Aircraft Cabin Pressurization Energy Harvesting

An energy harvesting, aircraft technology, used in aircraft parts, control mechanical energy, machines/engines, etc., can solve problems such as reducing aircraft fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

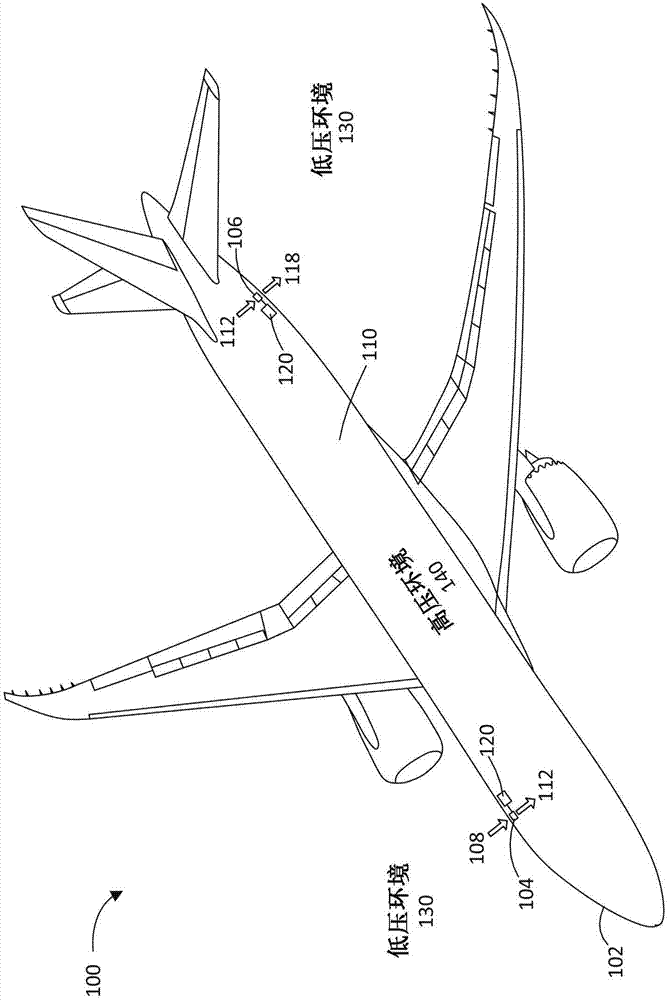

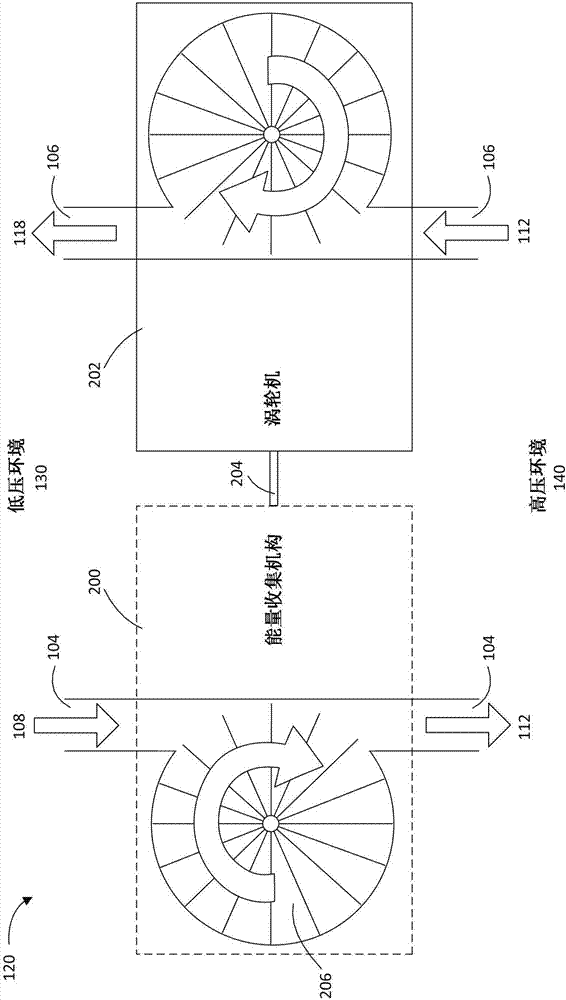

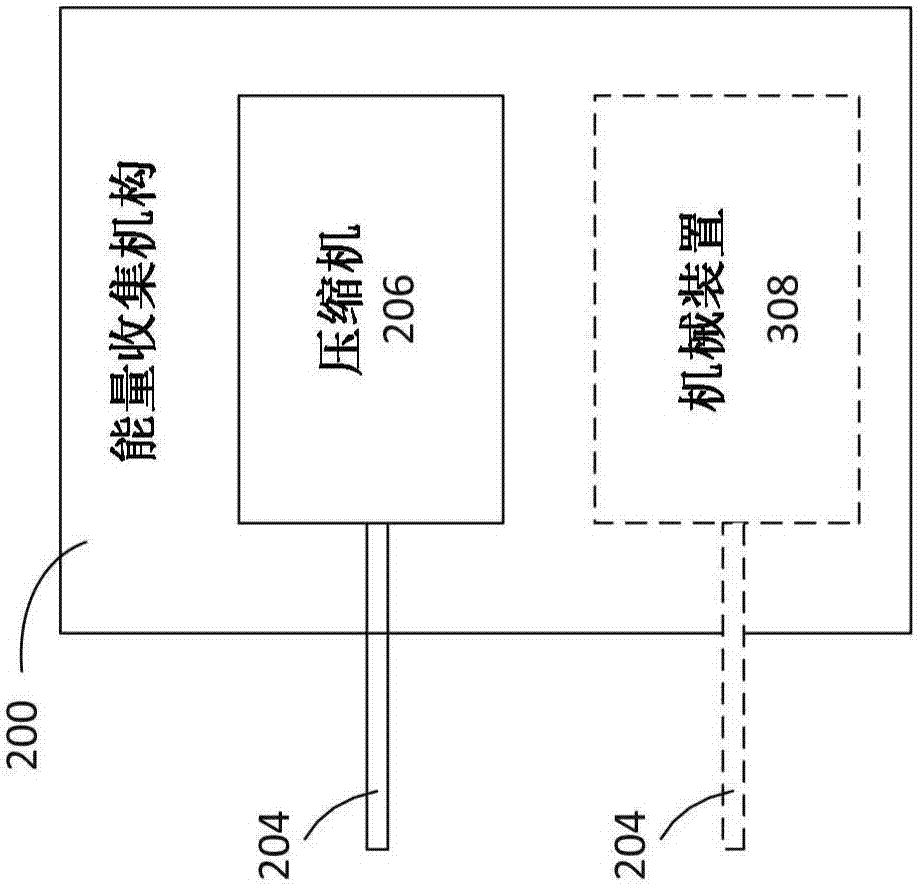

[0015] The following detailed description relates to energy harvesting systems, and to corresponding methods of utilizing energy harvesting systems to harvest energy from aircraft cabin pressurization systems. As noted above, conventional aircraft cabin pressurization systems recycle cabin air to provide pressurized air by compressing cool ambient air from outside the aircraft cabin, while exhausting warmer pressurized air back into ambient air outside the aircraft cabin. This air pressurization system reduces fuel efficiency because the aircraft engine utilizes the additional fuel to overcome the additional rotational resistance of the generator used to power the air compressor.

[0016] Using the concepts and techniques described herein, the energy harvesting system utilizes warm pressurized air that expands into a low pressure environment as it is discharged from the aircraft cabin. Various embodiments discussed herein direct exhaust air through a turbine, which may be coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com