Device and method for quickly detecting air leakage of ultraviolet germicidal lamp

A technology of ultraviolet light and germicidal lamps, which is applied in the field of inspection, can solve the problems of unreliable inspection methods and long cycle times, achieve the effects of shortening the production cycle, solving lamp tube leakage, and improving quality reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

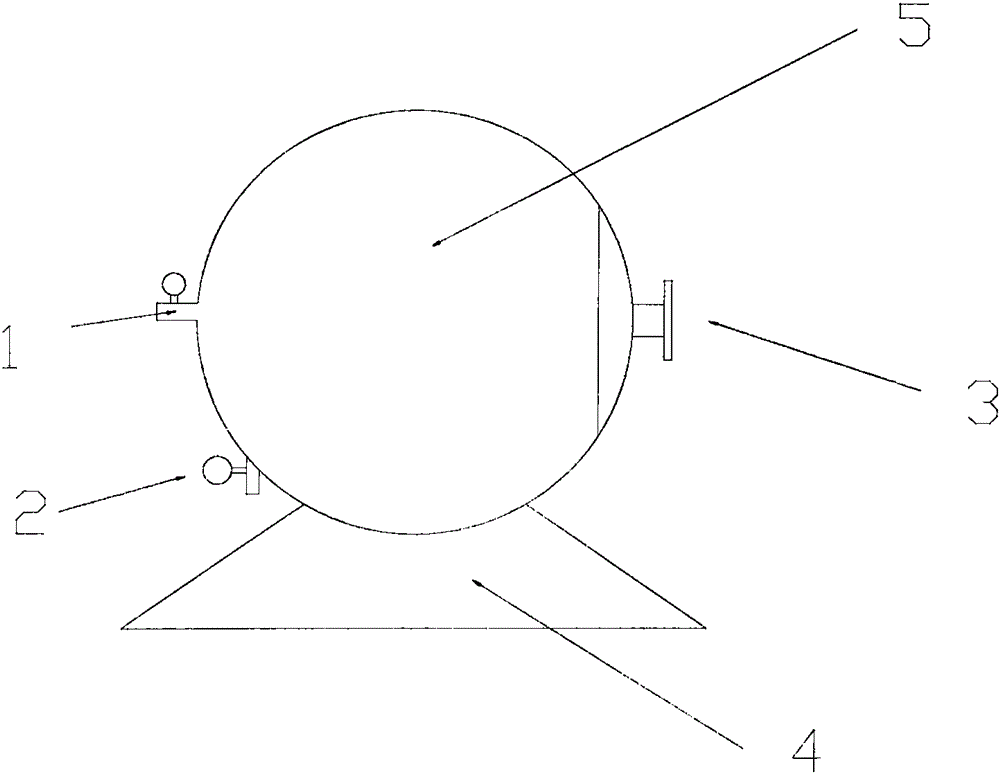

[0027] The structure of this embodiment, such as figure 1 , one A device for quickly checking air leakage of ultraviolet germicidal lamps, the device for quickly checking air leakage of ultraviolet germicidal lamps is a hyperbaric cabin body 5, the hyperbaric cabin body 5 is located on the cabin body support platform 4, and the hyperbaric cabin body 5 is provided with There are high-pressure cabin door 3, in-cabin pressurization valve 1, pressure-stabilizing and pressure-relieving valve 2. The setting of the hyperbaric cabin body 3 of the present invention mainly serves to facilitate the placement of the lamp tube to be tested, and to realize the enhancement of the pressure difference between the inside and the outside of the lamp tube, thereby facilitating rapid inspection of air leakage; the setting of the cabin body support platform 4 in the present invention , mainly to facilitate the support of the high-pressure cabin body 5; wherein the role of the booster valve 1 in t...

Embodiment 2

[0029] On the basis of Embodiment 1, this embodiment further defines that the hyperbaric cabin body 5 is a spherical hyperbaric cabin, and here the shape of the hyperbaric cabin body 5 is limited, preferably a spherical hyperbaric cabin, and the cabin body support platform 4 The shape of the upper end matches the shape of the hyperbaric cabin body 5. The upper end of the cabin support platform 4 is a circular arc end, and other parts in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] On the basis of the above-mentioned embodiments, this embodiment further defines that the in-cabin booster valve 1 and the pressure-stabilizing and pressure-relieving valve 2 are set on the same side of the high-pressure cabin body 5, and the in-cabin boosting valve 1 is located at the pressure-stabilizing and releasing valve. Press the upper end of valve 2. Here, the positional relationship between the pressure-increasing valve 1 and the pressure-stabilizing and releasing valve 2 in the cabin is limited, mainly for the convenience of operation and the taking out and putting in of the lamp tube to be tested. Other parts in this embodiment are the same as those in the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com