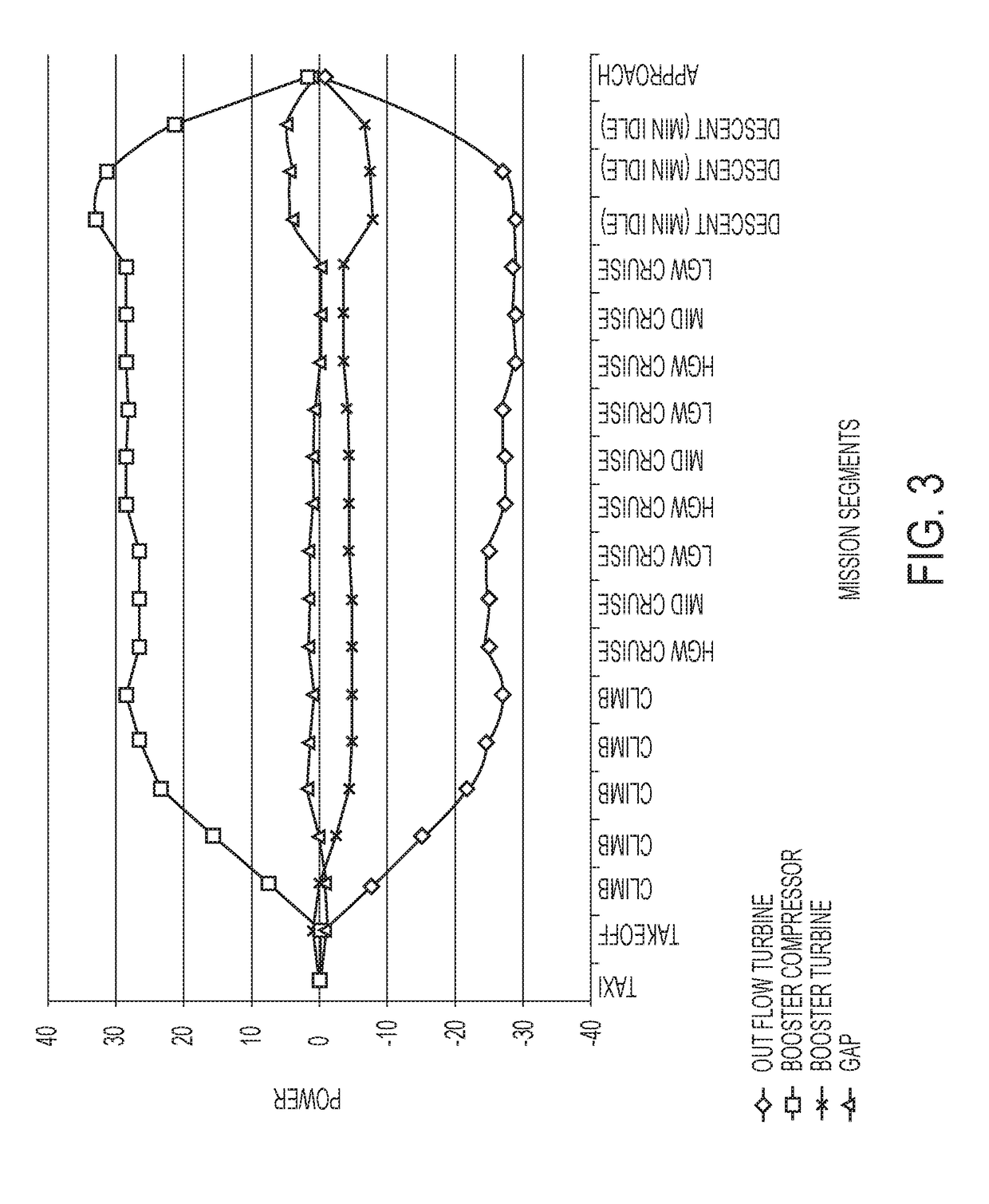

Smart hybrid electric and bleed architecture

InactiveUS7970497B2Domestic stoves or rangesSpace heating and ventilationPower extractionCabin pressurization

Owner:HONEYWELL INT INC

Smart hybrid electric and bleed architecture

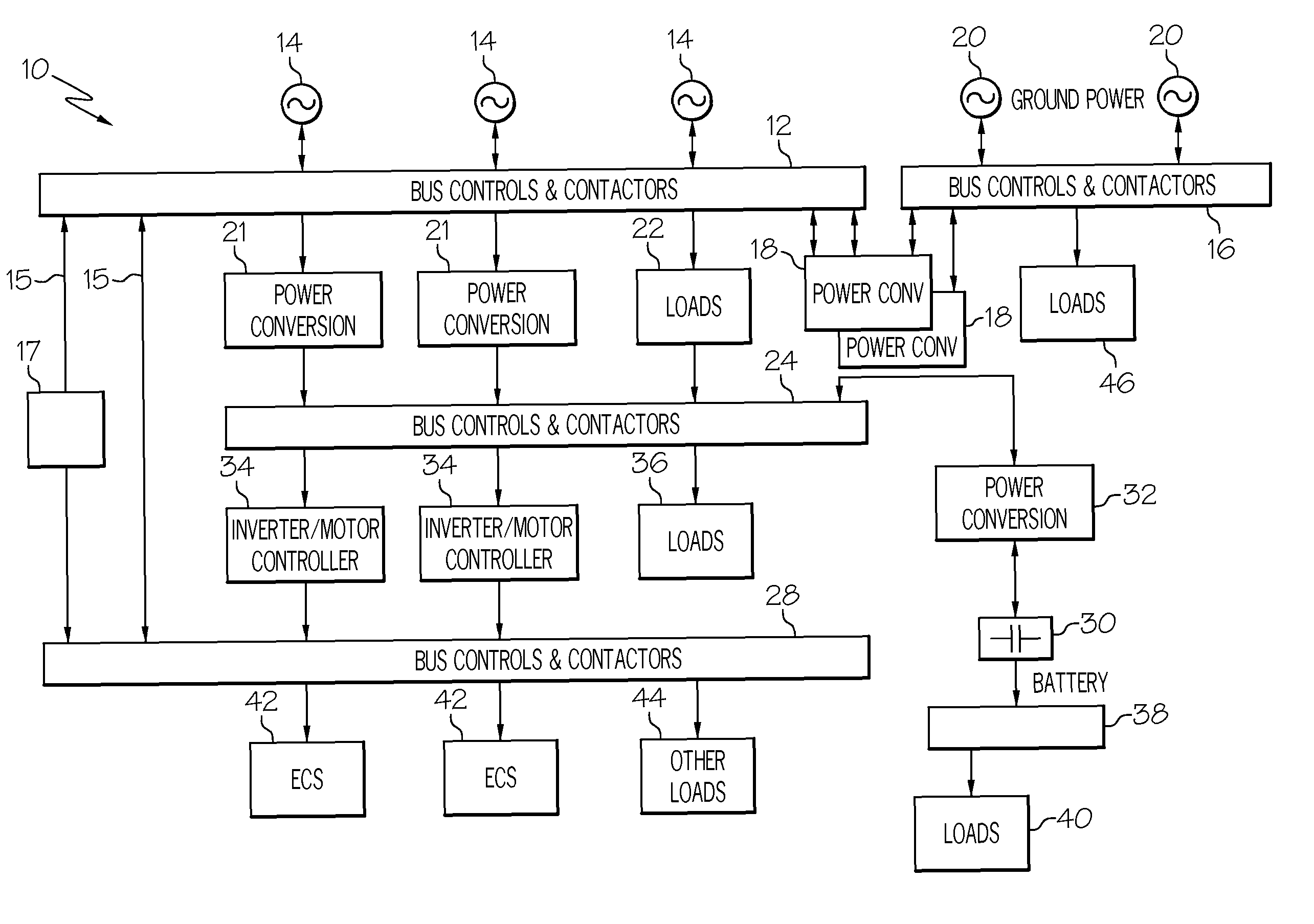

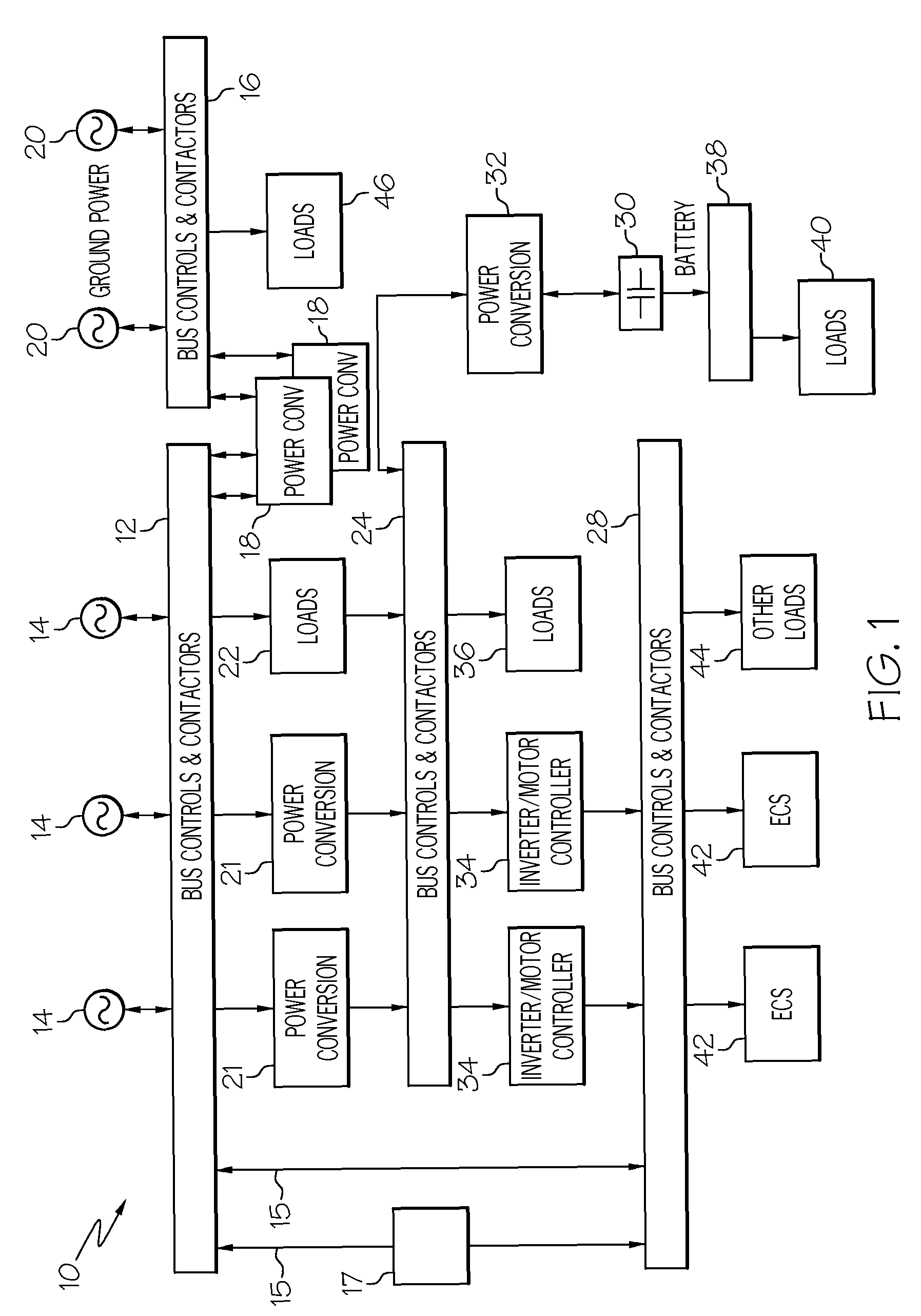

An aircraft architecture may be designed to create an optimal balance between electric power and bleed power in order to match or improve current more electric architecture (MEA) performance while simplifying power extraction from the engines as well as simplifying the electrical system. Conventional aircraft architectures may use electric only ECS and cabin pressurization systems (so-called “no bleed” systems). Alternatively, older conventional aircraft may use strictly engine bleed air to provide power for ECS and cabin pressurization systems. The present invention, on the other hand, provides an architecture which may optimize the use of both engine bleed air and MEA designs to provide a system that may be simpler and potentially more reliable and available as compared to conventional aircraft architectures.

