Patents

Literature

163 results about "Inerting system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

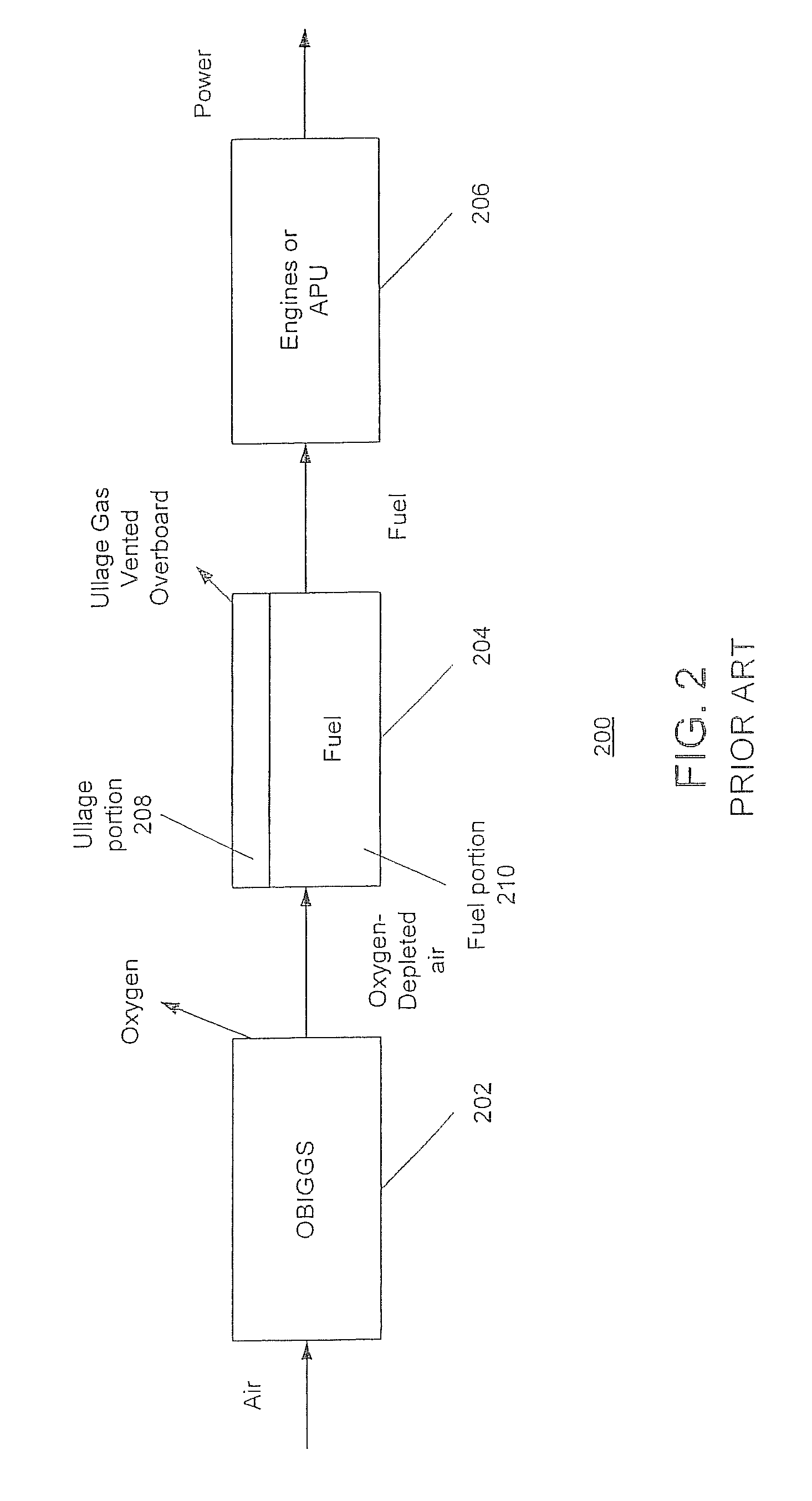

An inerting system decreases the probability of combustion of flammable materials stored in a confined space, especially a fuel tank, by maintaining a chemically non-reactive or "inert" gas, such as nitrogen, in such a space. "Inerted" fuel tanks may be used on land, or aboard ships or aircraft.

