System and method for automatically detecting leak noise in an aircraft

A detection system, a technology for aircraft, applied in the direction of detecting the presence of fluid at the leak point, vibration measurement in solids, liquid tightness measurement using liquid/vacuum degree, etc. Expensive experiments, etc., to avoid false detections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

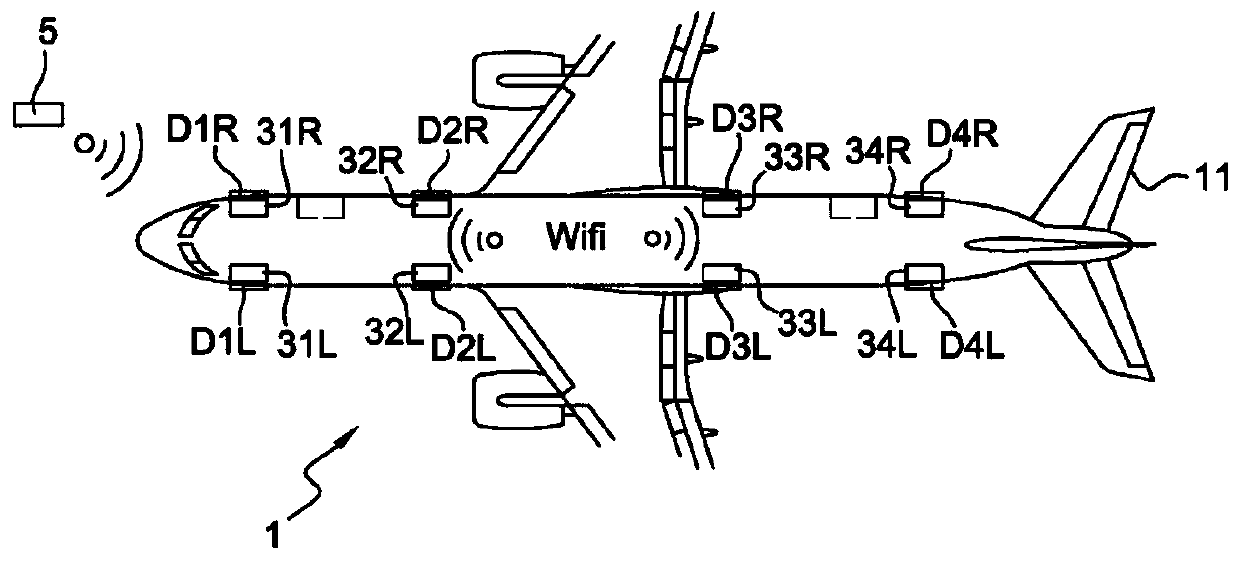

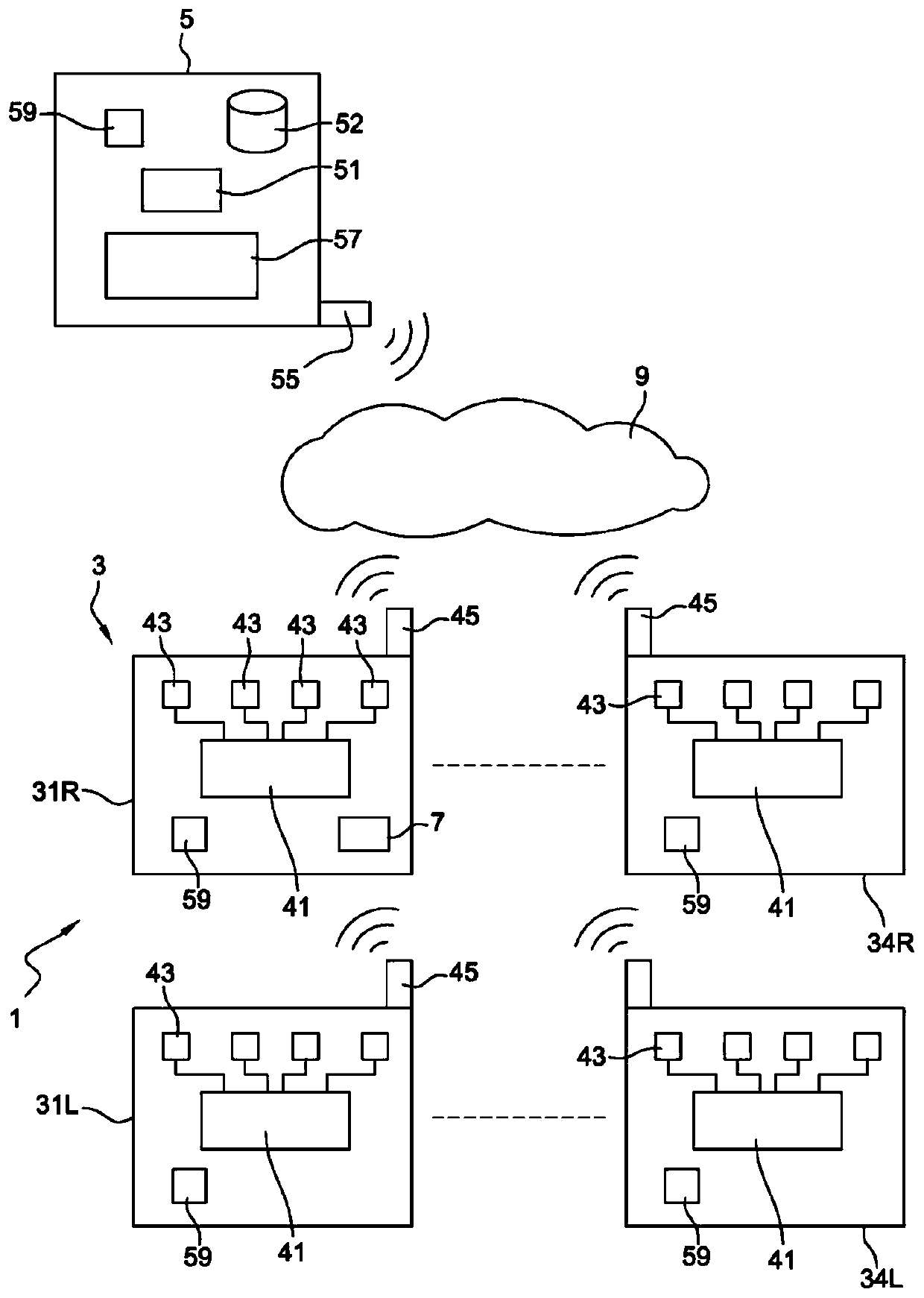

[0052] In particular, the principle of the invention is the automatic detection of leak noise in an aircraft, allowing tests to be performed on the ground and at multiple operating pressure gradients.

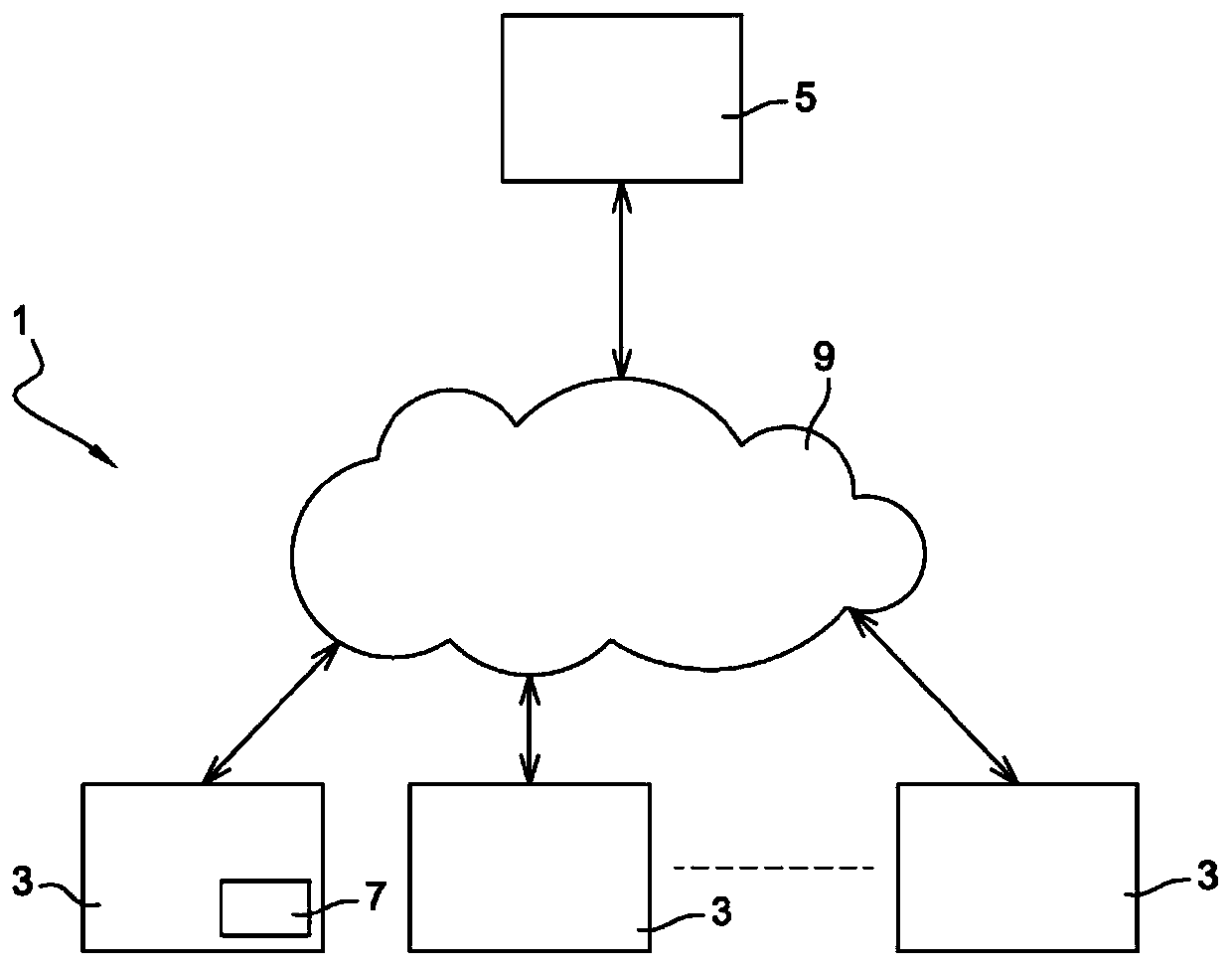

[0053] figure 1 A system for detecting leakage noise in an aircraft according to the invention is schematically shown.

[0054] According to the invention, the detection system 1 comprises at least one acquisition device 3 and a monitoring device 5 . The acquisition devices 3 are configured to measure noise, and at least one of the acquisition devices 3 is also equipped with a pressure sensor 7 .

[0055] More specifically, each acquisition device 3 is intended to be installed in an area of interest of the aircraft, for example on a door, in order to acquire data relating to the current noise in the area of interest. The acquisition means 3 equipped with pressure sensors 7 are also configured to acquire data relating to the current pressure gradient between the cabin of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com