Owner:HONEYWELL INT INC

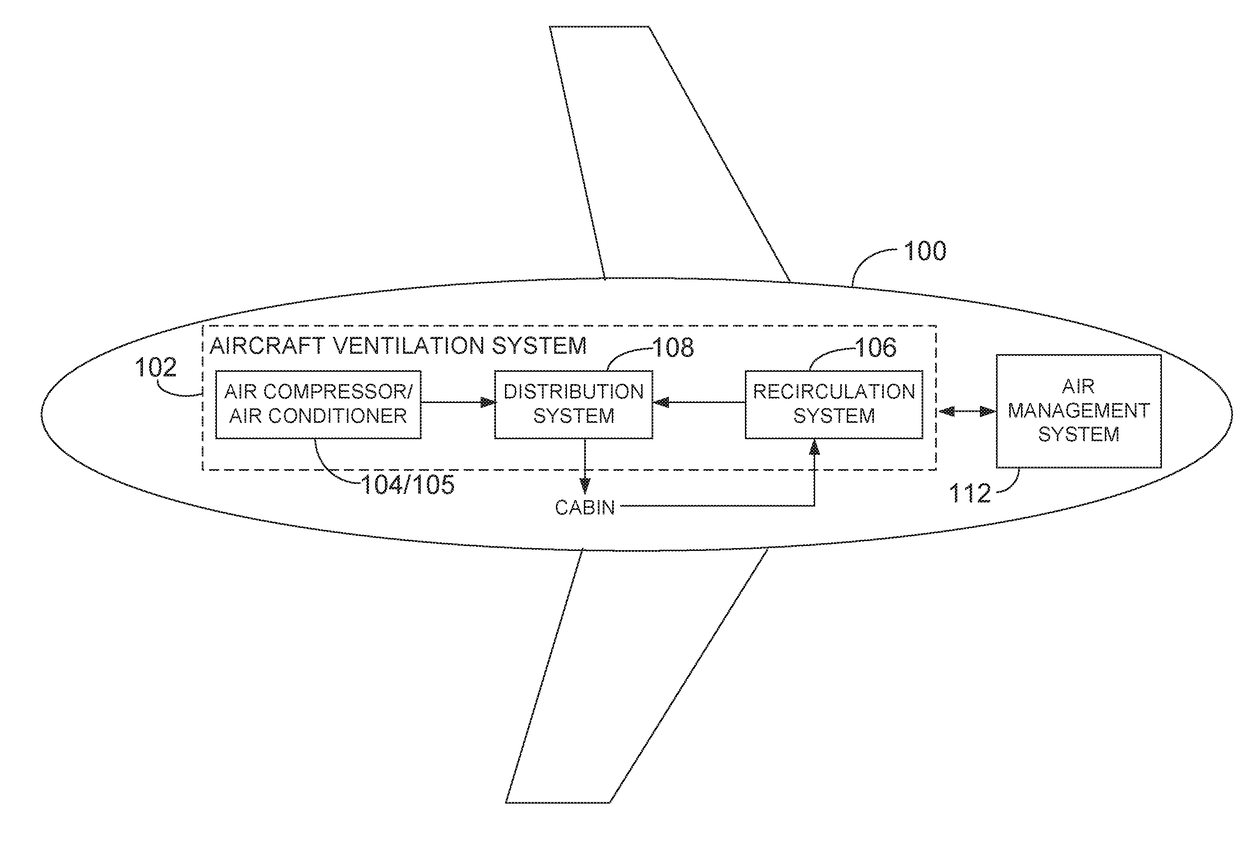

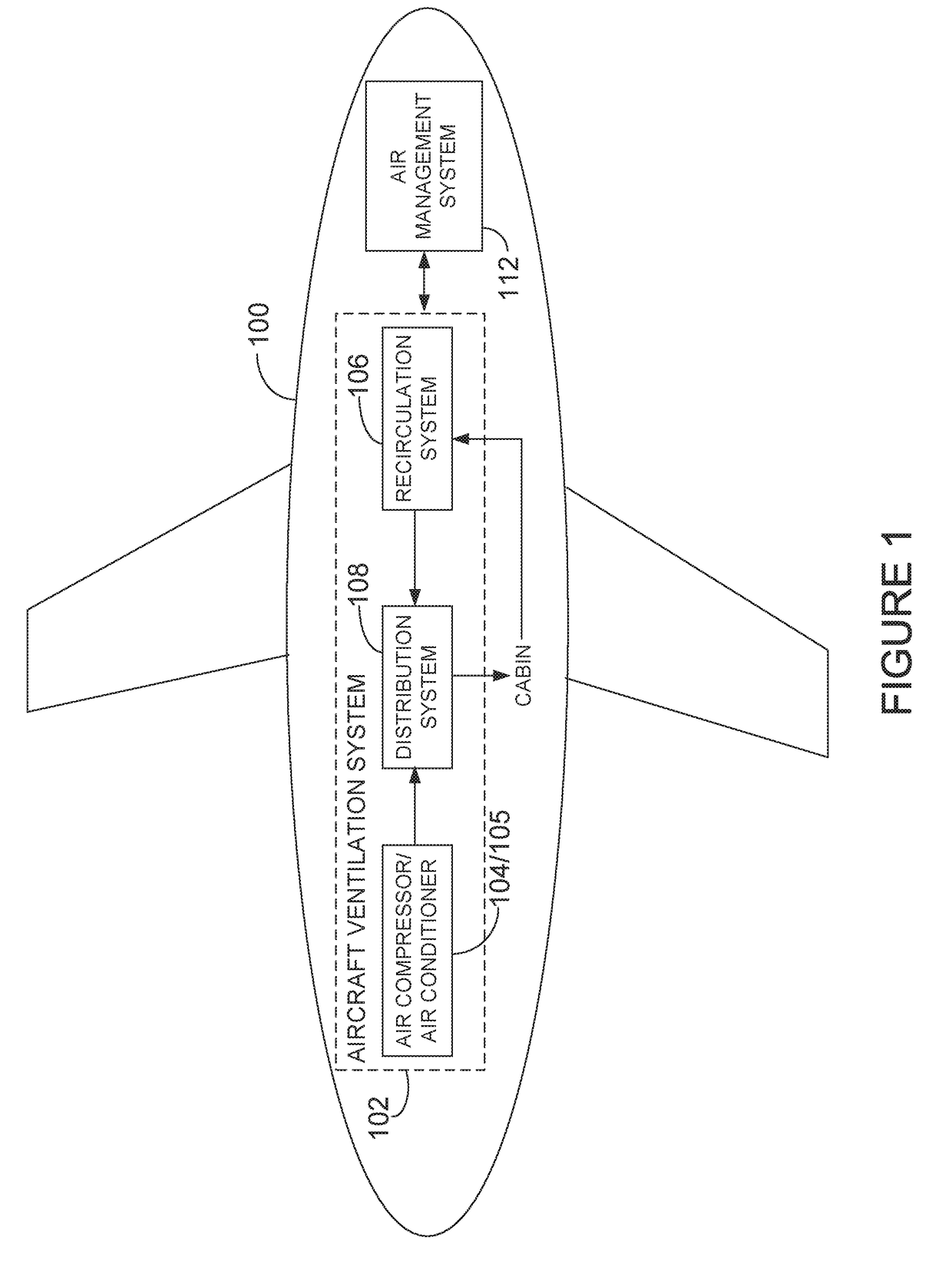

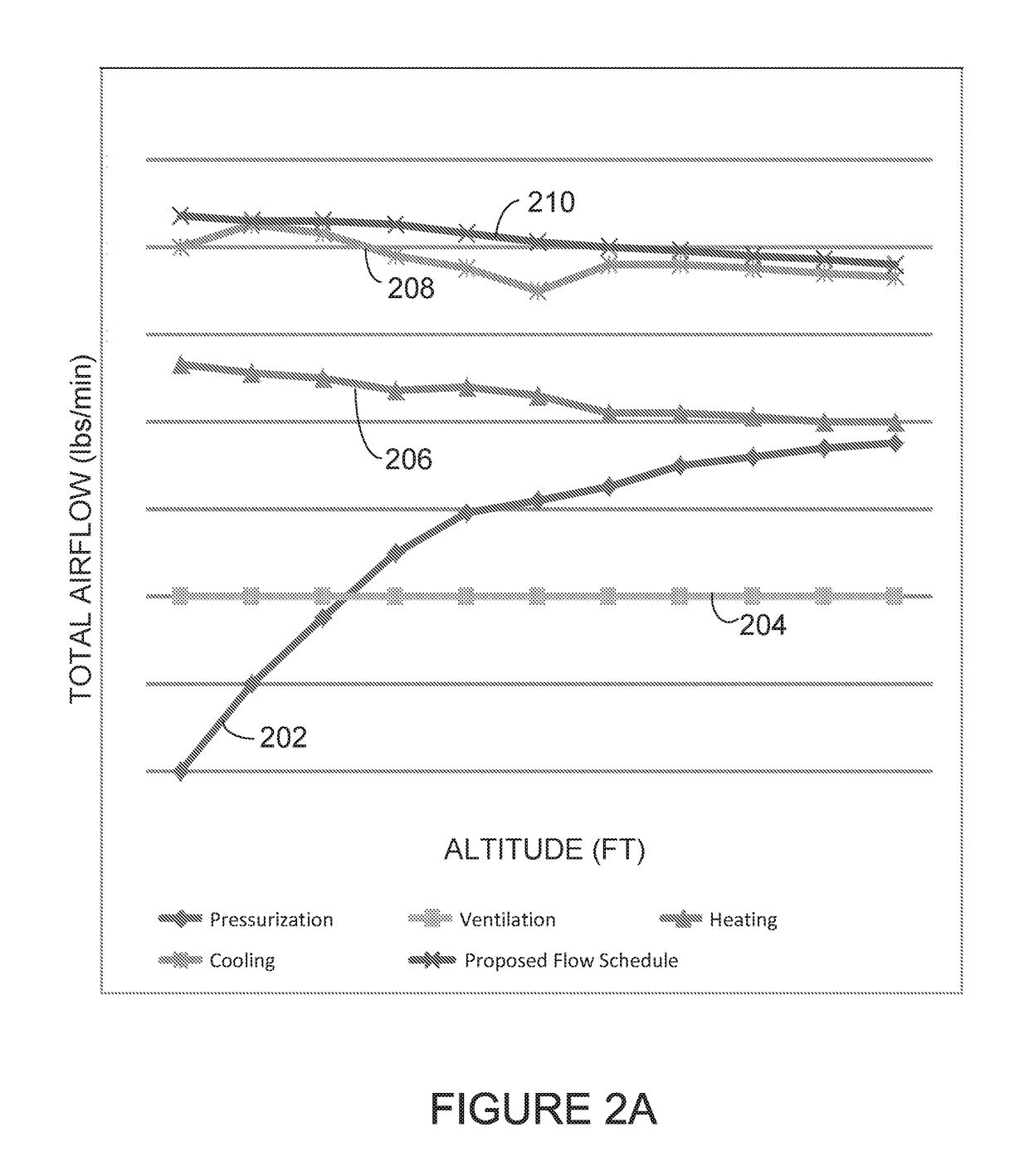

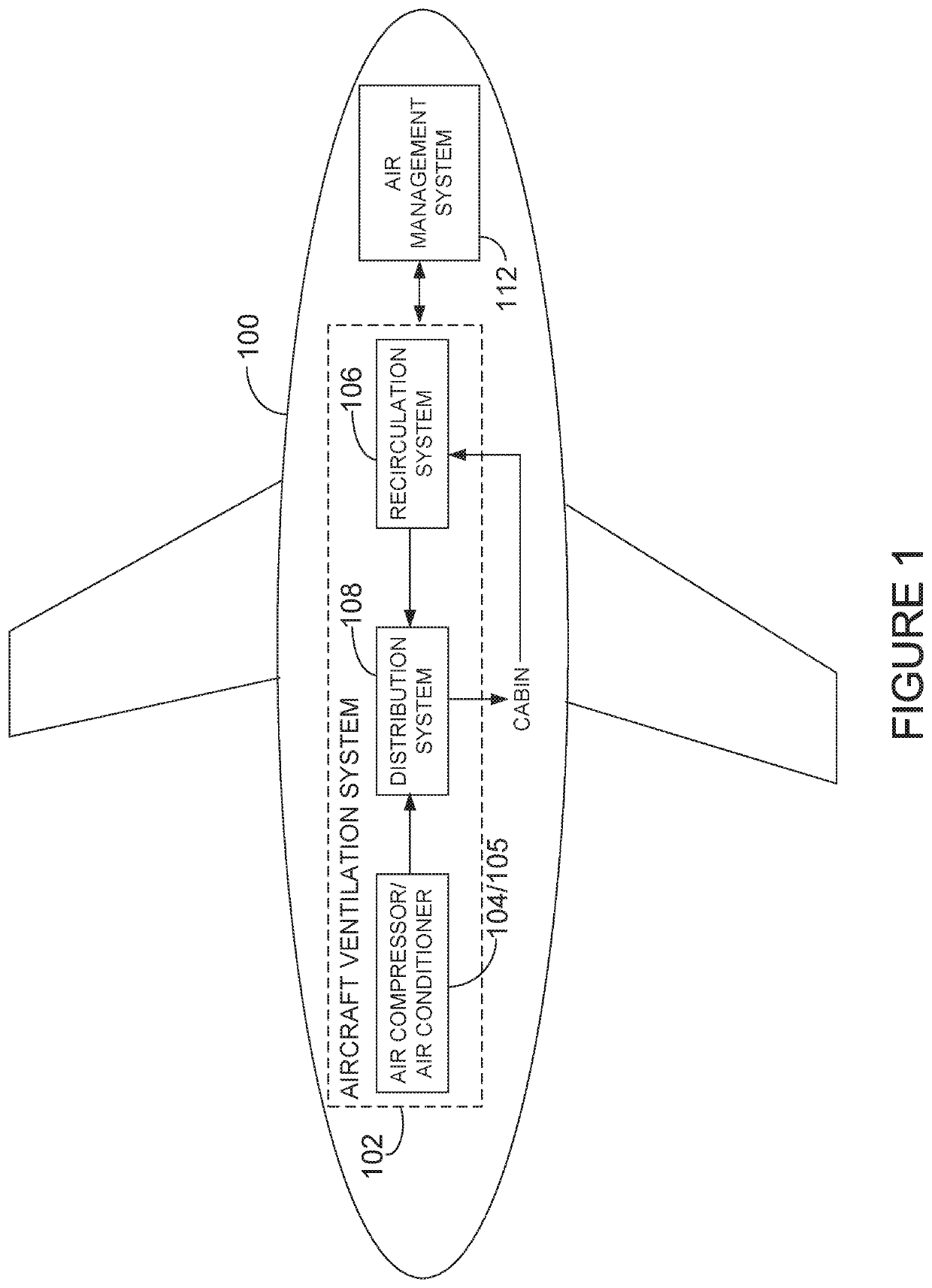

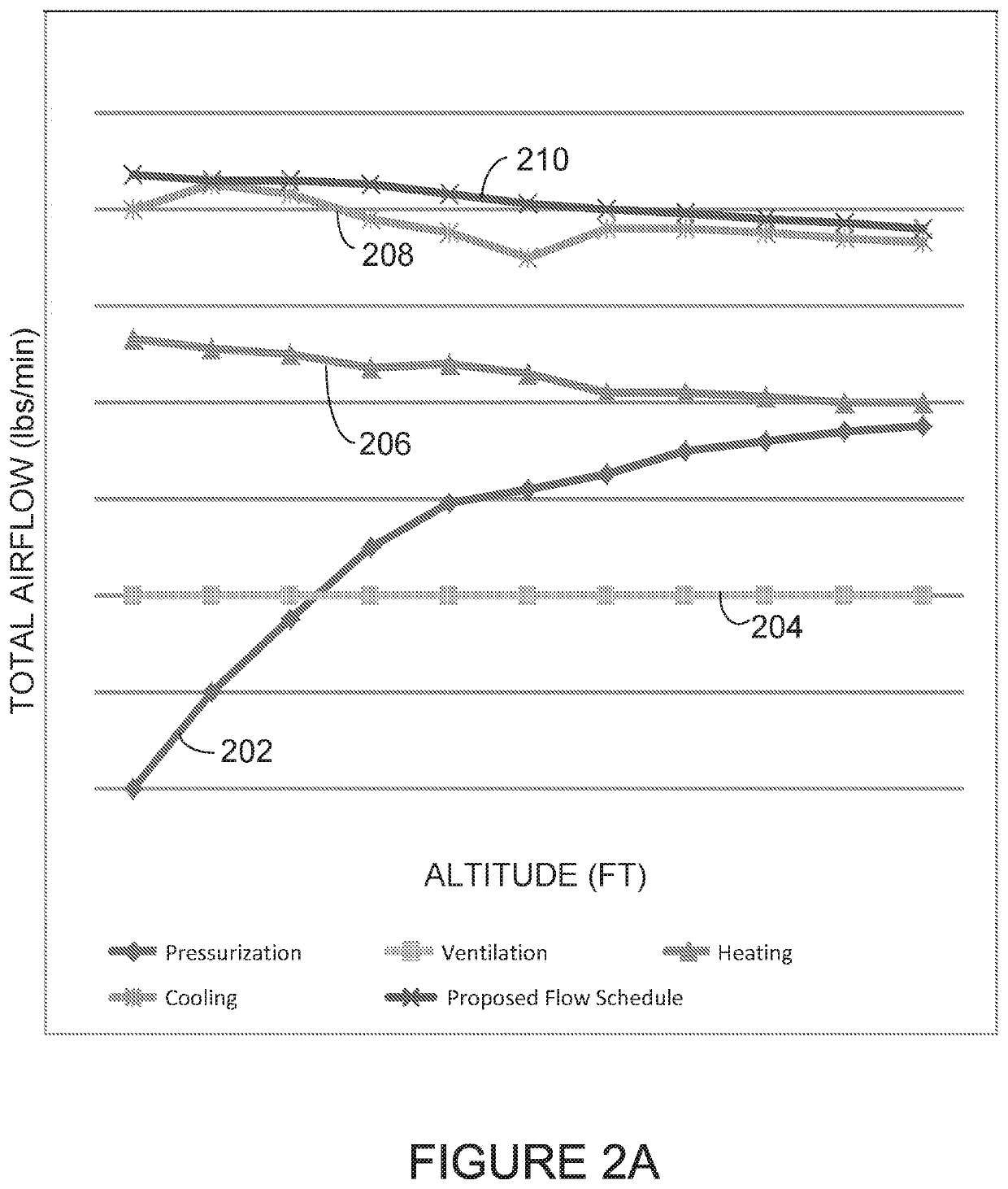

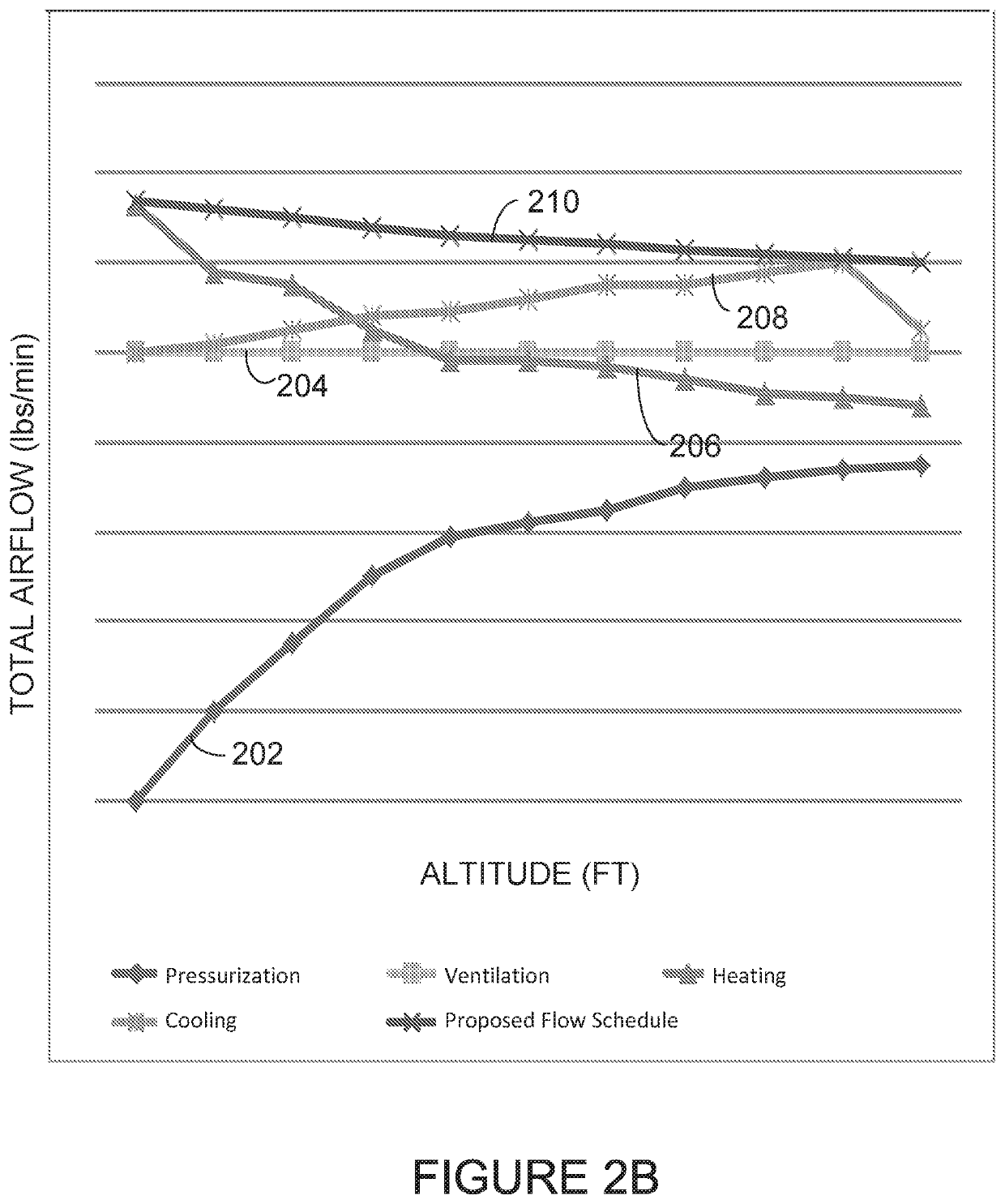

Airflow management in cabin of aircraft

ActiveUS20180148182A1Reduce airflowAir-treatment apparatus arrangementsEnergy efficient board measuresTemperature controlNacelle

Cabin air is managed in the aircraft as a function of the minimum requirements for defined air quality needs, temperature control needs, and cabin pressurization needs. Airflow may be varied dynamically as a function of aircraft or cabin altitude, and the minimum requirements for airflow may be determined in real time so as to dynamically set an airflow schedule.