Advanced carbon dioxide fuel tank inerting system

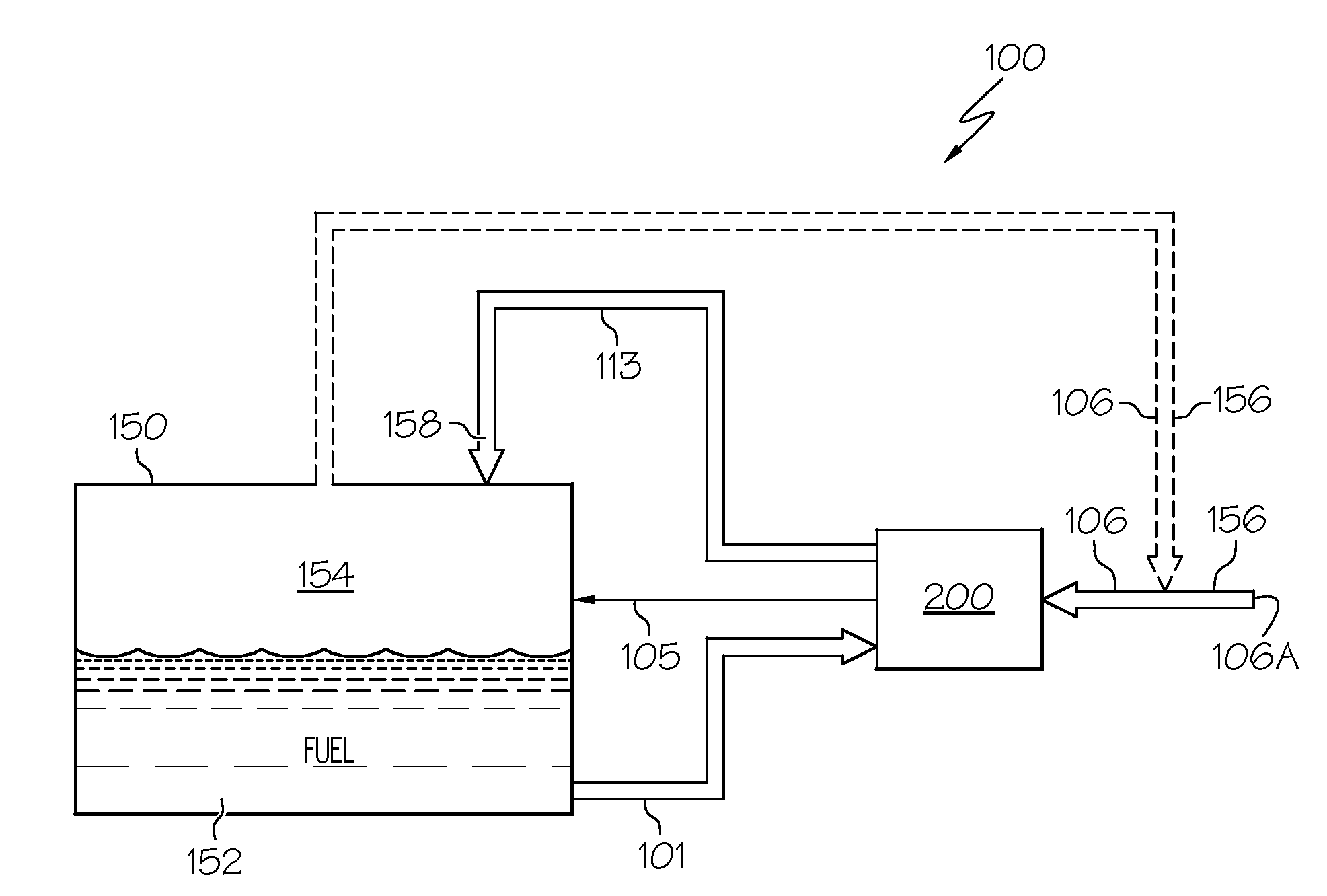

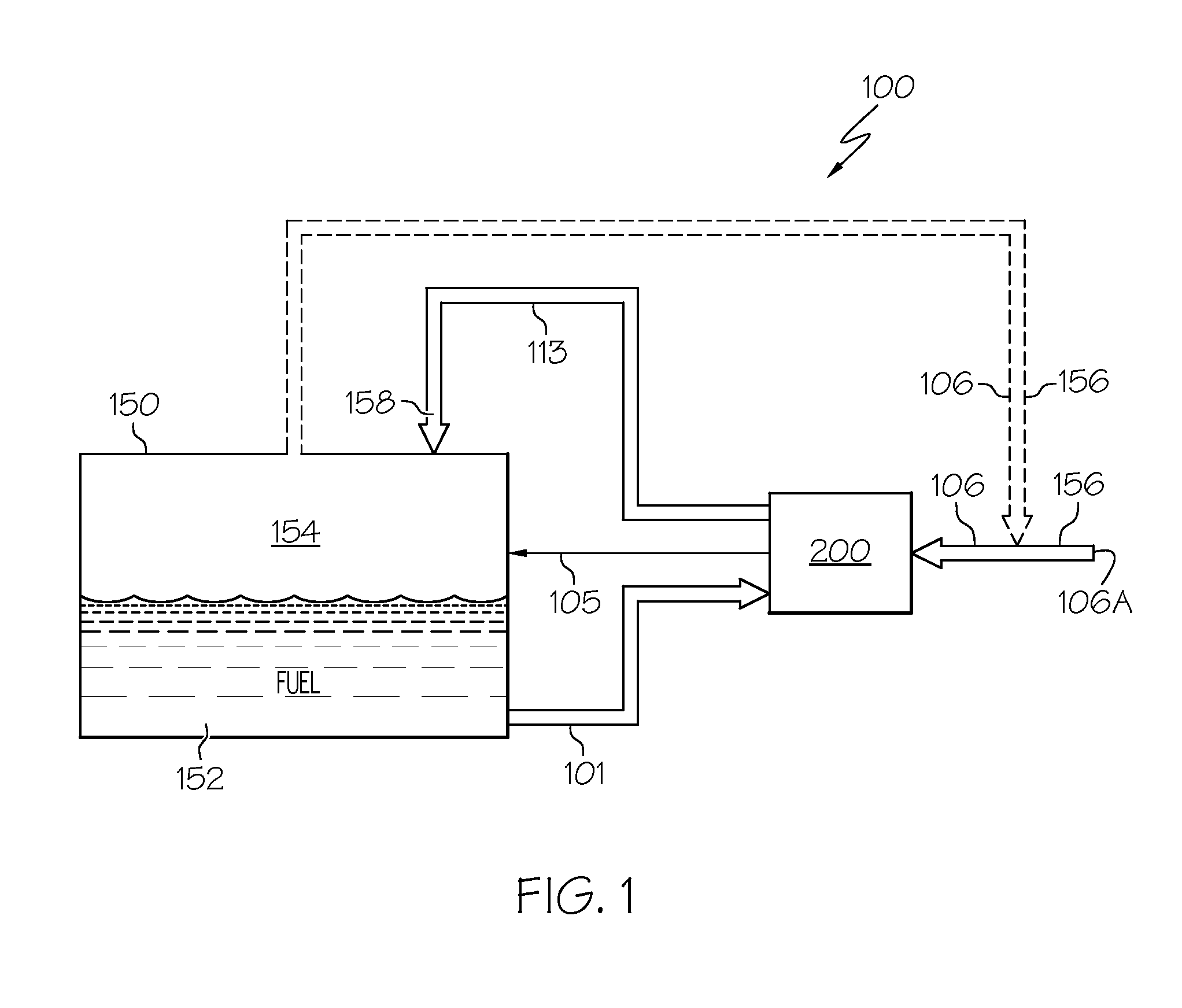

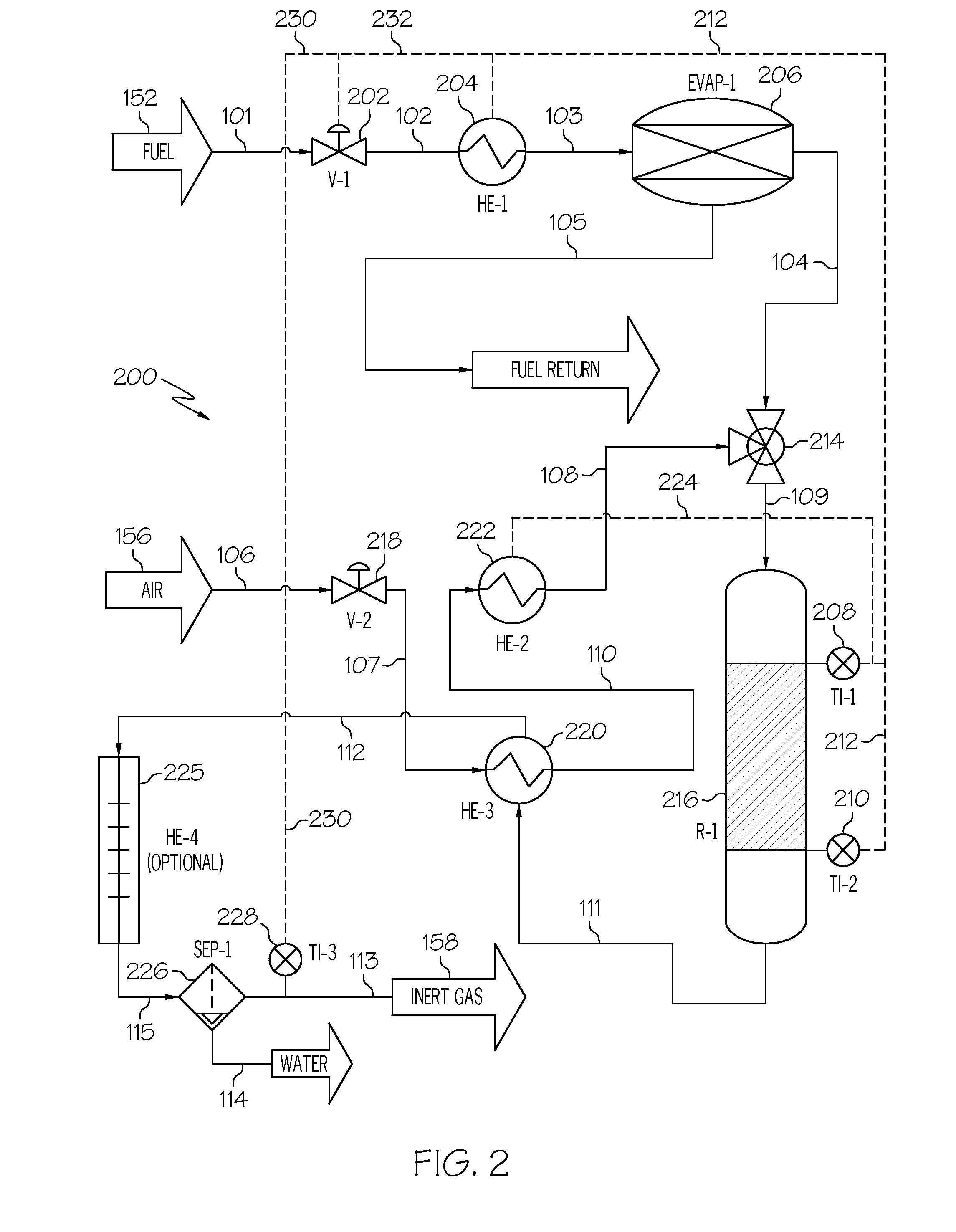

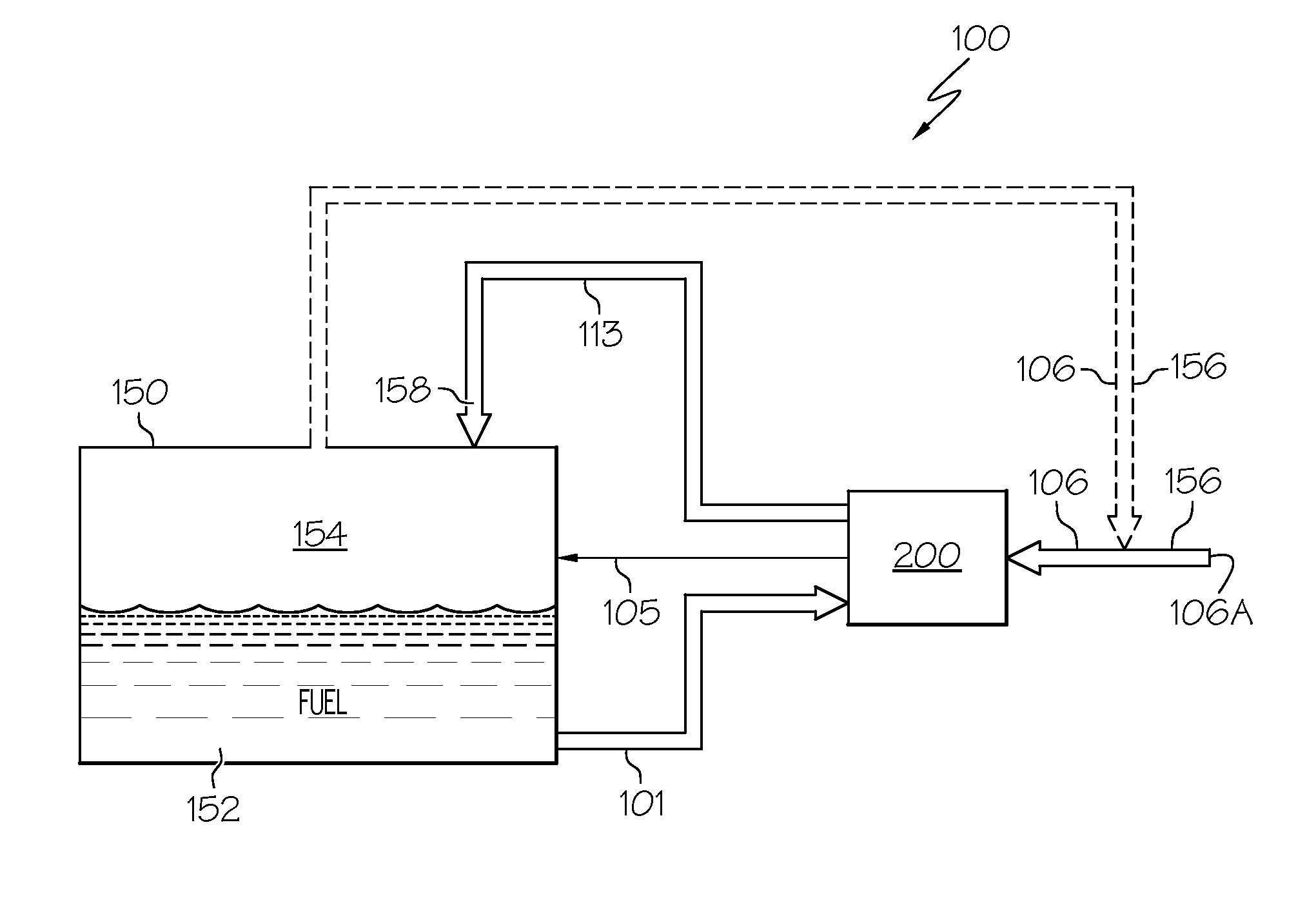

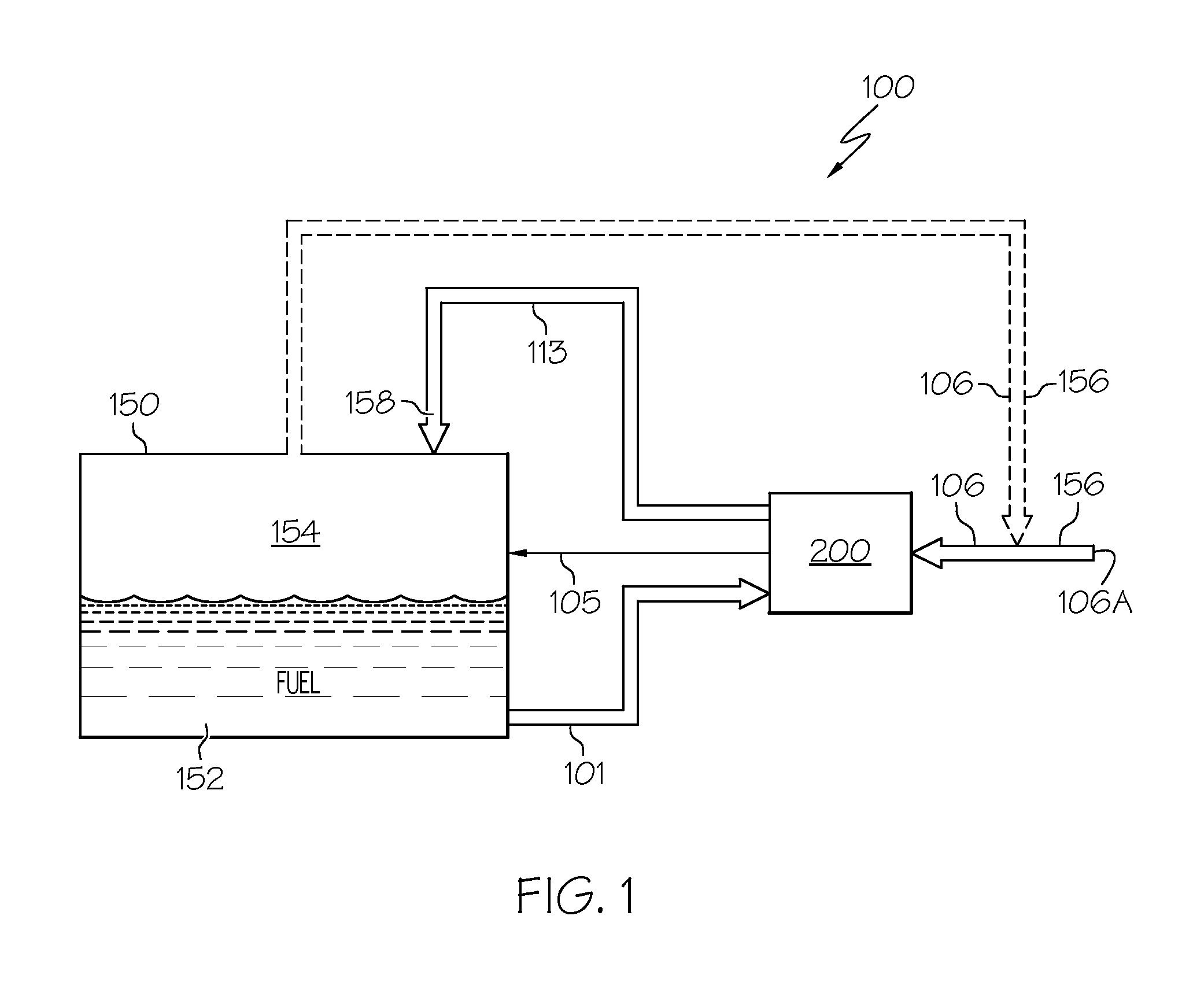

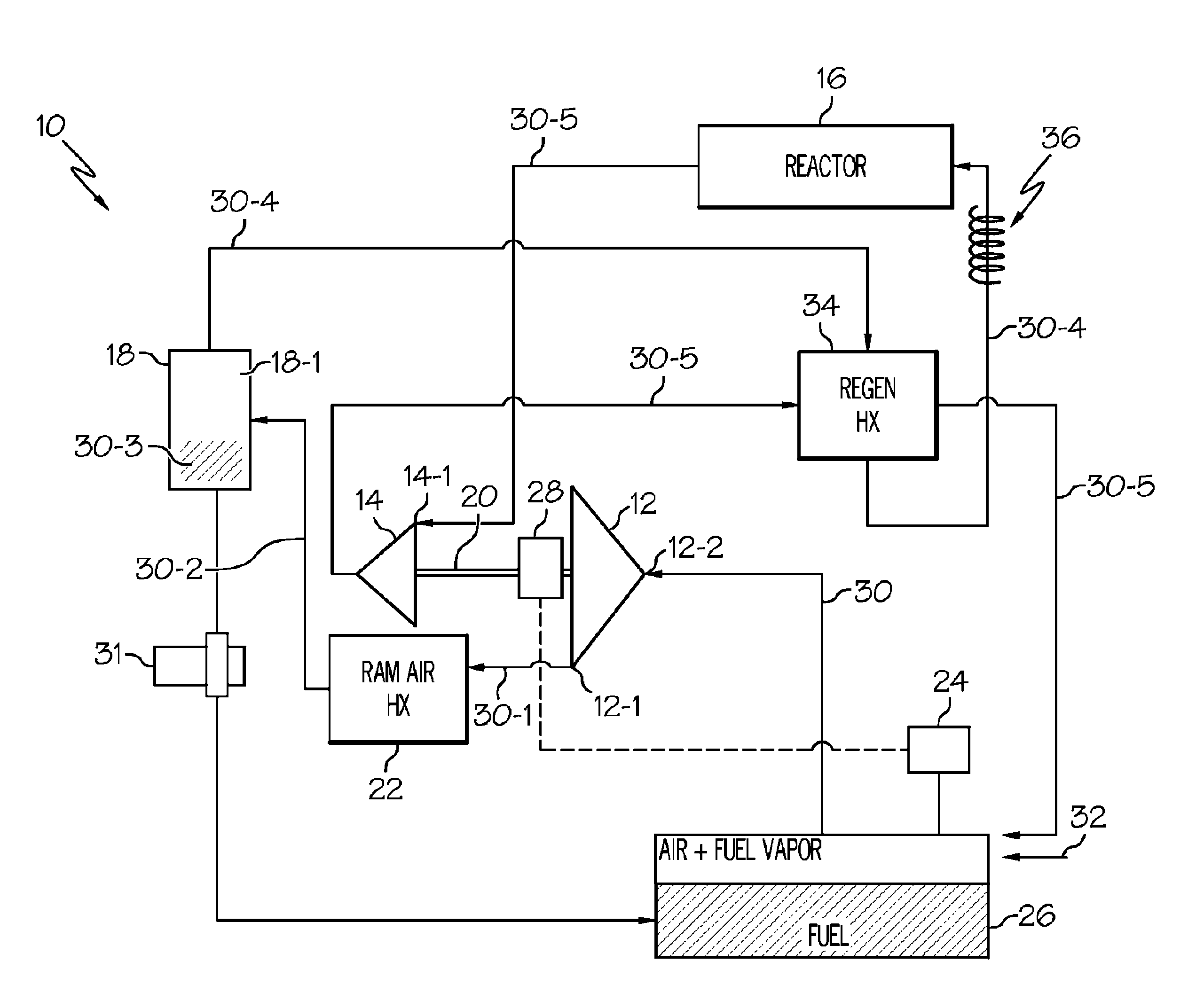

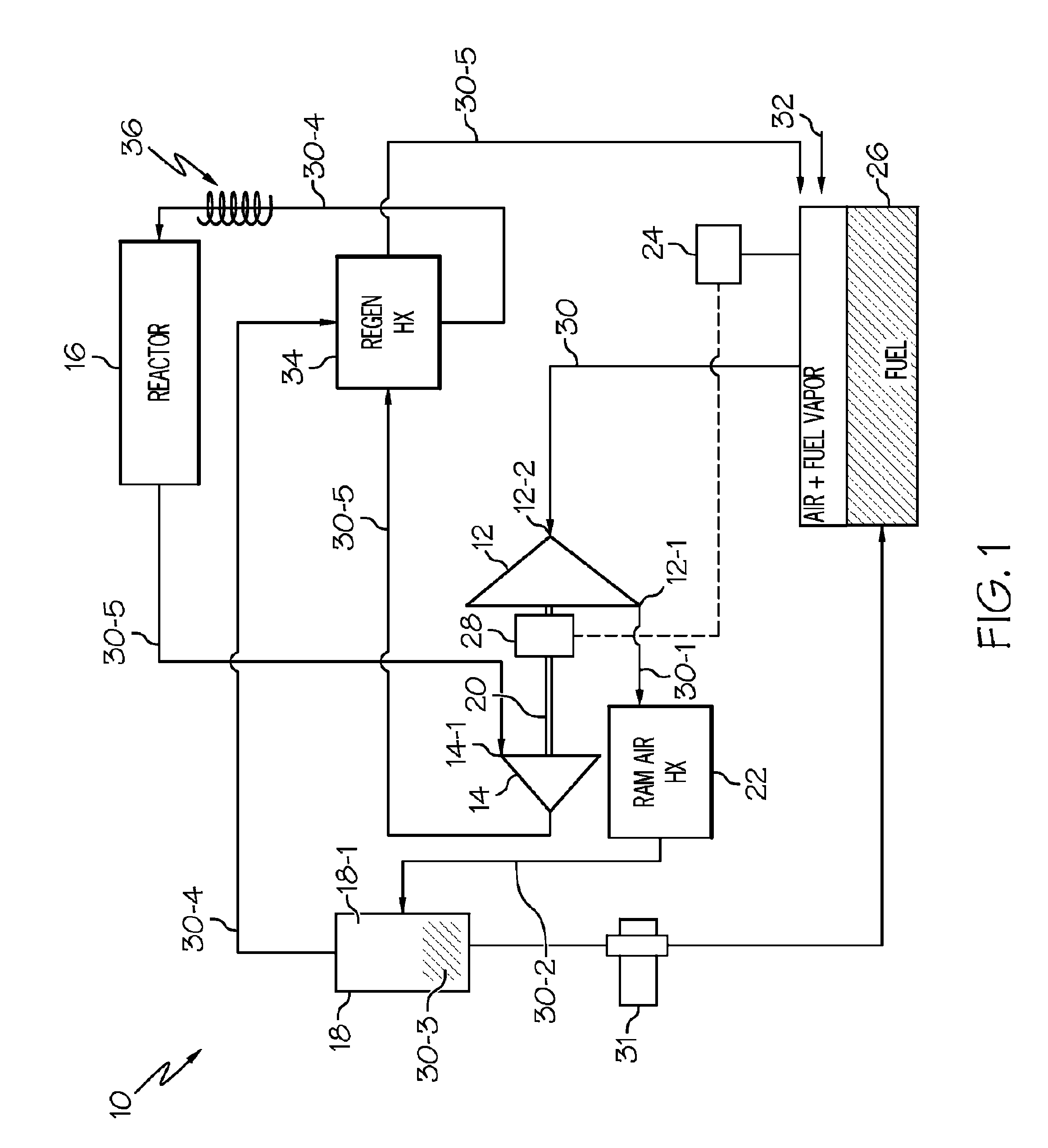

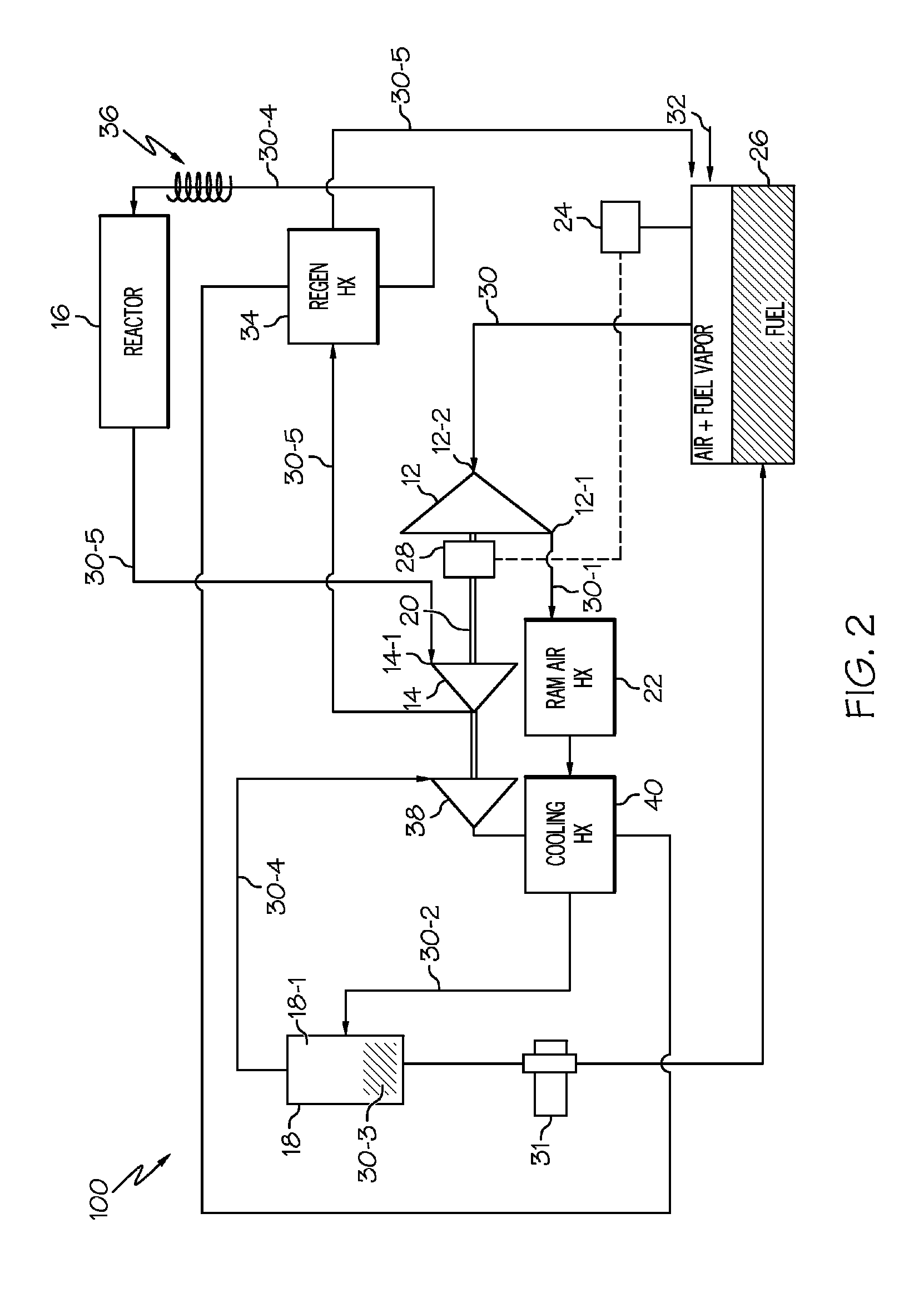

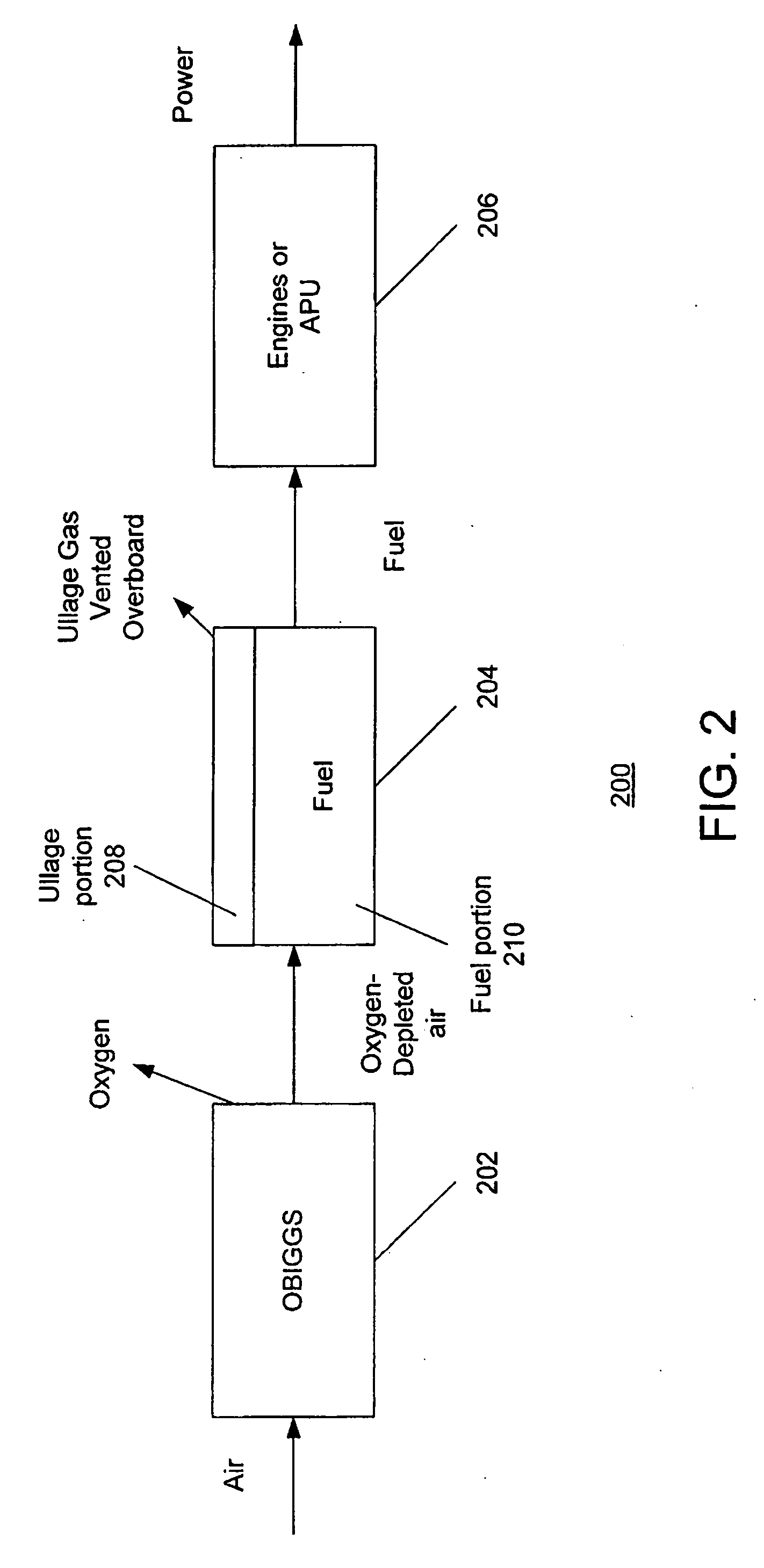

