Split bioreactor

A bioreactor, split technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve human errors, high pollution risks, and can not meet the needs of cell and tissue culture. Environmental nutrition conditions and other issues, to achieve the effect of improving use efficiency, ensuring sterile environment, and reliable sterile environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

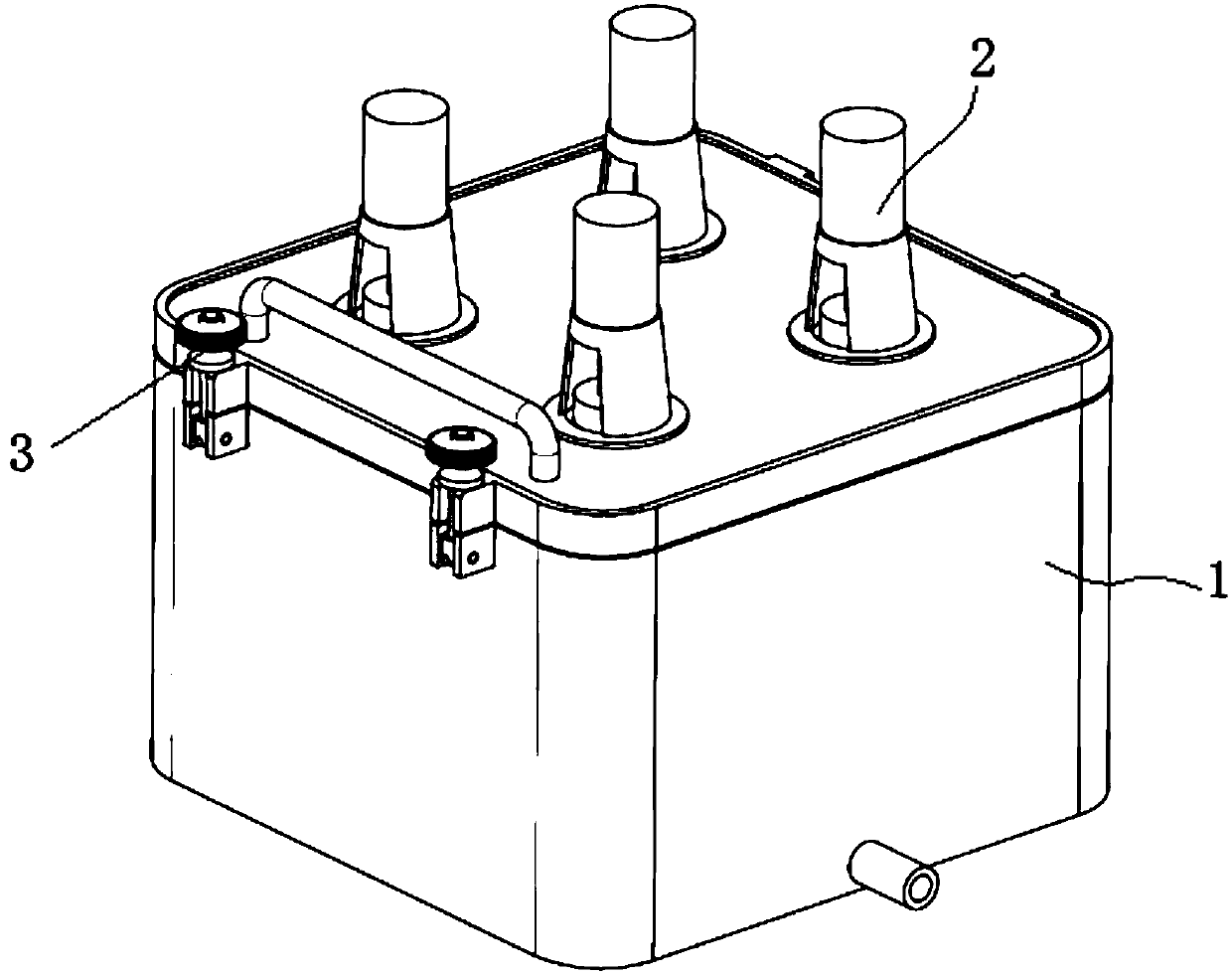

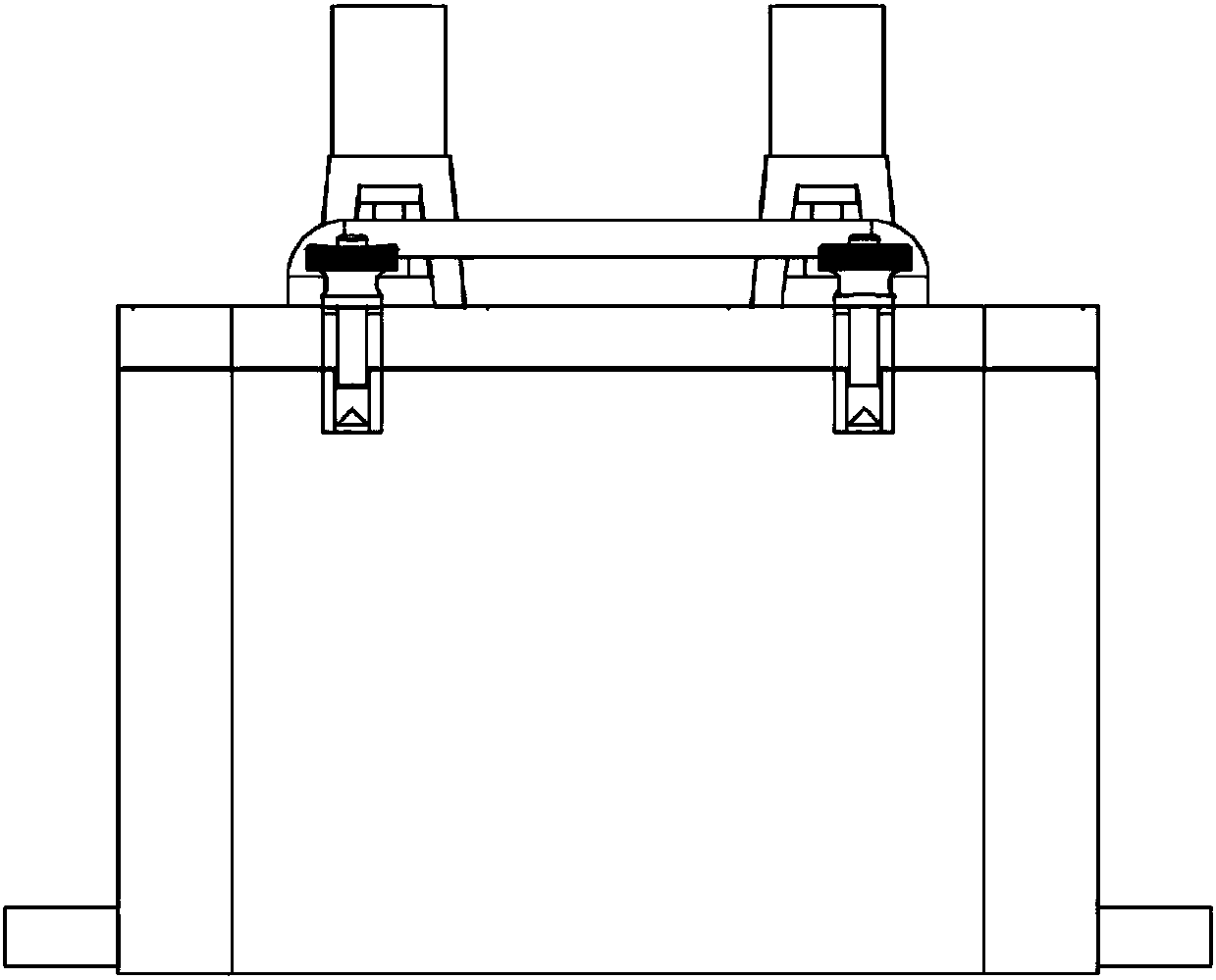