Owner:BOMBARDIER CORP

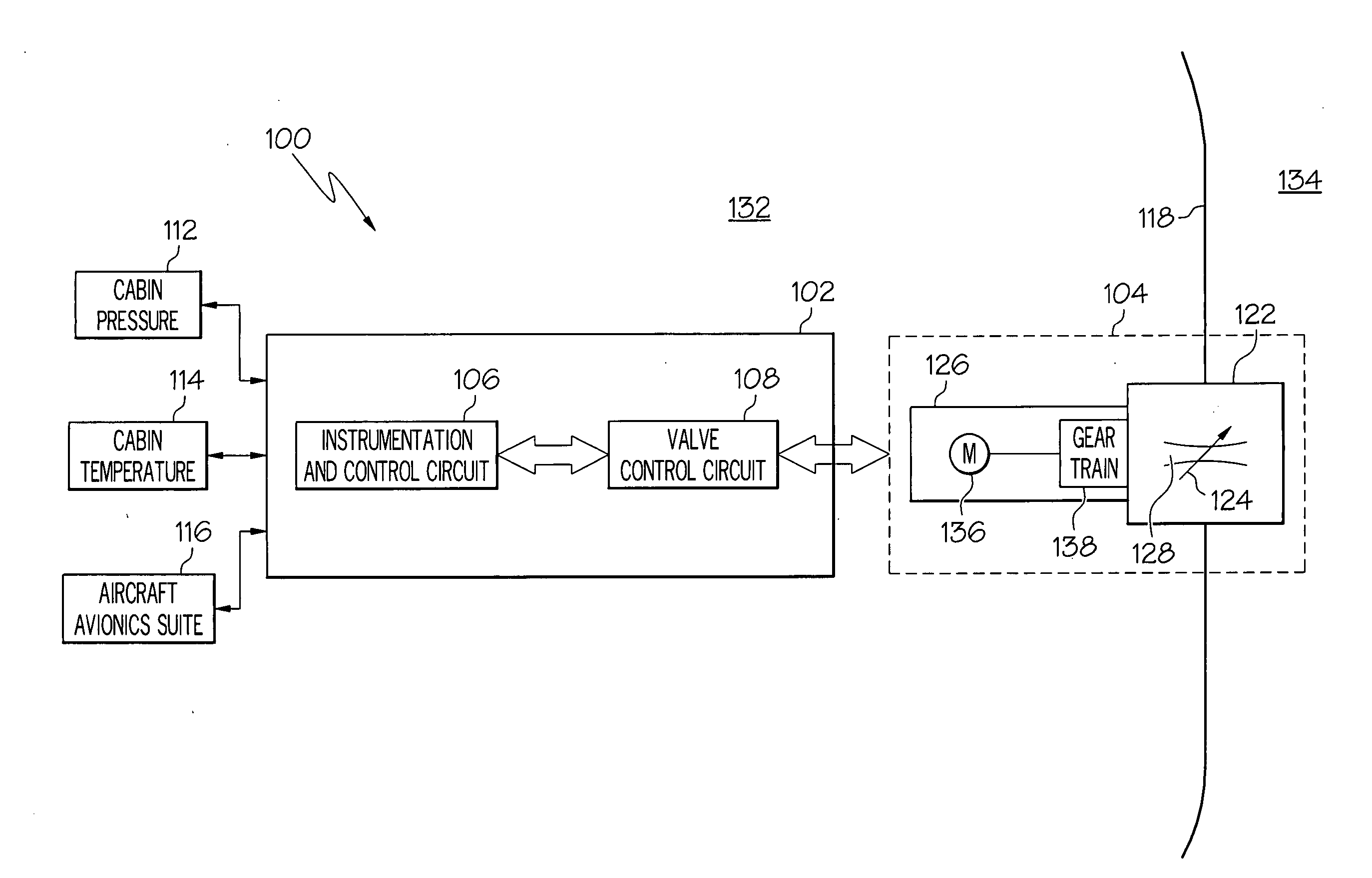

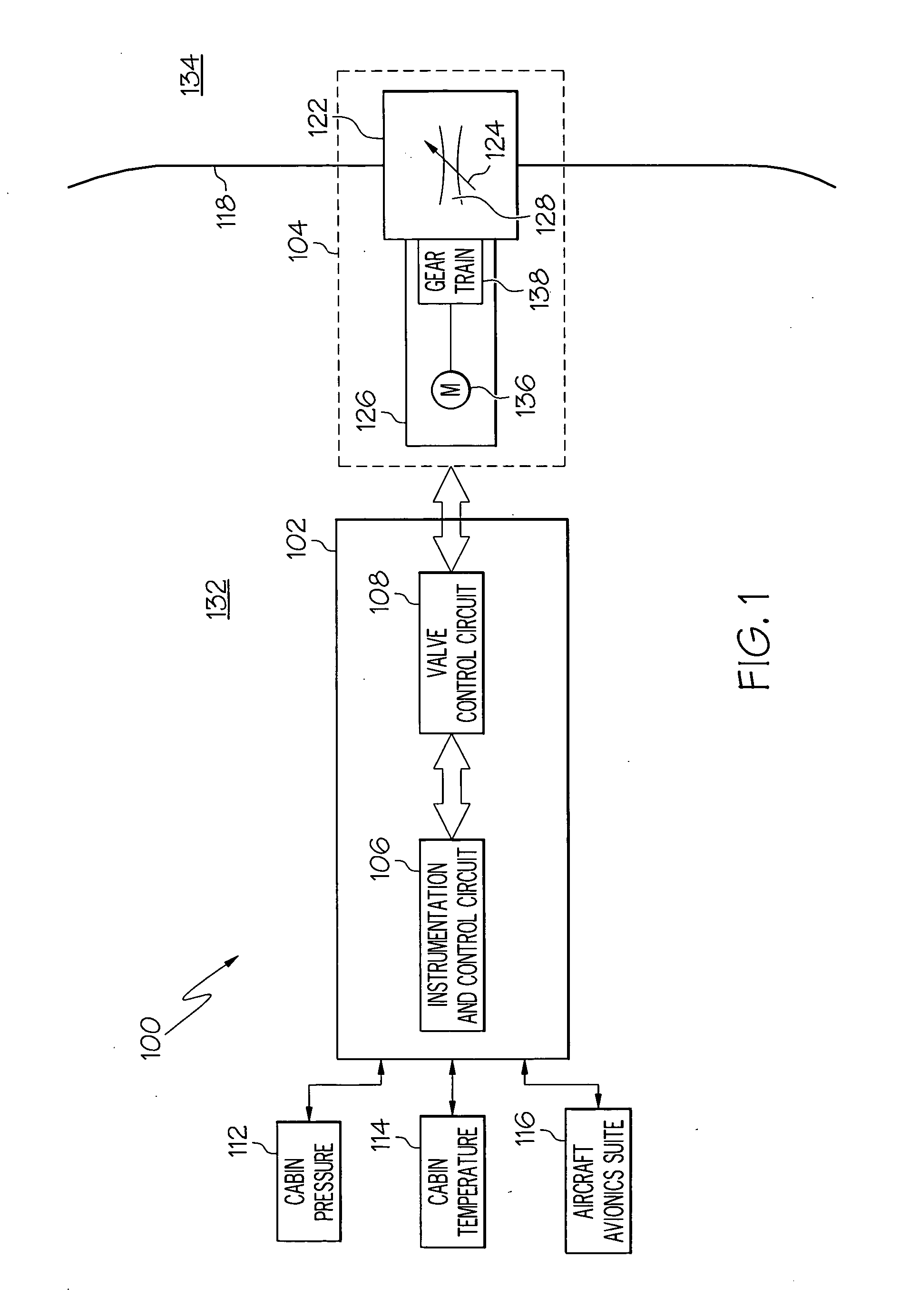

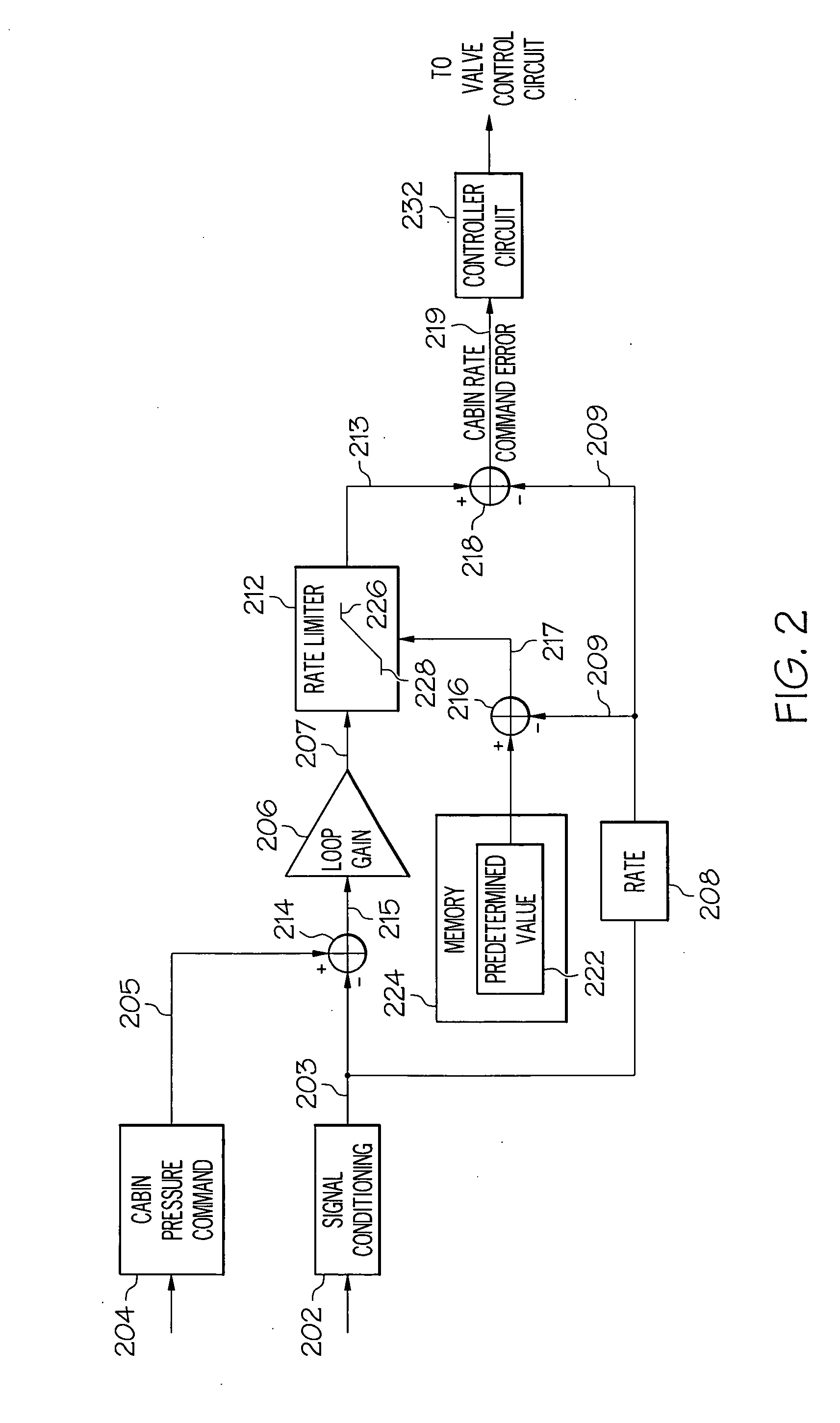

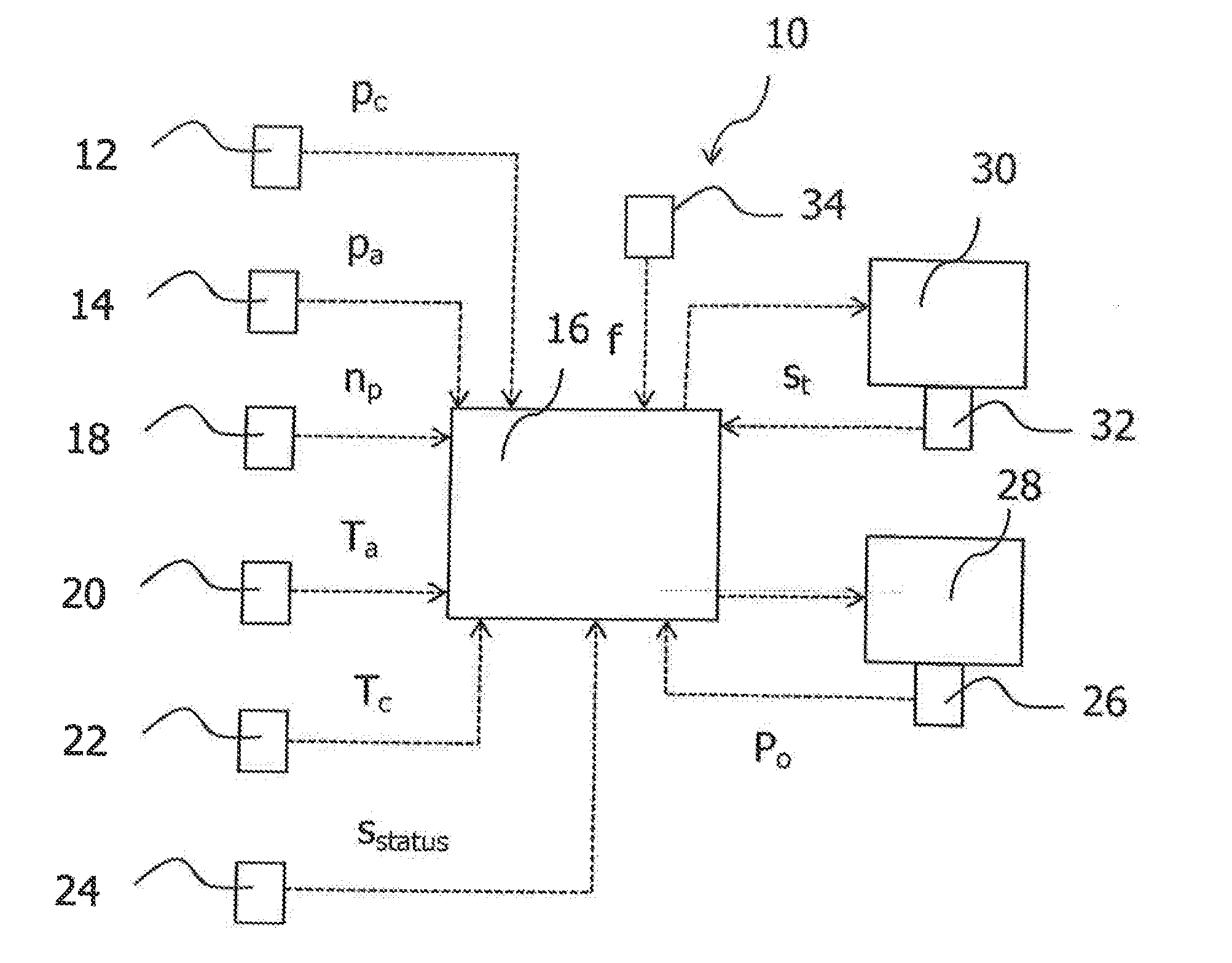

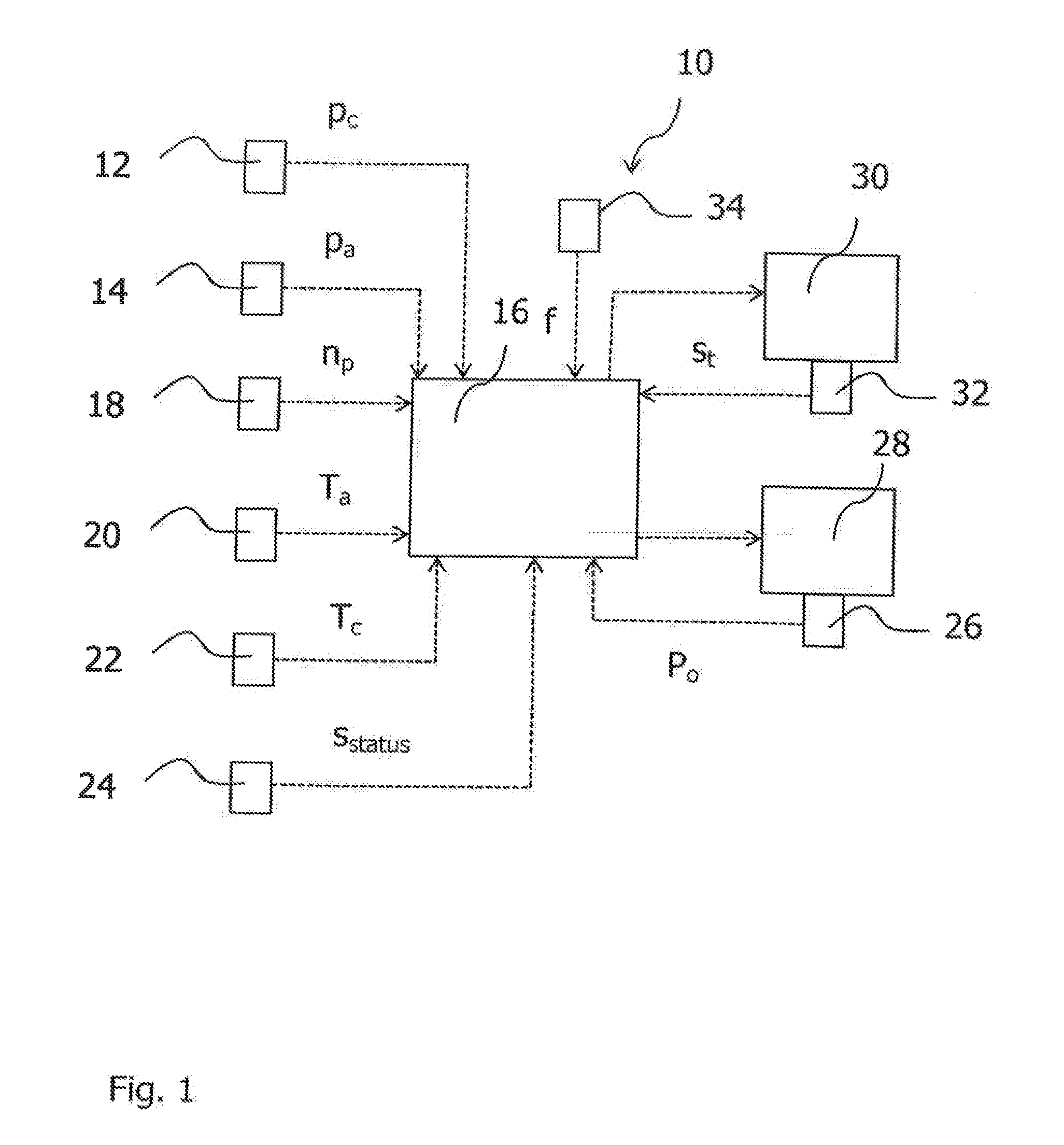

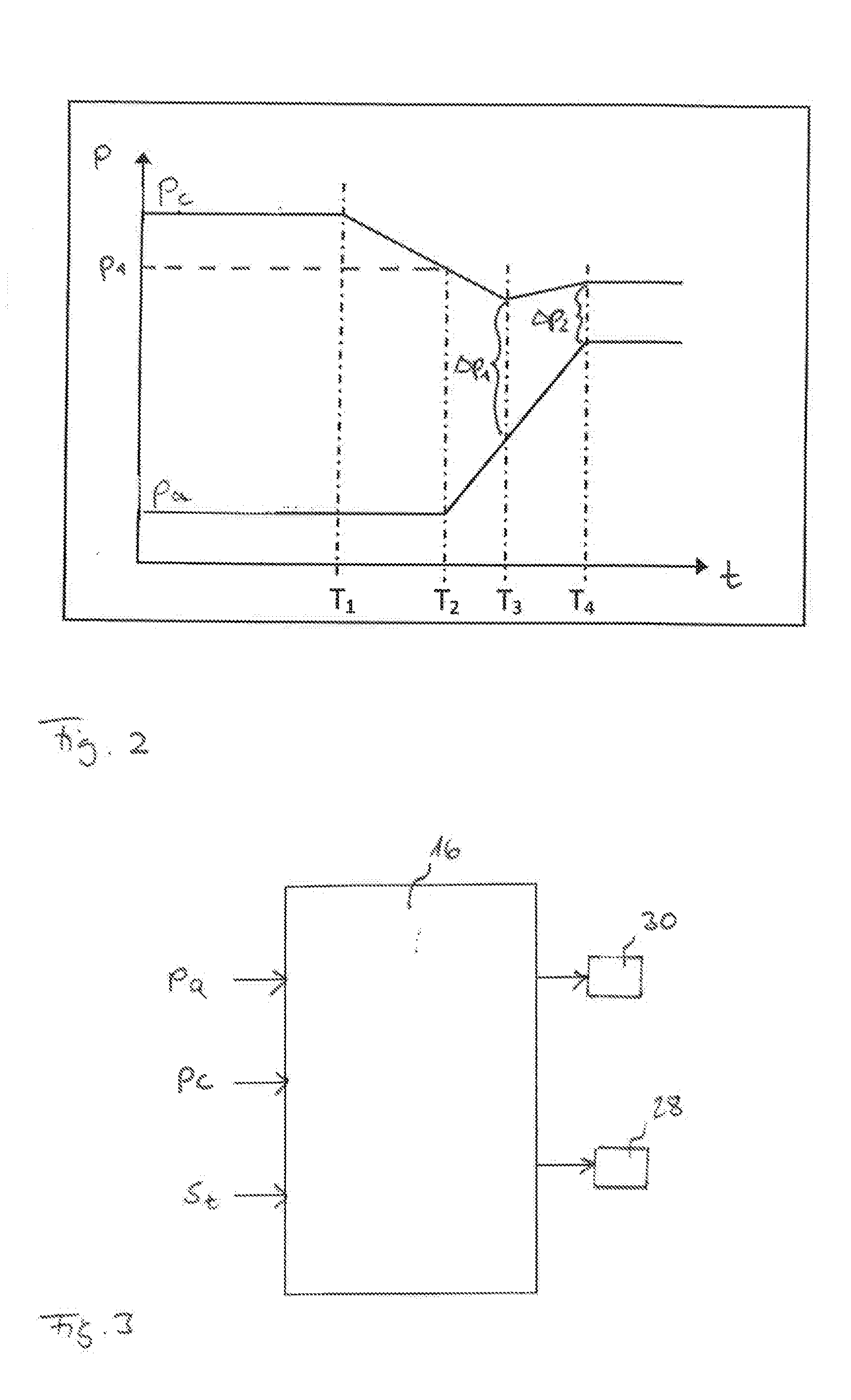

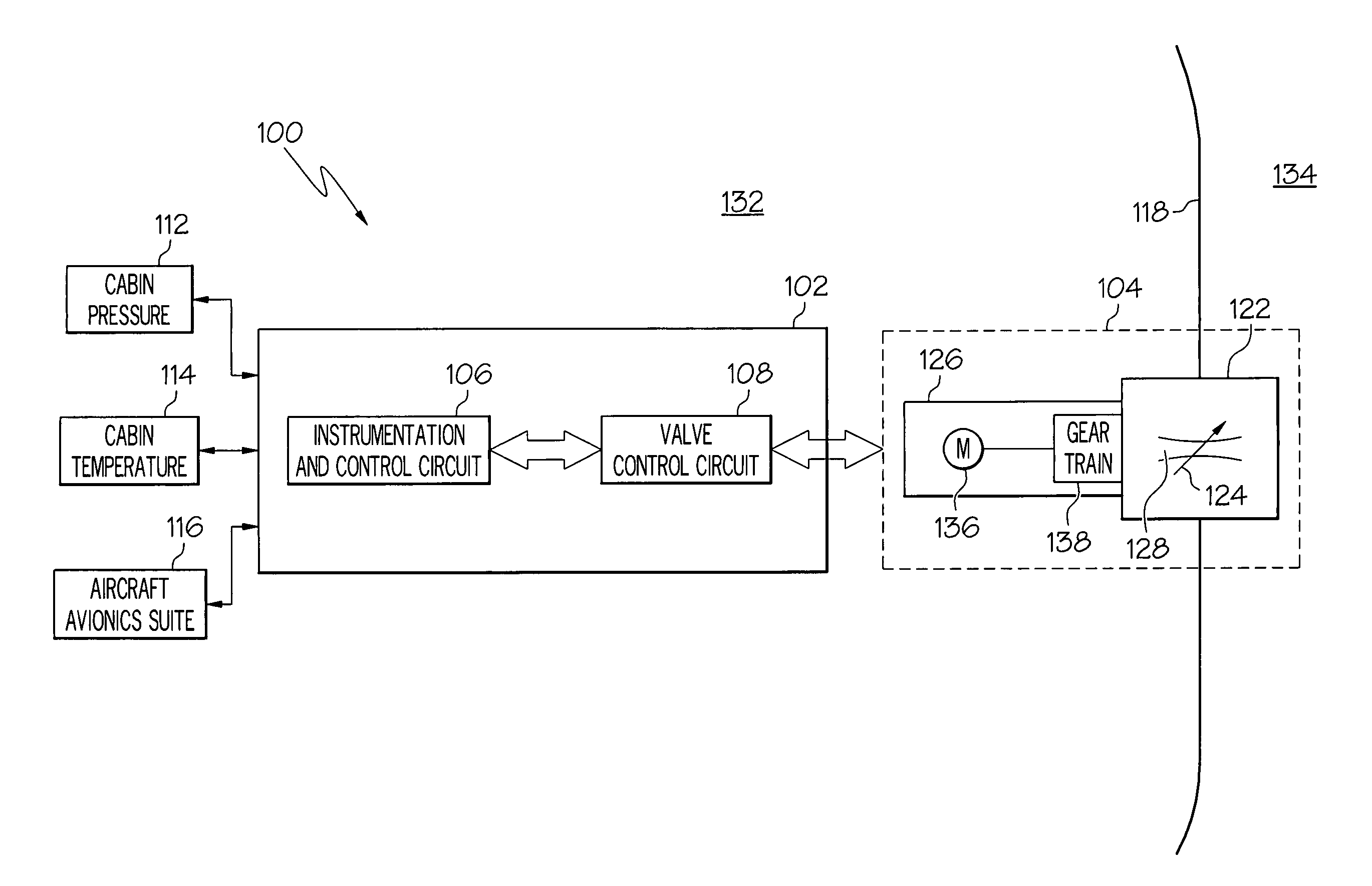

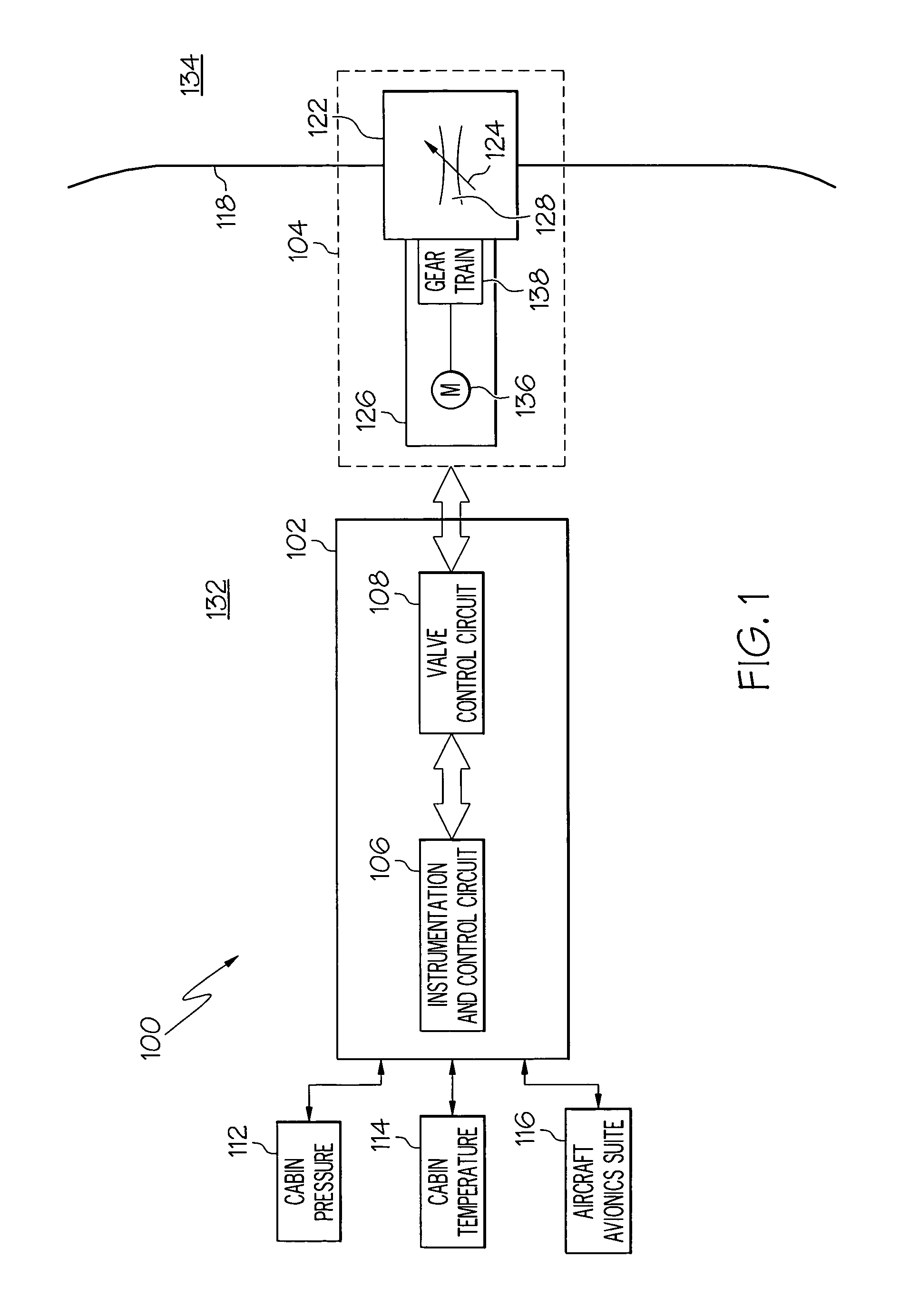

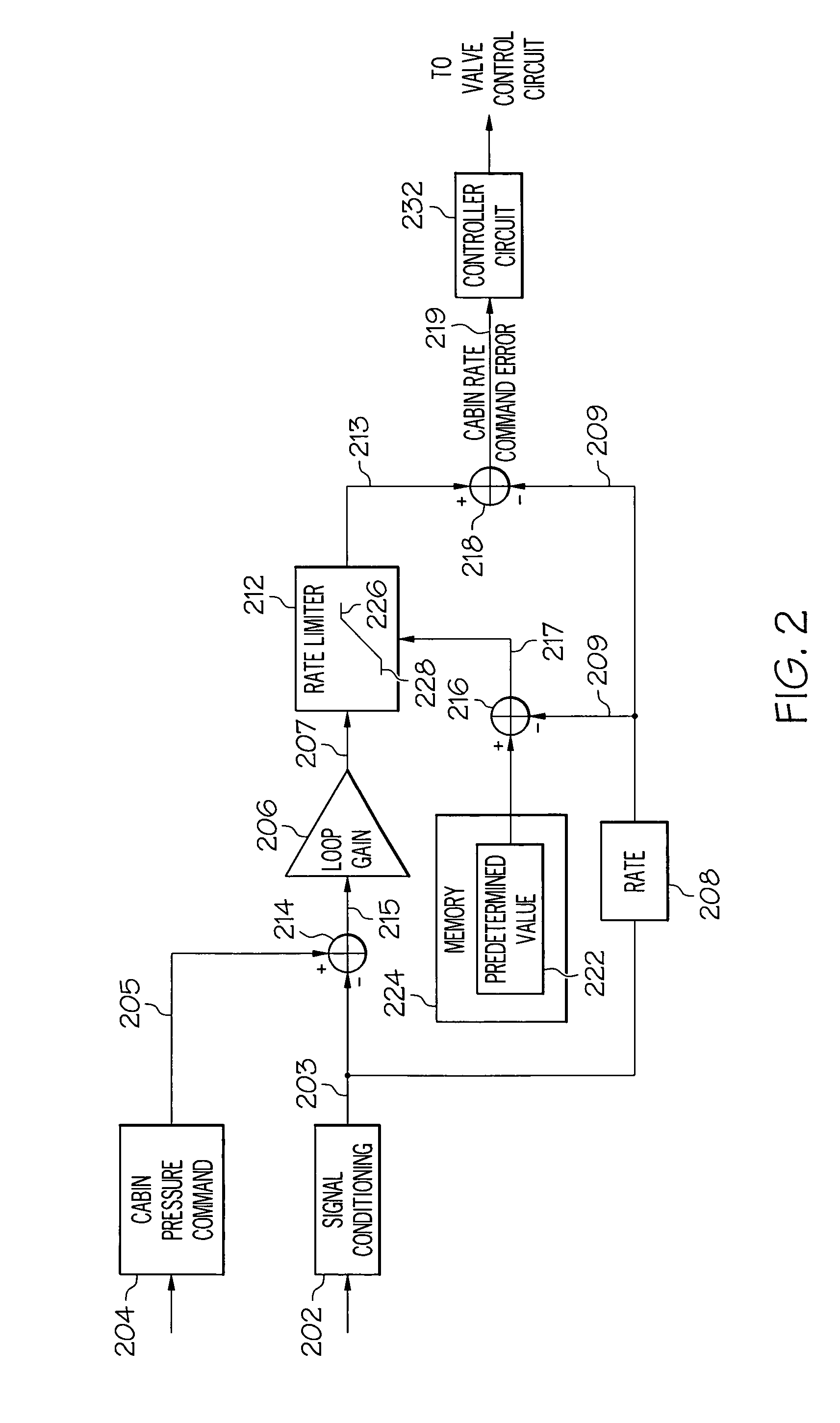

Aircraft cabin pressure control system and method that improves cabin pressurization during take-off

ActiveUS20070102576A1Quickly and consistentlyFaster rateAir-treatment apparatus arrangementsEnergy efficient board measuresControl systemSimulation

A cabin pressure control system and method improves cabin pressurization during aircraft take-off operations. The cabin pressure control system sets a cabin pressurization rate limit based on a cabin pressurization rate error. The cabin pressurization rate error is derived from a comparison of a sensed cabin pressure rate-of-change value and a predetermined cabin pressurization rate value.

Owner:HONEYWELL INT INC

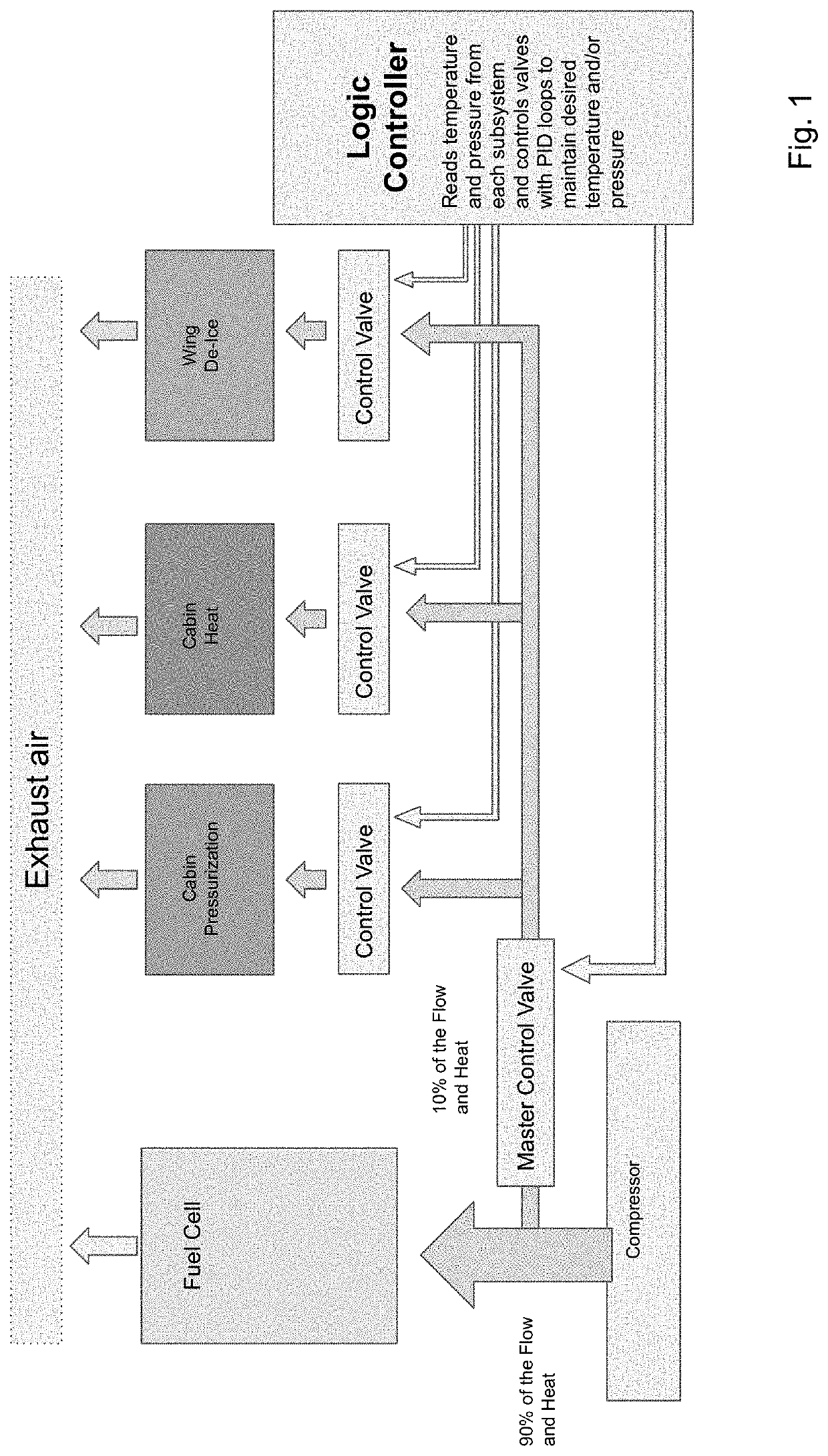

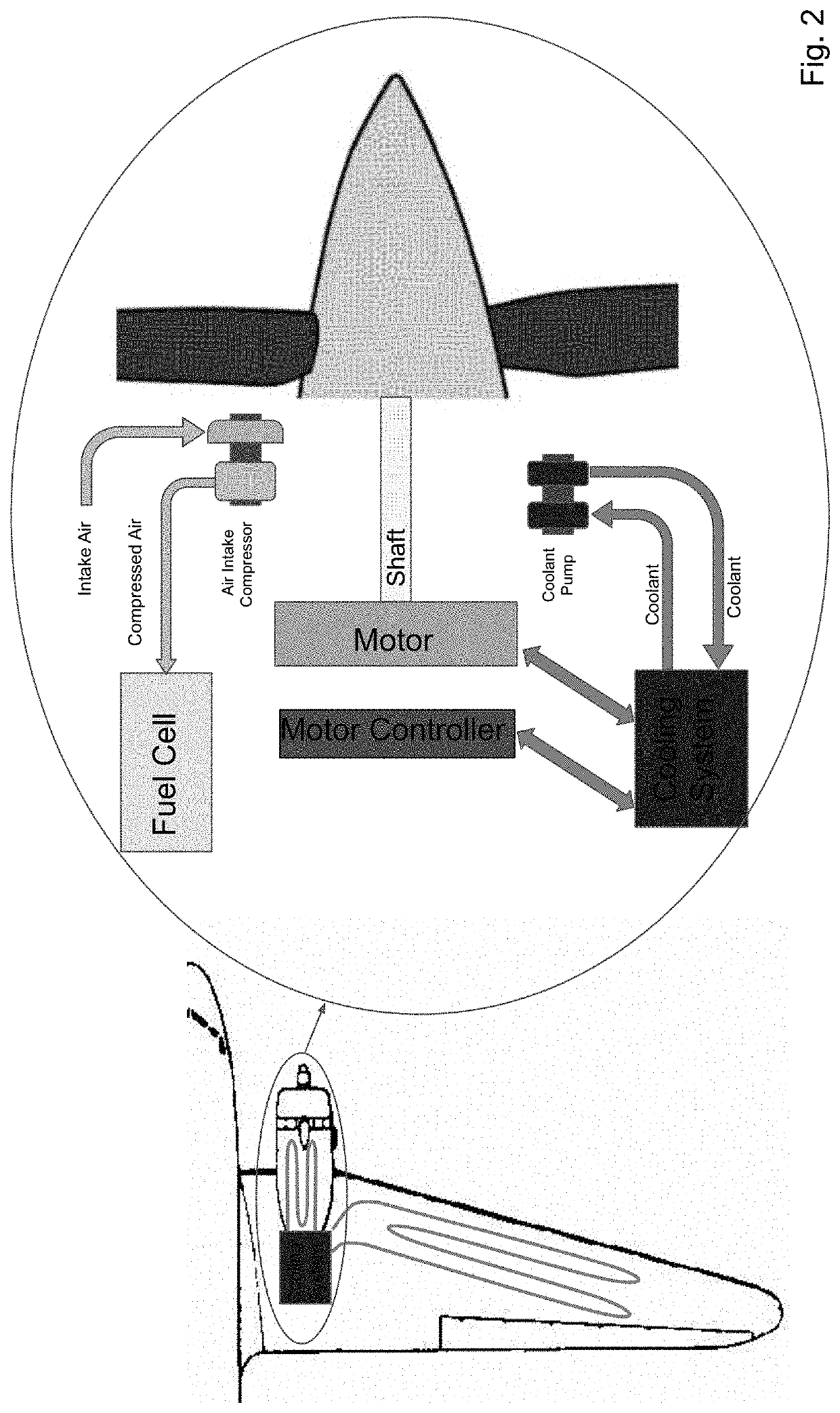

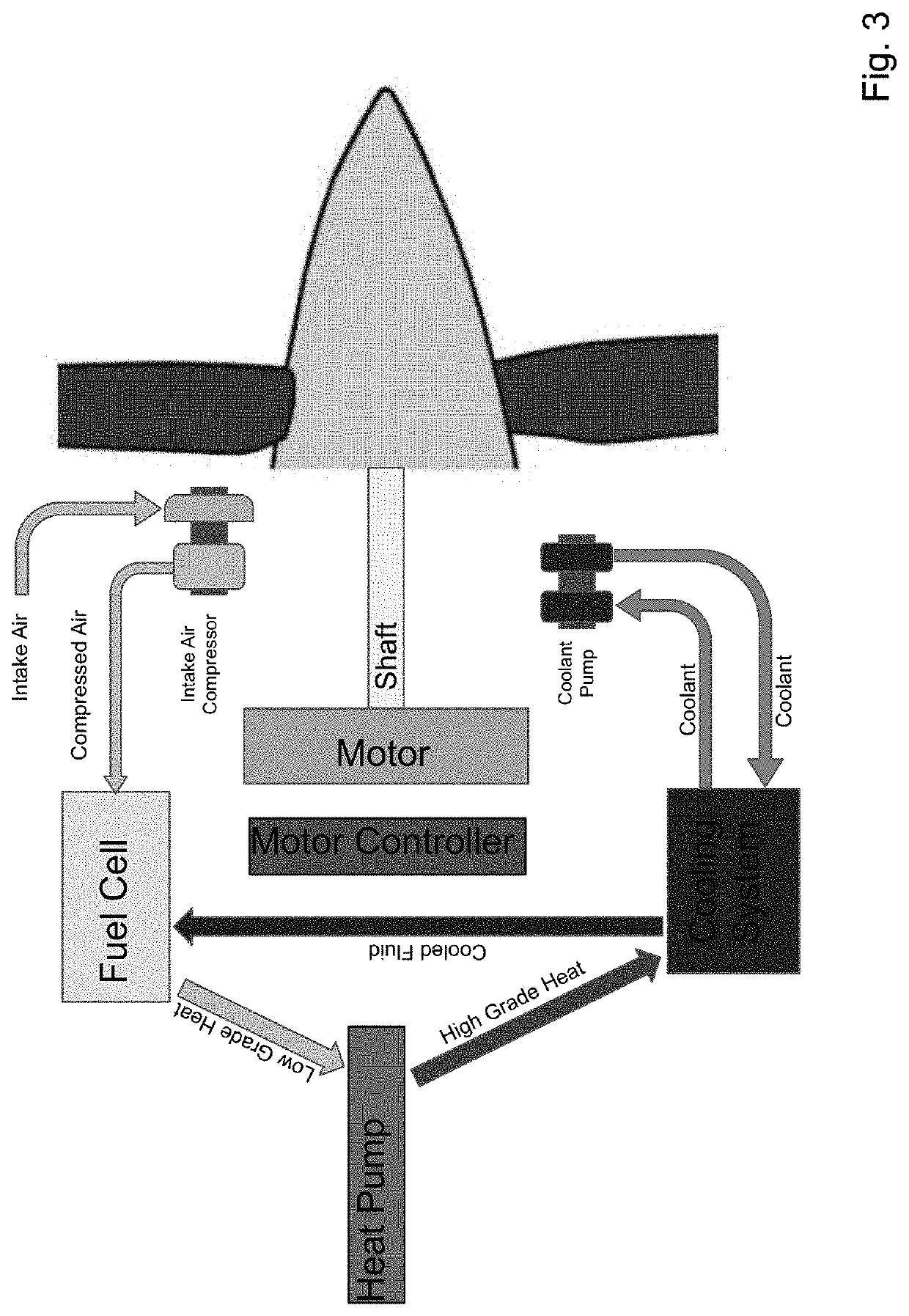

Advanced FuelCell Integration Into Aircraft

InactiveUS20200385127A1Power installationsAir-treatment apparatus arrangementsNacelleExtreme weather

A system that allows using a fuel cell air compressor for cabin pressurization, cabin heat, and wing de-icing. One of the fuel cell's primary components, the compressor produces the pressure necessary to operate. The operating pressure is much higher than necessary for cabin pressurization so bleed air can be used for this purpose. Compressing air requires a lot of energy, and much of that energy is transferred into the air being compressed. This warm, compressed air could then be used to heat up the passenger cabin. Similarly the warm compressed air produced from the fuel cell compressor can be used to inflate the pouches on the leading edges of the wings to remove ice in the event of extreme weather. A control system is provided to operate each individual system. These systems will require control over multiple lines and valves, and will be registering feedback from pressure sensors mounted at each point. The onboard computer system will monitor user inputs and control outputs corresponding to each system.

Owner:ZEROAVIA INC

Method and system for emergency ventilating and pressurizing an aircraft cabin

ActiveUS20140162542A1Improve comfortAvoid accumulationAir-treating devicesRailway heating/coolingNacelleDifferential pressure

A method for emergency ventilating and pressurizing an aircraft cabin comprises determining a cabin pressure within the aircraft cabin and determining an ambient pressure in an aircraft environment. Descent of the aircraft is initiated when the cabin pressure falls below a predetermined threshold value. A supply of ambient air from the aircraft environment into the aircraft cabin is initiated, when, during descent of the aircraft, a differential pressure between the cabin pressure and the ambient pressure falls below a first calculated threshold value. The supply of ambient air into the aircraft cabin and an operation of an air outflow valve of a cabin pressurization system of the aircraft are controlled such that a flow of ambient air into the aircraft cabin corresponds to at least a predetermined minimum value and the differential pressure between the cabin pressure and the ambient pressure does not fall below a second calculated threshold value.

Owner:AIRBUS OPERATIONS GMBH

Multi-electric aircraft electric environment control system

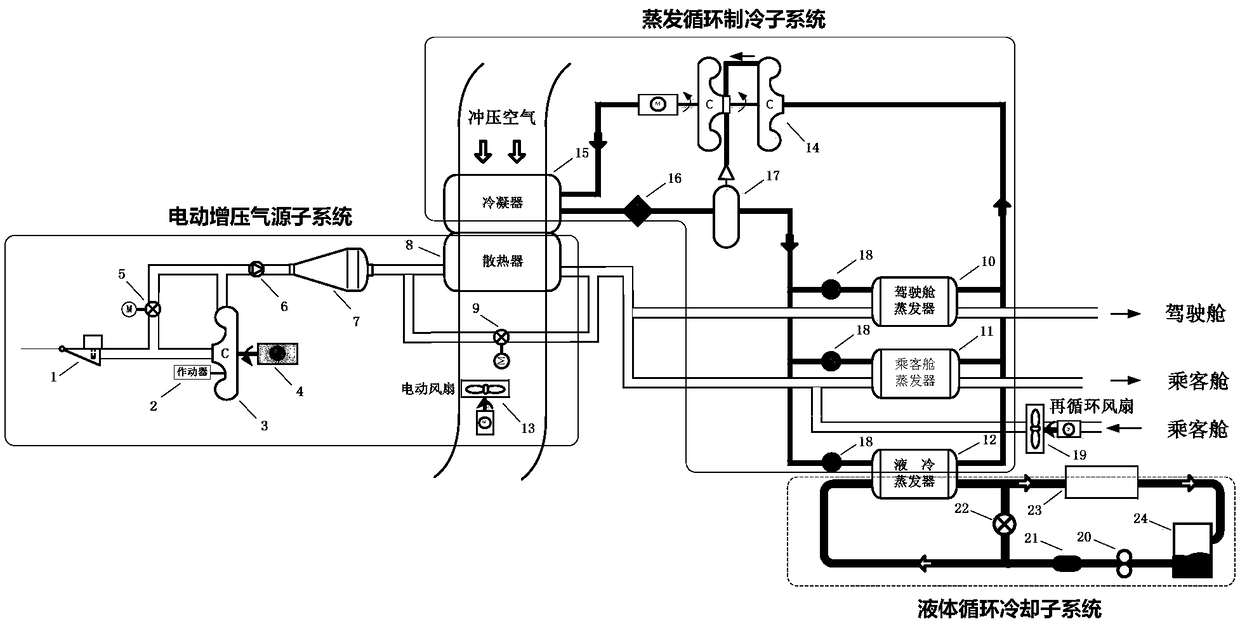

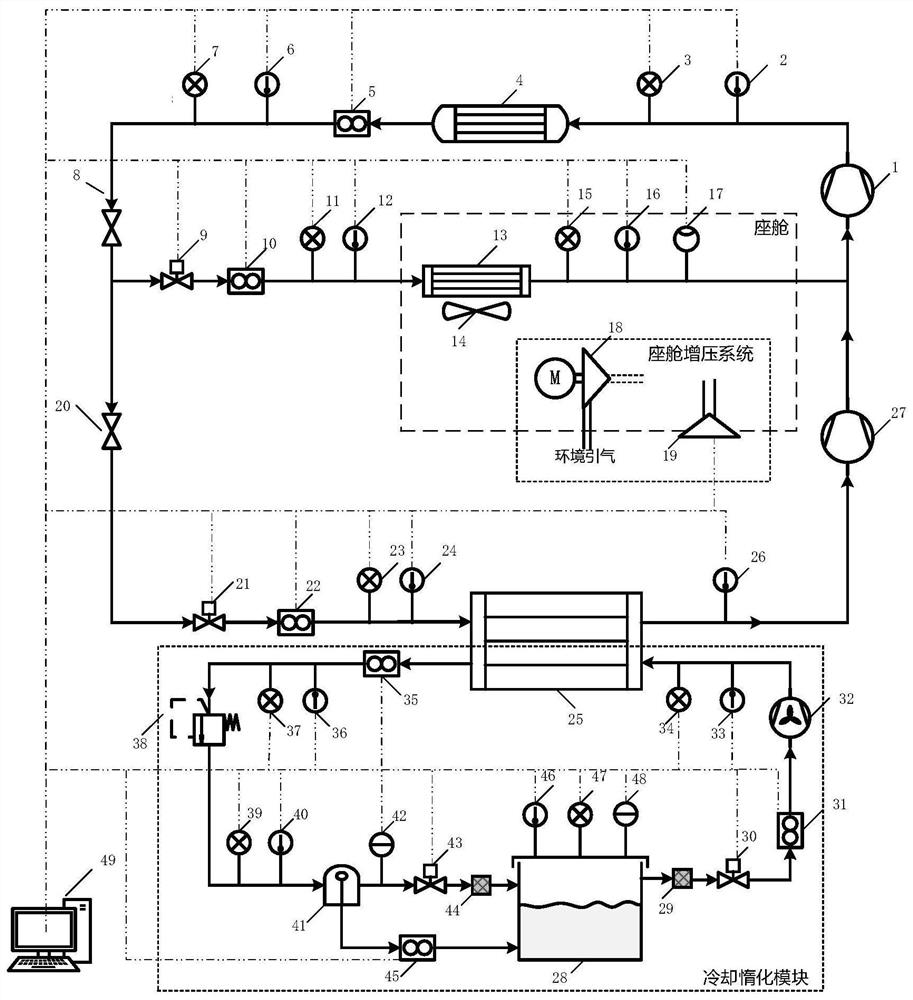

ActiveCN109367791AHigh densityImprove operational efficiencyAir-treatment apparatus arrangementsElectric aircraftVolumetric Mass Density