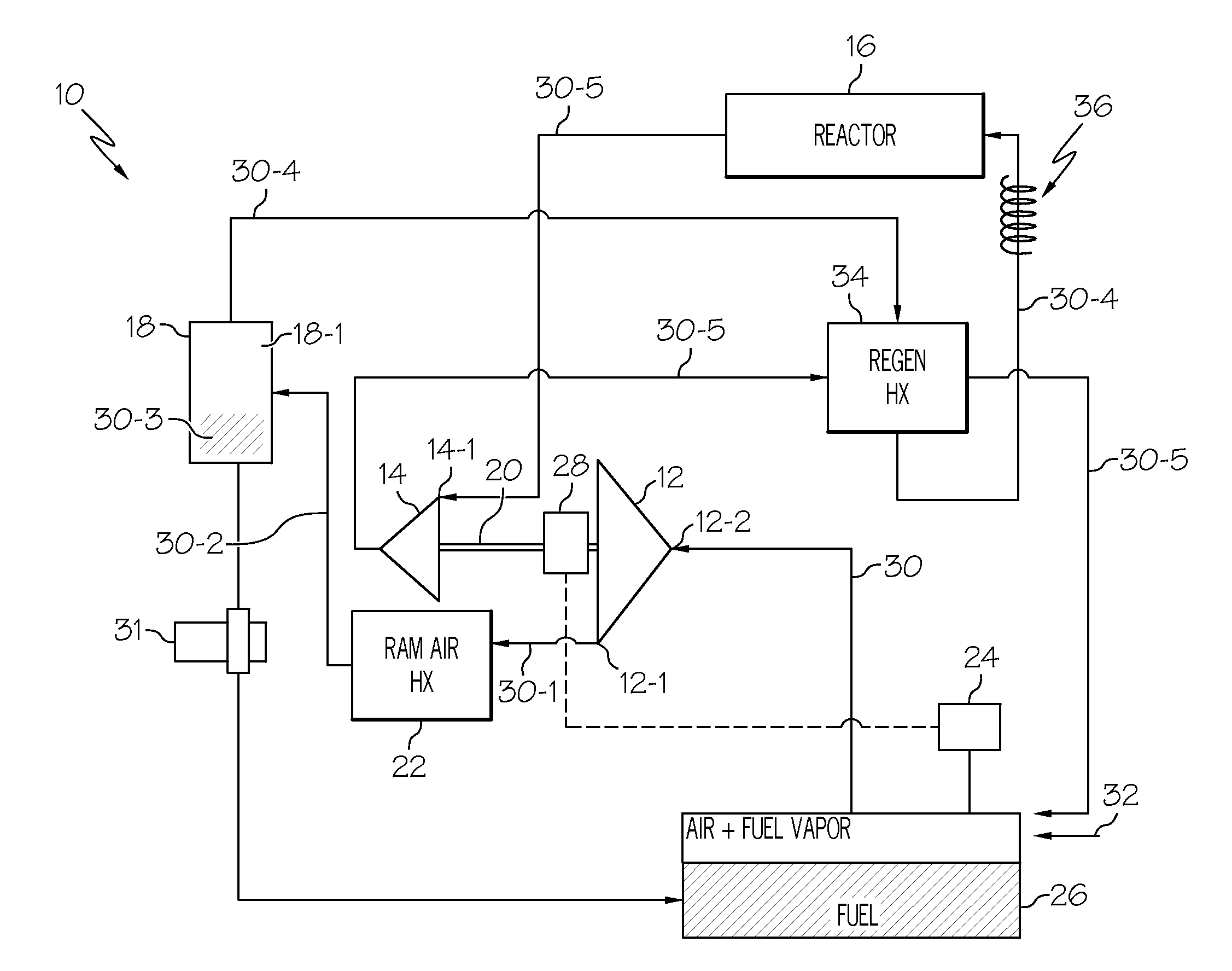

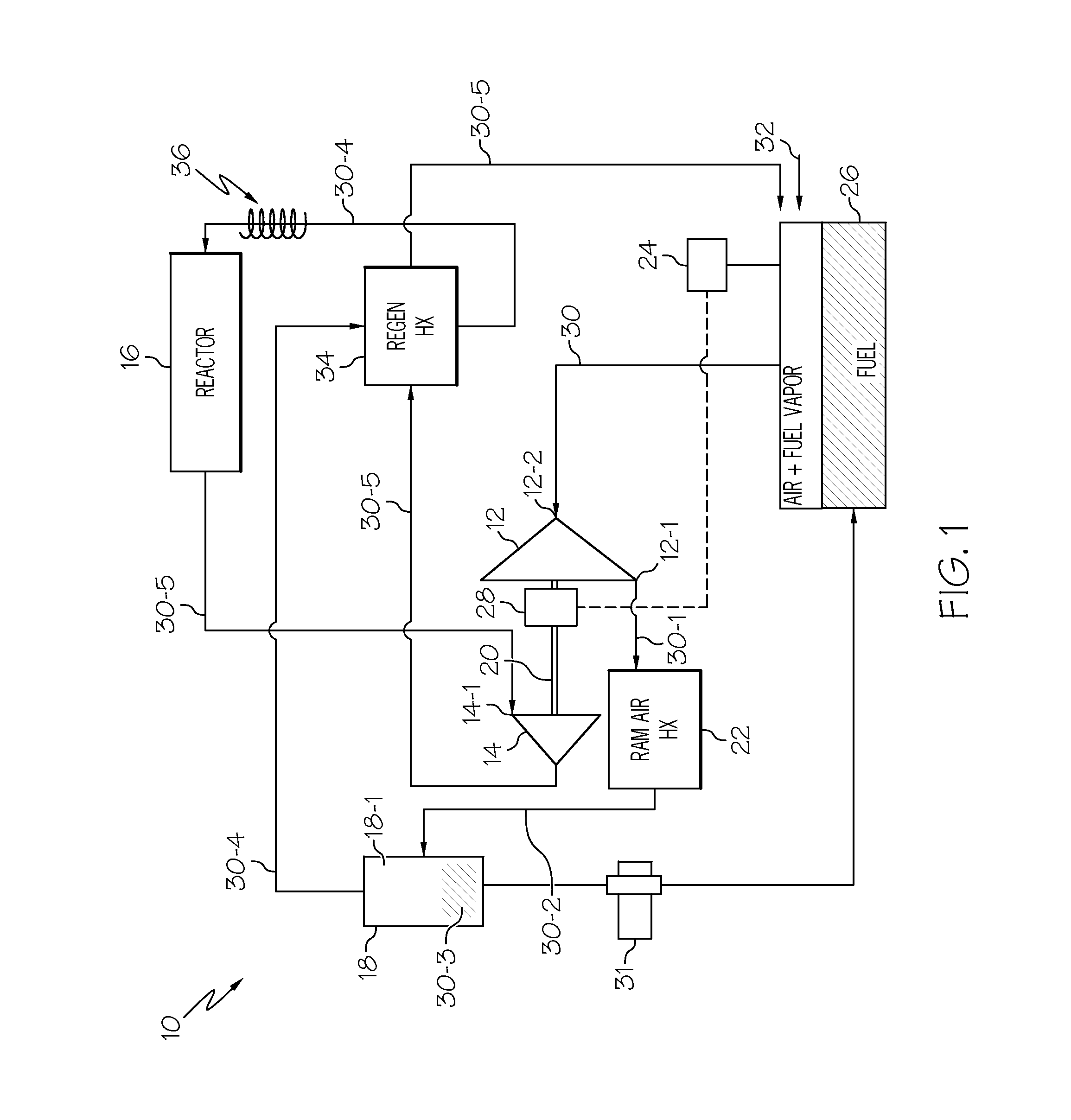

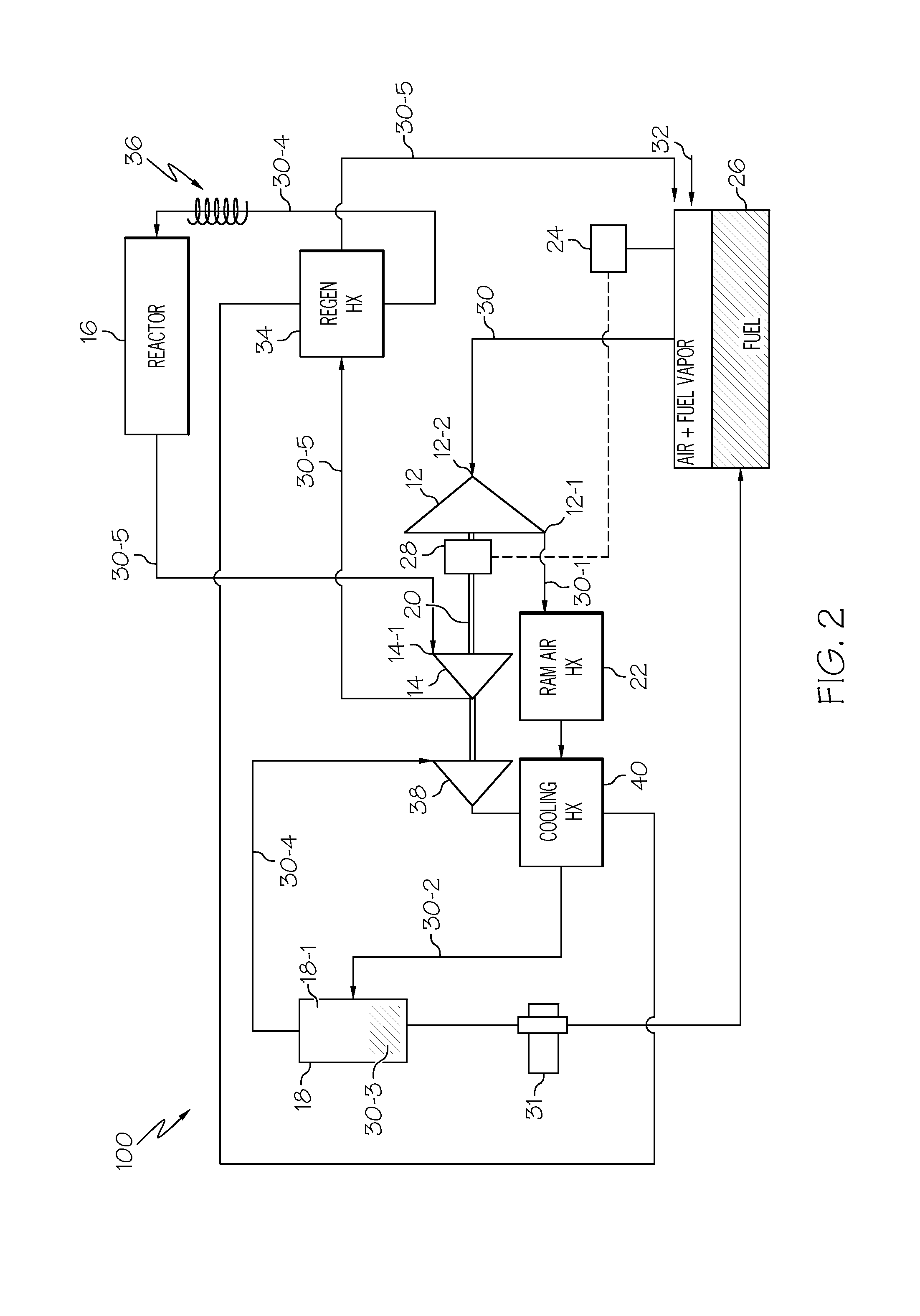

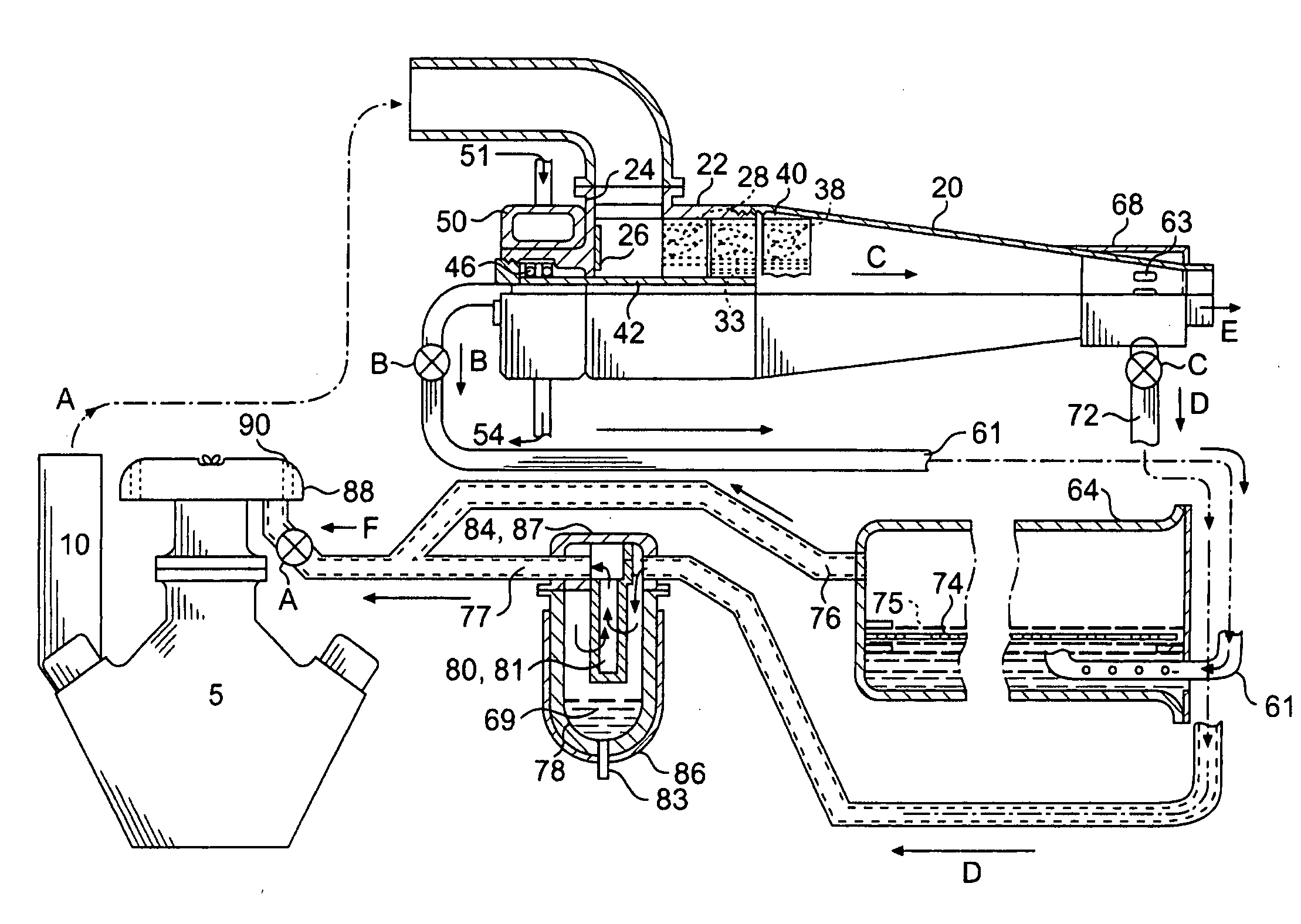

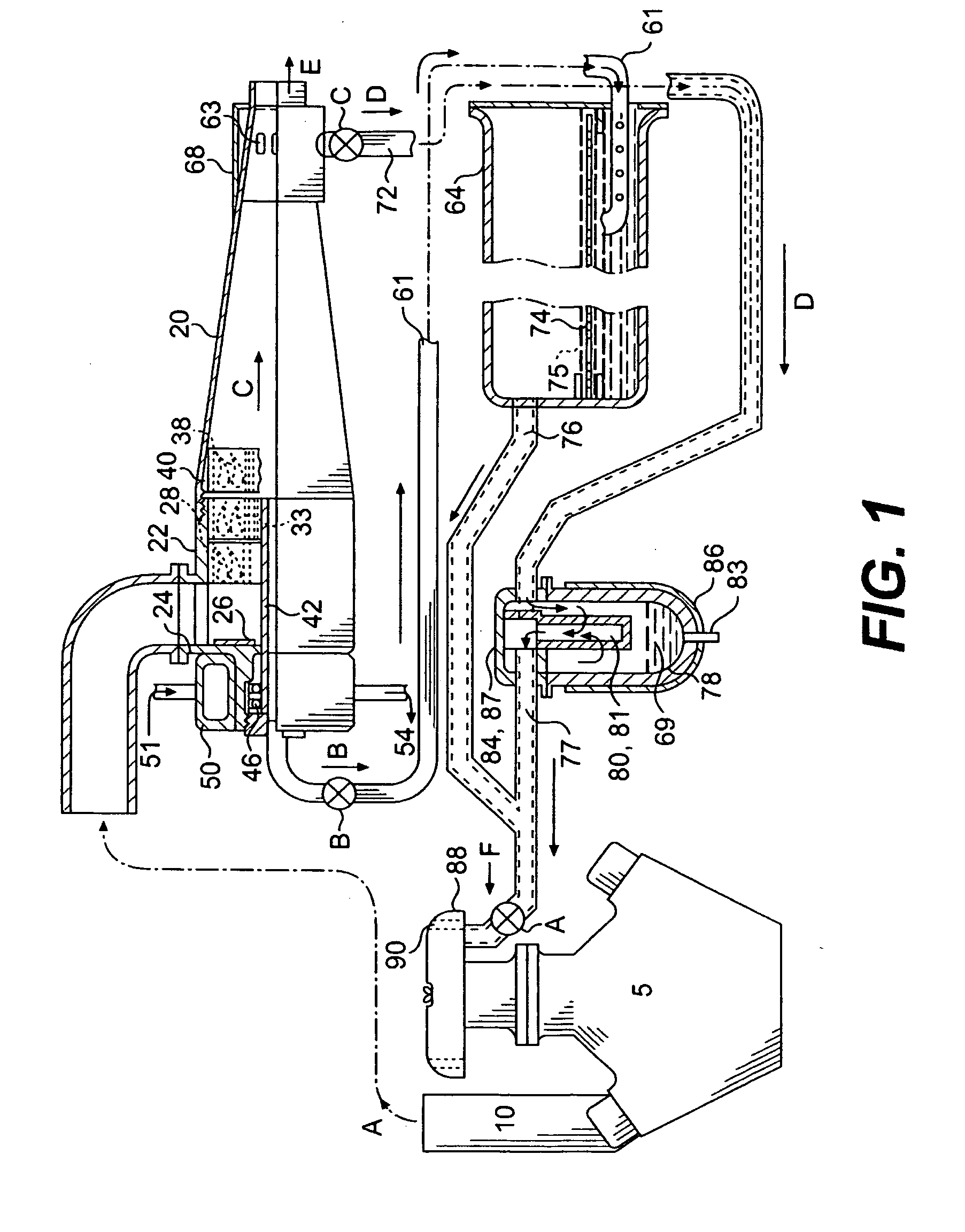

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

On-board fuel inerting system

InactiveUS6634598B2Effective monitoringExplosion is minimized and eliminatedPower plant fuel tanksFuel tank safety measuresUllageNitrogen gas