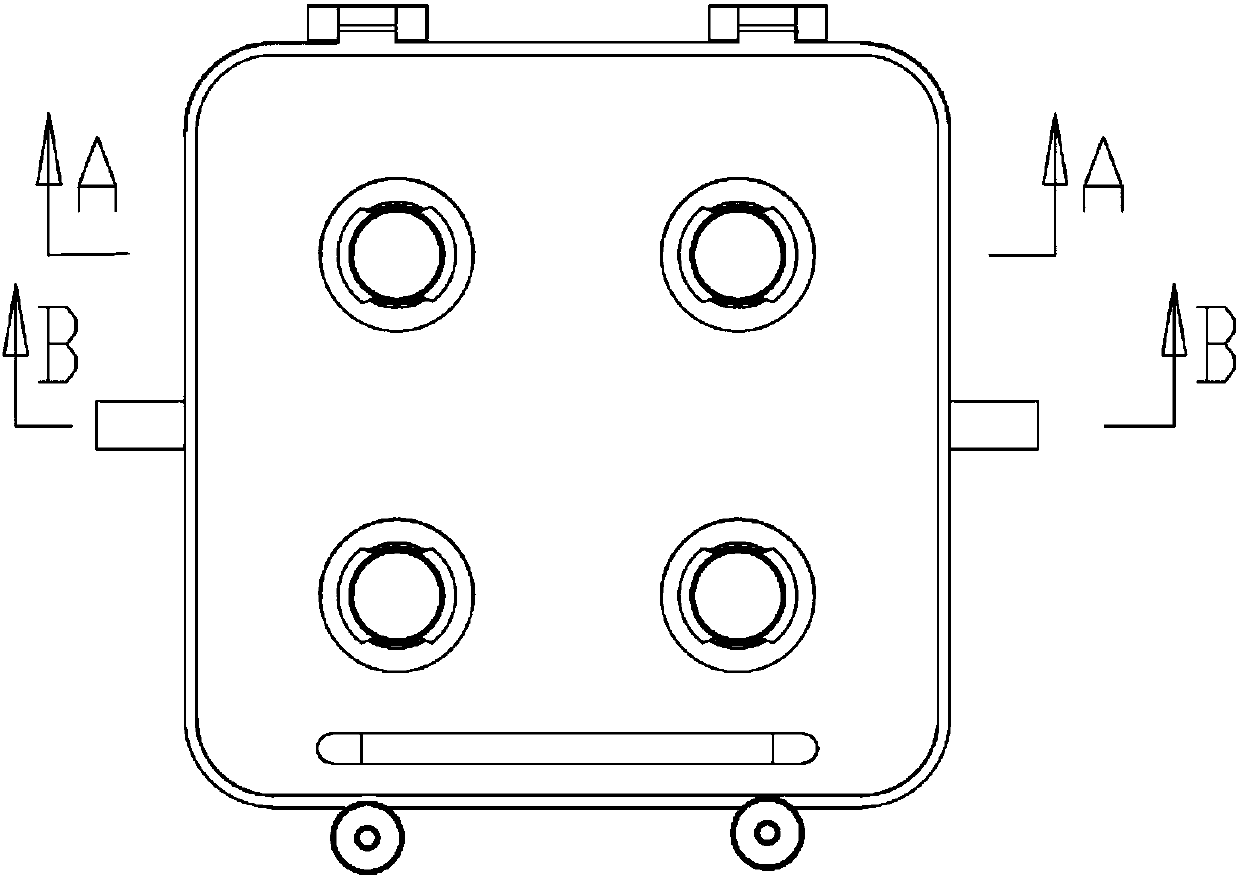

[0030] Such as Figure 1 to Figure 12 As shown, a split bioreactor is composed of a pressurized cabin 1, a culture cabin 4, and a pressurized sealing device 2. Several culture chambers 4 with independent sealing structures can be placed in the pressurized chamber 1, and related connecting components are removed to obtain a more reliable aseptic environment and minimize contamination from the reactor. The independent design of the 4 culture cabins makes it possible for us to change the liquid every other day, and the independent culture cabins can be cultured routinely during non-pressurized time. By replacing the culture chamber, the use efficiency of the pressurized chamber can be improved.

[0031] The pressurized cabin 1 is made up of a pressurized cabin box body 1-1 and a pressurized cabin cover 1-2. Pressurized gas inlet and outlet pipes 1-3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com