The invention belongs to the field of multi-electric aircraft environmental control, and relates to a multi-electric aircraft environment control system. The system comprises an electric pressurization gas source subsystem, an evaporative circulation refrigeration subsystem and a liquid circulation cooling subsystem. According to the scheme, an electric compressor is used for providing a gas source for an aircraft, in combination with a evaporative circulation refrigeration technology and a liquid circulation cooling technology, the needs of aircraft cabin pressurization, gas supply, heating,equipment cooling are met, the system has the characteristics of being free of engine air bleeding, high in cooling capacity and cooling heat flow density, excellent in operating efficiency and the like, and safety and comfort of onboard personnel and the reliable operation of electronic equipment can be ensured.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

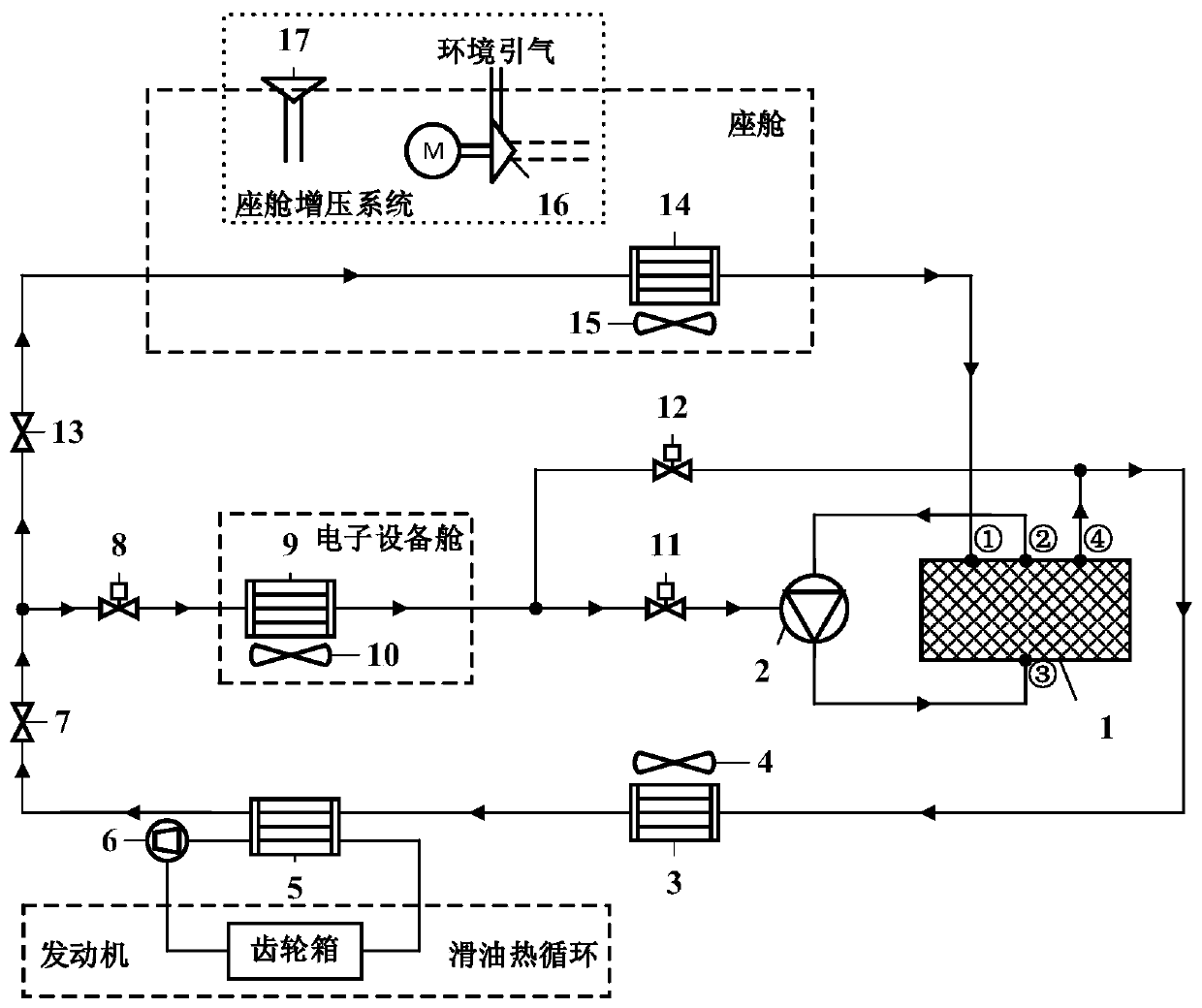

Multi-cabin double-system environment control system of helicopter

ActiveCN110901925AReduce the impactImprove mobilityAir-treatment apparatus arrangementsControl systemEnvironmental control system

The invention discloses a multi-cabin double-system environment control system for a helicopter, which can realize conversion between refrigeration of an electronic equipment cabin of the helicopter and refrigeration and heating of a cabin, and comprises a cabin pressurization system without engine air entraining, so that the influence of the environment control system on a power source is reduced, and the maneuvering characteristics of the helicopter are improved. By the adoption of the compressor middle air supplementing technology, after primary throttling, part of refrigerant flows into the electronic equipment cabin for heat absorption and cooling, and then enters the compressor in an air supplementing mode; the remaining refrigerant continues to be throttled to lower pressure, flowsinto a cabin side evaporator (during refrigeration) or an environment side evaporator (during heating) for heat absorption, and then flows into the air suction end of the compressor; the exhaust temperature of the compressor can be reduced, normal work of a refrigerating system in a high-temperature environment is achieved, and it is guaranteed that an environment control system can effectively operate in an all-weather and wide-working-condition environment; and lubricating oil heat and heat dissipating capacity of electronic equipment are recycled, so that real-time comprehensive managementof the whole machine energy is realized, and the heating efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

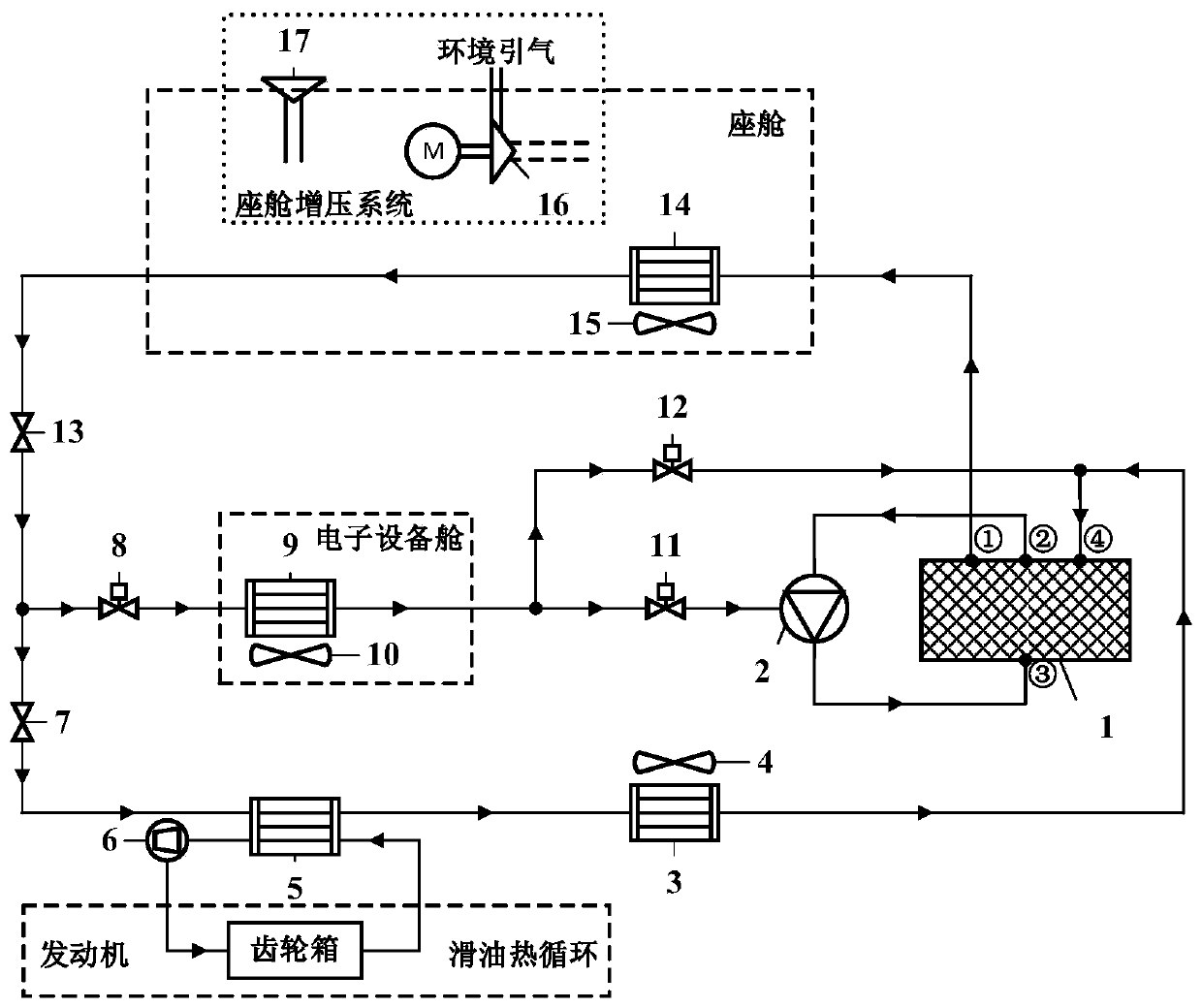

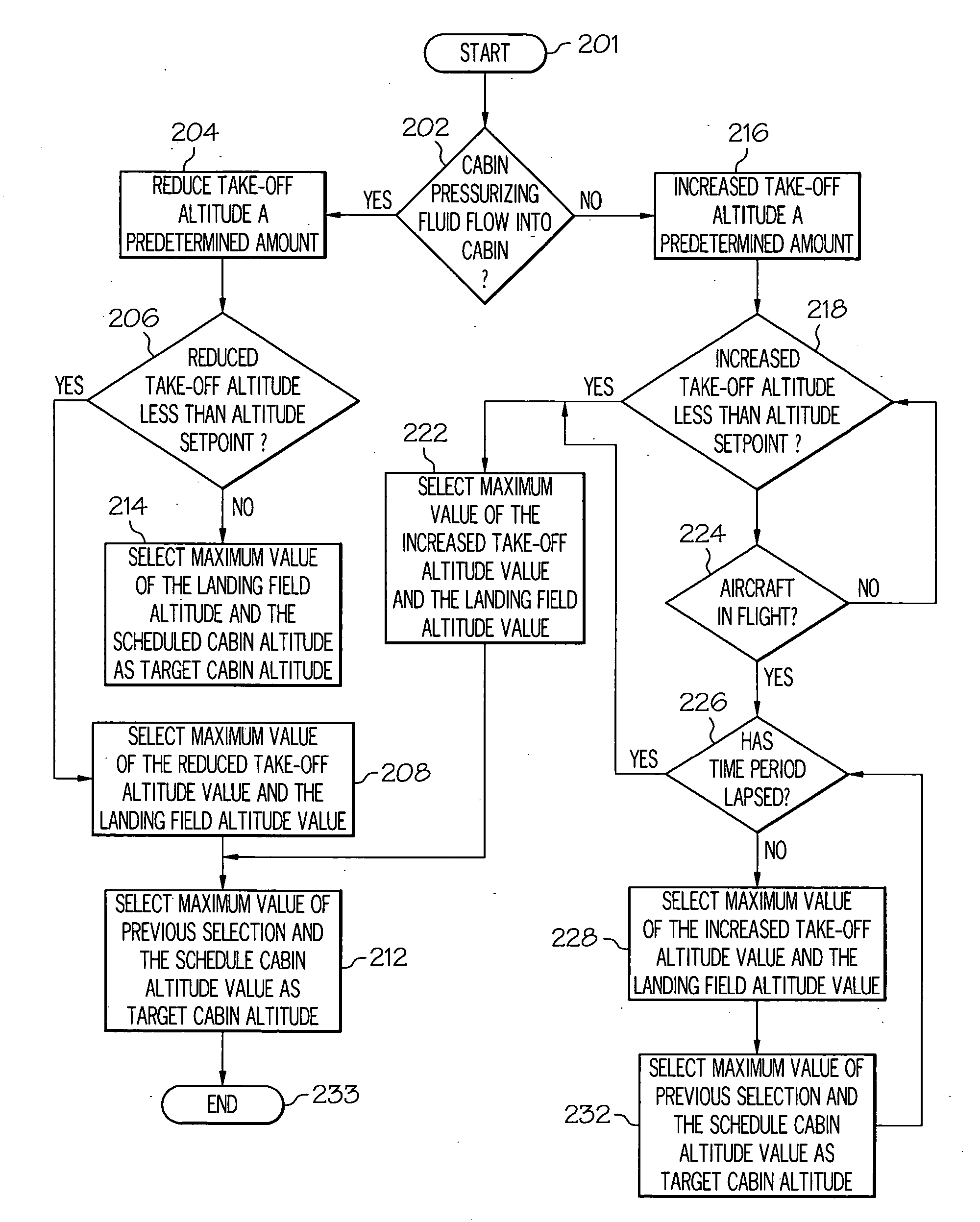

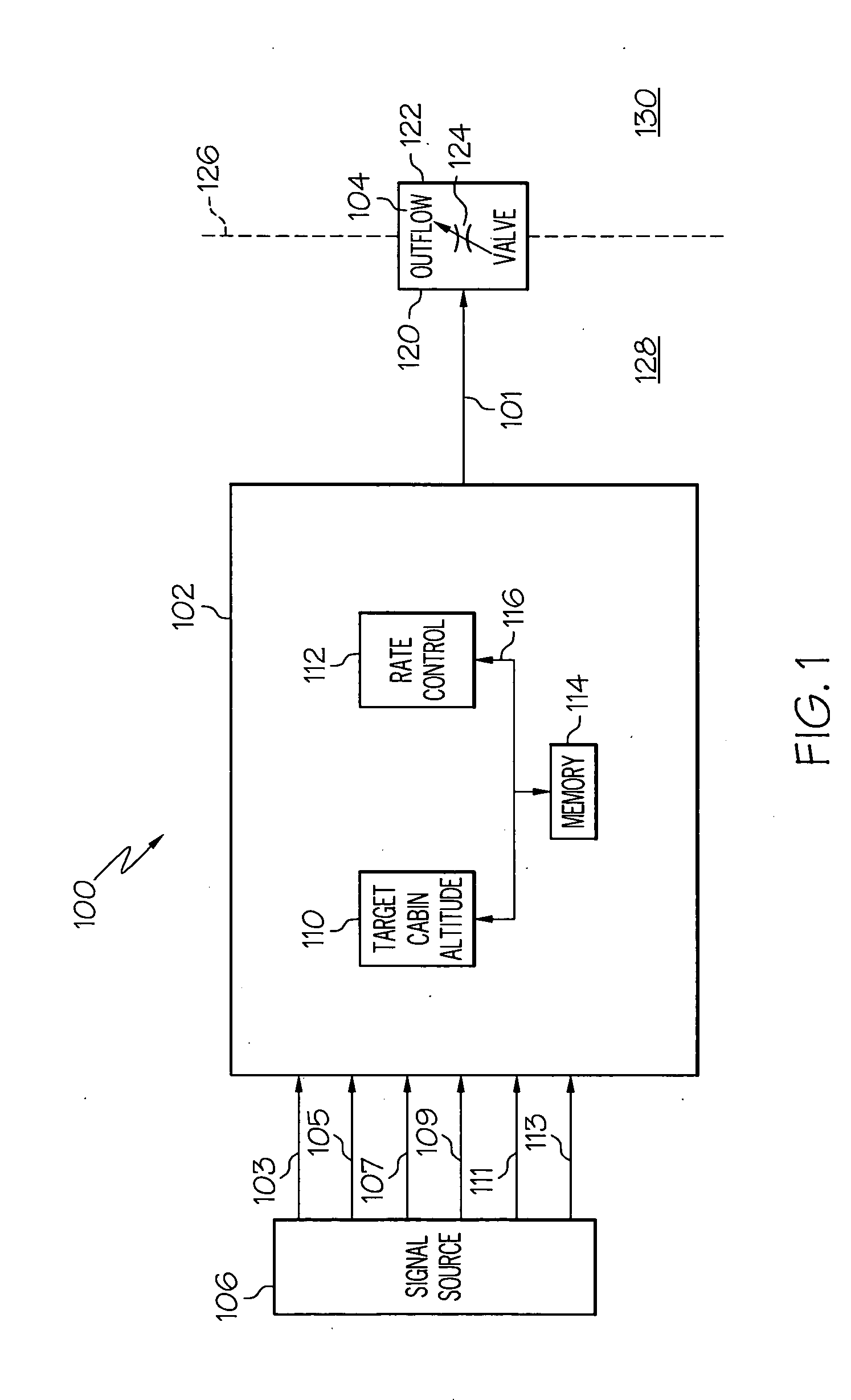

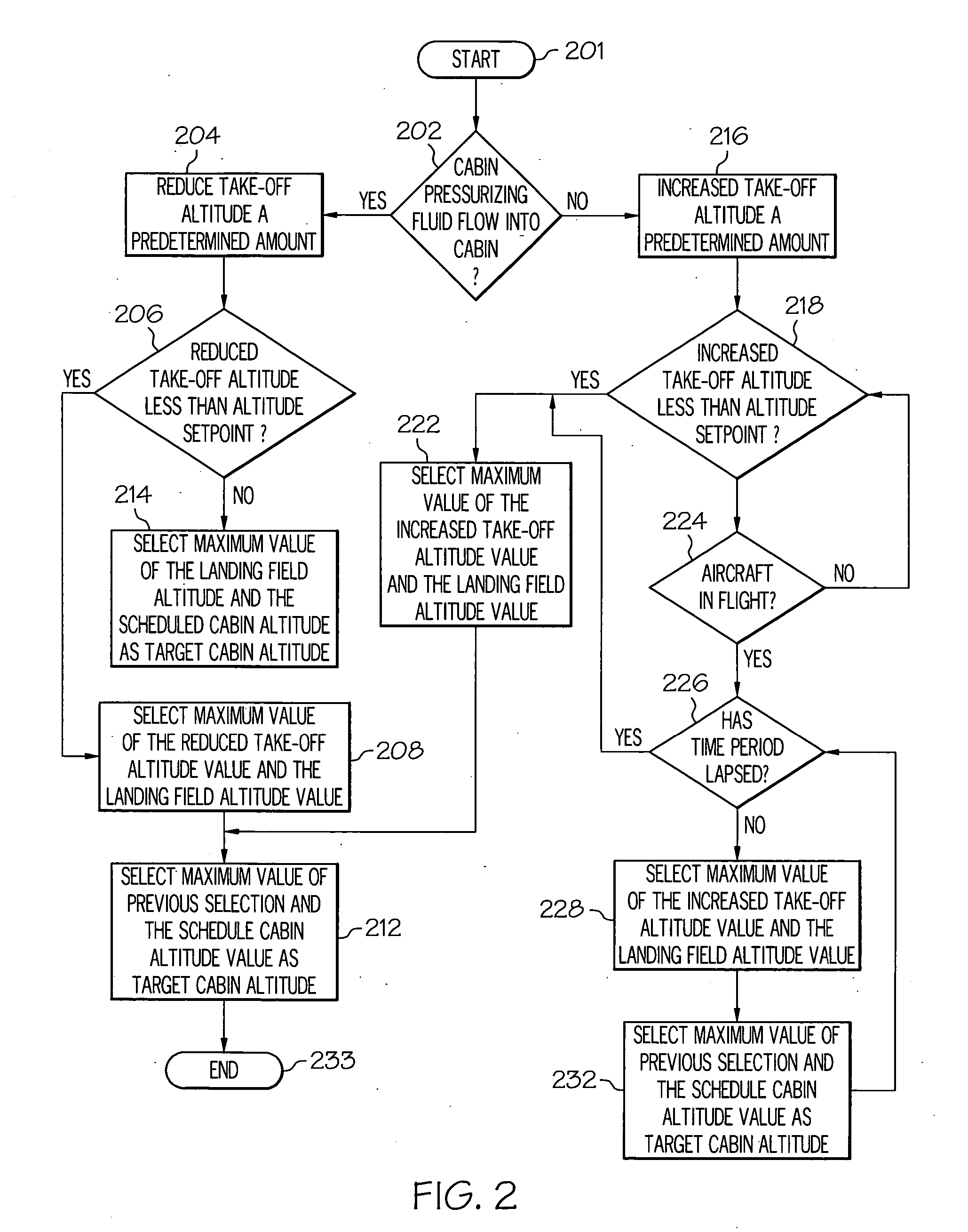

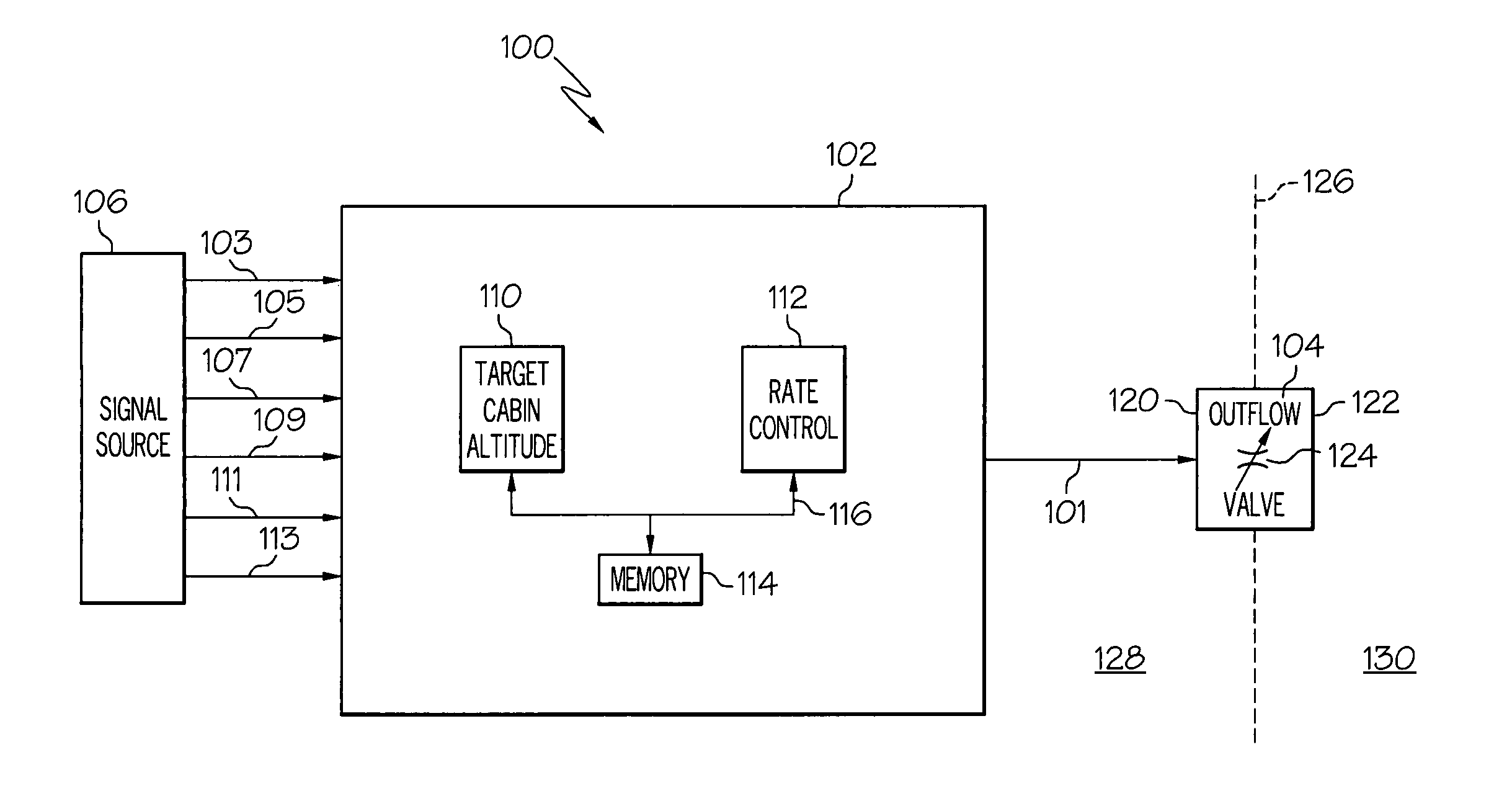

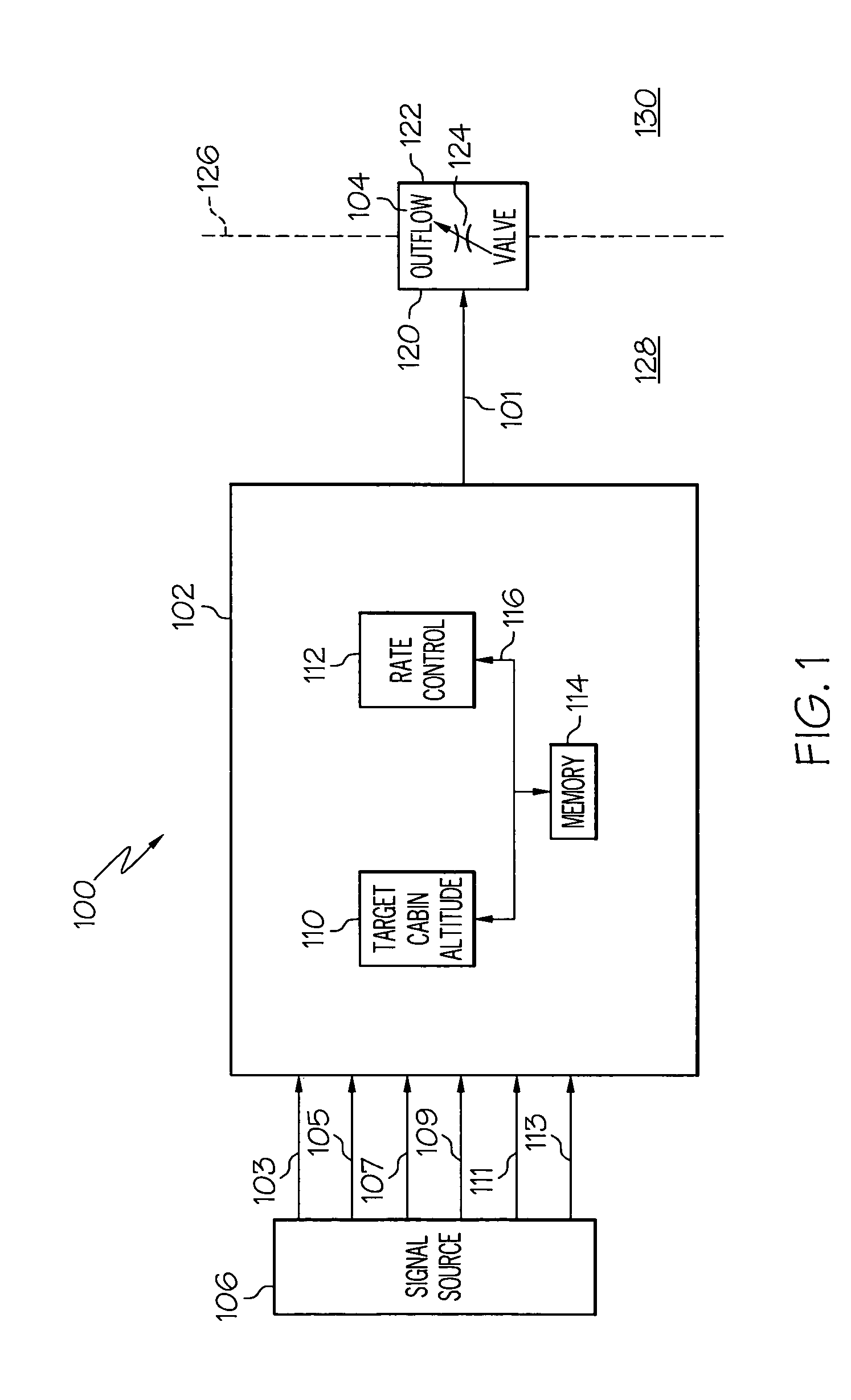

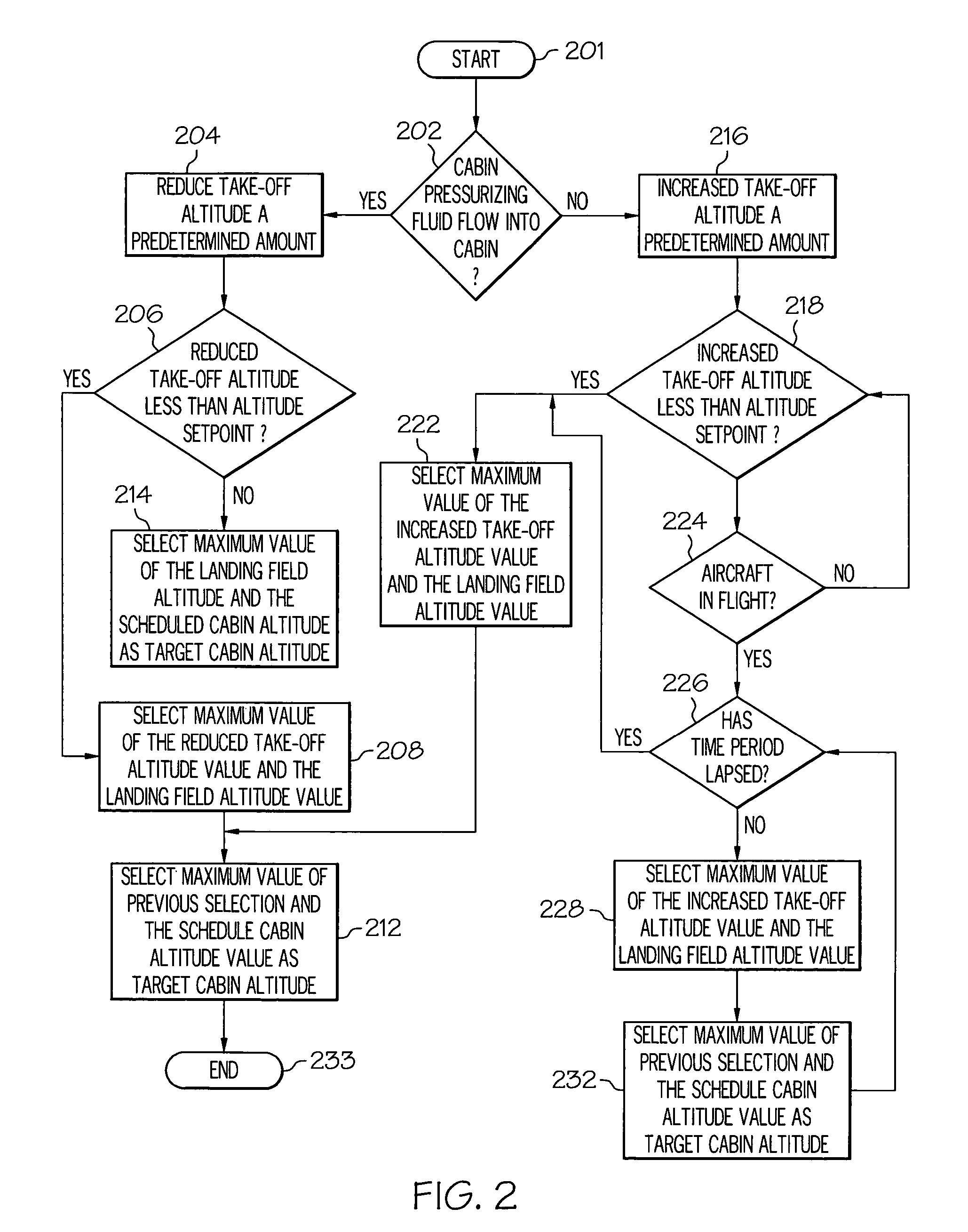

Cabin pressure control system and method that accommodates aircraft take-off with and without a cabin pressurization source

An aircraft cabin pressure control system implements control logic that significantly reduces potentially uncomfortable pressure bumps that can occur during aircraft take-off rotation both with and without cabin pressuring fluid flowing into the aircraft cabin. The control logic implemented by the cabin pressure control system, among other things, determines whether the cabin pressurizing fluid is flowing into the aircraft cabin. If the cabin pressurizing fluid is flowing into the aircraft cabin, aircraft cabin altitude is controlled to at least a first predetermined minimum altitude value below the take-off altitude. If the cabin pressurizing fluid is not flowing into the aircraft cabin, aircraft cabin altitude is controlled to at least a second predetermined minimum altitude value above the take-off altitude.