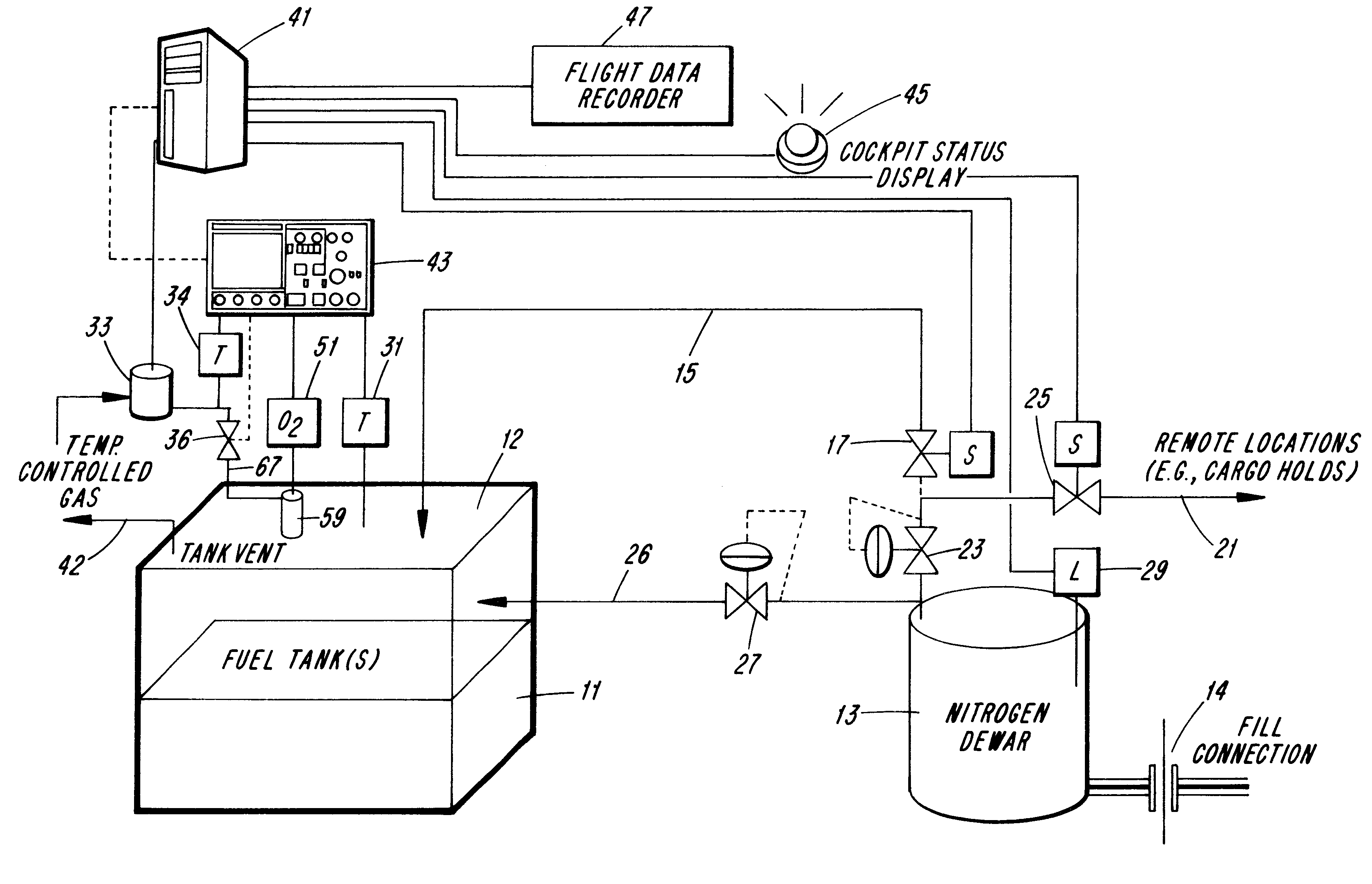

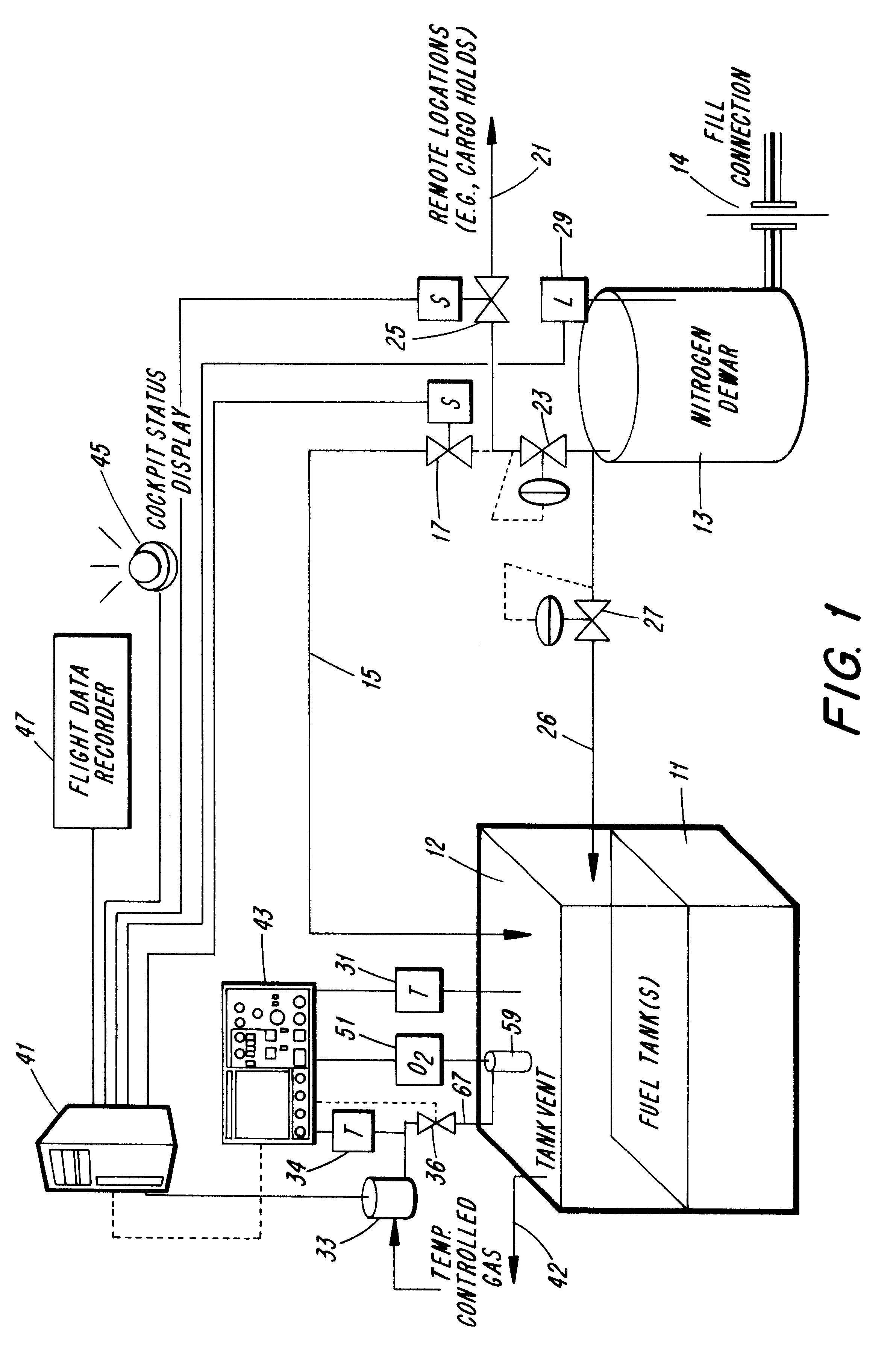

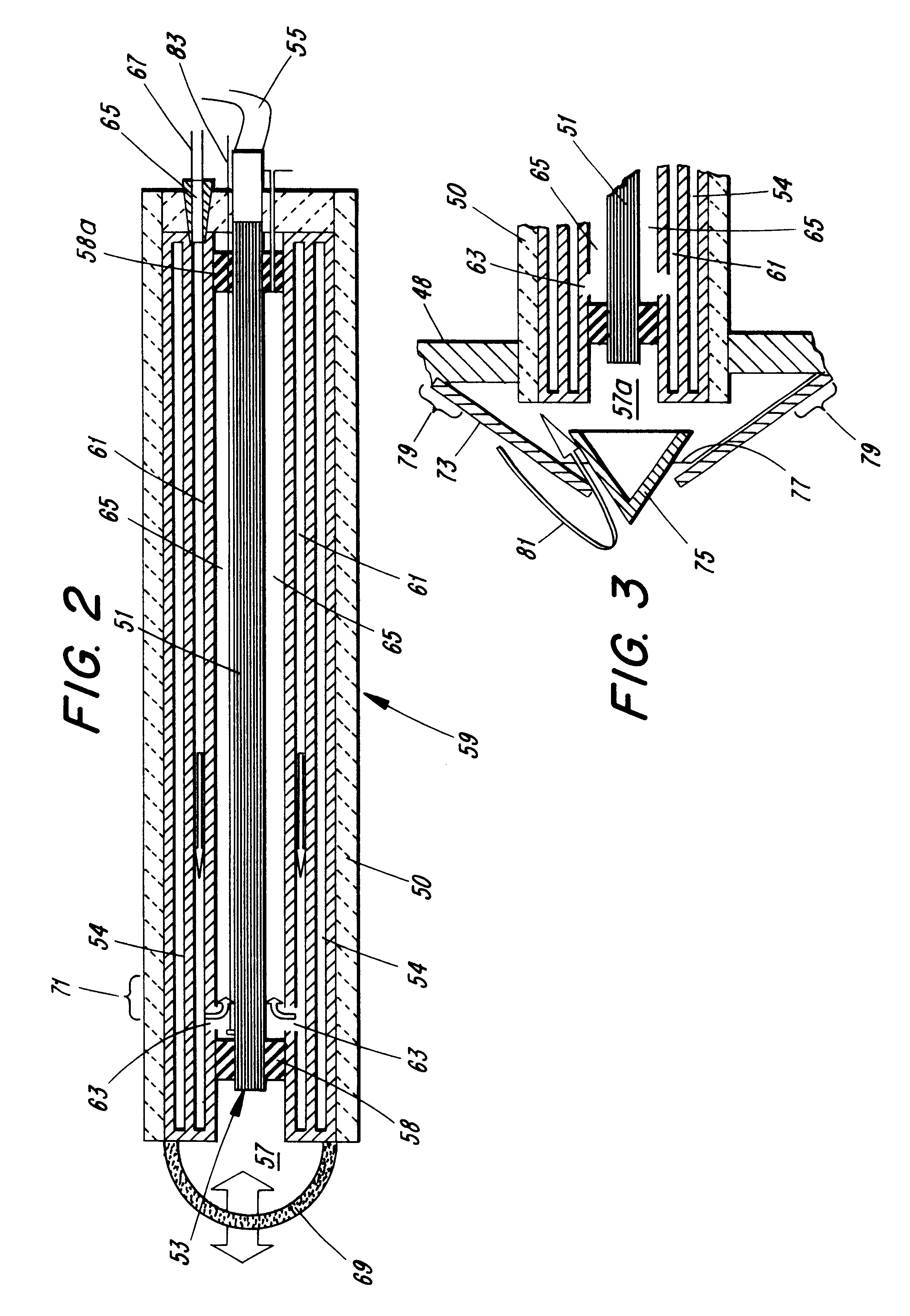

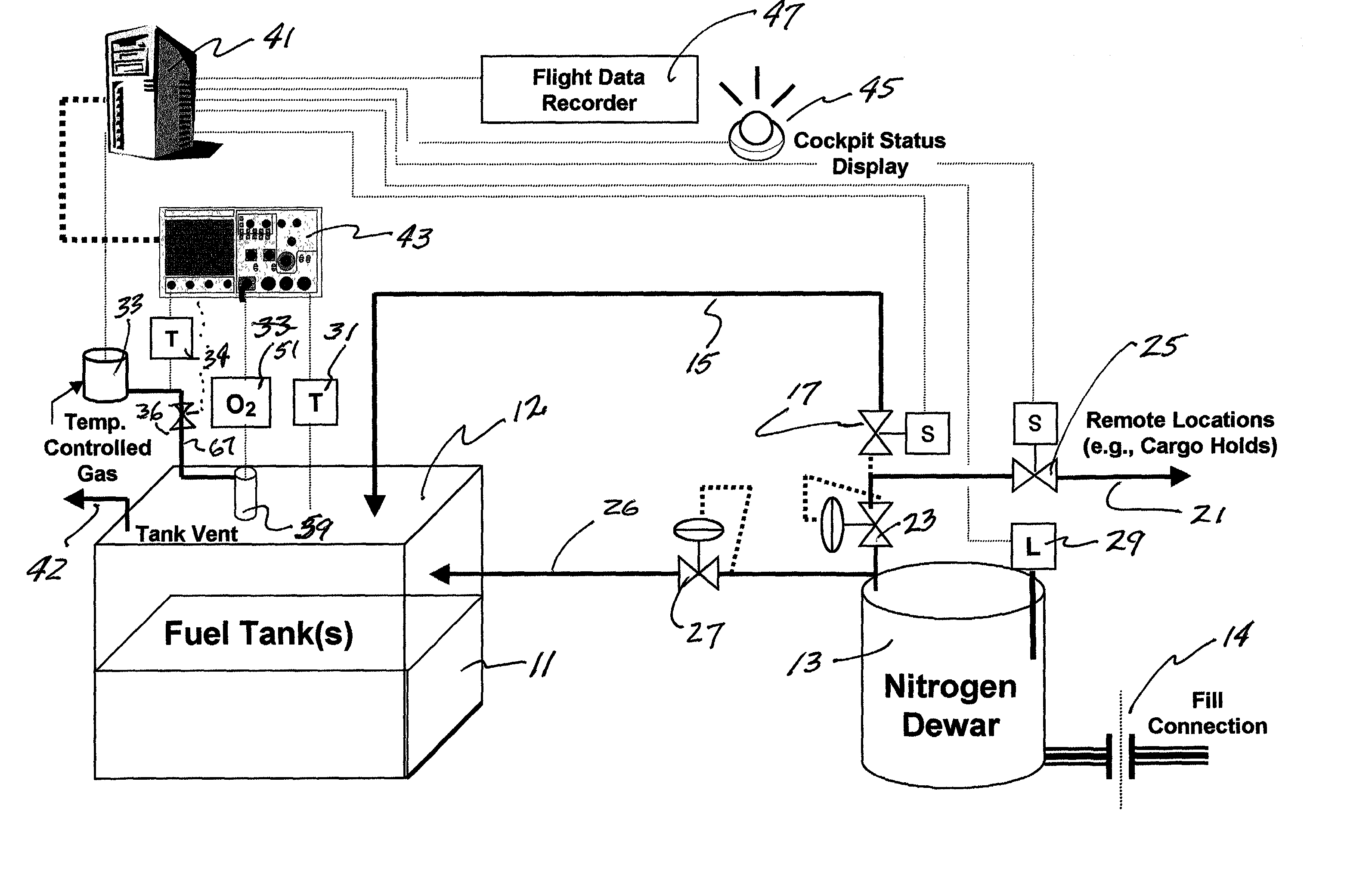

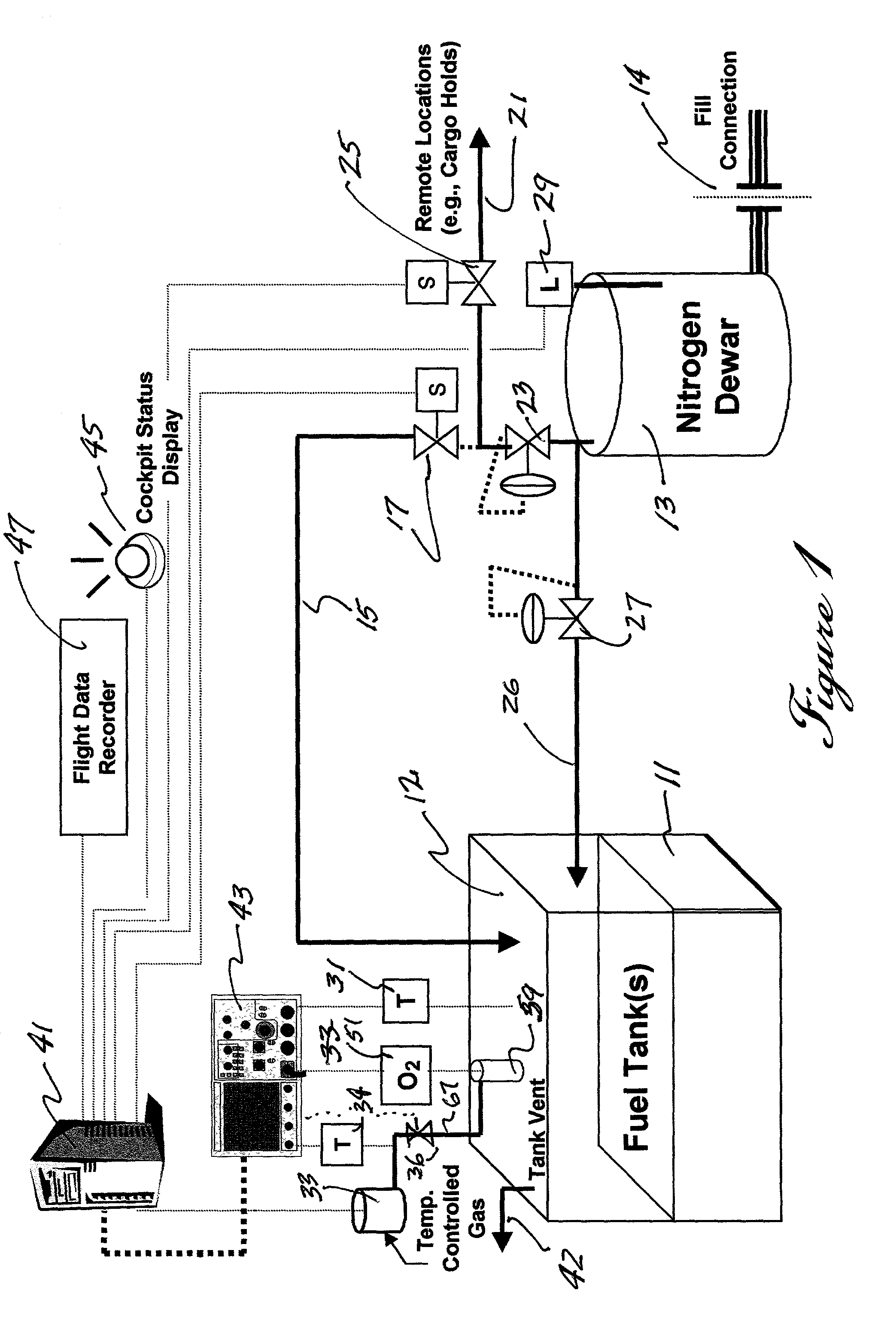

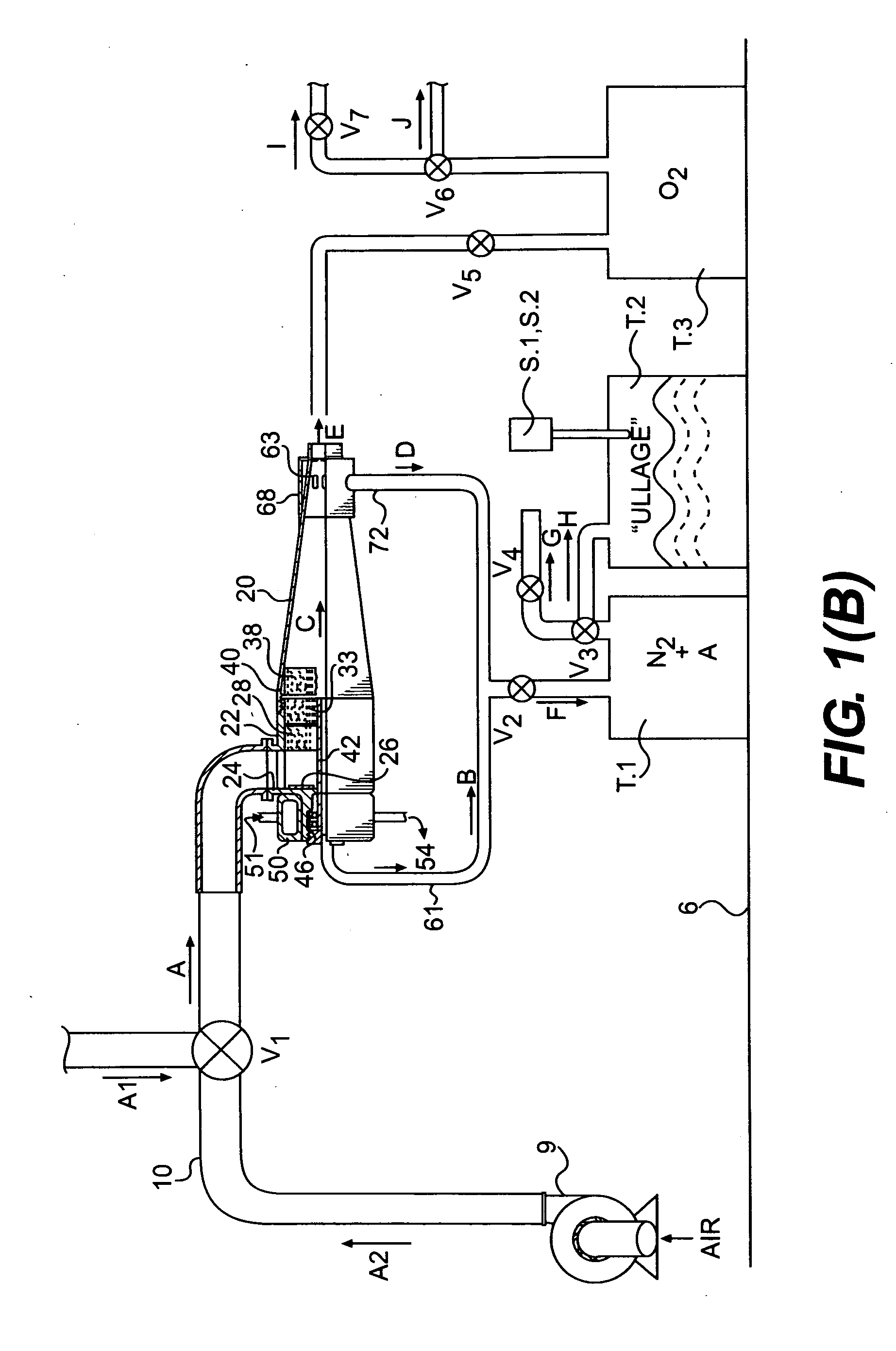

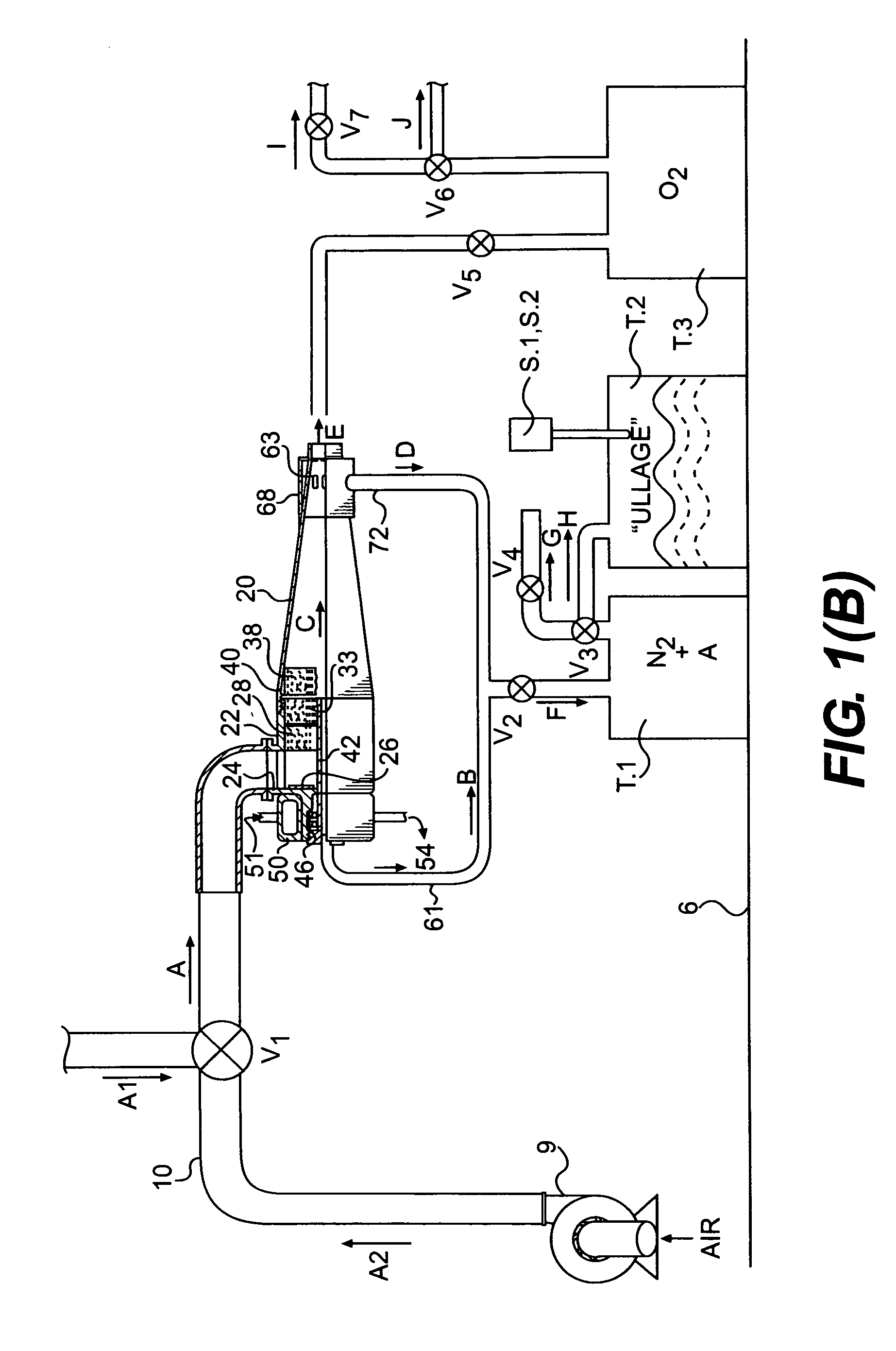

An inerting system is disclosed that is adaptable to inert the fuel tank of a vehicle, most typically an aircraft, that includes an oxygen detector to monitor the oxygen partial pressure of the vapors in the ullage (i.e., the overfuel) volume of the tank, a source of an inert gas (e.g., nitrogen) in valved communication with the ullage of the tank, and a detector for sensing the oxygen content in the ullage of the tank and controlling the flow of inert gas to the tillage to maintain that volume with a proportion oxygen that will not support combustion in the event of an ignition source or intrusion of another potentially explosive occurrence within said tank. A specific fiberoptic probe which enables monitoring oxygen content within the tank without introducing a source of electrical current within the tank is also disclosed.

Owner:SUSKO KENNETH

Commercial aircraft on-board inerting system

ActiveUS7152635B2Reduce flammabilityImprove flammabilityLiquid fillingPower plant fuel tanksInerting systemOn board