Owner:HONEYWELL INT INC

Cabin pressure control system and method that accommodates aircraft take-off with and without a cabin pressurization source

ActiveUS7462098B2Aircraft controlAir-treatment apparatus arrangementsControl systemCabin pressurization

Owner:HONEYWELL INT INC

Aircraft cabin pressure control system and method that improves cabin pressurization during take-off

ActiveUS7950987B2Quickly and consistentlyComfortableAir-treatment apparatus arrangementsEnergy efficient board measuresRate limitingControl system

Owner:HONEYWELL INT INC

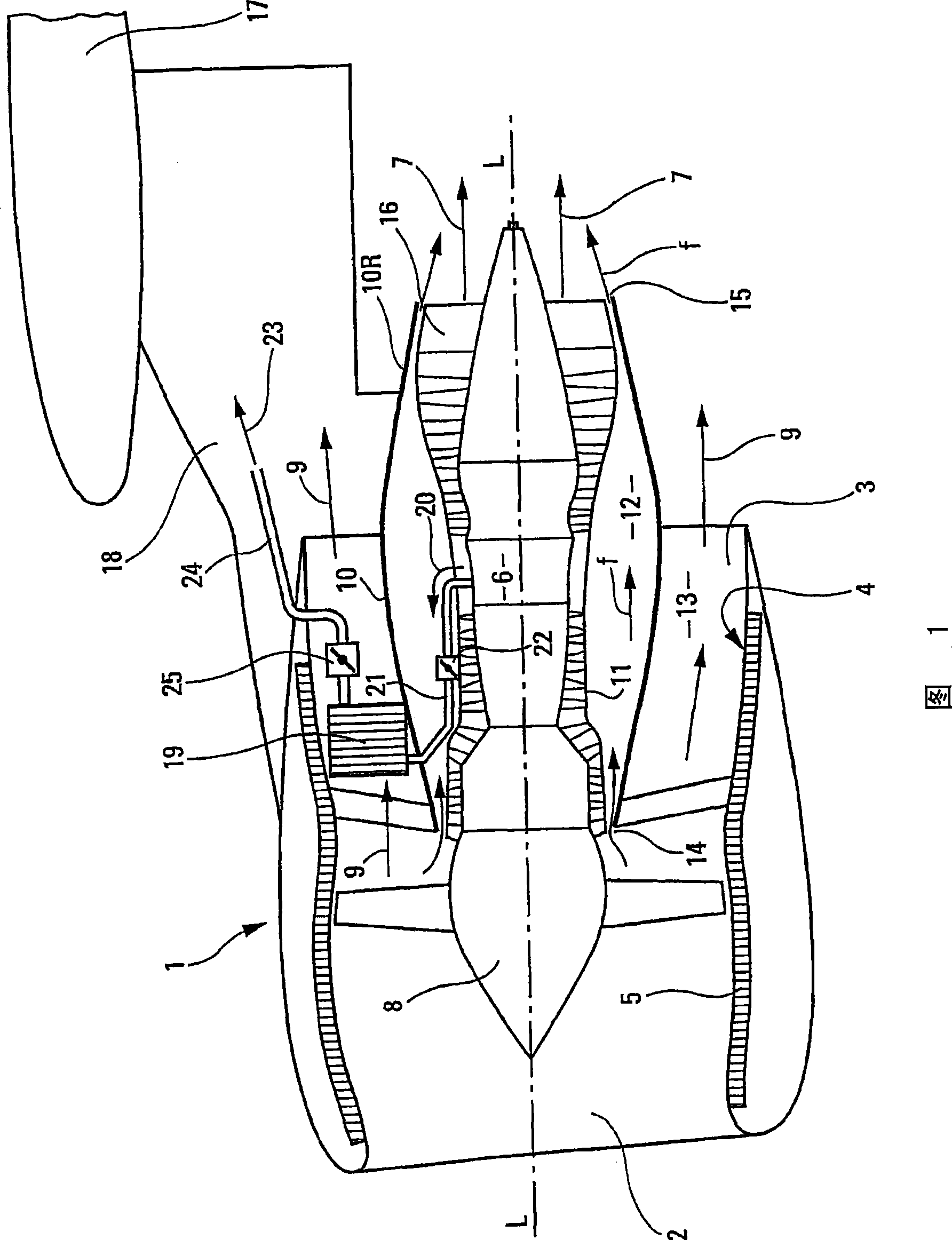

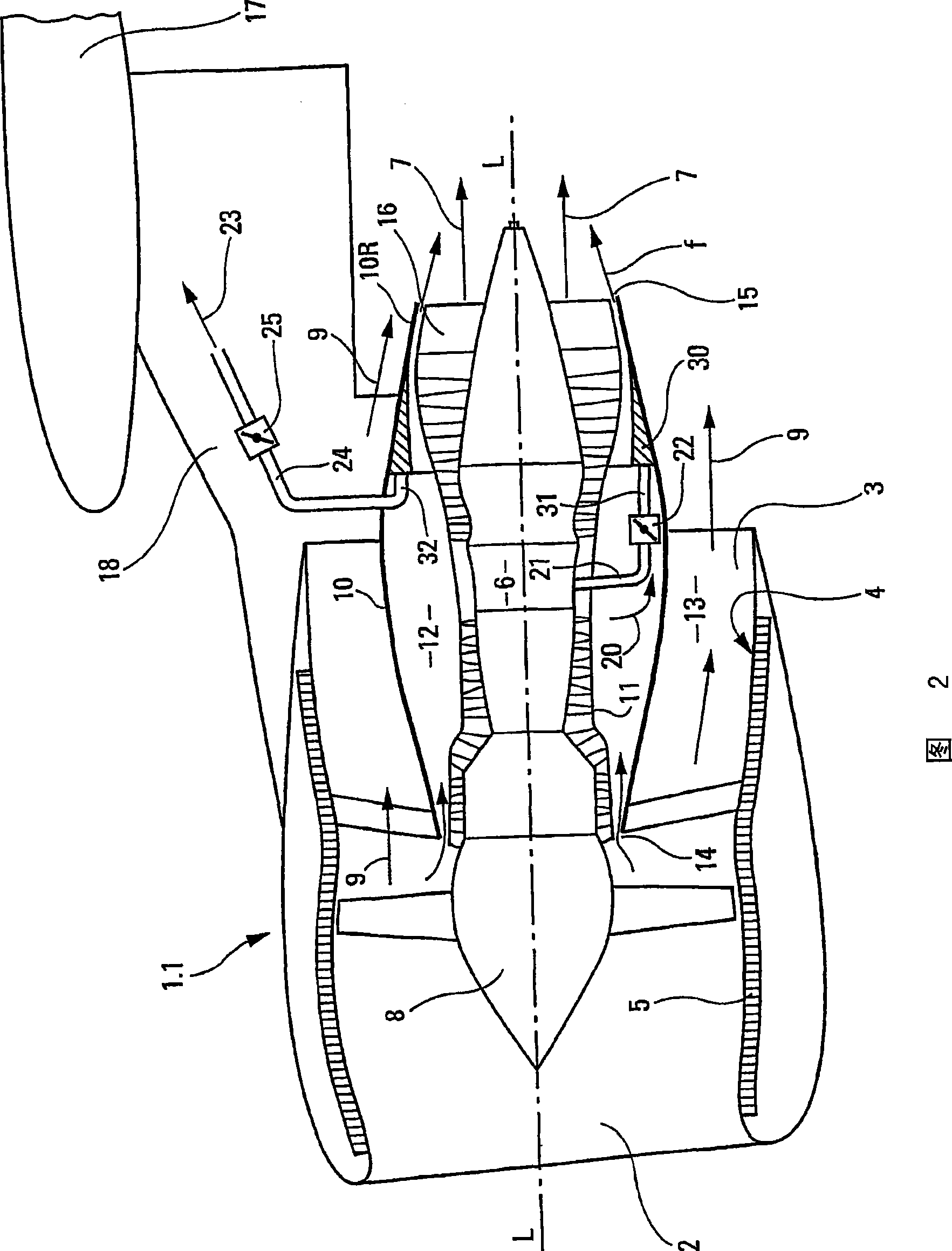

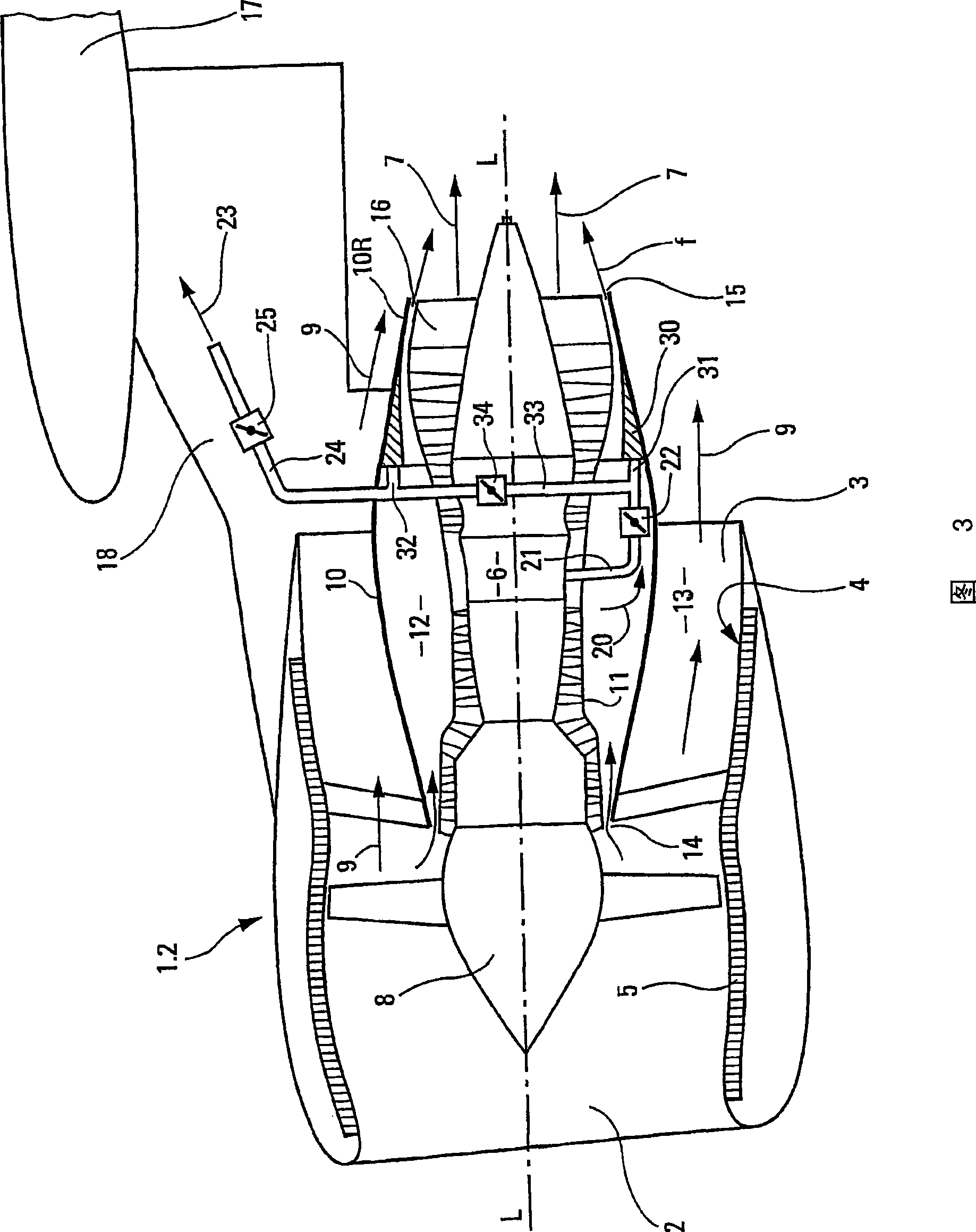

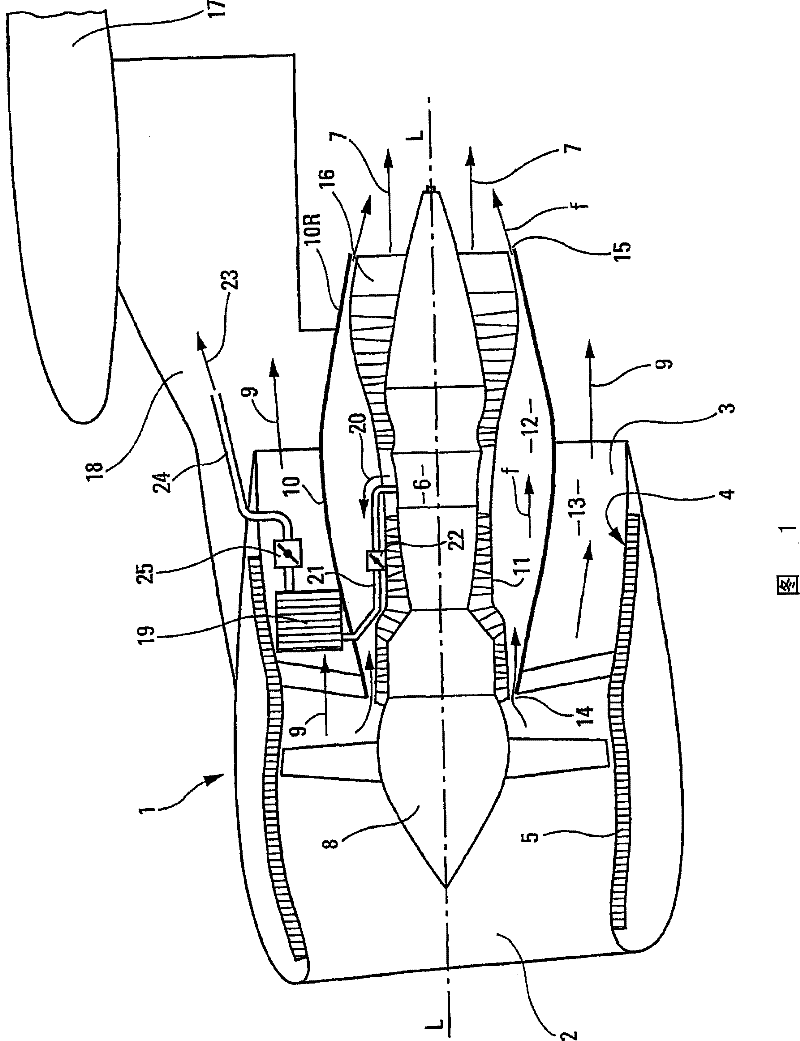

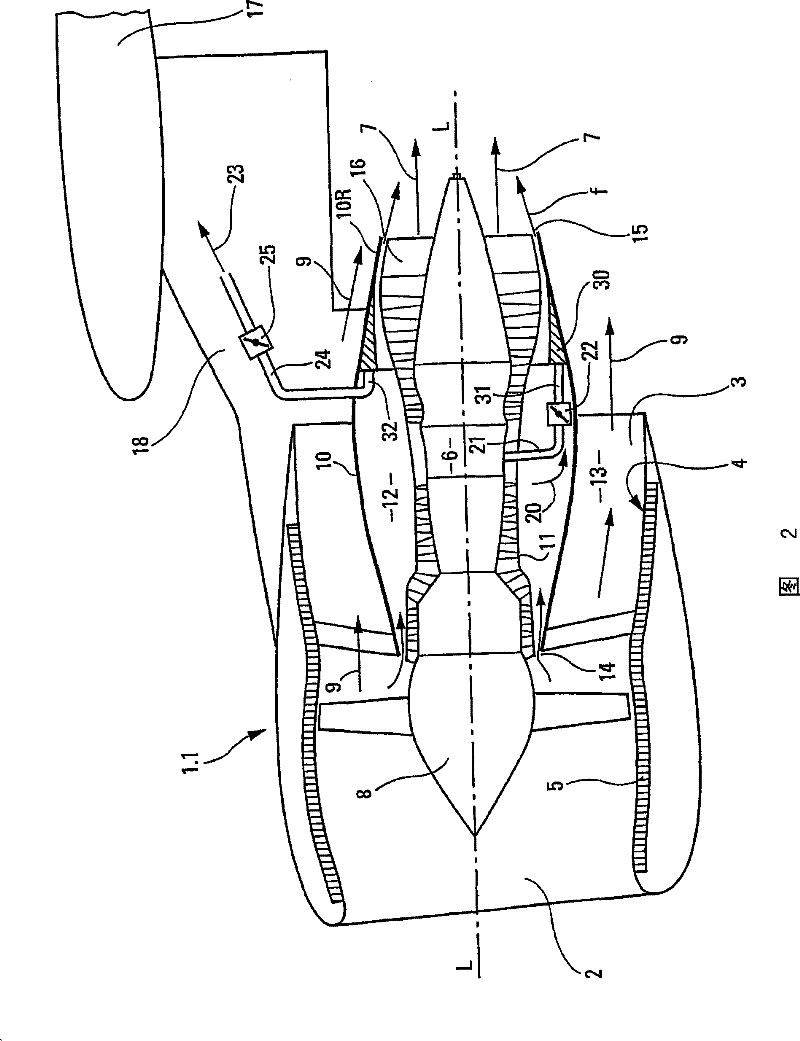

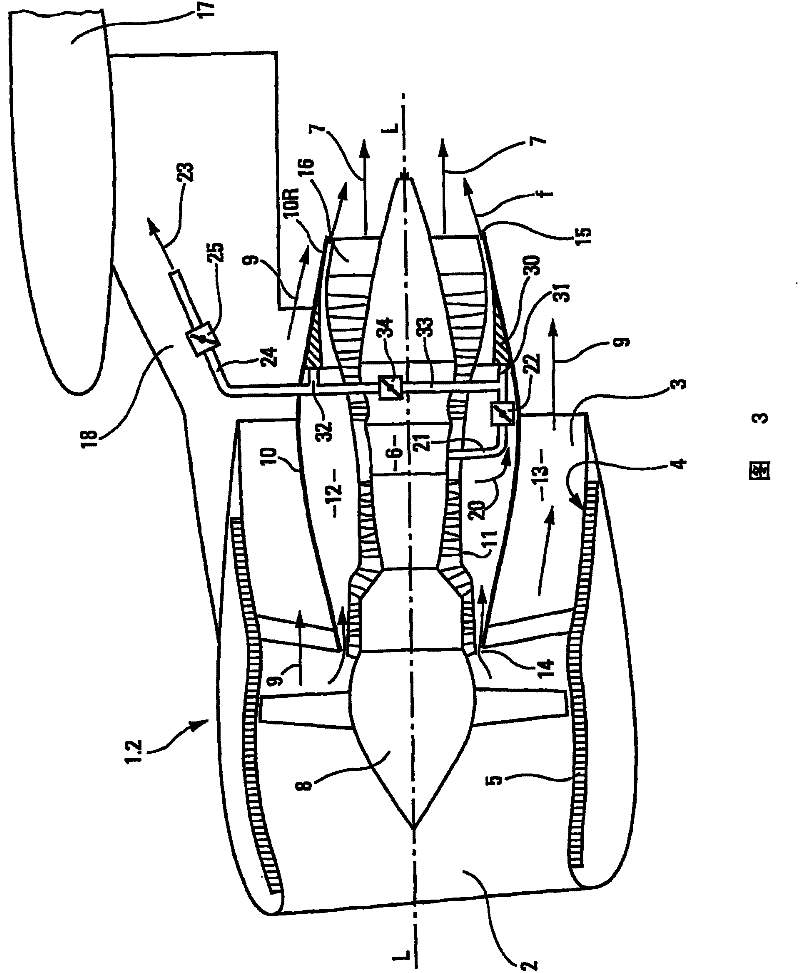

Dual flow turbine engine equipped with a precooler

ActiveCN101374722AAvoid aerodynamic disturbancesAvoid Disadvantages of EjectionEngine fuctionsAir-treatment apparatus arrangementsTurbineCabin pressurization

Owner:AIRBUS OPERATIONS (SAS)

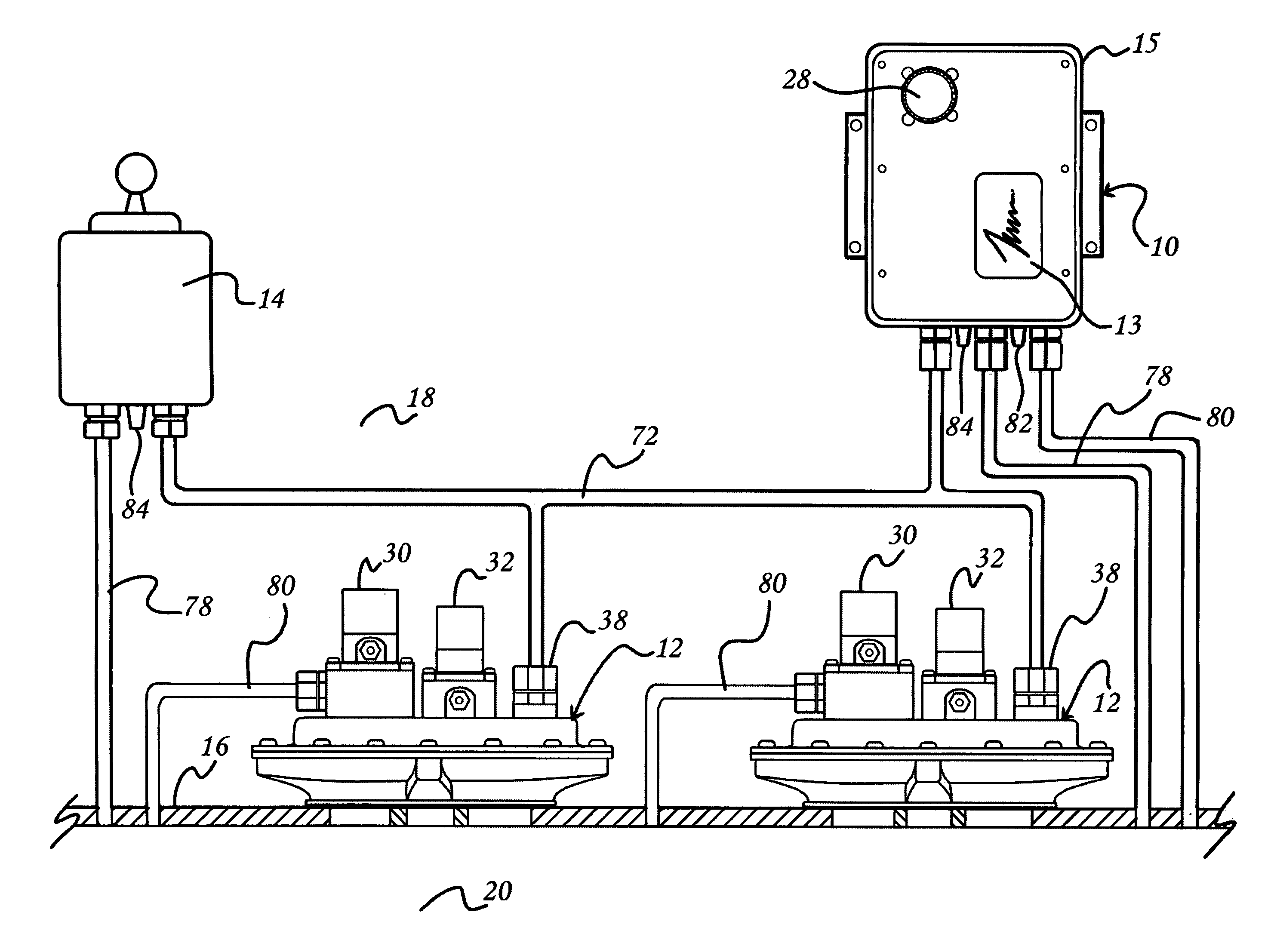

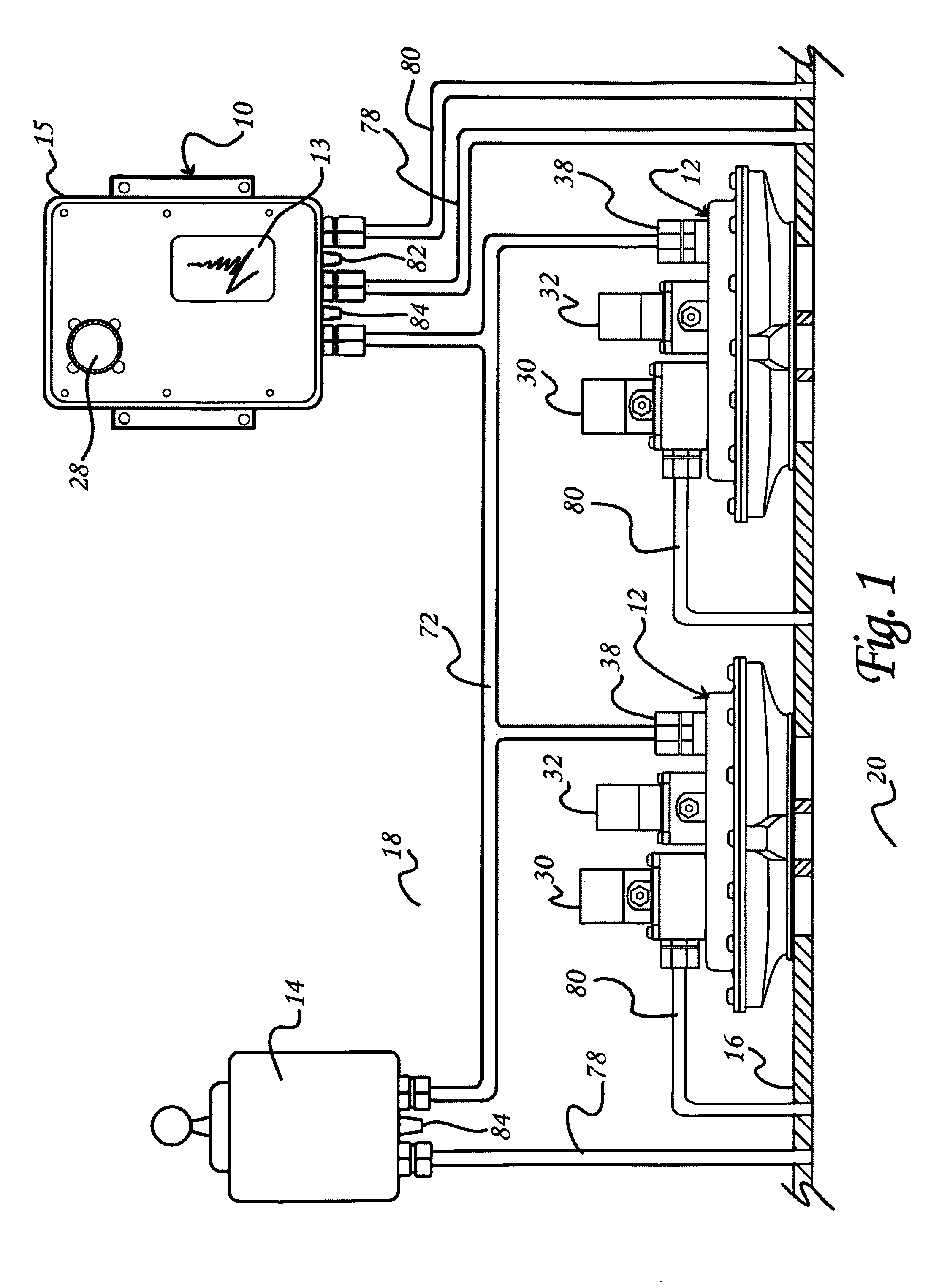

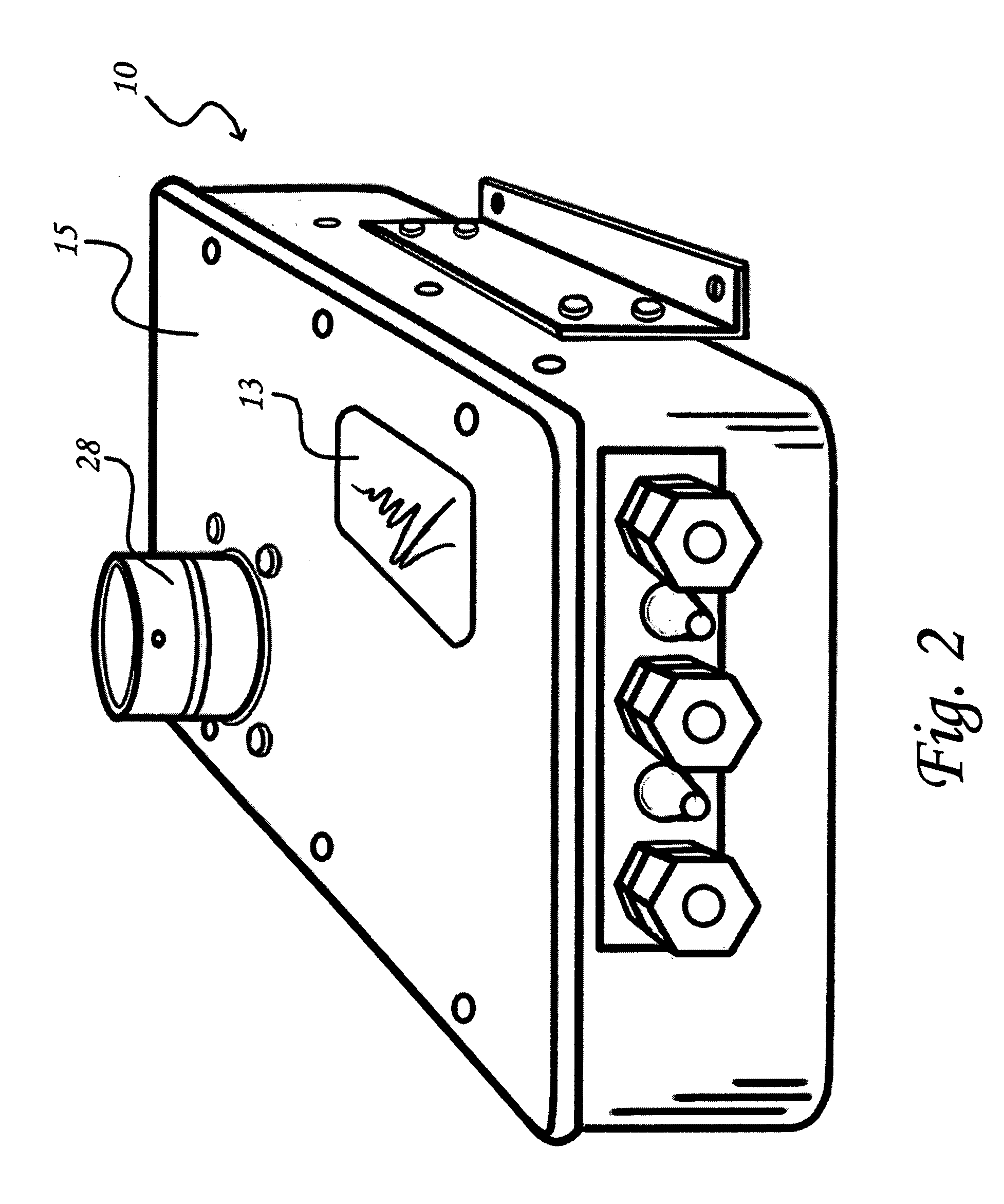

Aircraft cabin pressurization control apparatus

InactiveUS20060252360A1Eliminate needAir-treatment apparatus arrangementsControl systemElectrical connection

A cabin pressure control apparatus that has an outflow valve that operates with a reference chamber without the need of using bleed air from the aircraft engines to adjust the pressure within the reference chamber. The invention has only pneumatic connections and no electrical connections to the outflow valve. Intrinsic negative differential protection is provided. Control solenoid(s) and pump(s) are internal to the controller for protection and simplified interconnection. The apparatus can be easily fitted in the aircraft without requiring additional cockpit panel space. The aircraft pressurization control apparatus is fully backward compatible with existing pressurization control systems as currently being manufactured by Kollsman, Inc.

Owner:ENVIRO SYST

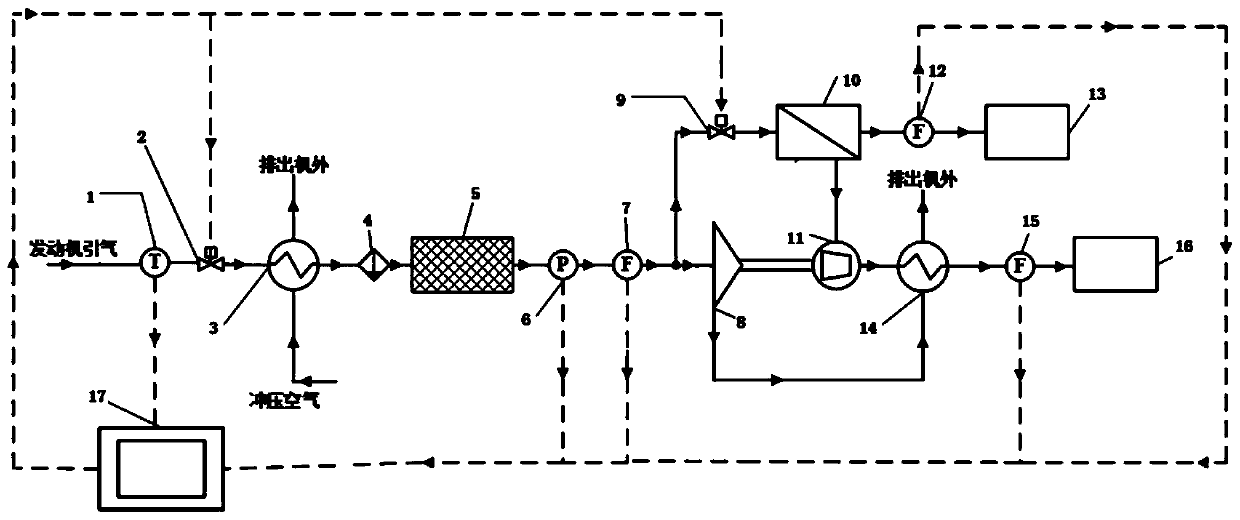

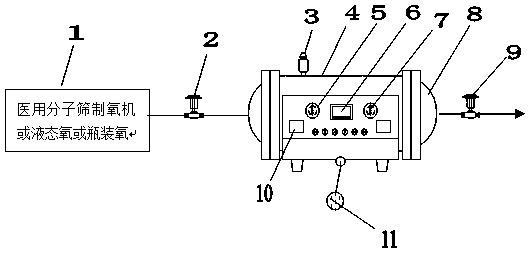

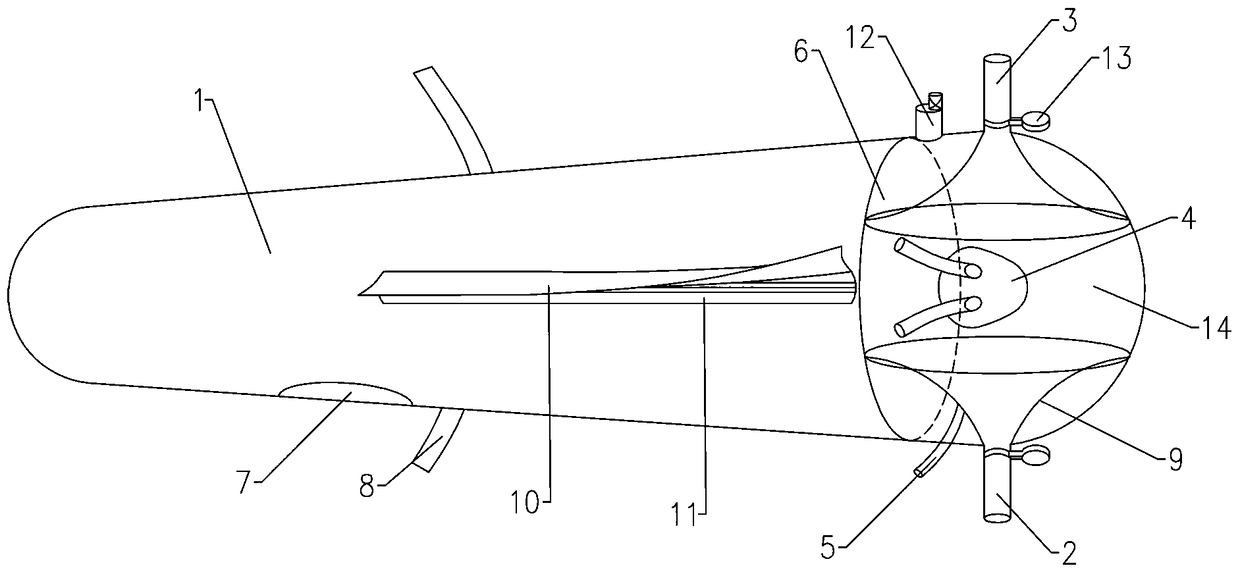

Cabin pressurizing oxygen supply system based on aerodynamic turbine driving

PendingCN110963060AIncrease speedReduce volumeAir-treatment apparatus arrangementsFuel tank safety measuresElectric controlAir compressor

The invention discloses a cabin pressurizing oxygen supply system based on aerodynamic turbine driving. The cabin pressurizing oxygen supply system comprises a temperature sensor, a first electric control valve, a first heat exchanger, a water separator, a Venturi pressure stabilizer, a pressure sensor, a first flow sensor, an aerodynamic turbine, a second electric control valve, a hollow fiber membrane separator, a centrifugal compressor, a second flow sensor, a second heat exchanger, a third flow sensor and a controller. According to the invention, the centrifugal compressor driven by the aerodynamic turbine is used for recycling the oxygen-enriched gas of the hollow fiber membrane separator. The oxygen content of the cabin is increased, the pressure height of the cabin is conveniently increased, and the requirement for the structural strength of the cabin is effectively reduced; the air entraining amount of an engine air compressor is reduced, and the compensation loss of an airplane is reduced; the system has no motor drive and is feasible to manufacture; the aerodynamic turbine has the advantages of being high in rotating speed, small in size and large in flow and meets the technical requirement for cabin pressurization and oxygen supply.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Airflow management in cabin of aircraft

ActiveUS11059593B2Reduce airflowAir-treatment apparatus arrangementsEnergy efficient board measuresTemperature controlNacelle

Cabin air is managed in the aircraft as a function of the minimum requirements for defined air quality needs, temperature control needs, and cabin pressurization needs. Airflow may be varied dynamically as a function of aircraft or cabin altitude, and the minimum requirements for airflow may be determined in real time so as to dynamically set an airflow schedule.

Owner:BOMBARDIER INC

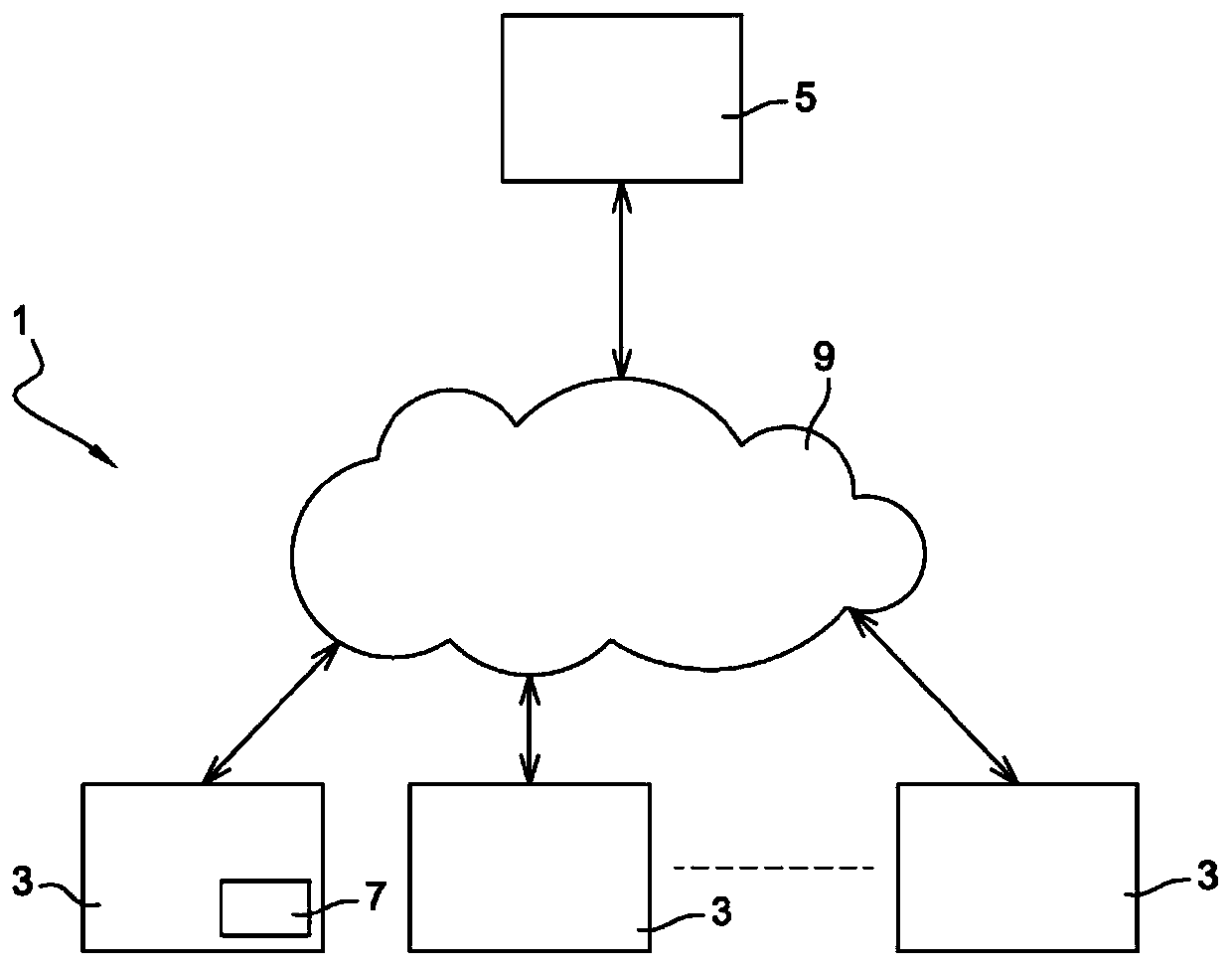

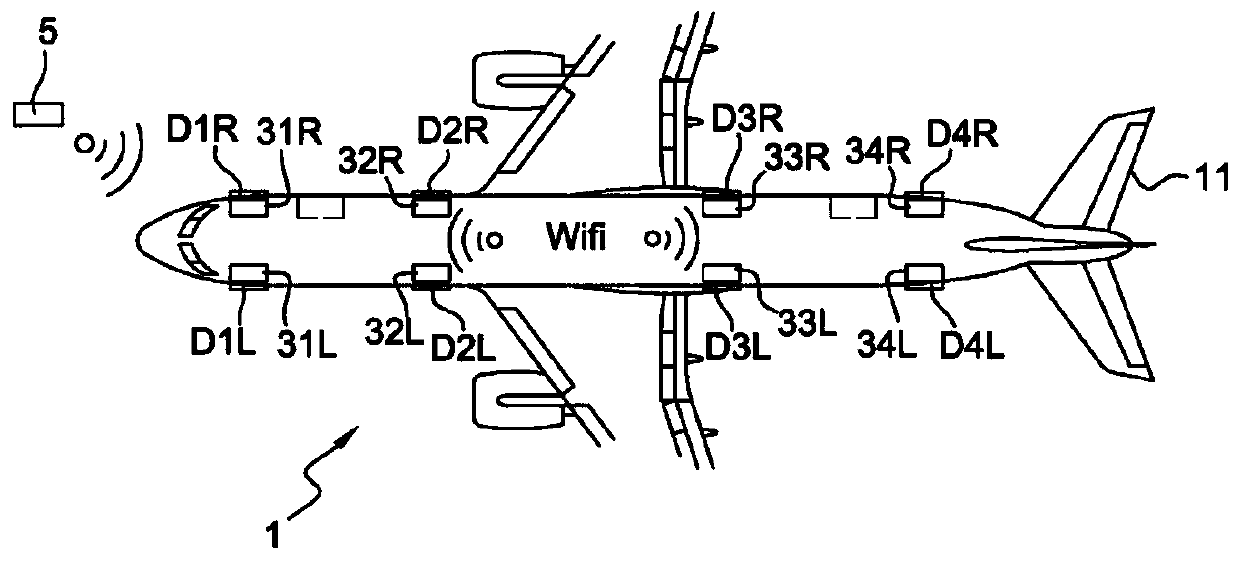

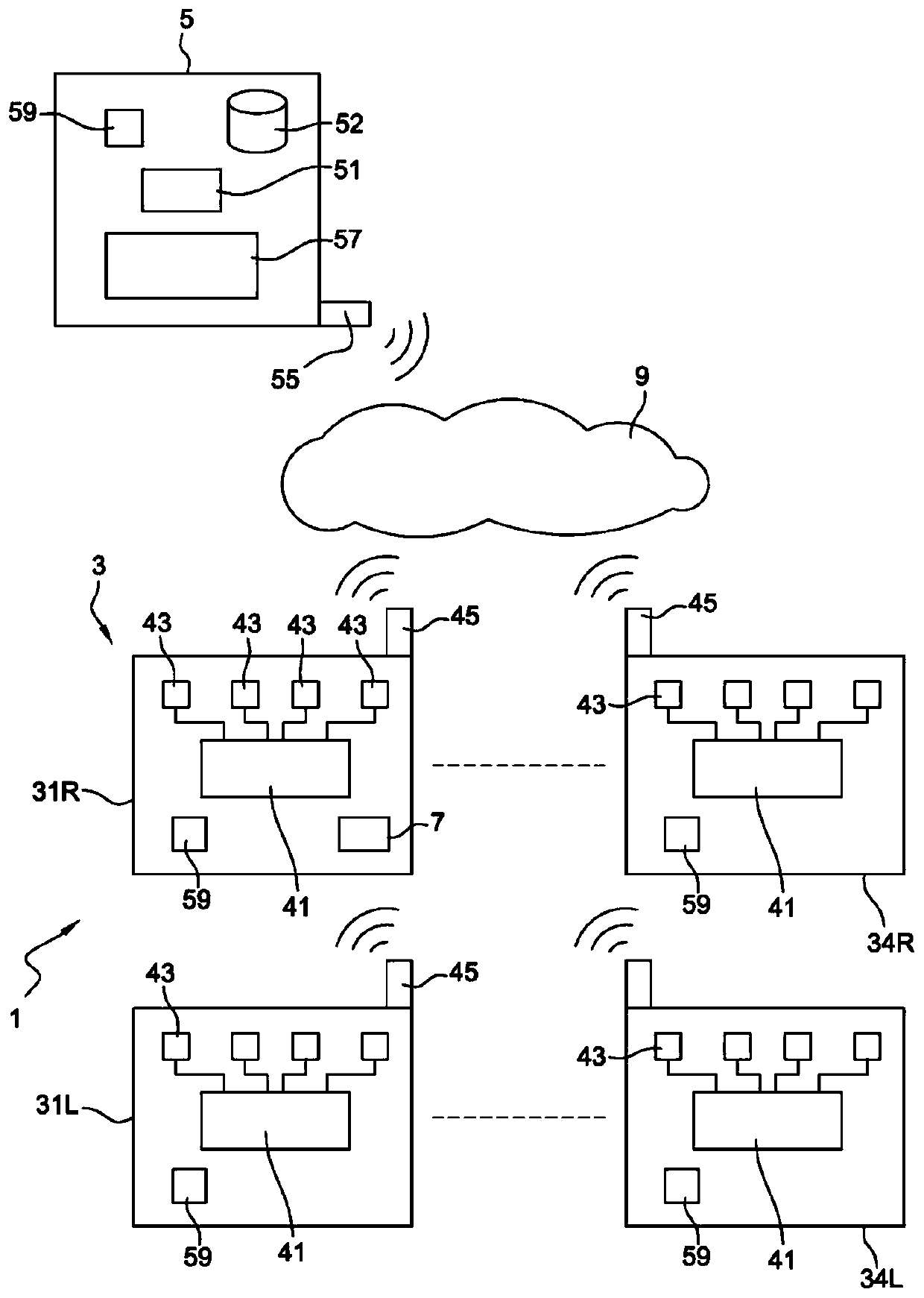

System and method for automatically detecting leak noise in an aircraft

PendingCN109941455APrevent false detectionEasy to installVibration measurement in solidsDetection of fluid at leakage pointFlight testFlight vehicle

The invention proposes a method and a system for detecting leak noise in an aircraft, making it possible to perform ground tests in complete safety and over an entire cabin pressurization range, thusavoiding having to resort to a plurality of in-flight tests, said system includes: at least one acquisition device (3) intended to be installed in at least one area of interest of the aircraft (11), said acquisition device (3) being configured to acquire data in relation to current noise in said area of interest and data in relation to a current pressure gradient between the cabin of the aircraftand the outside, and a monitoring device (5) configured to control the acquisition of the data by said at least one acquisition device and to receive said acquisition data in order to detect any leaknoise in said at least one area of interest.