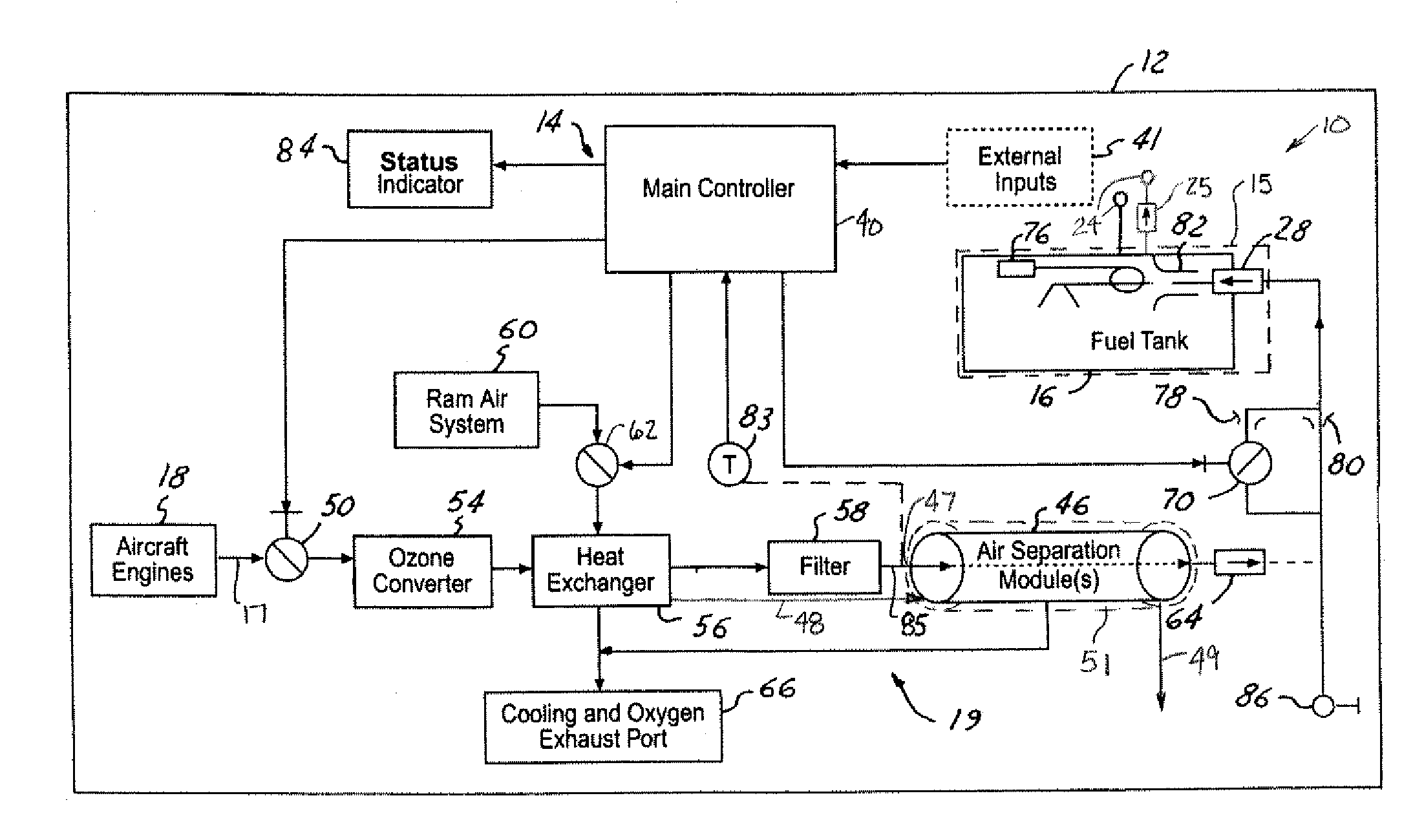

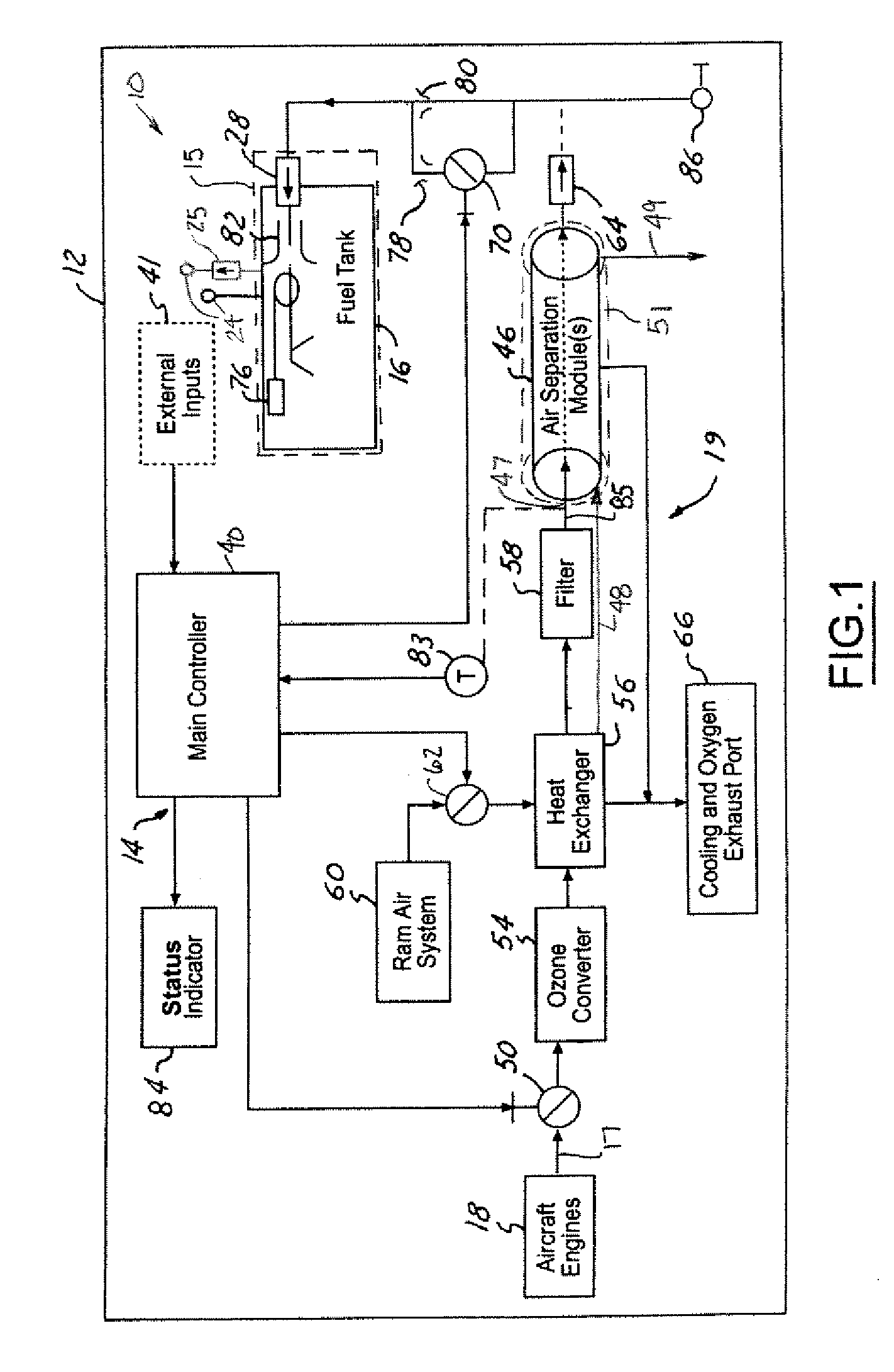

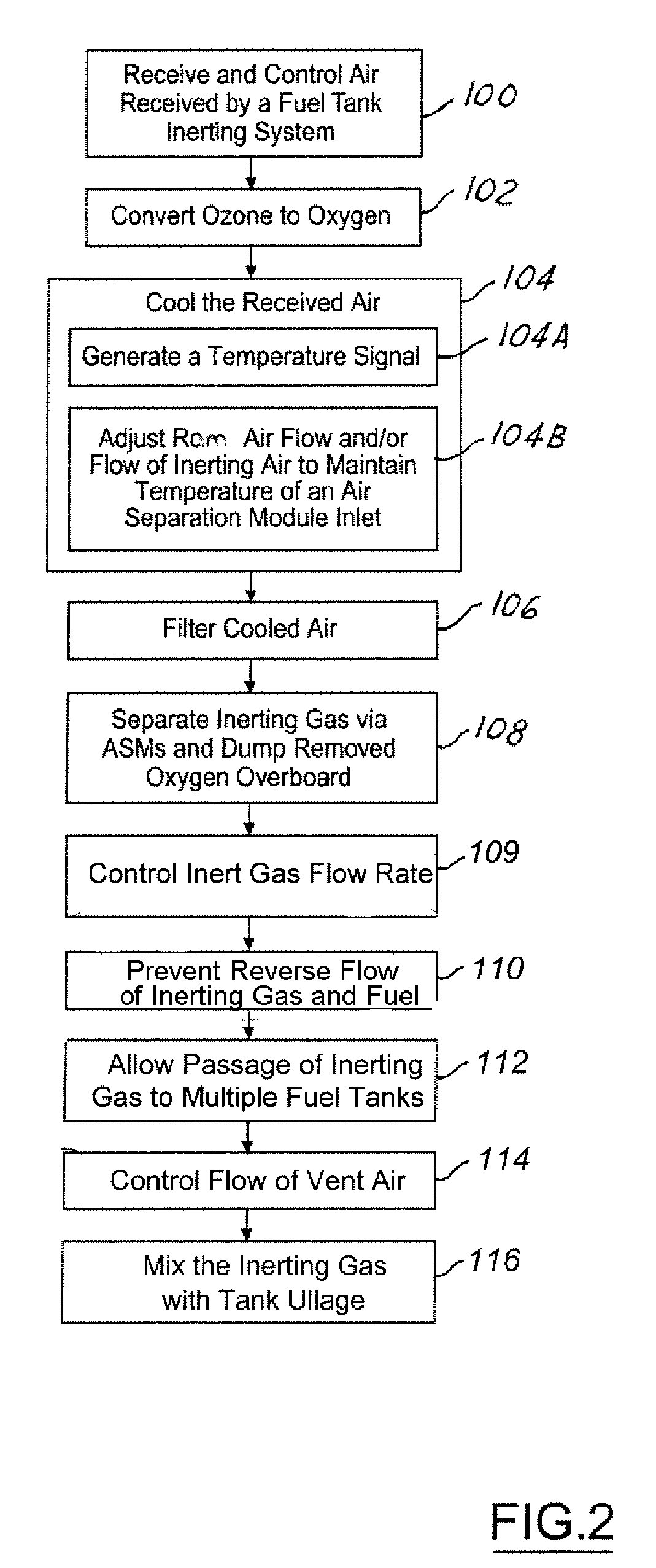

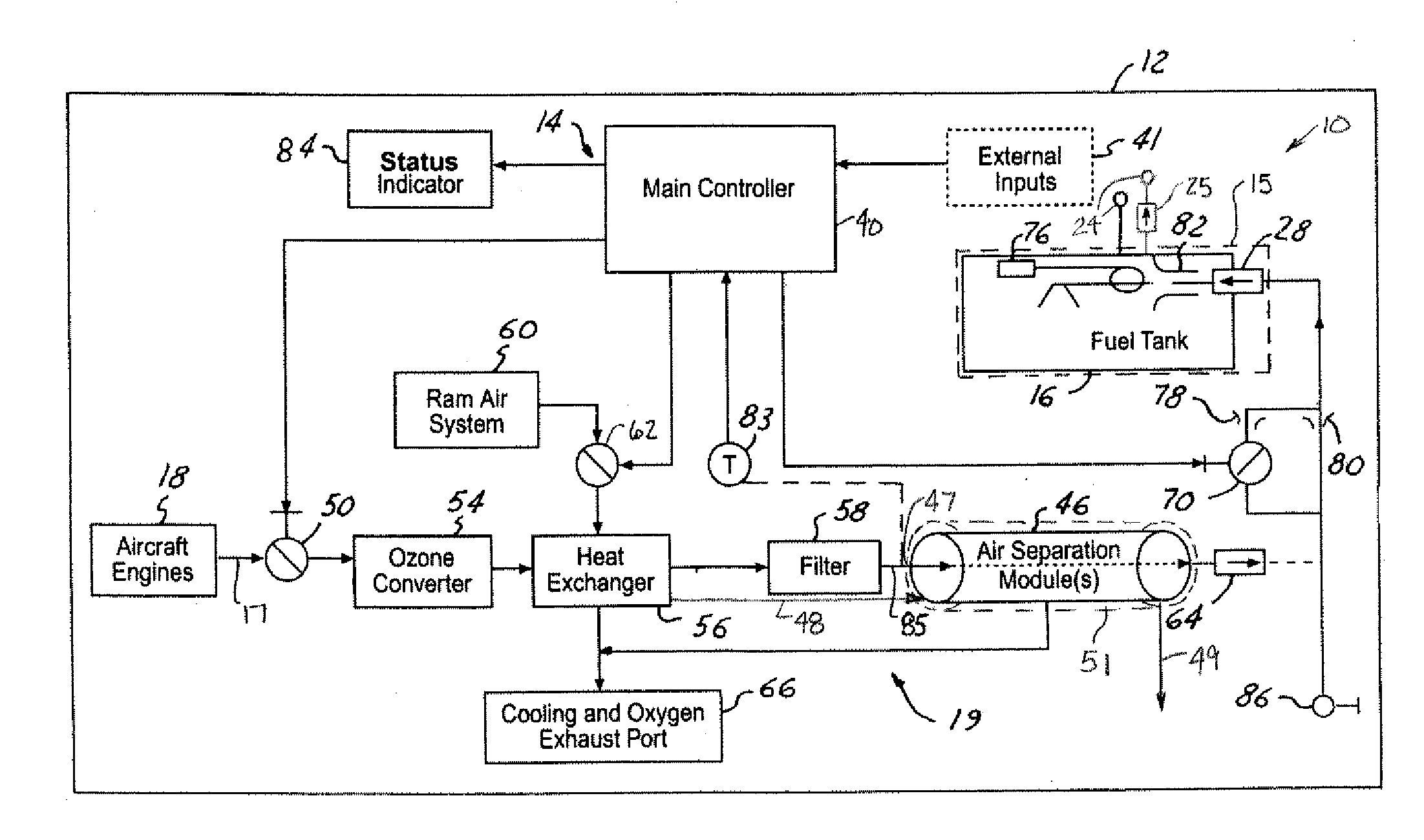

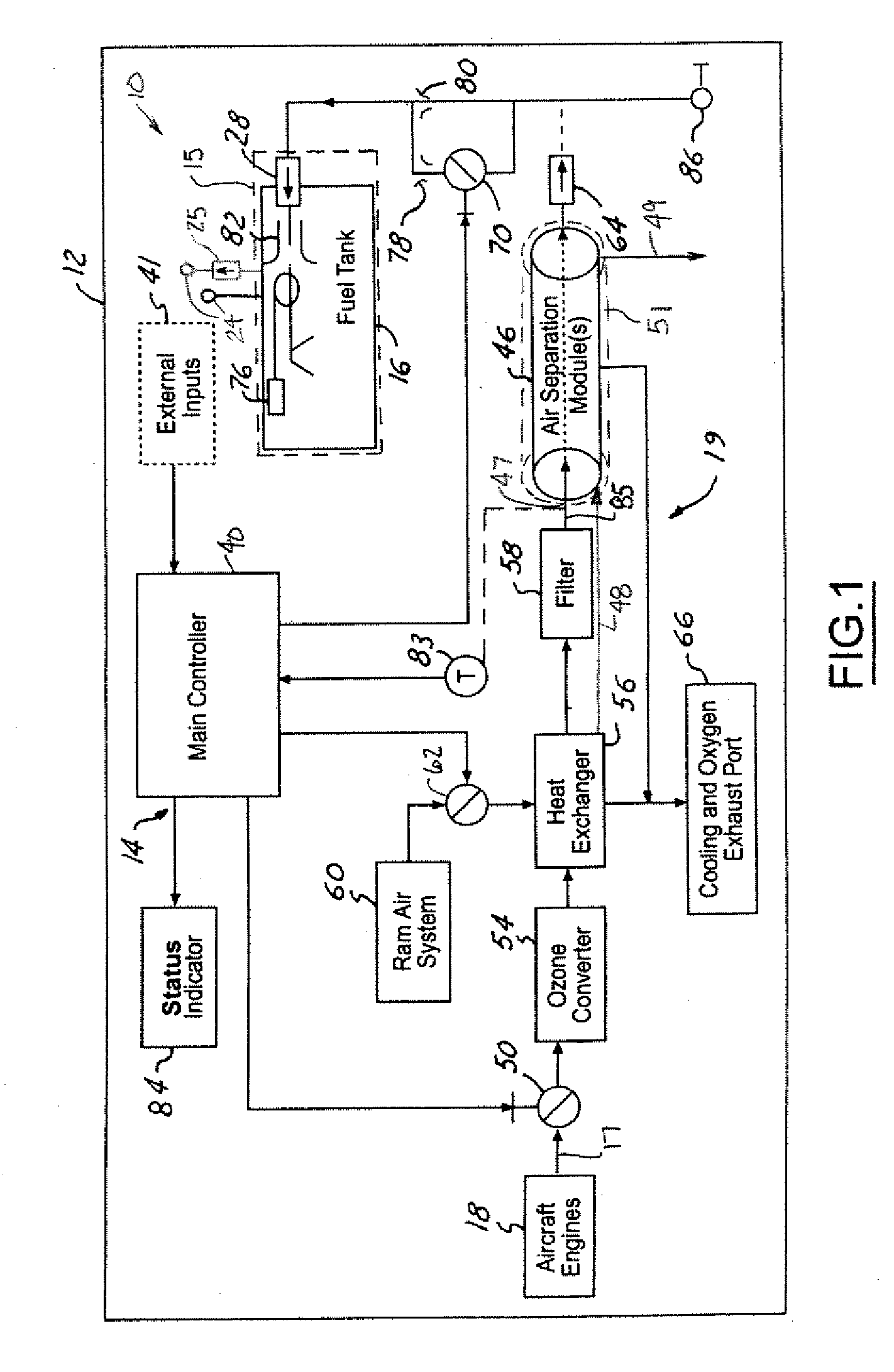

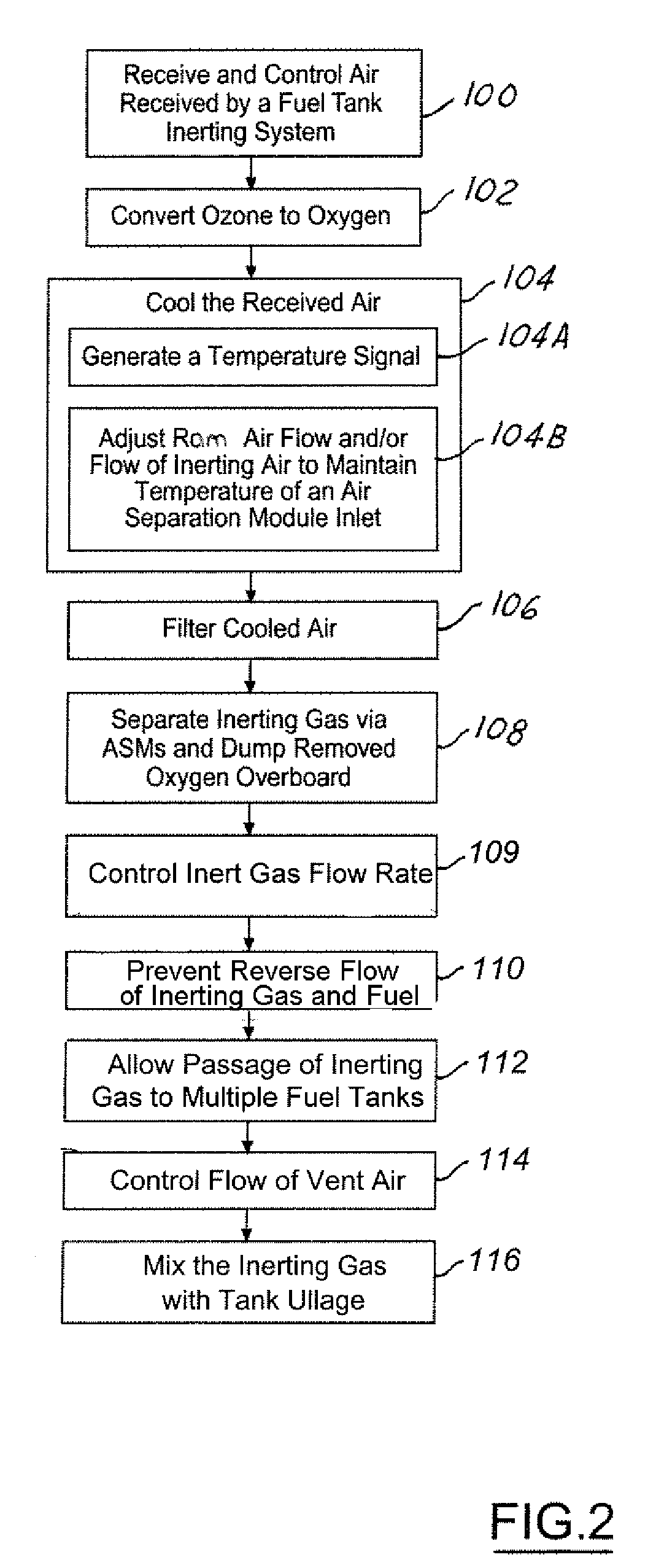

An inerting system (10) for an aircraft (12) includes one or more fuel tank circuits (15) associated with fuel tanks (16). An air source (17) supplies pressurized air. A heat exchanger (56) cools the pressurized air. An air separation module (46) is in fluid communication with the heat exchanger (56) and separates inerting gas from the pressurized air. A controller (40) controls flow of the inerting gas from the air separation module (46) to the fuel tanks (16).

Owner:THE BOEING CO

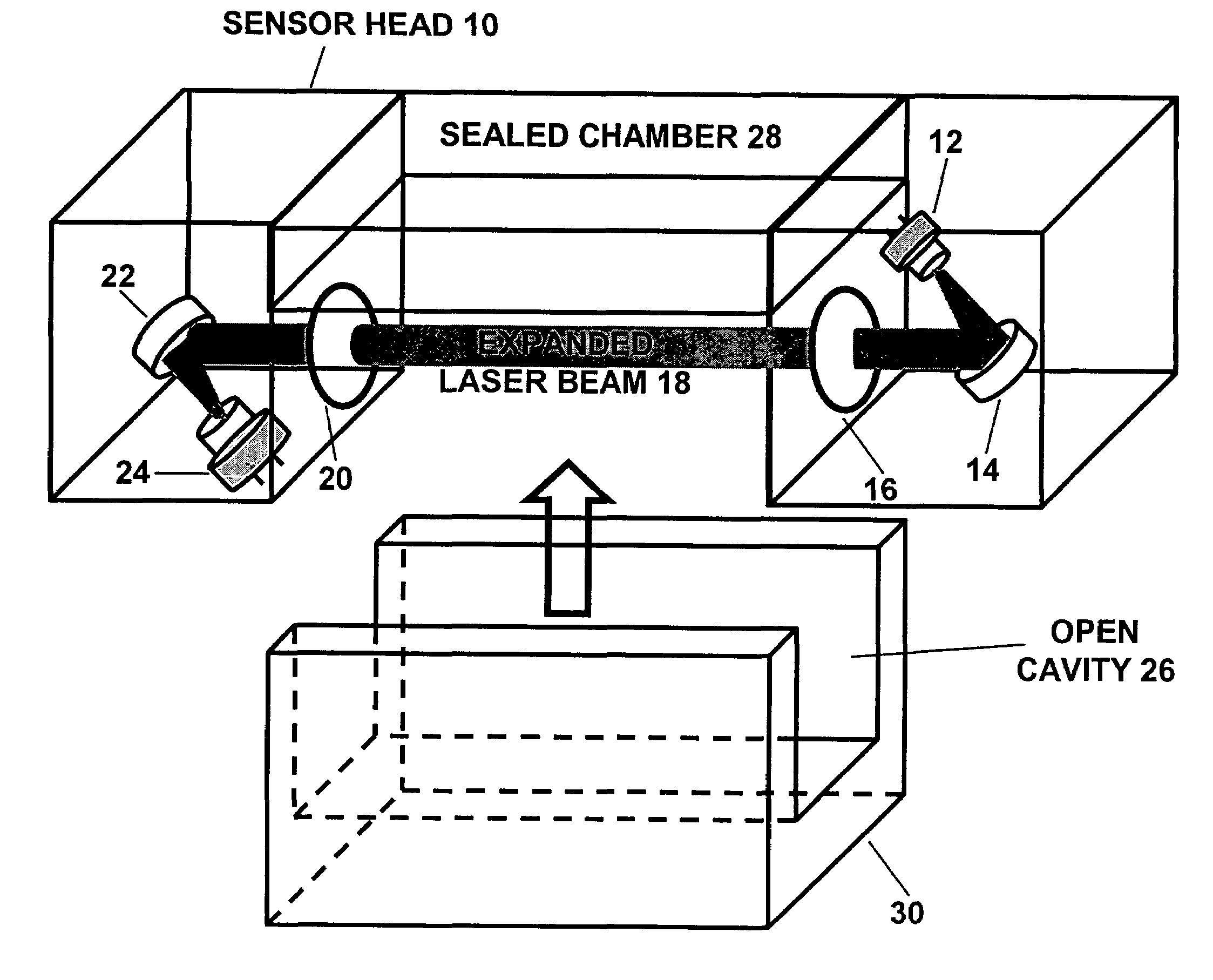

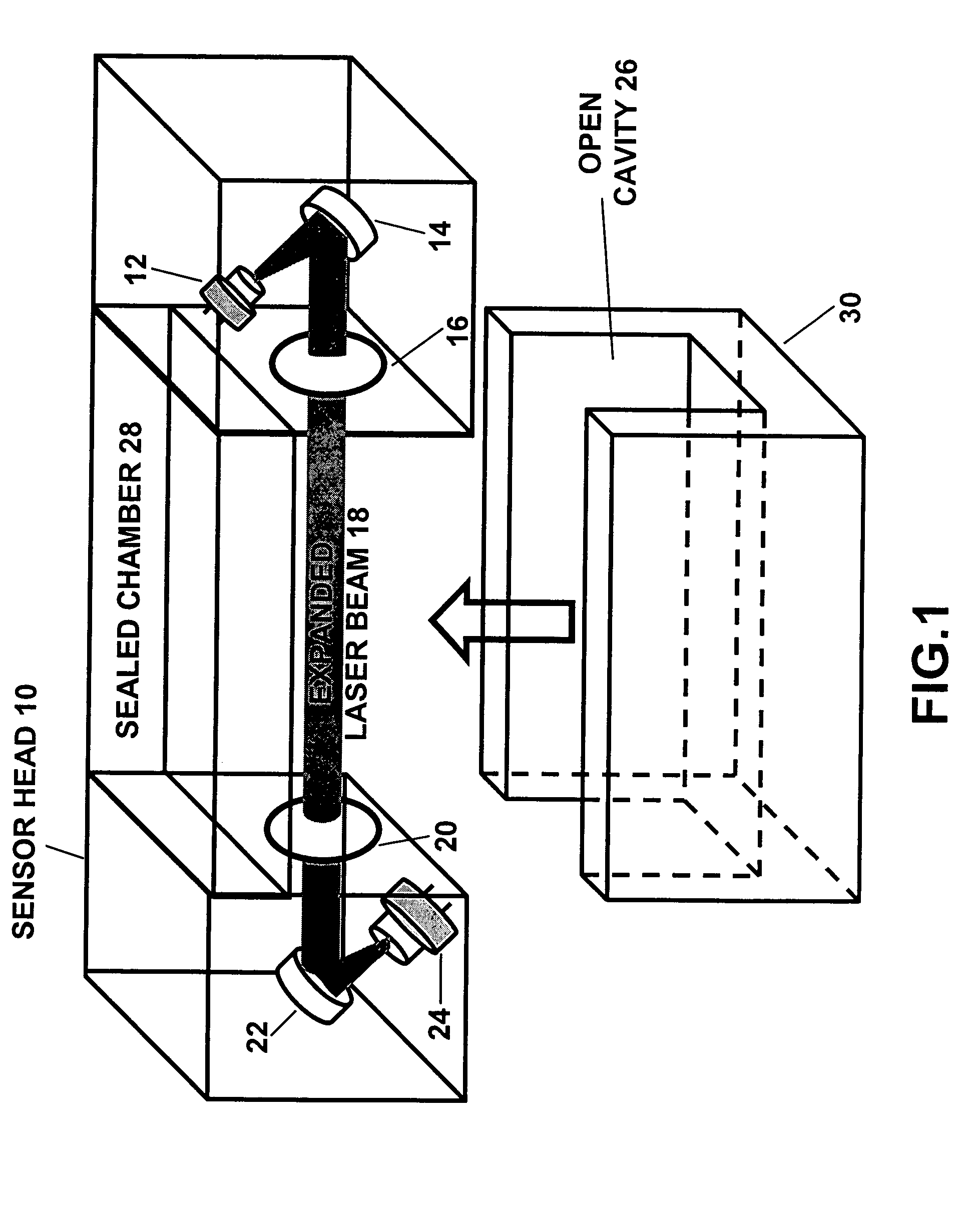

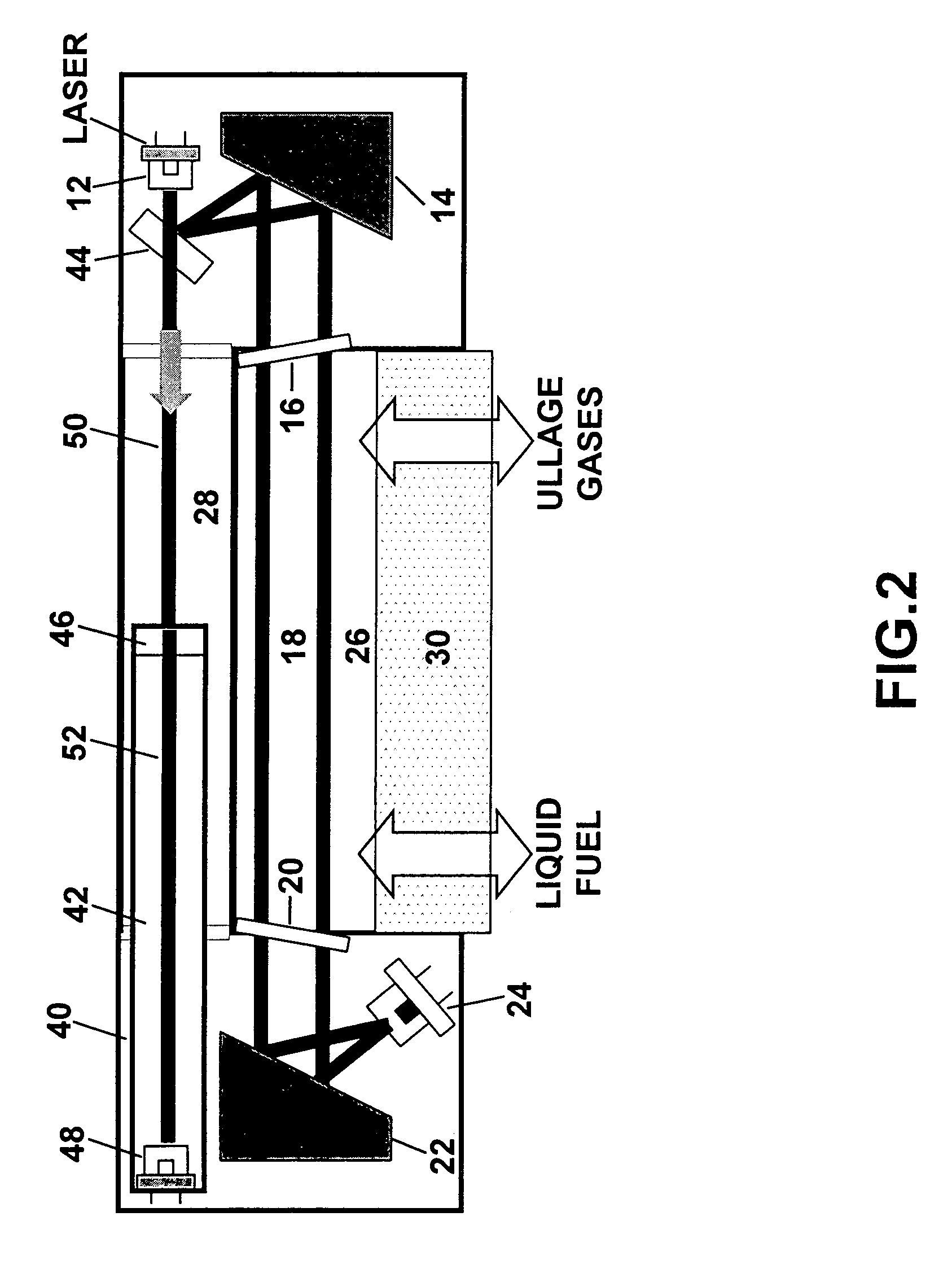

Oxygen sensor for aircraft fuel inerting systems

ActiveUS20050286054A1Transmissivity measurementsColor/spectral properties measurementsFuel tankEngineering