Owner:AIRBUS OPERATIONS (SAS) +1

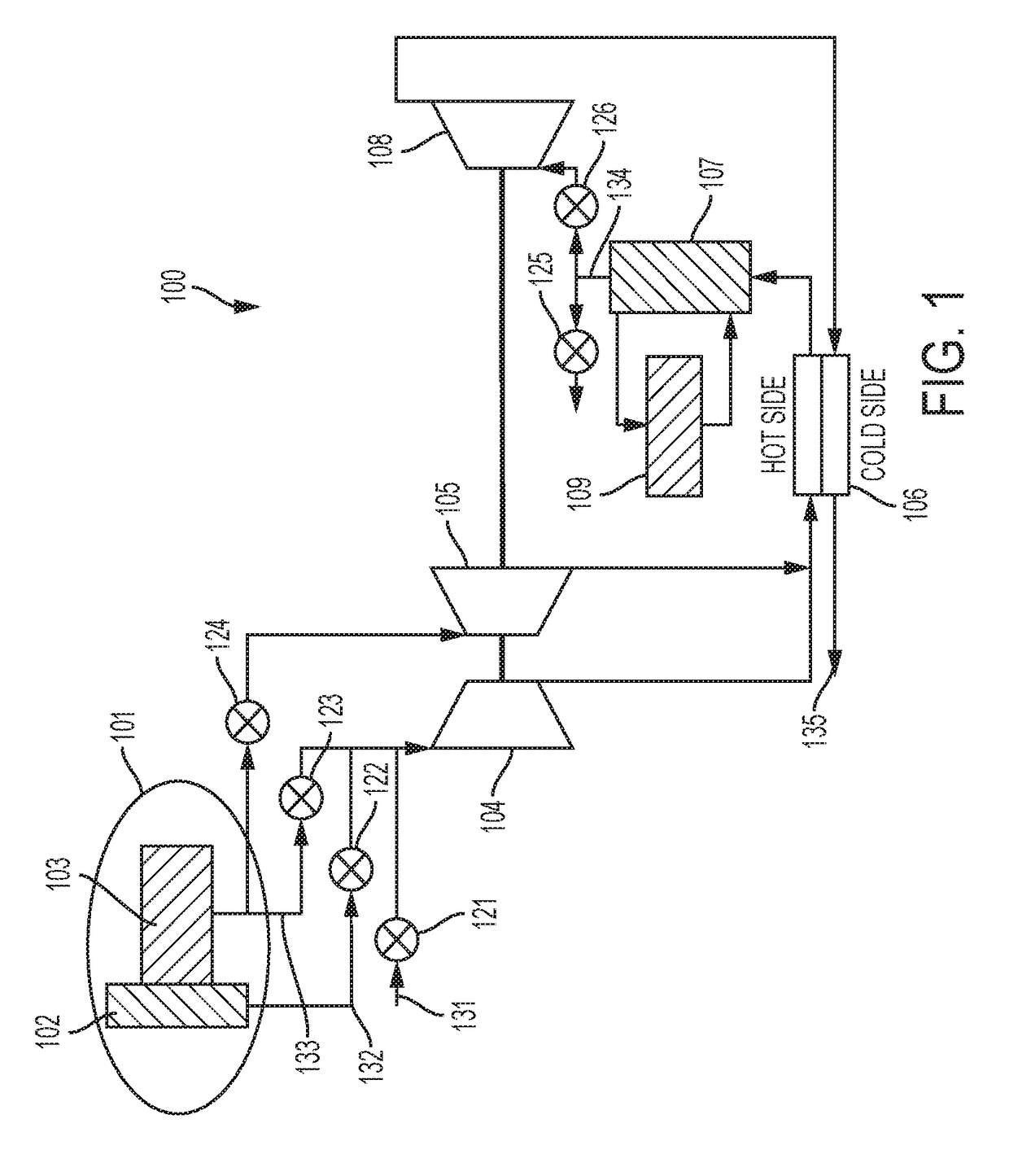

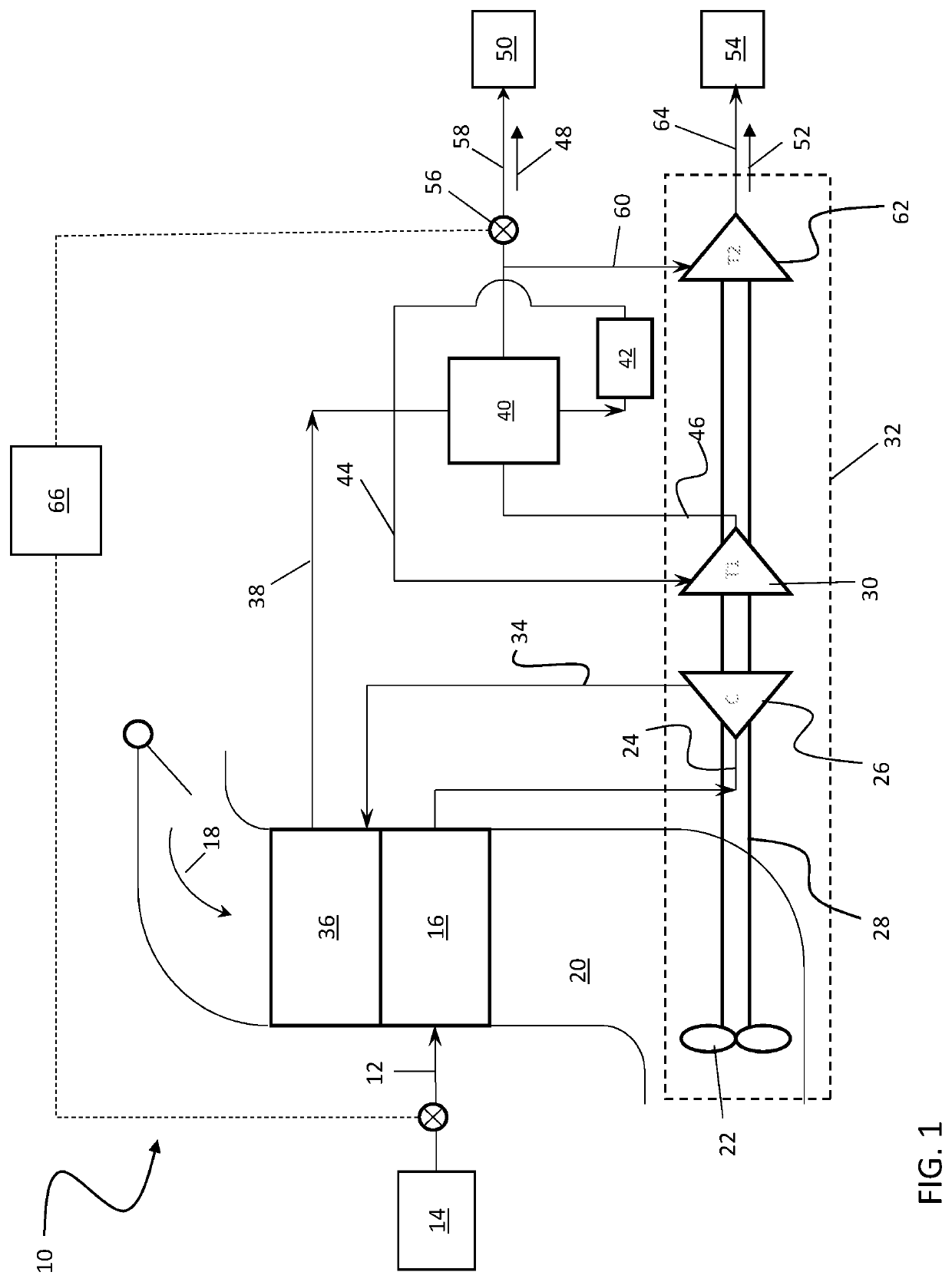

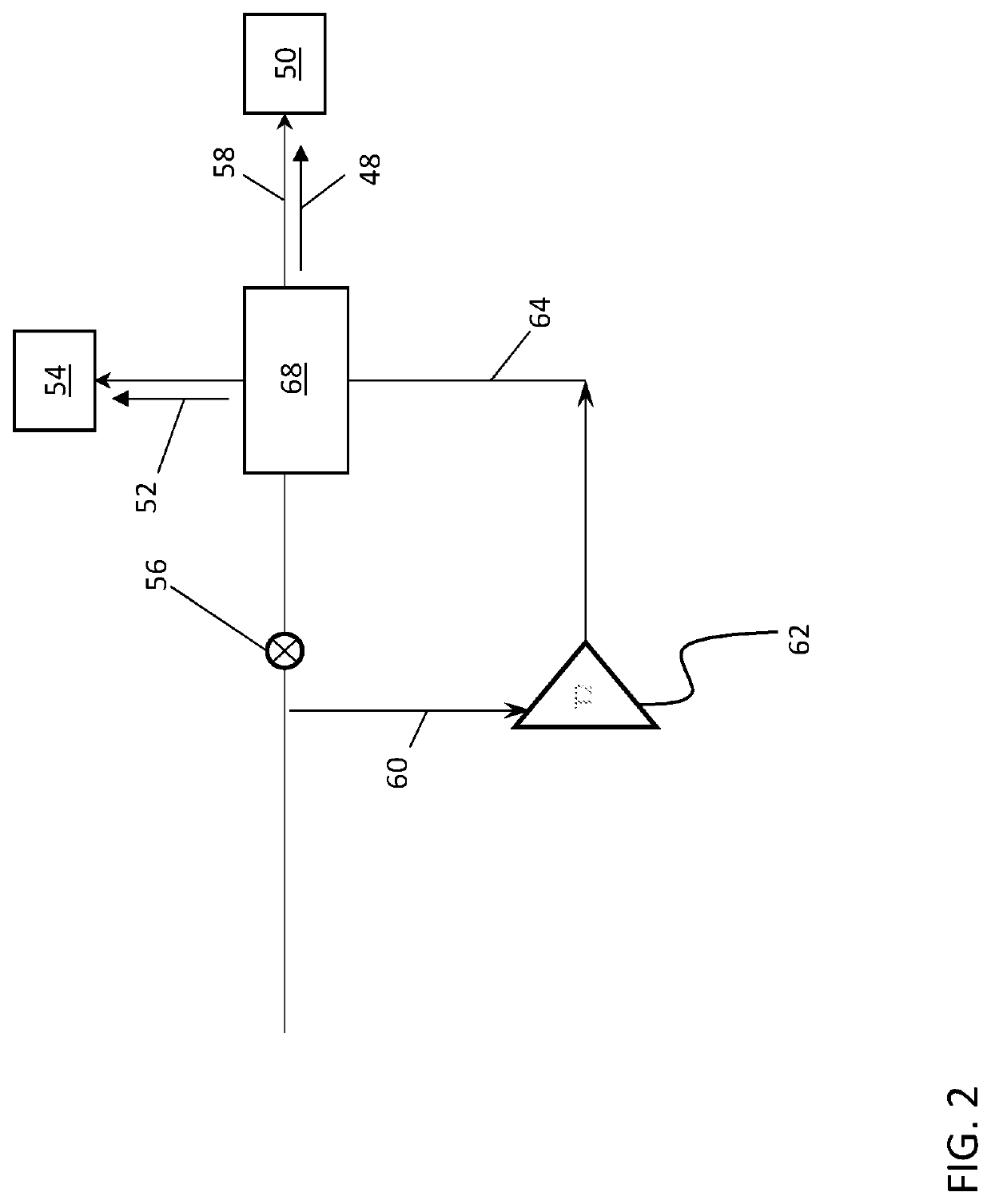

Cabin outflow air energy optimized cabin pressurizing system

ActiveUS20190039738A1Air-treatment apparatus arrangementsEnergy efficient board measuresNacelleMotor drive

A pressurization system includes a first compressor that receives a ram air, a fan air, or engine air; a first turbine that is on a common shaft with the first compressor and wherein the first turbine receives an engine air; a main heat exchanger downstream of the first compressor and the first turbine; an internal environment suitable for human occupants and downstream of the main heat exchanger; a second turbine downstream of the internal environment; the second turbine may be on the common shaft with the first compressor and first turbine; or a generator downstream of the second turbine; a motor downstream of the generator; and wherein the motor drives the first compressor.

Owner:HONEYWELL INT INC

Helicopter temperature regulation and oil tank explosion-proof system

ActiveCN113232867AEasy to modifyEasy maintenanceAir-treatment apparatus arrangementsFuel tank safety measuresInerting systemLiquid fuel

The invention discloses a helicopter temperature regulation and oil tank explosion-proof system which comprises a first-stage compressor, a condenser, a second-stage compressor, a first-stage evaporation refrigeration cycle system, a second-stage evaporation refrigeration cycle system, a cooling inerting module, a cabin pressurization system and a main controller. The first-stage evaporation refrigeration cycle system is connected with the cabin pressurization system, and a generated cooling capacity is used for reducing the temperature of a passenger cabin and a cabin; the second-stage evaporation refrigeration cycle system is connected with the cooling inerting module; the cooling inerting module is used for inerting liquid fuel oil in an onboard oil tank; and high-temperature and high-pressure refrigerant steam output by a first-stage compressor is condensed through a condenser and then subjected to pressure reduction treatment, one part of the steam is output to a first-stage evaporation cold circulation system, and the other part of the steam is output to a second-stage evaporation cold circulation system. The system solves the problem of insufficient air entraining pressure of the helicopter, reduces the total weight of an environment control system and an inerting system, and has the advantages of simple structure, reliable performance, safety, environmental protection and convenience in installation and maintenance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

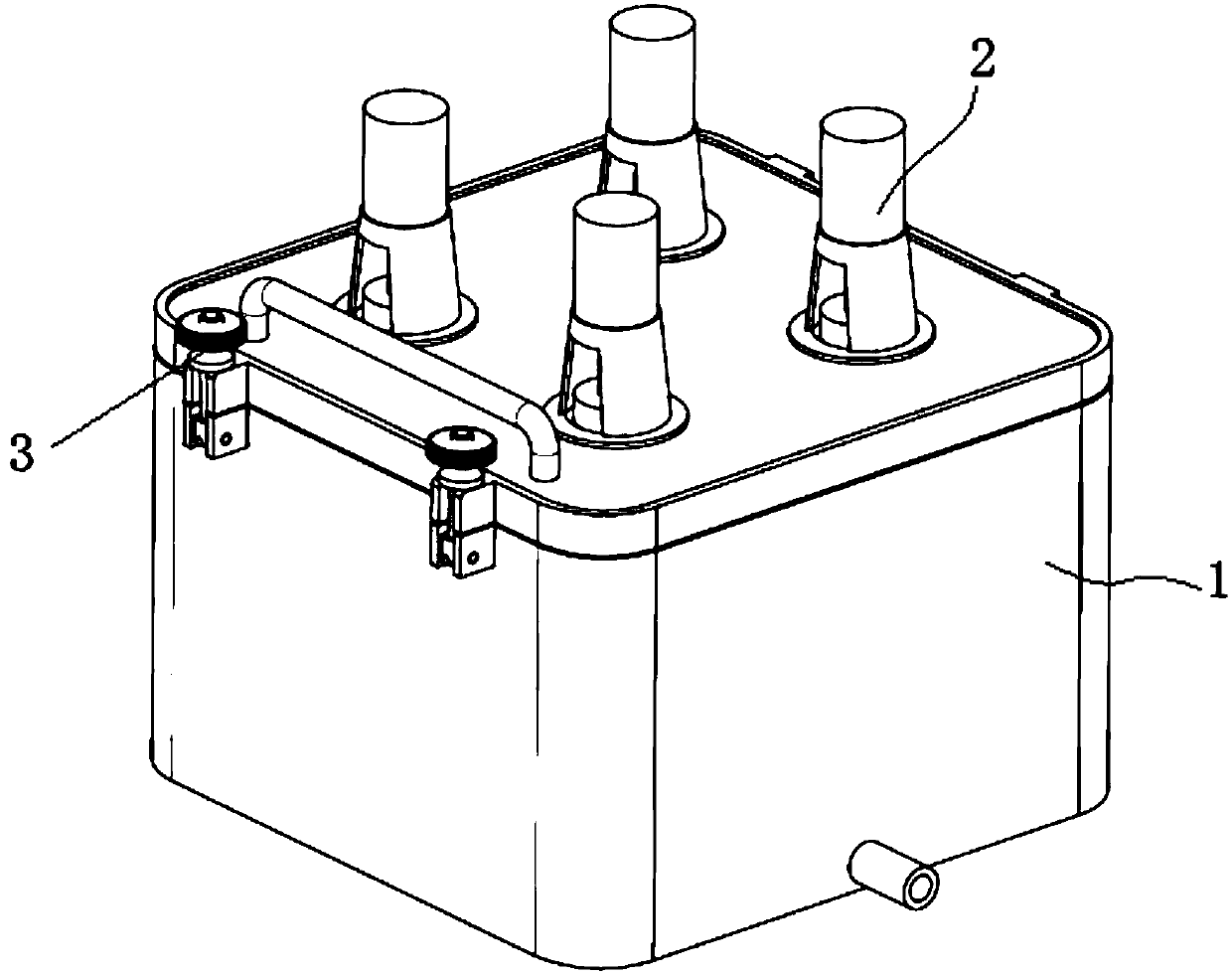

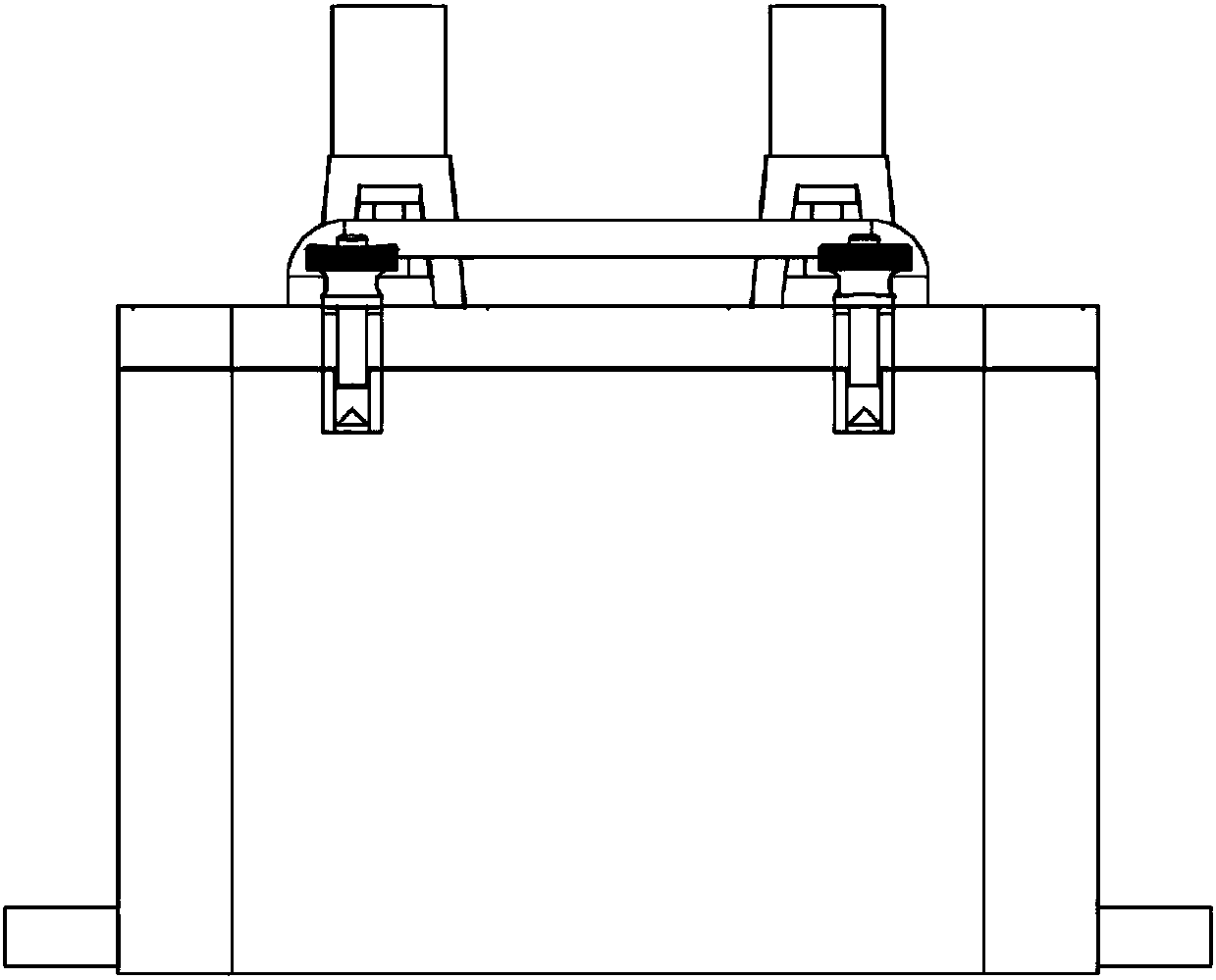

Device and method for quickly detecting air leakage of ultraviolet germicidal lamp

InactiveCN105067205AQuick checkoutSolve the problem of air leakageFluid-tightness measurement using electric meansEngineeringHigh pressure

The present invention discloses a device and a method for quickly detecting the air leakage of an ultraviolet germicidal lamp. The device for quickly detecting the air leakage of the ultraviolet germicidal lamp is composed of a high-pressure cabin body and the high-pressure cabin body is arranged on a cabin body bracket bench. The high-pressure cabin body is provided with a high-pressure cabin door, a cabin pressurization valve and a steady-pressure decompression valve. The method specifically comprises the steps of vacuumizing a to-be-tested lamp tube, and hermetically filling the inert gas inside the lamp tube; 2) placing the above lamp tube processed in the step 1) in the high-pressure cabin body, connecting the high-pressure cabin body with a pressurization pump, and switching on the cabin pressurization valve to pressurize the high-pressure cabin body; 3) switching on the steady-pressure decompression valve to take the to-be-tested lamp tube out of the high-pressure cabin body when the air pressure outside the to-be-tested lamp tube is 300-600 times the air pressure inside the to-be-tested lamp tube; 4) detecting the to-be-tested lamp tube by means of a high-frequency spark leak detector. The device is simple in operation method and greatly shortens the manufacturing cycle. Meanwhile, the quality reliability of products is improved. The air-leakage problem of lamp tubes in the lamp manufacturing industry can be solved.

Owner:宁波大榭开发区佑威光电有限公司

Pressure optimized sourcing of cabin pressurization and component air cooling

An environmental control system (ECS) for an aircraft includes at least one cooling turbine, and a turbine bypass valve disposed fluidly upstream of the at least one cooling turbine. The turbine bypass valve is configured to direct a first portion of an ECS output airflow to a first air load at a first pressure via a first outlet passage, and direct a second portion of the ECS output airflow across a cooling turbine of the at least one cooling turbine and to a second air load at a second pressure lower than the first pressure for cooling thereof.

Owner:HAMILTON SUNDSTRAND CORP

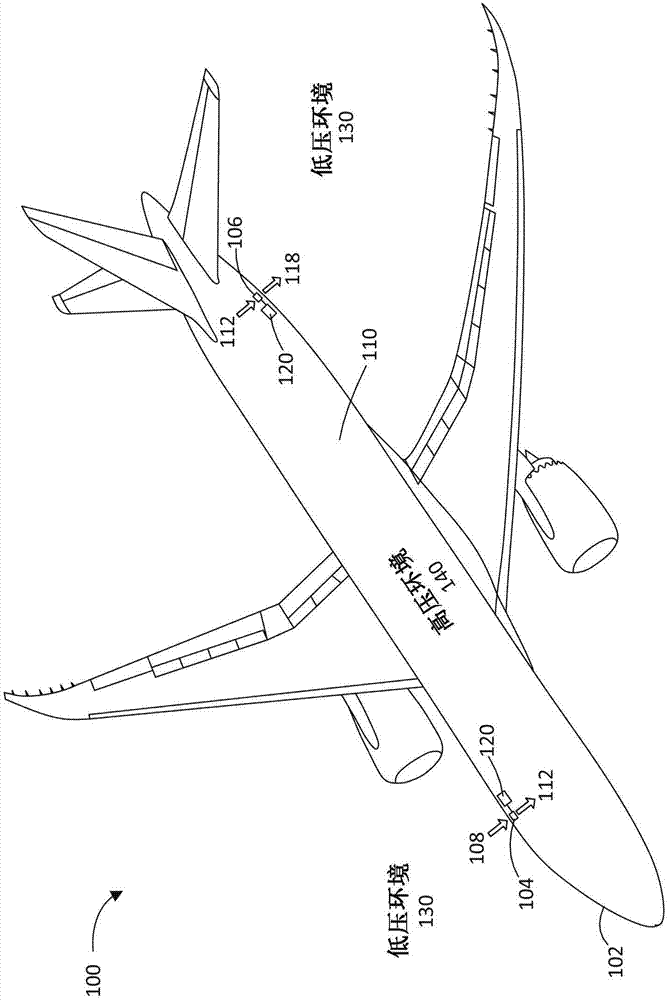

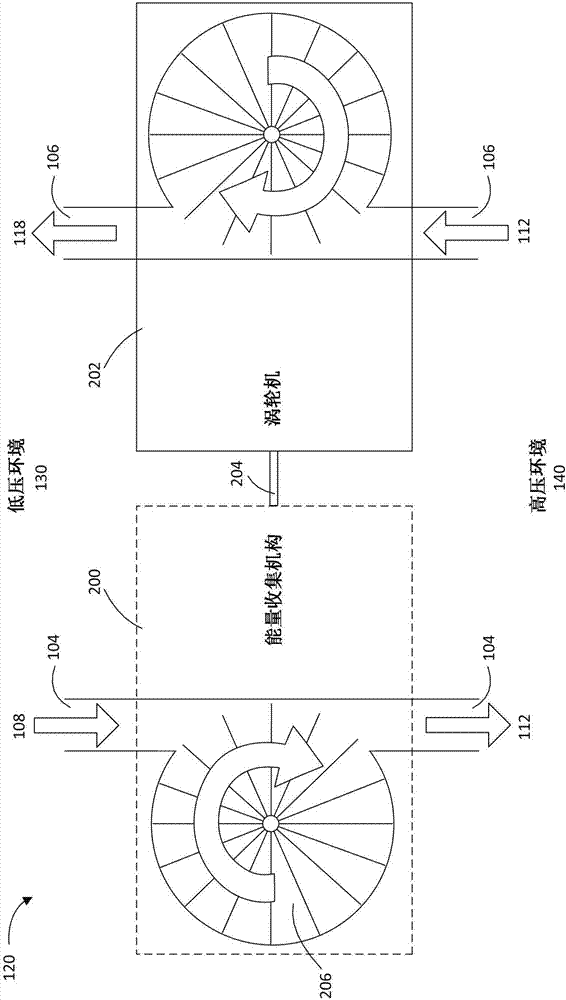

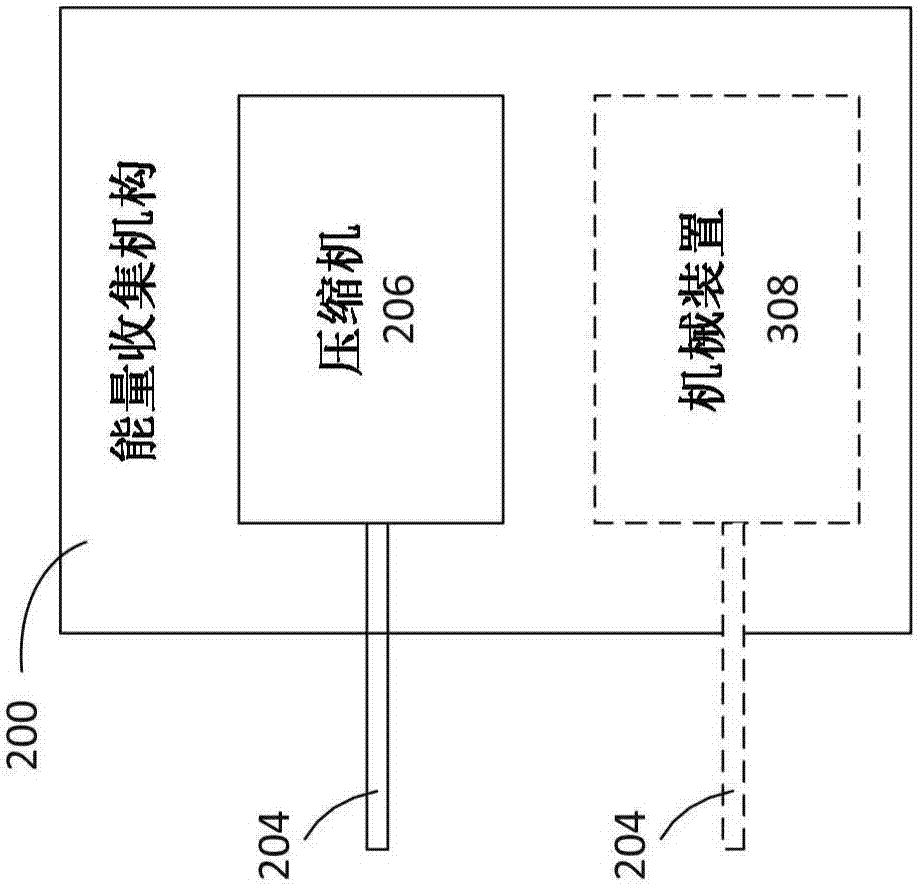

Aircraft Cabin Pressurization Energy Harvesting

An energy harvesting system is provided and a corresponding method for harvesting energy from an aircraft cabin pressurization system utilizing the same. According to one aspect, an energy harvesting system includes an aircraft cabin enclosing a high-pressure environment of pressurized air. An air input receives incoming air from a low-pressure environment and an air output expels outgoing air from the high-pressure environment. A turbine receives the pressurized air expelled from the aircraft cabin and utilizes the pressurized air to produce rotational motion on a turbine shaft. An energy harvesting mechanism is coupled to the turbine shaft and utilizes the rotational motion from the turbine shaft to compress the incoming air or to create electrical energy.

Owner:THE BOEING CO

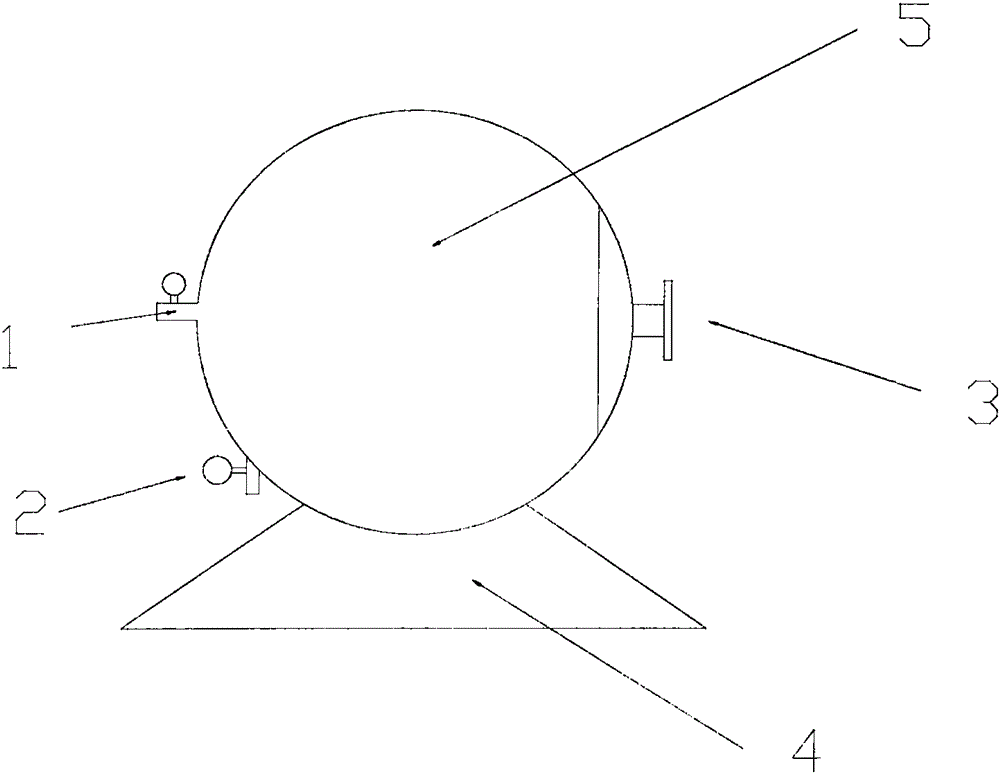

Carbon dioxide mixed oxygen hyperbaric oxygen treatment device and using method

PendingCN108784978AIncrease blood oxygen tensionQuickly relieve hypoxiaBreathing protectionTreatment roomsTreatment effectPressure reduction

The invention relates to a hyperbaric oxygen treatment device and a using method thereof, in particular to a carbon dioxide mixed oxygen hyperbaric oxygen treatment device and a using method. The device is provided with a sealed cabin body, and the cabin body is provided with a cabin pressurization valve, a cabin pressure reduction valve, a pressure sensor, a carbon dioxide concentration sensor and a controller; a cabin grounding device is arranged on the cabin body. The using method includes the steps that a patient enters the pressurized cabin body, and the cabin body is sealed; when the concentration of carbon dioxide in the cabin body reaches 1.2-2.2%, the cabin pressurization valve is switched on, oxygen is introduced for pressurizing the cabin body, and then the cabin pressurizationvalve is switched off when the pressure reaches a treatment set value; a carbon dioxide partial pressure value is detected and converted, after the set value is reached, the opening angle of the cabinpressurization valve and cabin pressure reduction valve is controlled, and oxygen is introduced for ventilation and gas exchange when the carbon dioxide partial pressure value in the cabin body is kept within a set value range and the pressure is unchanged. The device has the advantages of being simple in structure, convenient to use, capable of dilating blood vessels and improving blood circulation and blood oxygen tension of the human body, good in therapeutic effect and the like.