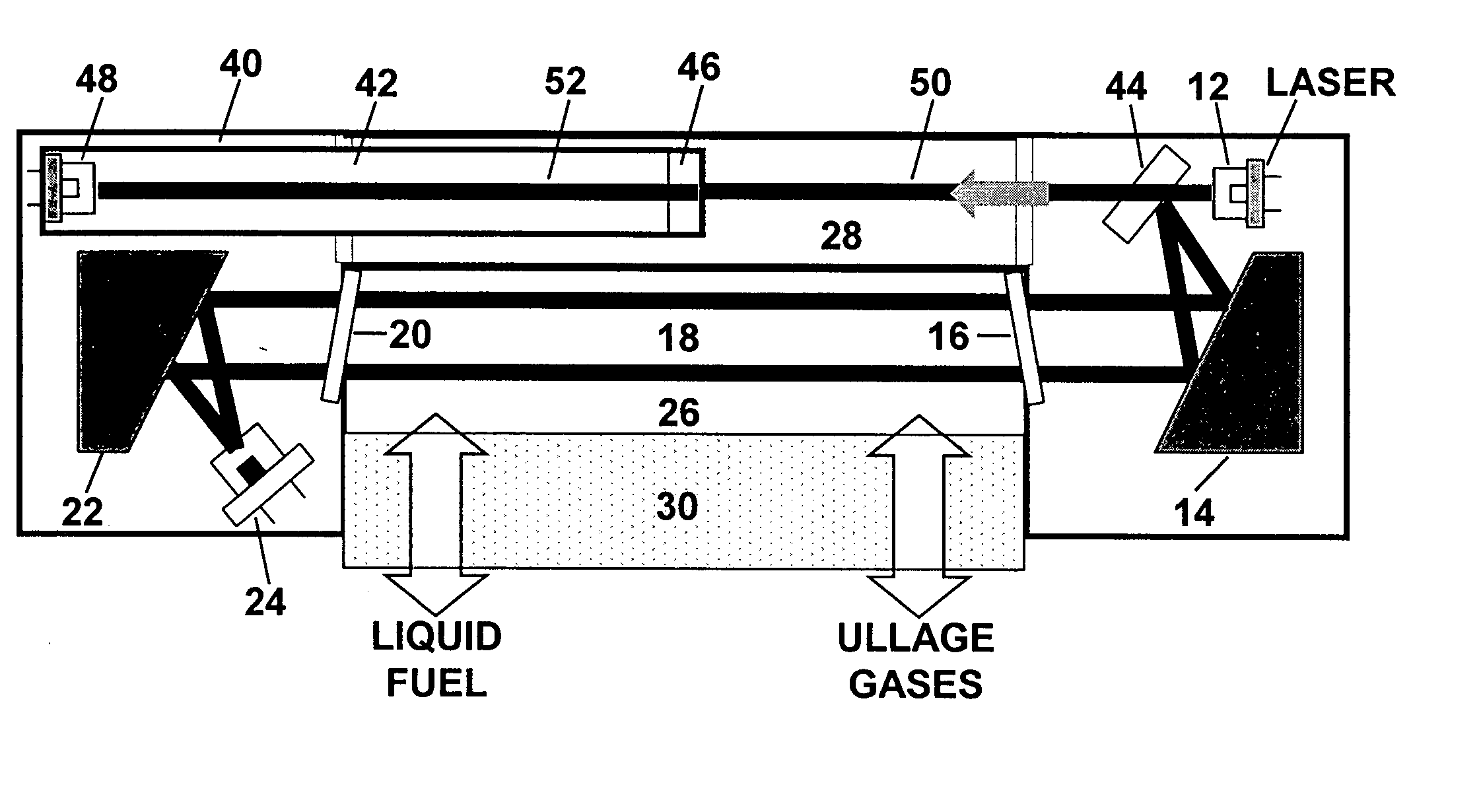

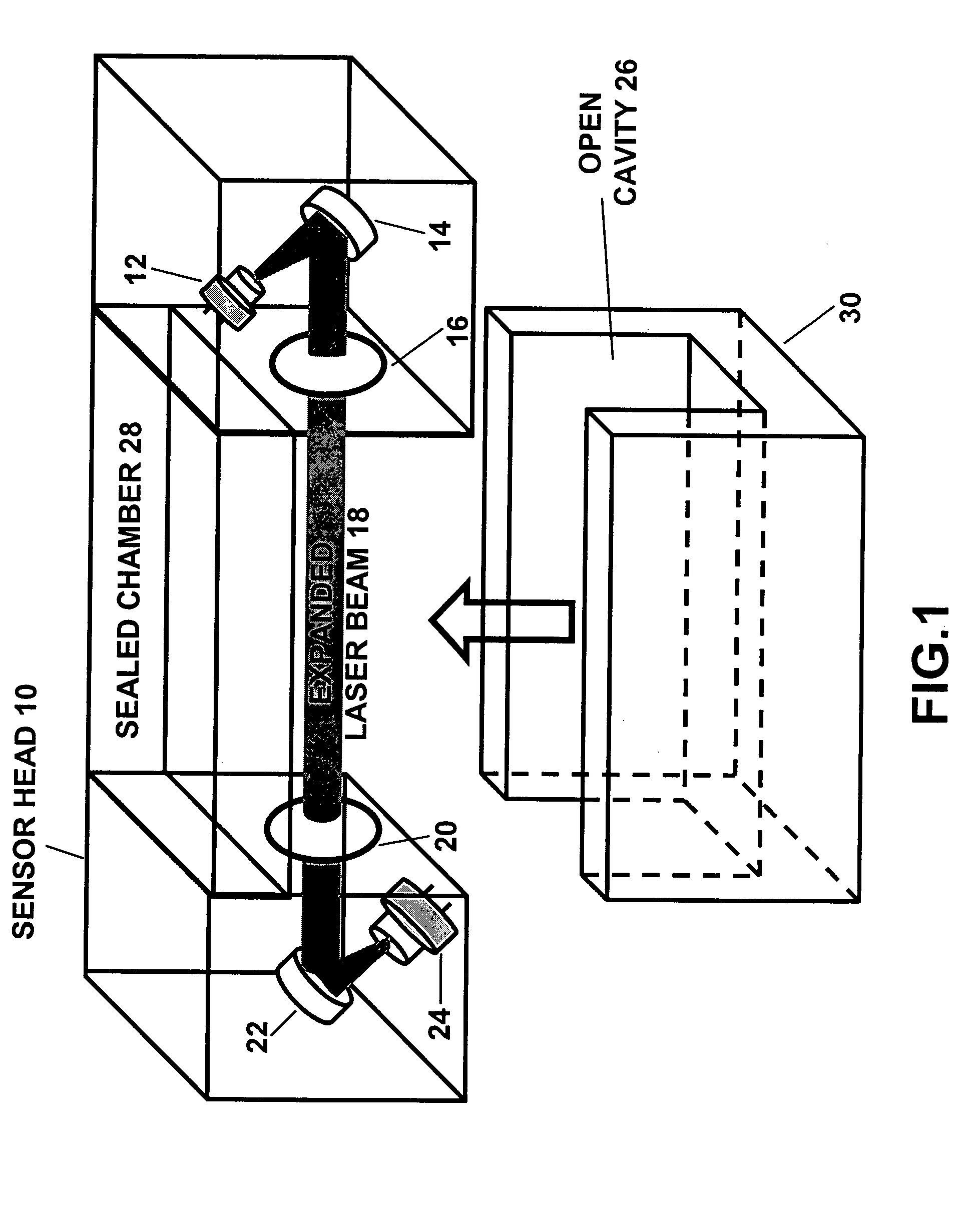

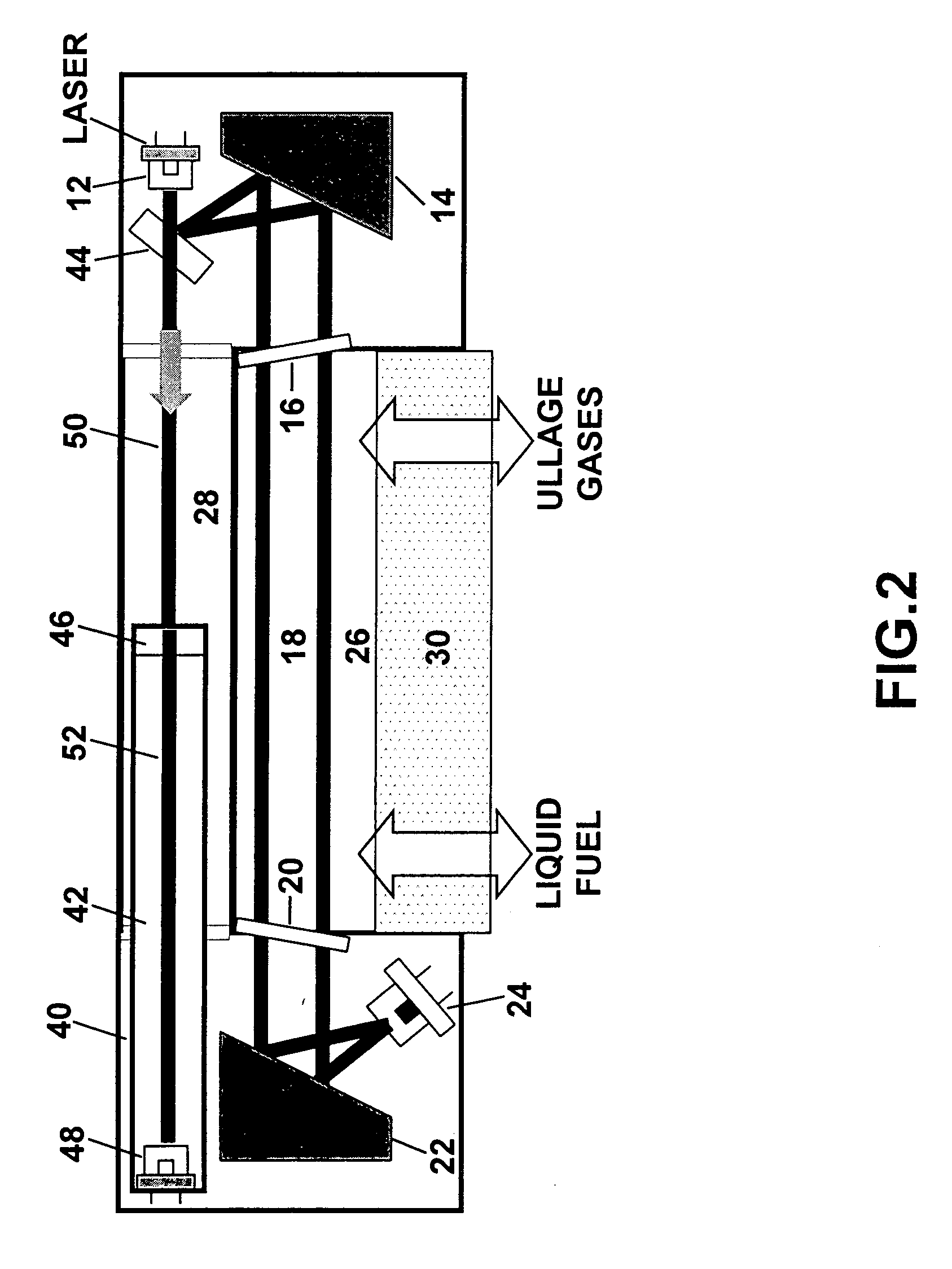

An apparatus and method for monitoring oxygen concentrations in fuel tank ullage comprising providing a sensor head comprising an optical cavity, exposing the optical cavity to an ambient gaseous environment of a fuel tank or air separation module, via a laser light source emitting wavelength modulated light through the cavity, and receiving the wavelength modulated light with a detector.

Owner:SOUTHWEST SCI

Advanced carbon dioxide fuel tank inerting system

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

Low power nitrogen enriched air generation system

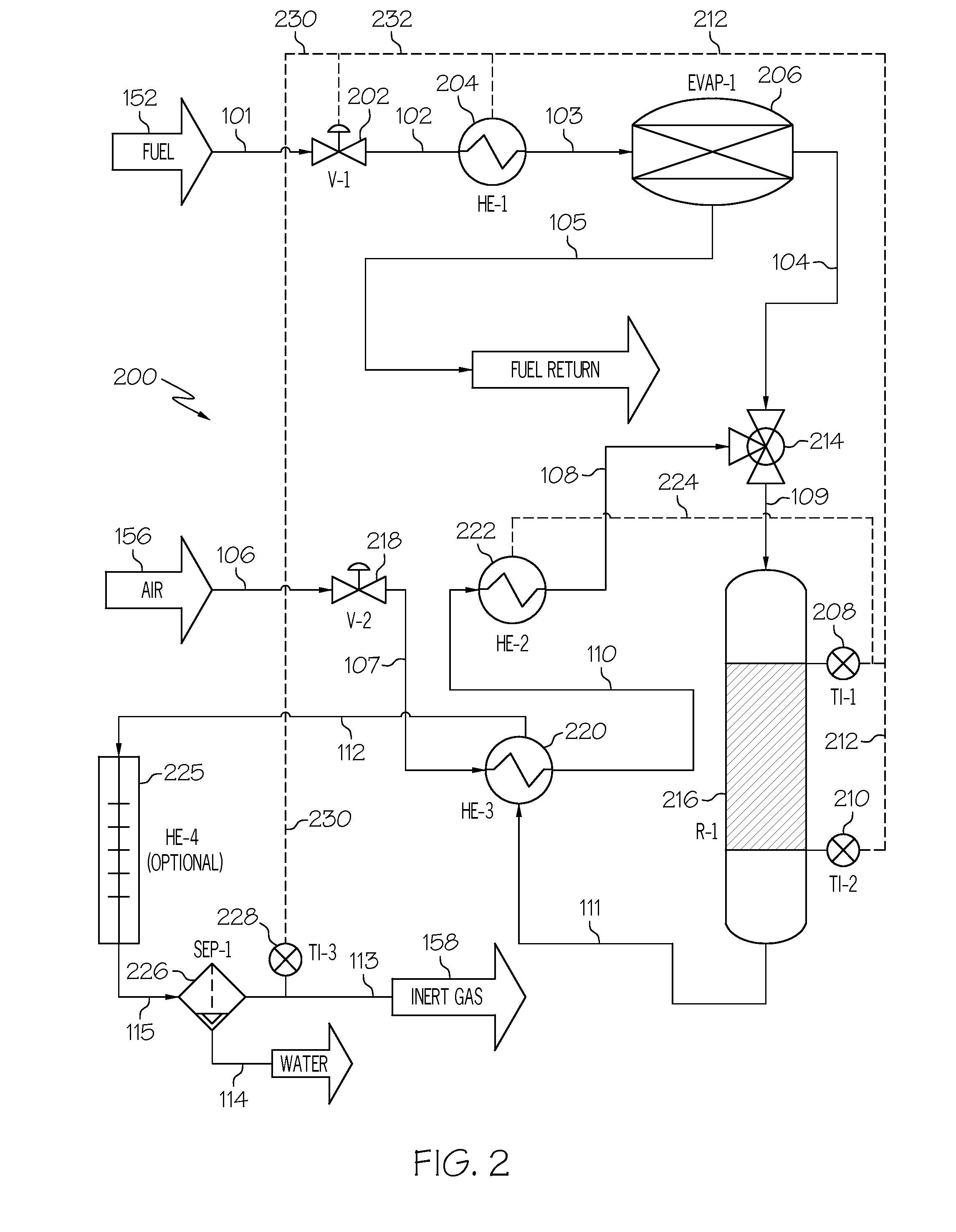

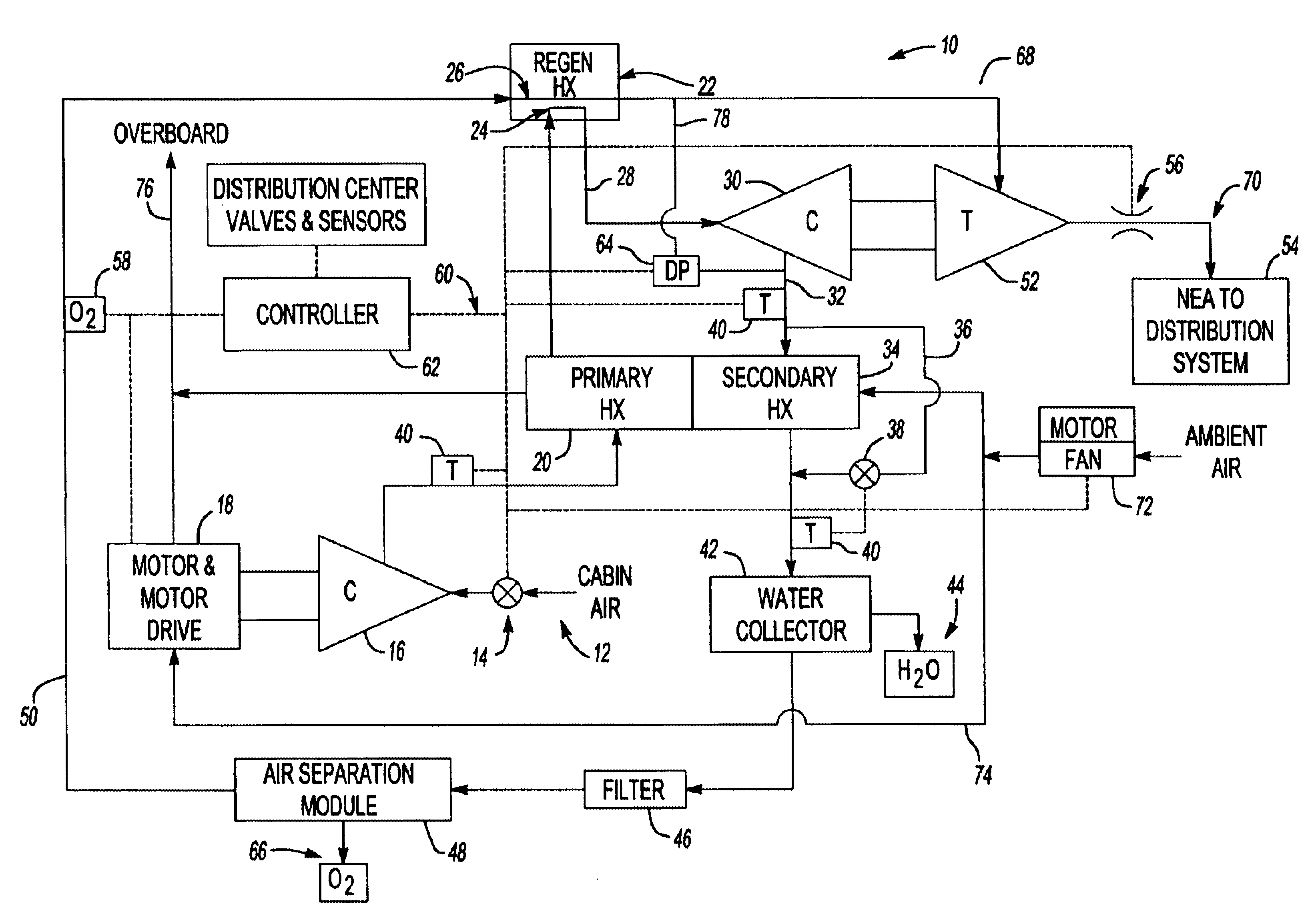

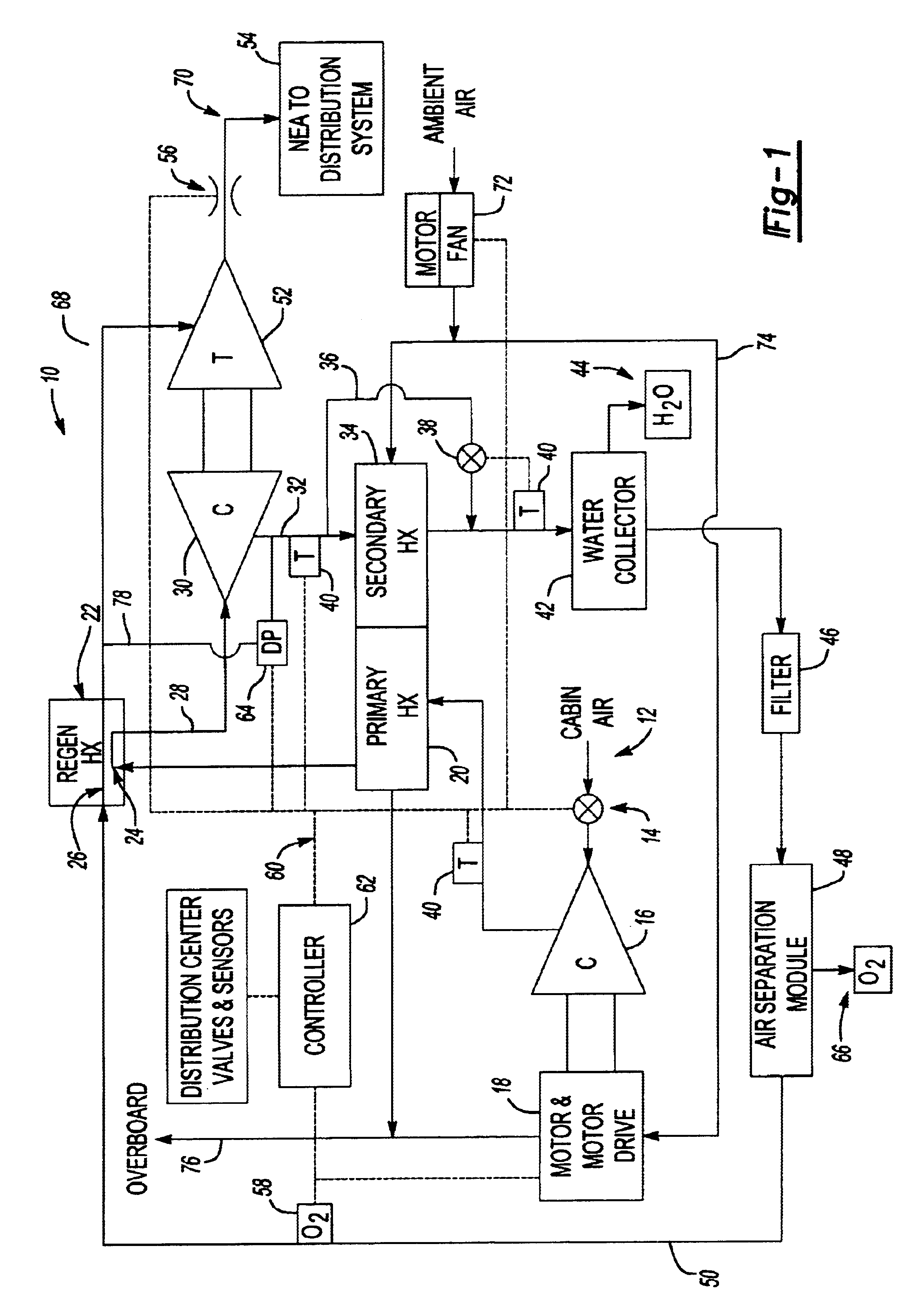

InactiveUS6913636B2Reduce capacityReduce weightDispersed particle filtrationAir-treatment apparatus arrangementsNacelleInerting system

An inerting system provides air with reduced oxygen content by flowing and directing air through an air separation module. Optimal working pressure for the air separation module is obtained with two compressors. A first compressor elevates air from the aircraft cabin to a second pressure. The second pressure is at an intermediate level below the working pressure of the air separation module. A second compressor elevates air from the second pressure to the working pressure. The second compressor is driven by air that is exhausted through a turbine. The pressure difference between air at the working pressure and air required by the fuel distribution system is used to power the turbine and drive the second compressor.

Owner:HAMILTON SUNDSTRAND CORP

Commercial Aircraft On-Board Inerting System

ActiveUS20050173017A1Reduce flammabilityMinimizing system sizeLiquid fillingAir-treatment apparatus arrangementsInerting systemOn board

An inerting system (10) for an aircraft (12) includes one or more fuel tank circuits (15) associated with fuel tanks (16). An air source (17) supplies pressurized air. A heat exchanger (56) cools the pressurized air. An air separation module (46) is in fluid communication with the heat exchanger (56) and separates inerting gas from the pressurized air. A controller (40) controls flow of the inerting gas from the air separation module (46) to the fuel tanks (16).

Owner:THE BOEING CO

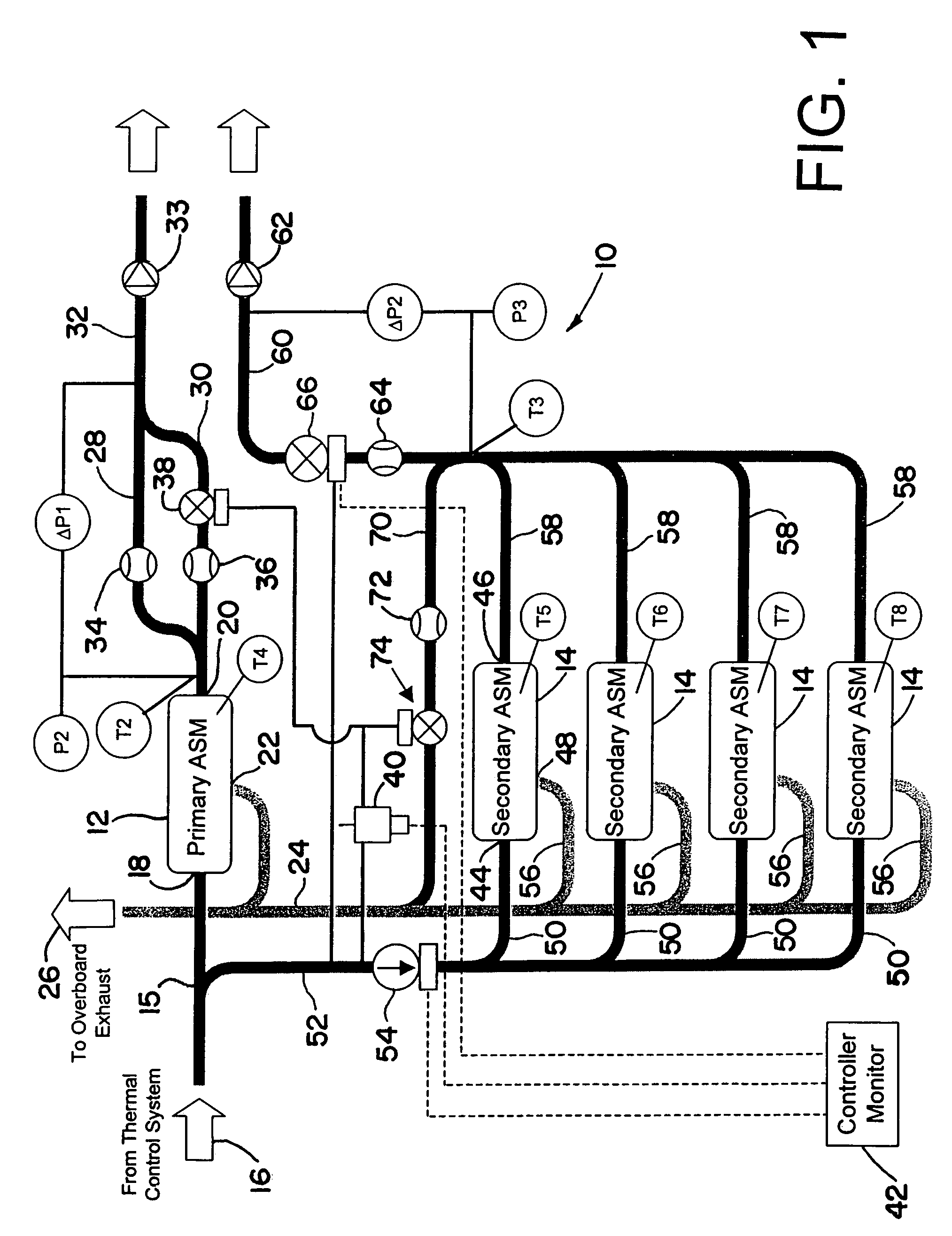

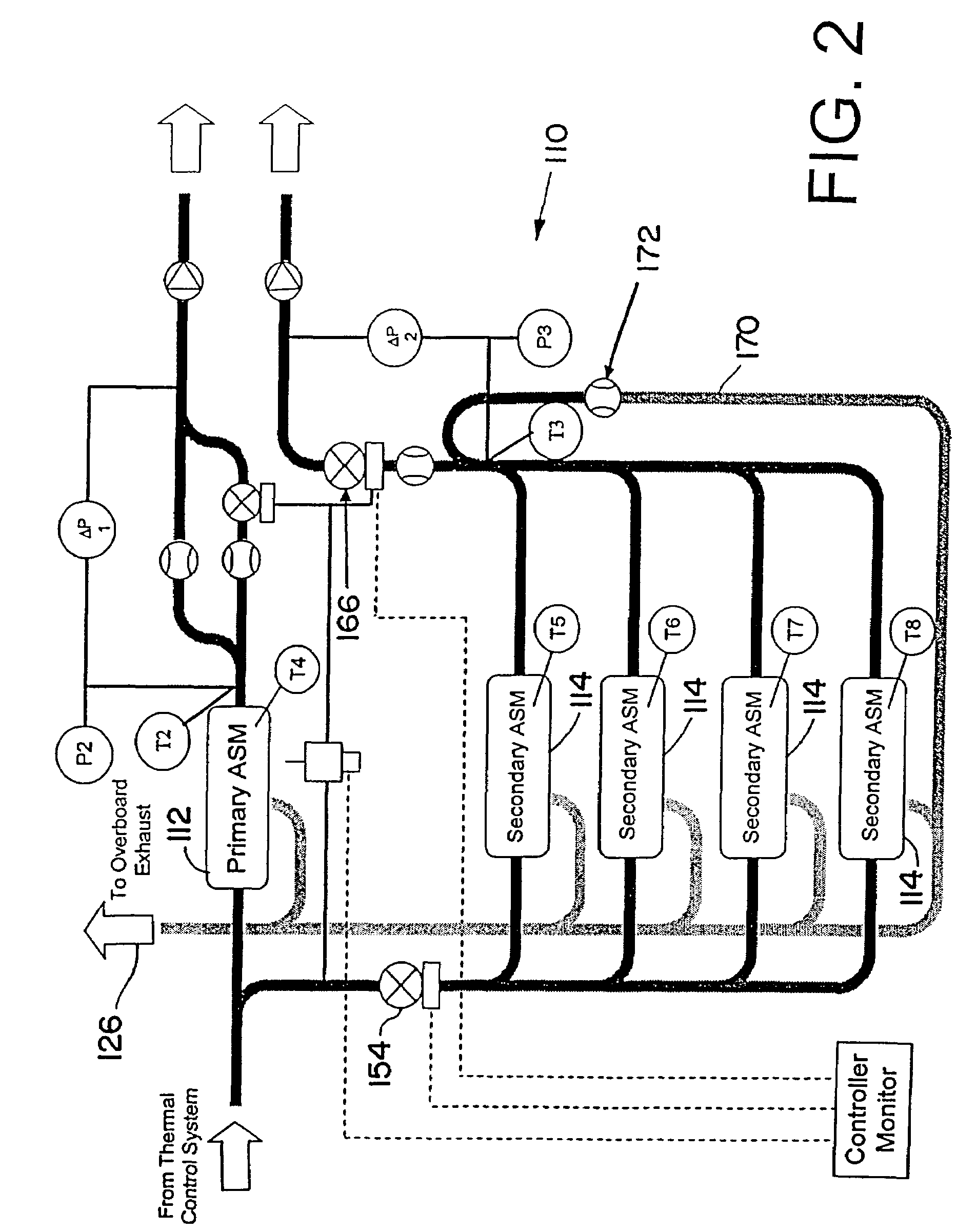

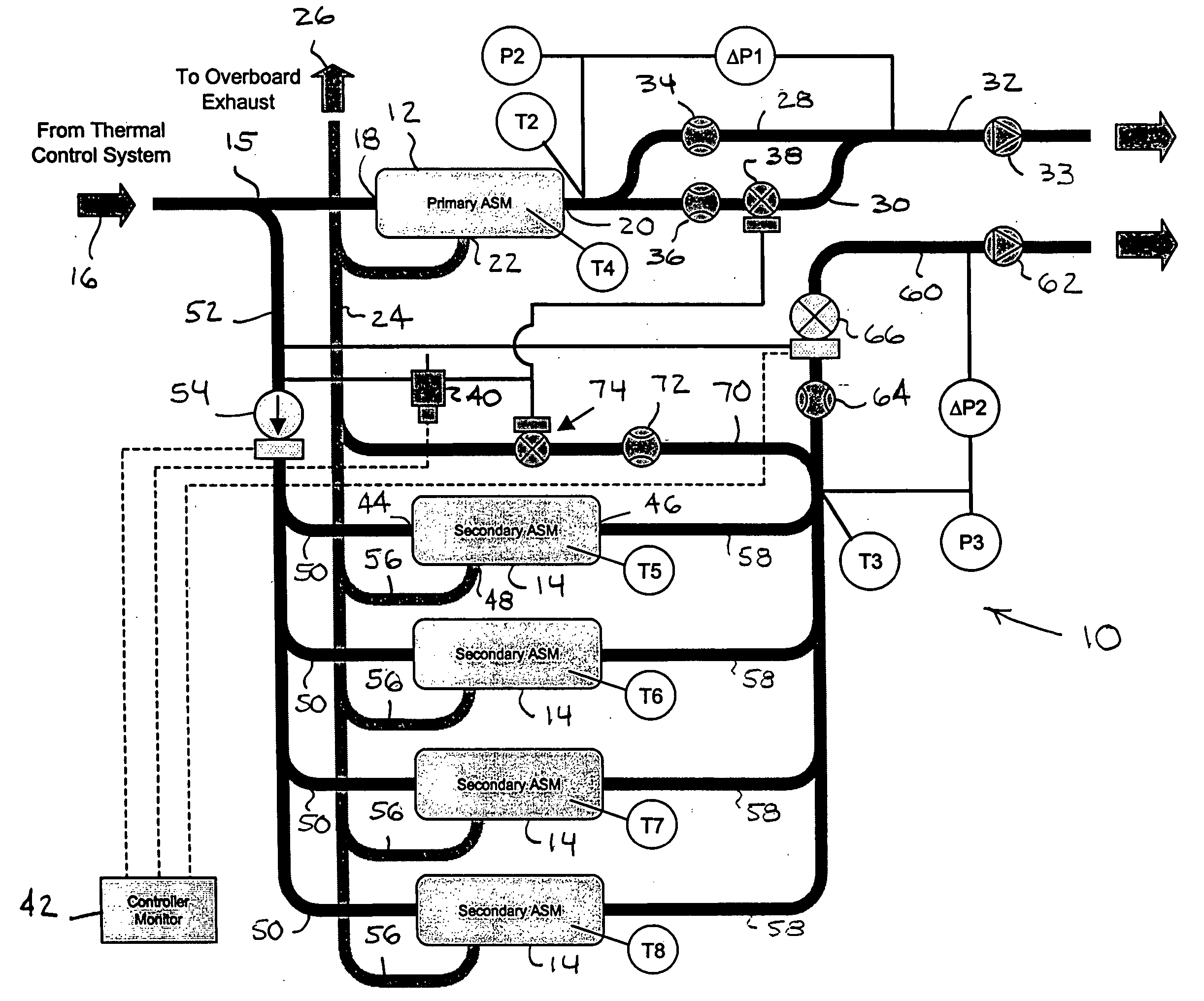

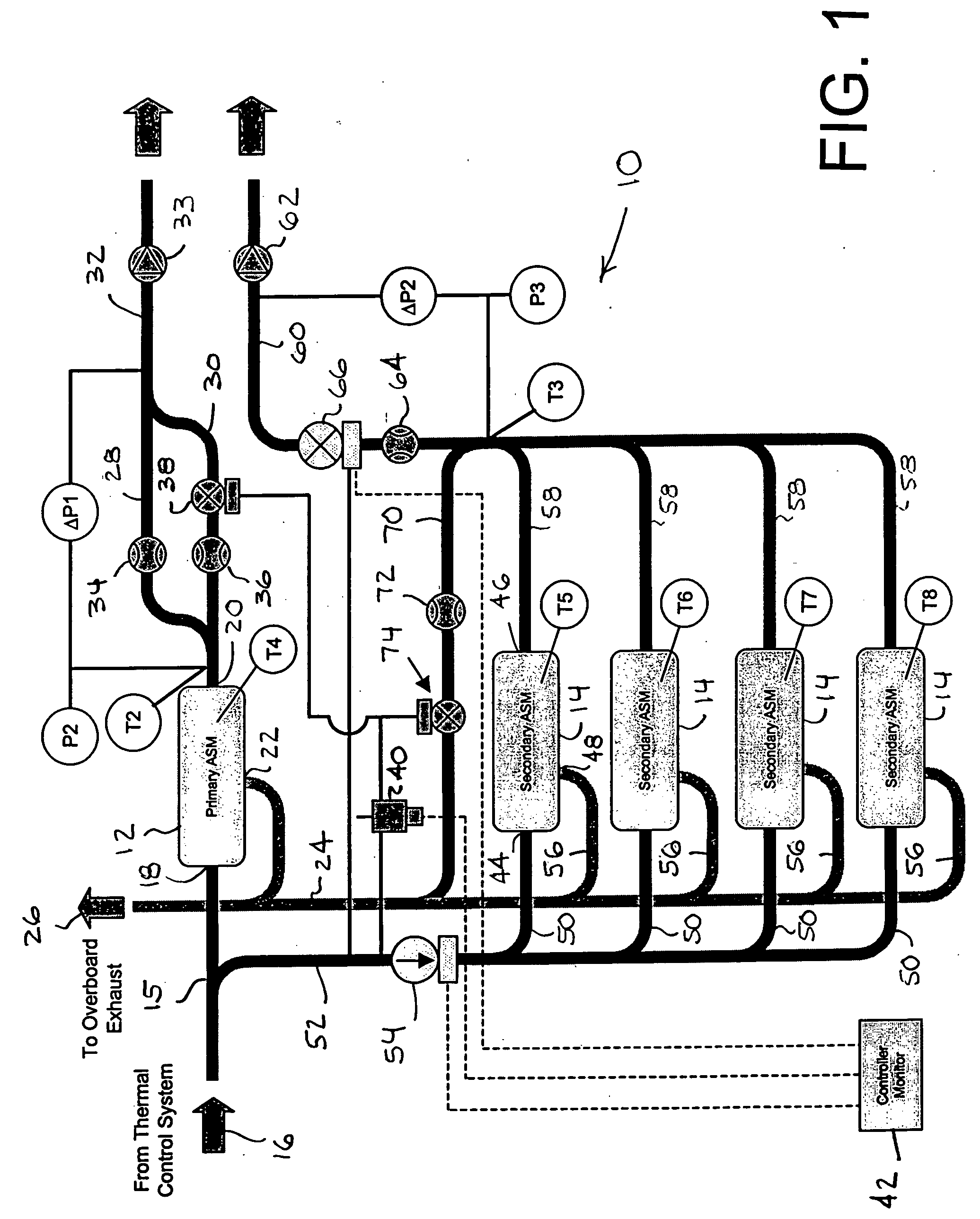

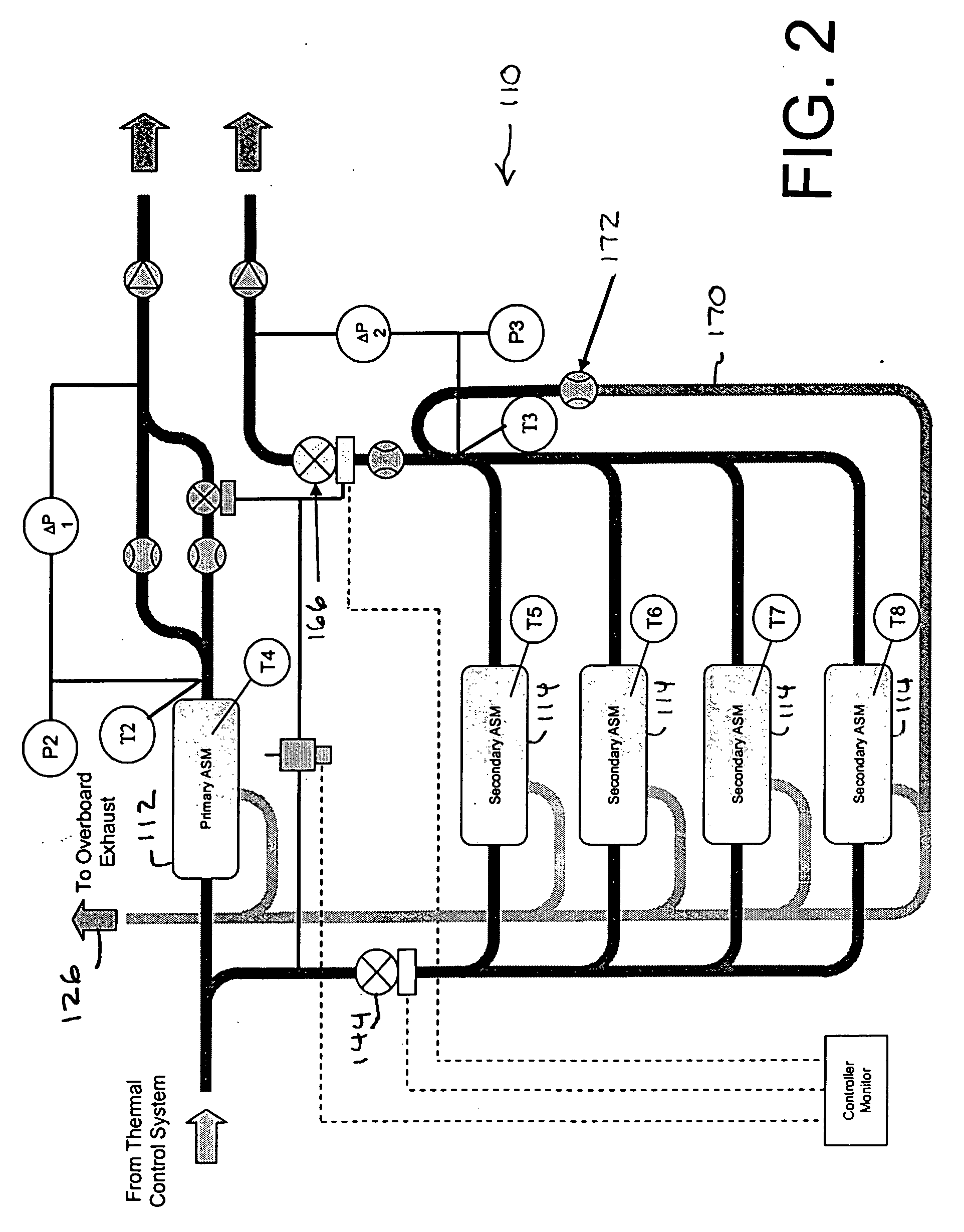

Air separation system and method with modulated warning flow

An inerting system and method characterized by a primary air separation module configured to communicate with an upstream source of pressurized air at elevated temperature for production of a primary downstream flow of nitrogen-enriched air to be delivered to a space to be inerted; a secondary air separation module configured to communicate with the upstream source of pressurized air at elevated temperature for production of a supplemental downstream flow of nitrogen-enriched air to be delivered to a space to be inerted when high nitrogen-enriched airflow is desired during a high flow period; and a flow controller configured to provide a warming flow through the secondary air separation module to heat the secondary air separation module to above ambient temperature during a warming period other than the high flow period.