Owner:威海威高海盛医用设备有限公司

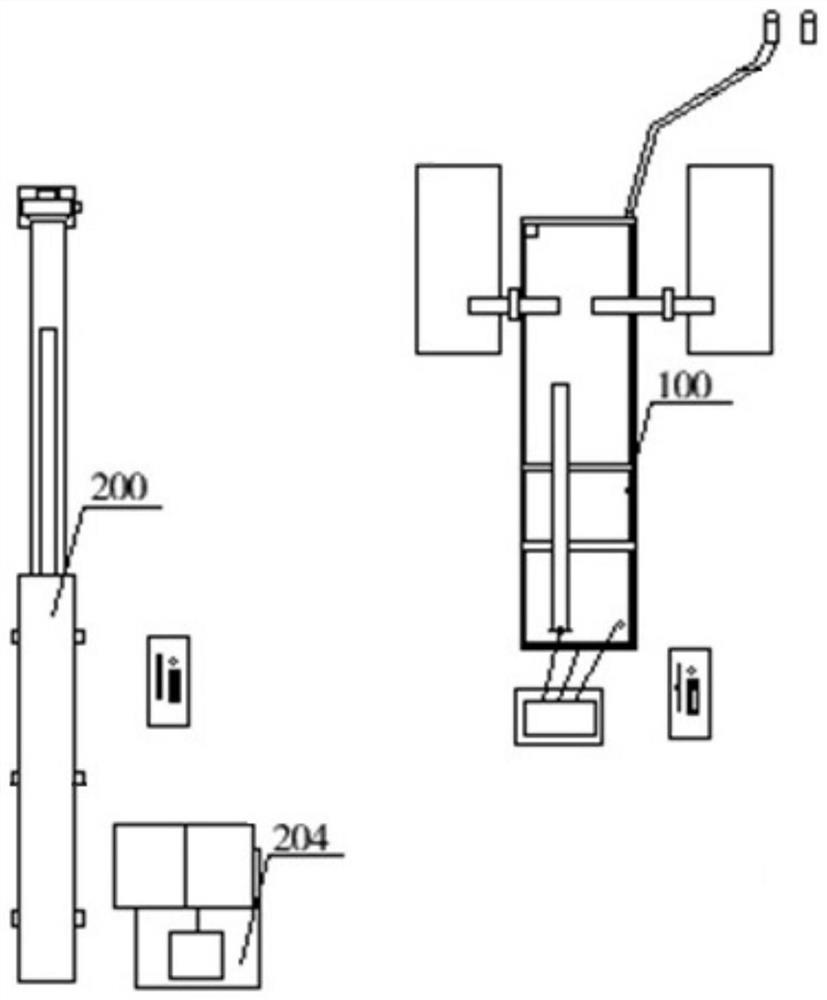

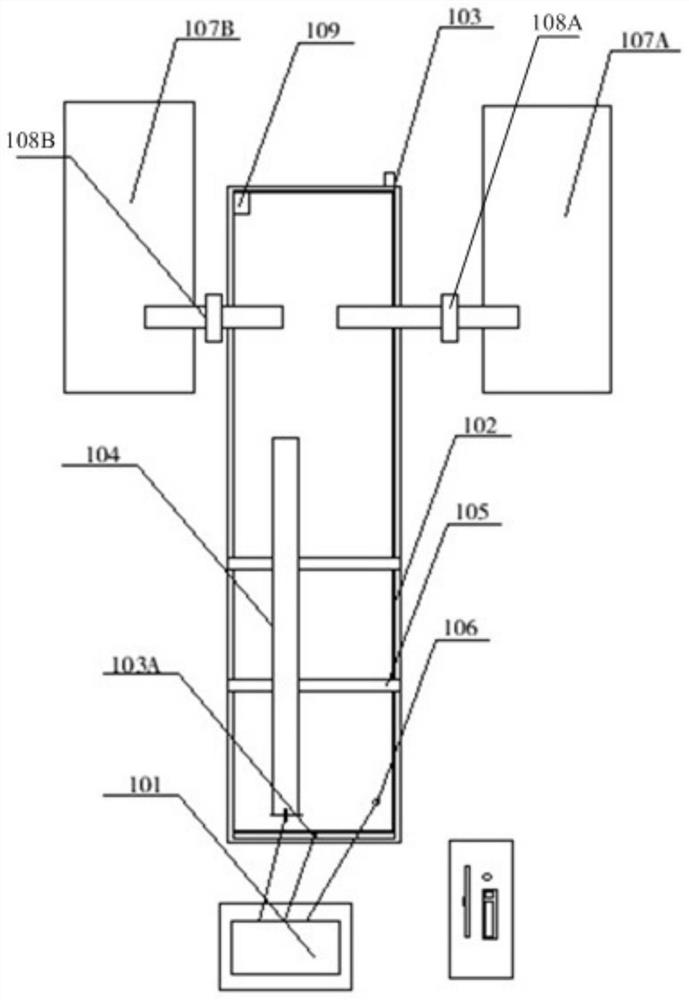

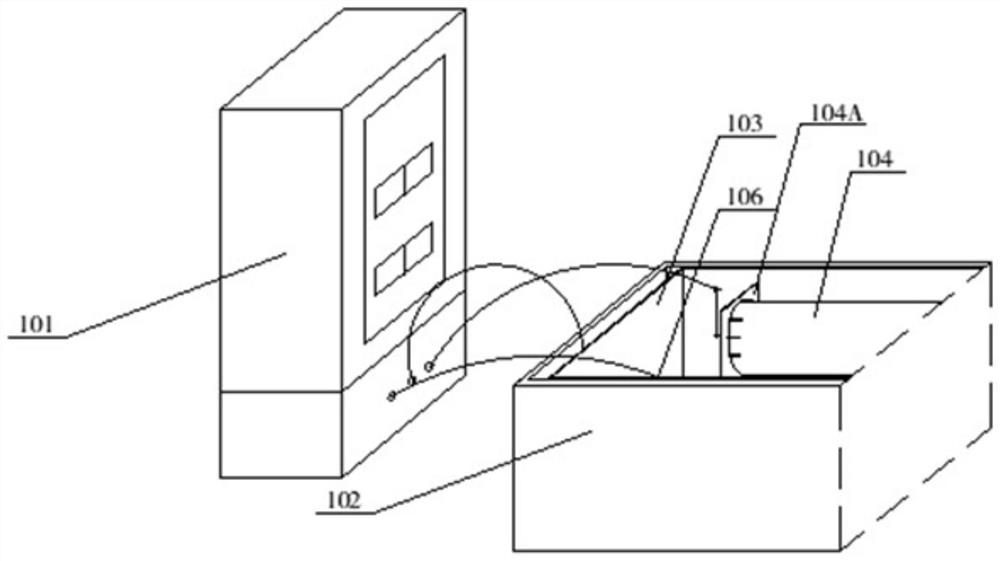

Full-immersion accelerated corrosion crushing device and method for submarine pipeline

ActiveCN113358553AHigh precisionShorten the timeWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesVideo monitoringElectrolysis

The invention discloses a full-immersion accelerated corrosion crushing device for a submarine pipeline. The full-immersion accelerated corrosion crushing device comprises a full-immersion accelerated corrosion simulation area and a deep sea pressure bin pressurization area, the full-immersion accelerated corrosion simulation area comprises an electrochemical workstation, an electrolysis test pool, a solution concentration control mechanism, a pipeline test piece placement mechanism and an electrode group, wherein the solution concentration control mechanism is used for adjusting the concentration of a corrosion medium in the electrolysis test pool, and the electrochemical workstation is used for providing corrosion current for the electrolysis test pool; the deep sea pressure cabin pressurization area comprises a pressure cabin, a test piece filling mechanism, a pressure control mechanism and an underwater video monitoring mechanism, the test piece filling mechanism is used for moving the pipeline test piece close to or out of the pressure cabin, and the pressure control mechanism is used for adjusting the pressure in the pressure cabin. The invention further discloses a submarine pipeline full-immersion accelerated corrosion crushing method based on the submarine pipeline full-immersion accelerated corrosion crushing device. According to the invention, a mode of firstly corroding and then pressurizing is adopted, the corrosion crushing process of the pipeline in an extreme environment is simulated, and the experiment precision is high.

Owner:SUN YAT SEN UNIV

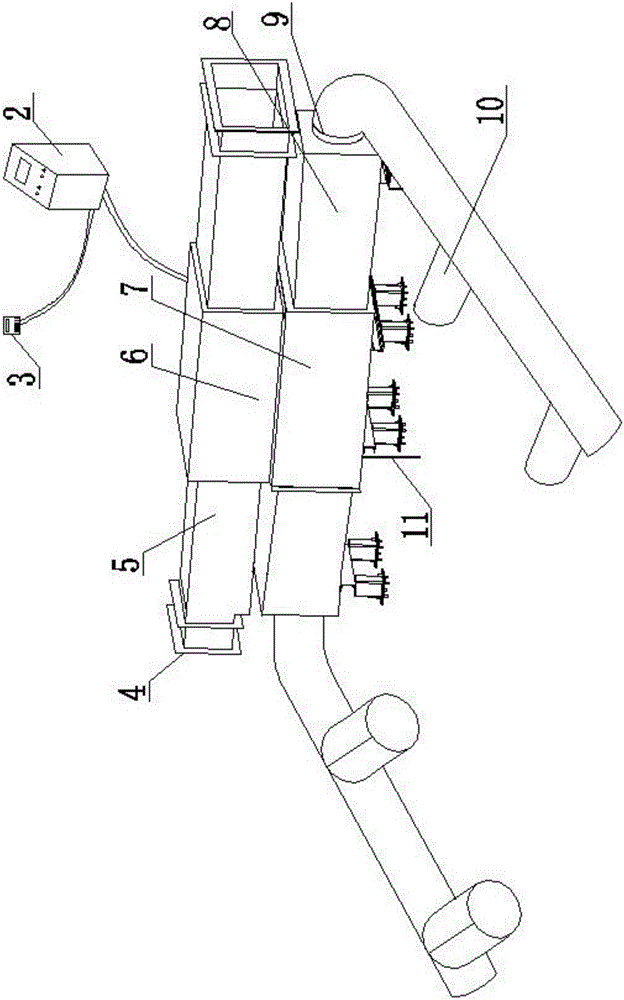

Pressurization and dehumidification device for cabin of marine wind turbine generator system

PendingCN106523301AIncrease pressureRelieve pressureEngine fuctionsMachines/enginesEngineeringExhaust pipe

The invention relates to a pressurization and dehumidification device for a cabin of a marine wind turbine generator system. The pressurization and dehumidification device comprises a booster pump, a heat exchanger, a PLC and sensors for detecting and collecting pressure signals and humidity signals in a cabinet cover, wherein the booster pump and the heat exchanger are arranged in the cabinet cover. The booster pump is connected with the heat exchanger through a gas pipeline. Suction pipes are arranged on the side face of the booster pump. Suction end openings of the suction pipes are connected with an air inlet formed in the outer wall of the cabinet cover. Exhaust pipes are arranged on the side face of the heat exchanger. Exhaust end openings of the exhaust pipes are arranged in the cabinet cover. A drainage pipeline communicating with the exterior of the cabinet cover is arranged at the bottom of the heat exchanger. The booster pump, the heat exchanger and the sensors are connected with the PLC through cables. By the adoption of the pressurization and dehumidification device, the functions of increasing the internal pressure of the cabinet cover and reducing the air humidification of the cabinet cover are achieved, at the moment, the internal pressure of the cabinet cover is greater than the external pressure of the cabin cover, external damp air can be isolated, and erosion of salt fog to internal parts of the cabinet cover is prevented effectively.

Owner:GUODIAN UNITED POWER TECH LIANYUNGANG CO LTD

Dual flow turbine engine equipped with a precooler

InactiveCN101374722BAvoid aerodynamic disturbancesAvoid Disadvantages of EjectionEngine fuctionsAir-treatment apparatus arrangementsTurbineCabin pressurization

Owner:AIRBUS OPERATIONS (SAS)

Portable Pressurized Therapy Chamber for Altitude Sickness First Aid

InactiveCN105496692BReduce volumeReduce weightBreathing protectionTreatment roomsField conditionsEmergency treatment

The invention relates to a portable pressurized treatment cabin for altitude sickness first aid, which belongs to first aid equipment. The technical solution adopted in the present invention is: a portable pressurized treatment cabin for altitude sickness first aid, including a portable pressurized cabin with a transparent upper half, a pressurized gas source, an auxiliary oxygen supply access pipeline and an inlet and outlet zipper, It is characterized in that it also includes a one-way pressurized intake pipeline, an adjustable one-way decompression exhaust pipeline, an emergency breathing system, an effective ventilation space partition curtain, an infusion treatment window, an auxiliary airtight belt for infusion operations, and an emergency relief system. Pressure exhaust port. The invention has the advantages that: the treatment cabin is made of film material, which is foldable, small in size, light in weight, simple in structure, easy to operate, and reliable in curative effect. Responding to the occurrence of complications and relieving the progress of severe patients, providing time for rescue.

Owner:宋继兰

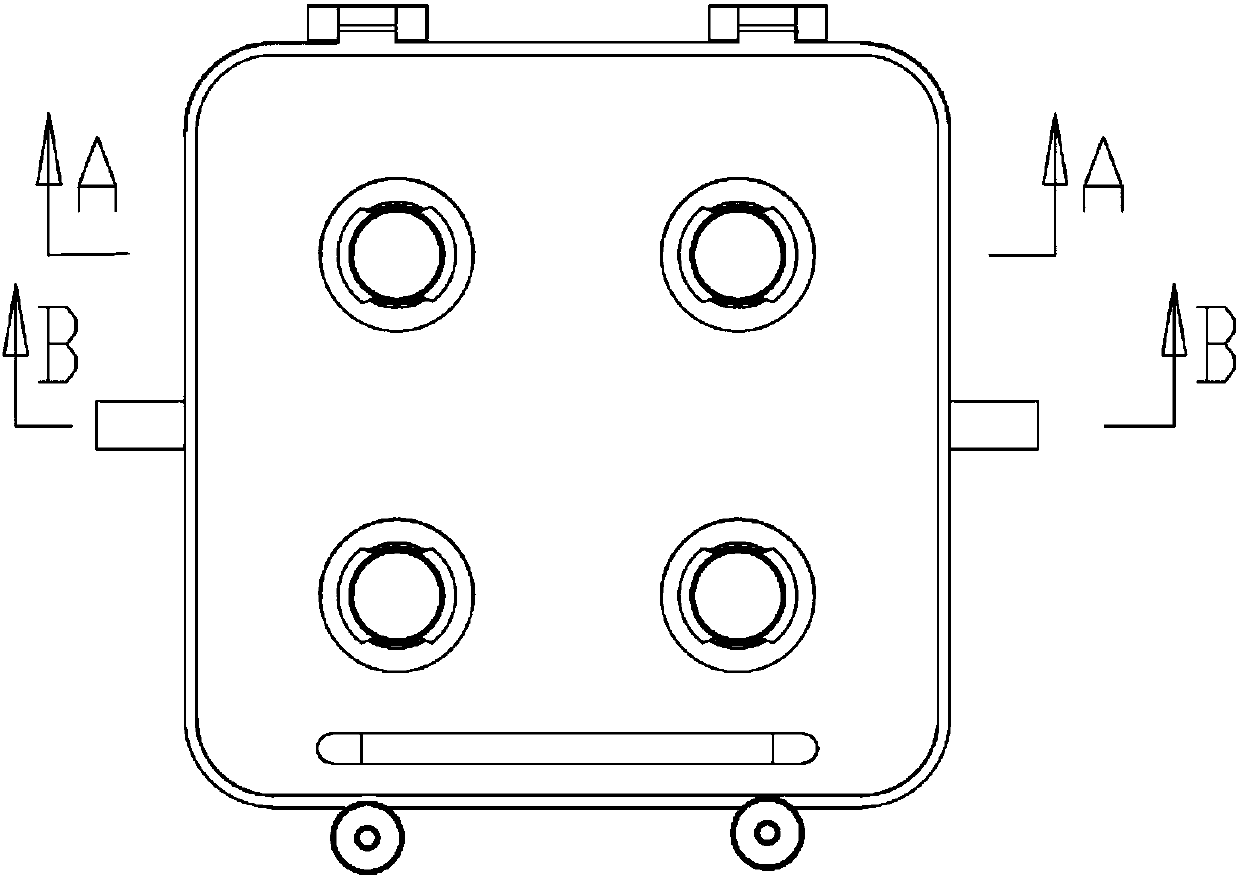

Split bioreactor

PendingCN107858285AReduce pollutionReduce weightBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringSilica gel

The invention relates to a split bioreactor. The split bioreactor is composed of a pressure bin, culture bins and pressure seal devices; the several culture bins with independent seal structures can be placed in the pressure bin, and the pressure bin use efficiency can be improved by replacing the culture bins; a pressure gas inlet pipe and a pressure gas outlet pipe are installed in a pressure bin box, the contact parts of a pressure bin cover and the pressure bin box are in sealed connection through a seal gasket, and the pressure bin cover is fixed to the pressure bin box through fast connectors; the pressure seal devices corresponding to the culture bins are installed on the pressure bin cover separately, annular mechanical grippers are connected with guide holes in the pressure bin cover through transmission rods on the annular mechanical grippers, and the transmission rods are in sealed connection with the guide holes in the pressure bin cover through seal elements. When the interior of the pressure bin is pressurized, the annular mechanical grippers press gel silica membranes of the culture bins under driving of the pressure seal devices, so that sealing is formed between the gel silica membranes and the upper end faces of culture tanks, liquid will not overflow when the pressure bin is pressurized, and safe sterile operation is achieved.

Owner:刘延群

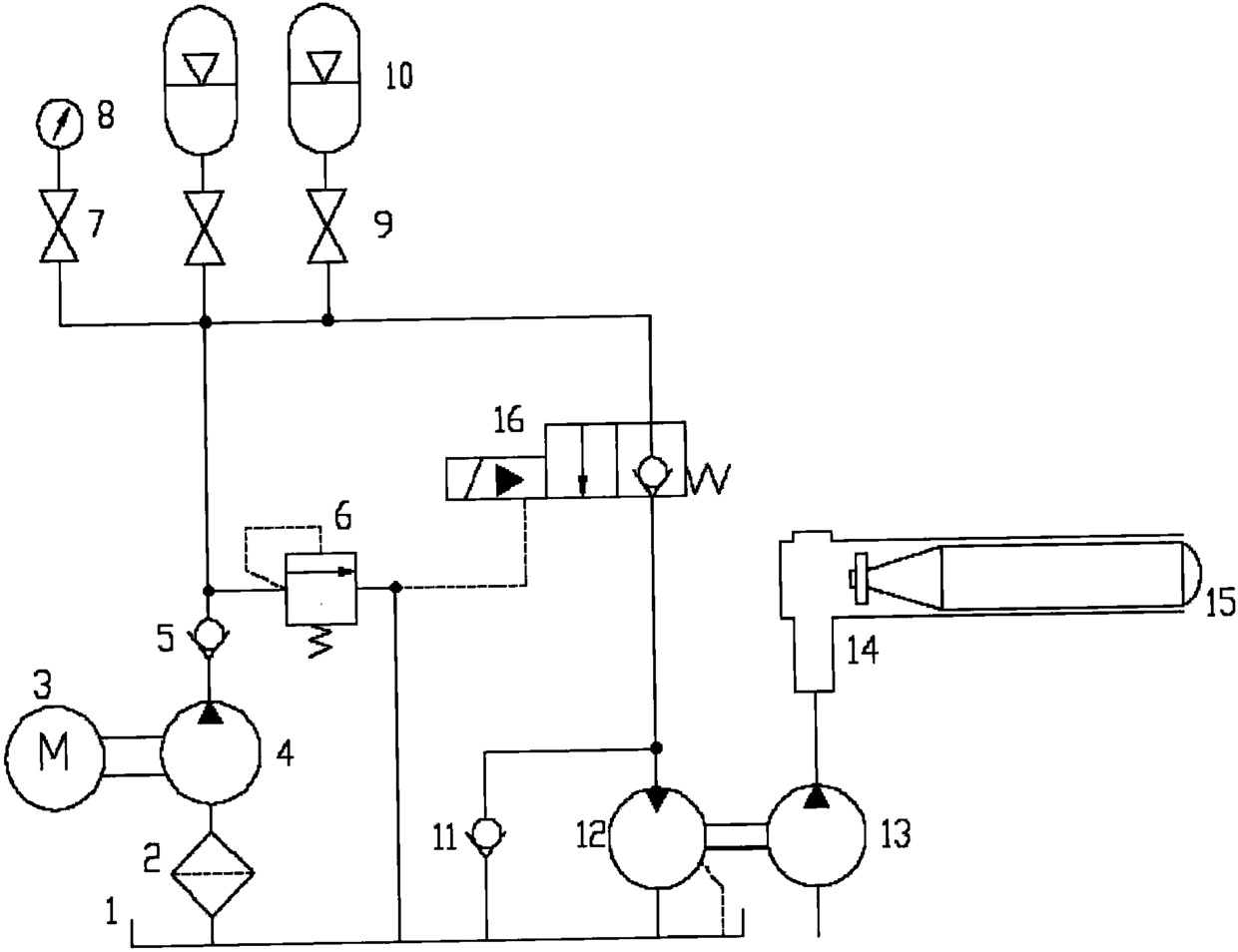

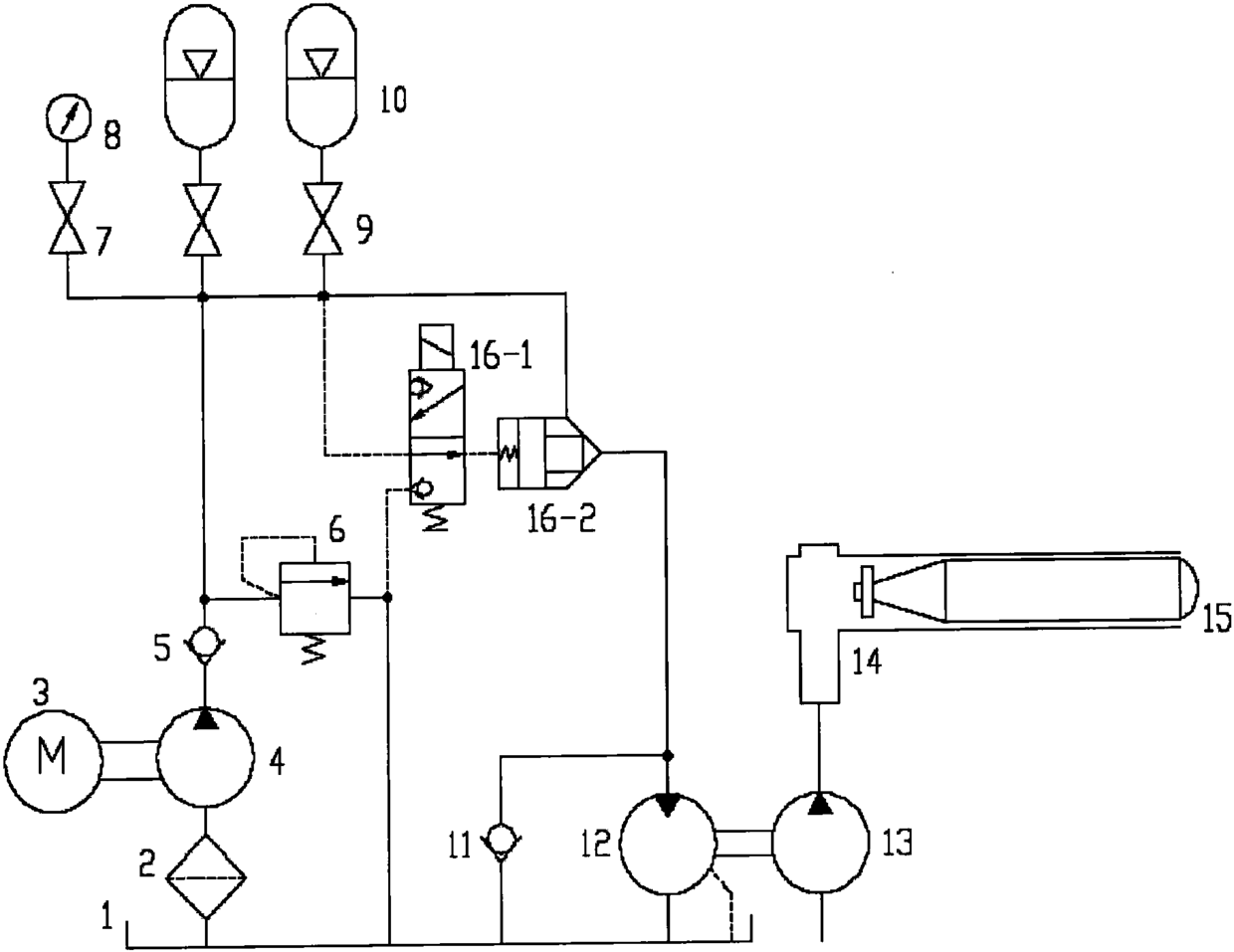

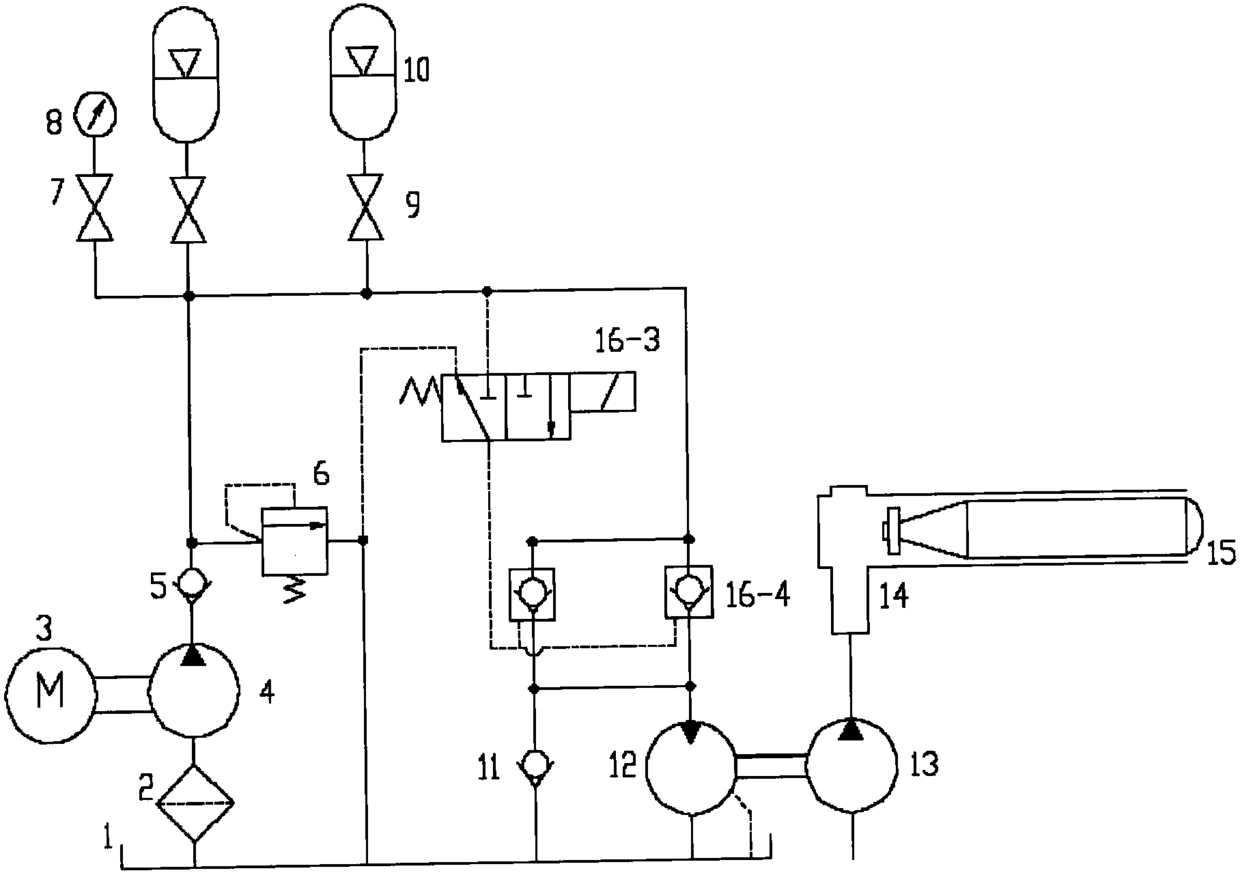

Accumulator-driven hydraulic motor and rotary pump underwater weapon launch power plant

ActiveCN108401550BReduce boostReduce exhaust noiseRocket launchersTorpedo launchersLow noiseRotary pump

The underwater weapon launching power device of the present invention is an accumulator-driven hydraulic motor and a rotary pump. Before the underwater weapon is launched, the motor is started, and under the action of the hydraulic pump, the hydraulic oil in the oil tank passes through the hydraulic pump, the first one-way valve , the spherical stop valve flows into the gas accumulator; the pressure gauge switch is connected with the pressure gauge, and the other end of the pressure gauge switch is connected with the outlet of the first one-way valve; when the reading of the pressure gauge reaches the preset value, it is closed Electric motor; when launching an underwater weapon, the electro-hydraulic reversing valve is energized to act, and the high-pressure oil in the gas accumulator enters the high-pressure port of the hydraulic motor through the spherical stop valve and the electro-hydraulic reversing valve, driving the hydraulic motor and driving it to rotate The water pump rotates at an accelerated speed, the inlet of the rotary water pump is connected with the seawater, the outlet of the rotary water pump is connected with the launch tube of the water cabin, and the large flow of seawater is output from the rotary water pump to the launch tube of the water cabin, and the underwater weapon is pushed out of the tube. The underwater weapon launching power device of the invention has low noise, low manufacturing cost and can avoid cabin pressurization.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com