Owner:PARKER INTANGIBLES LLC

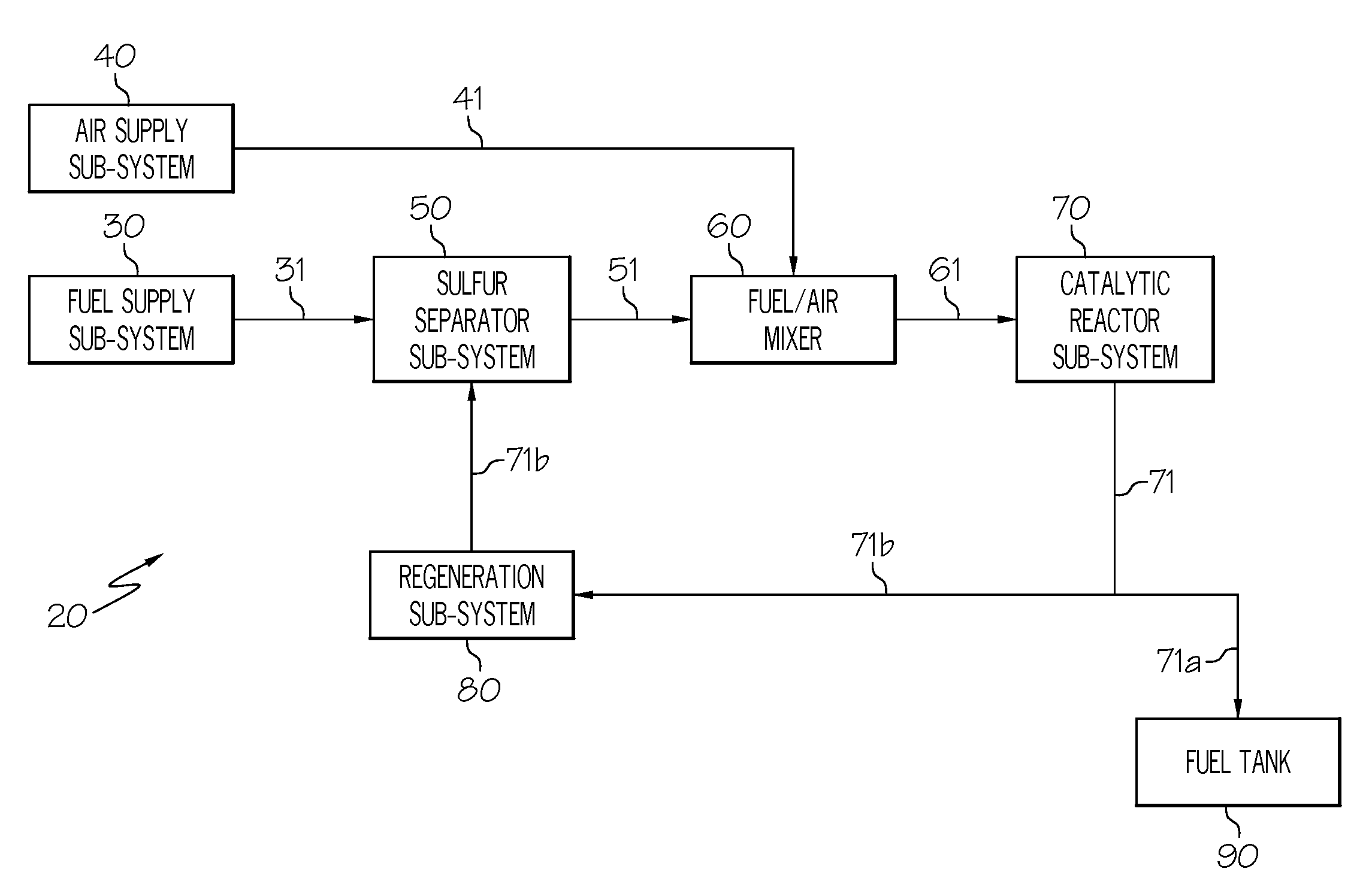

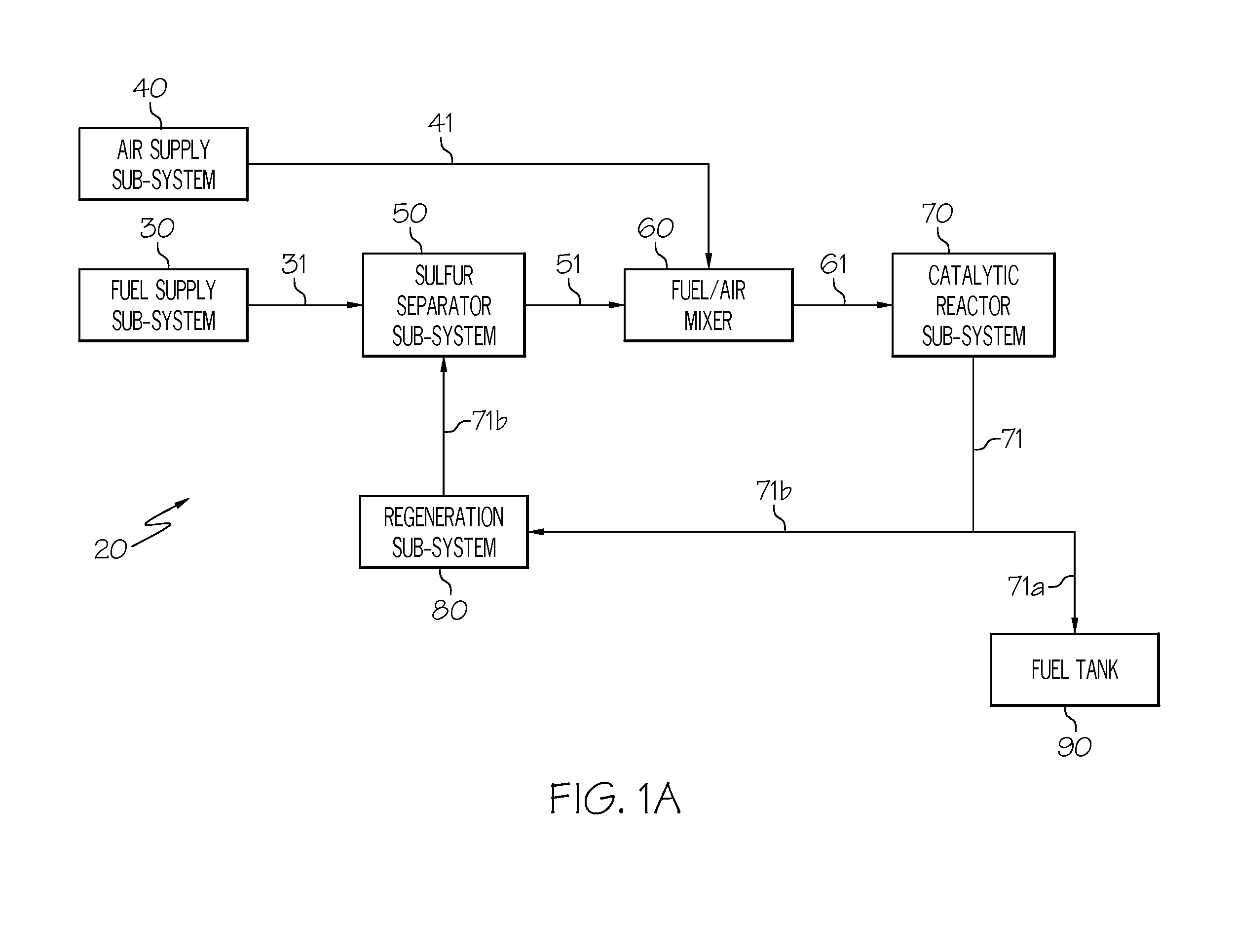

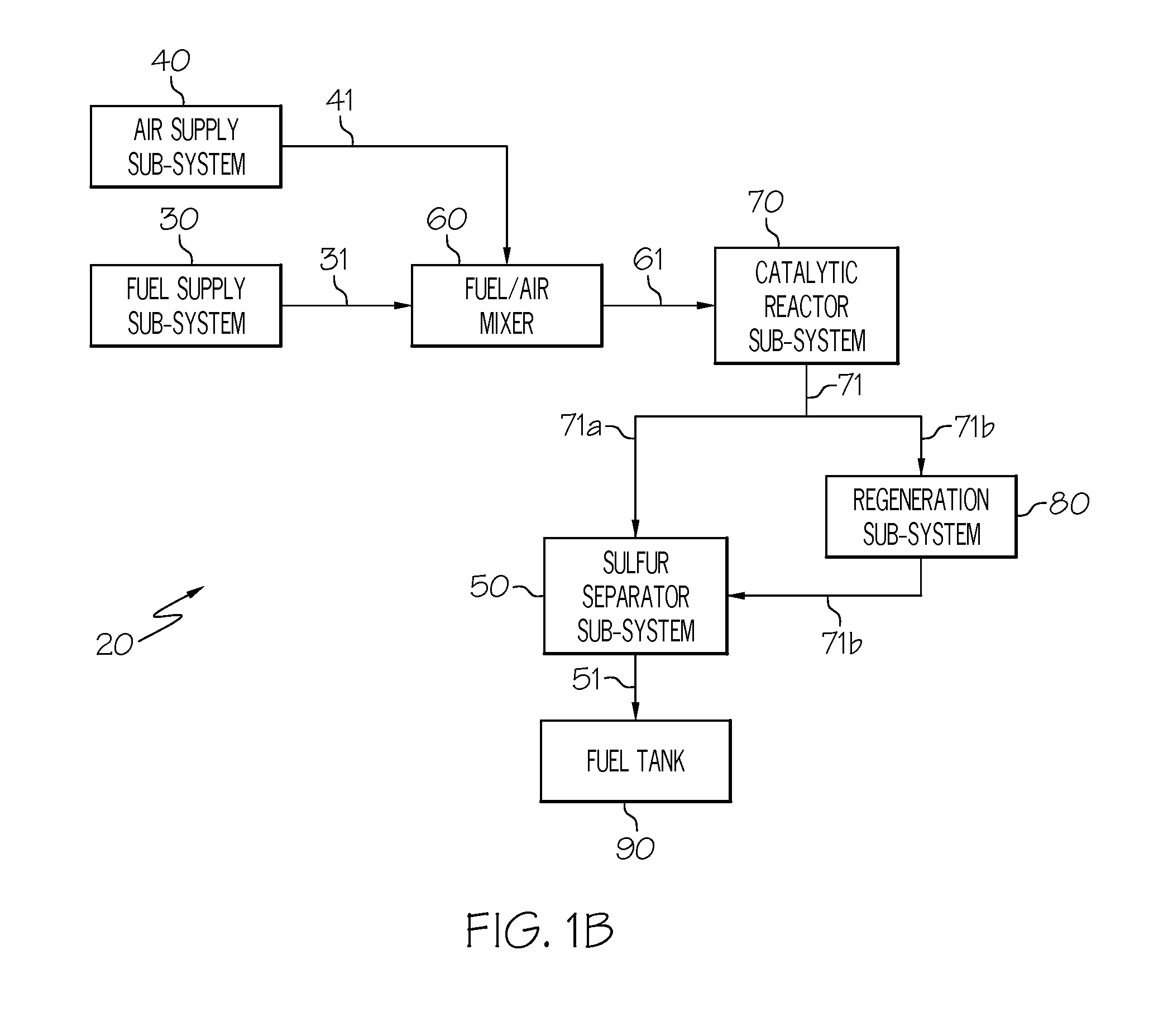

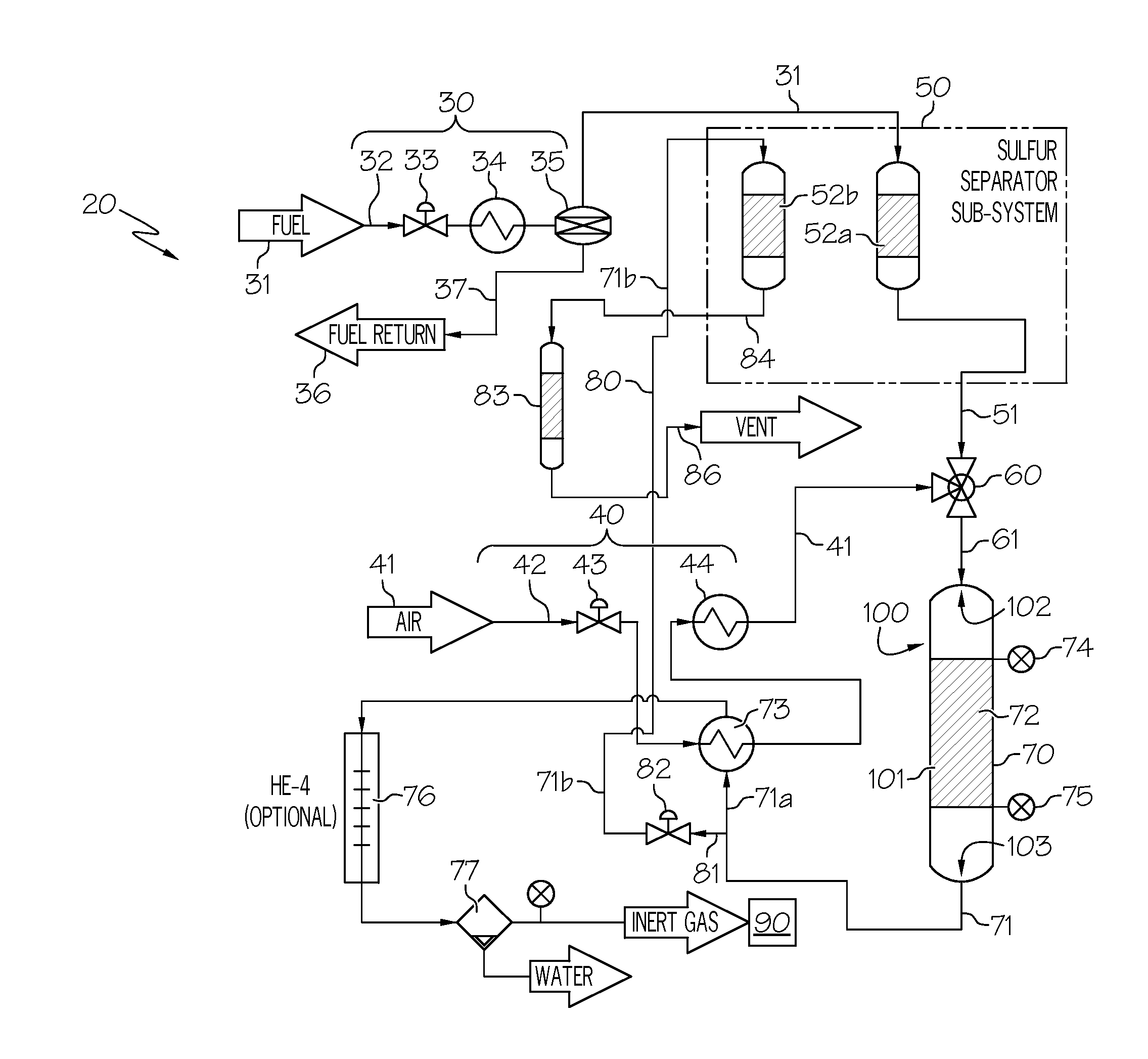

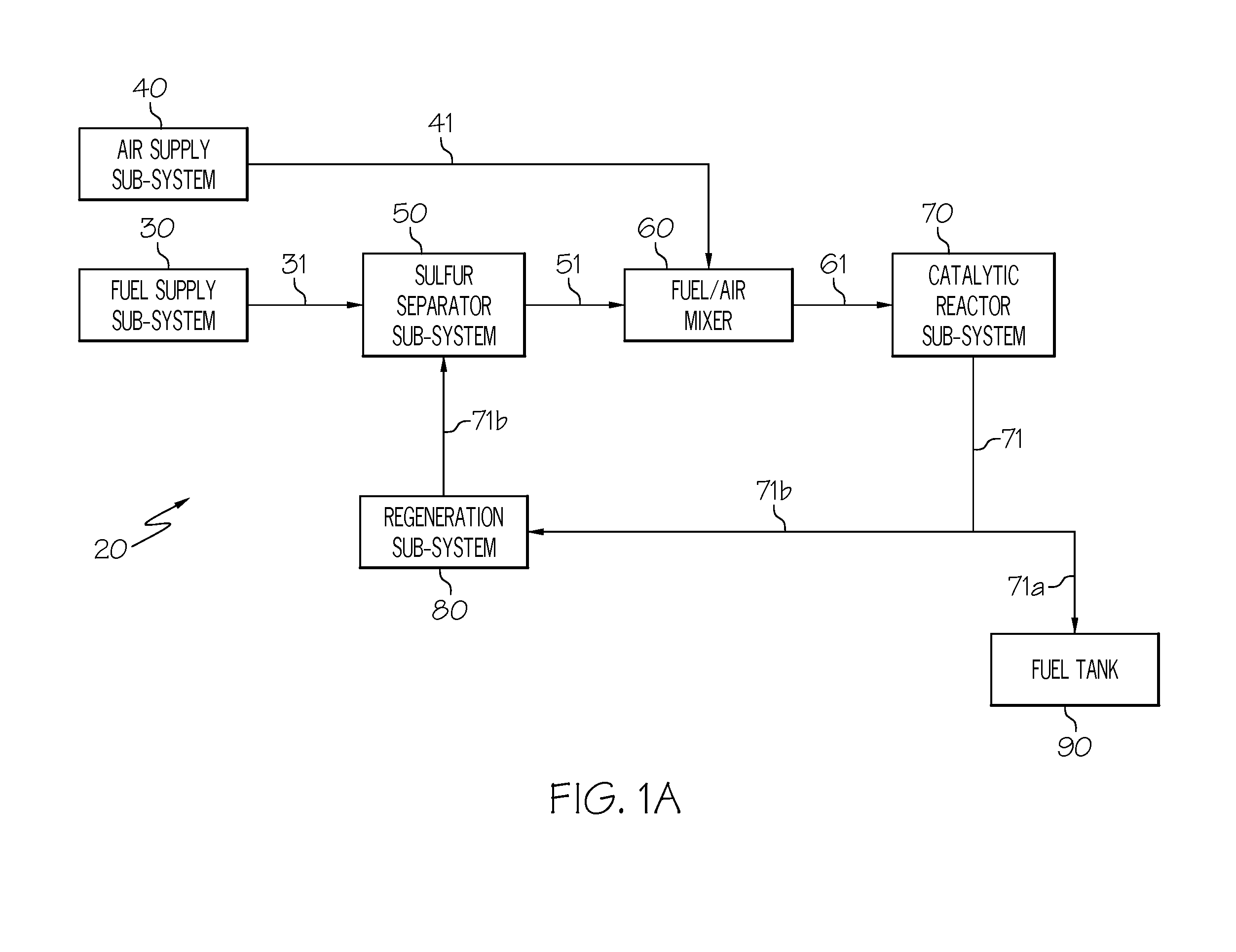

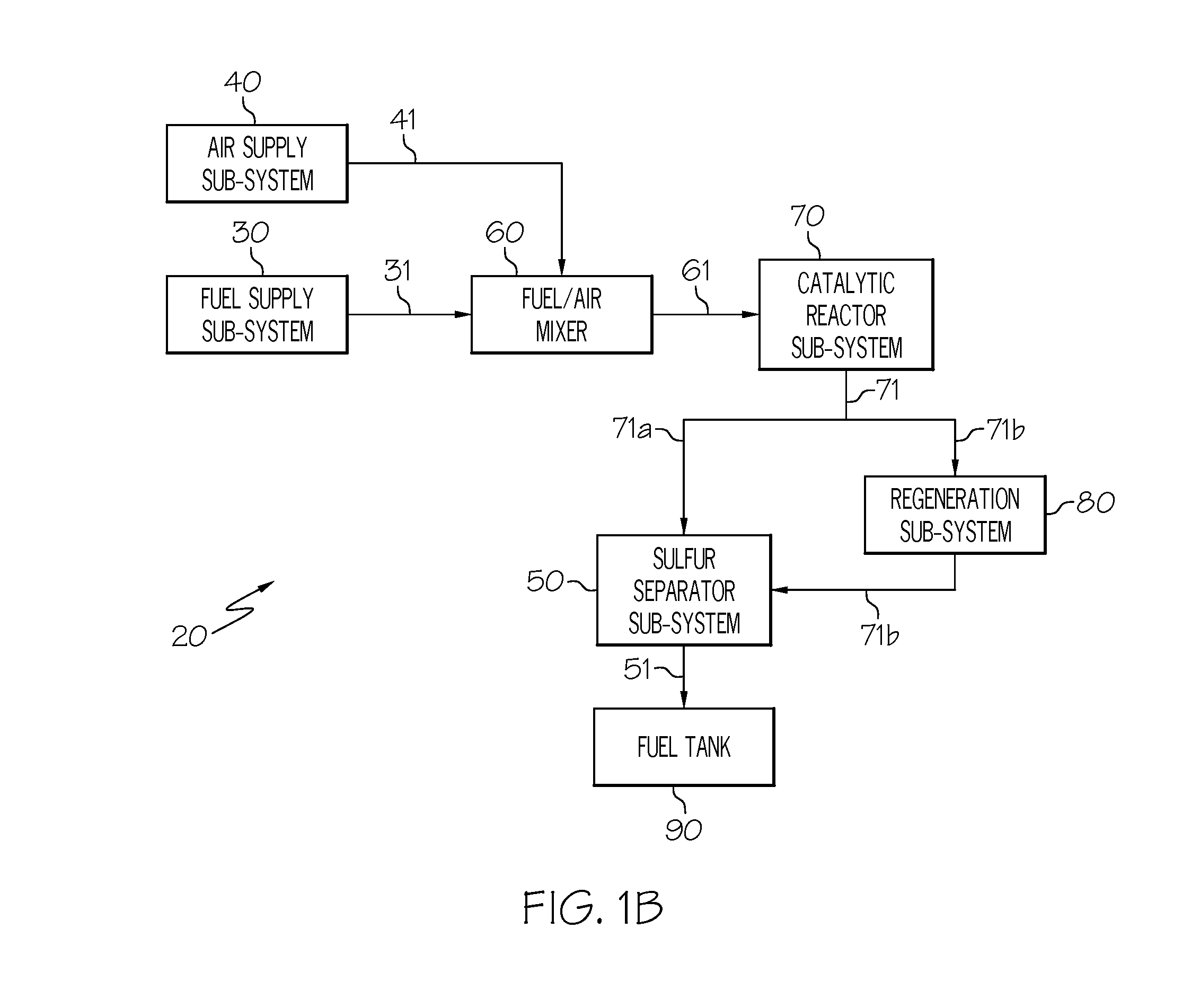

Advanced carbon dioxide fuel tank inerting system with desulfurization

A gas generating system comprises a catalytic reactor in fluid communication with a sulfur separator. The catalytic reactor oxidizes a fuel to provide a supply of carbon dioxide. The sulfur separator removes sulfur components from the stream before or after the fuel is oxidized. A portion of the hot exhaust gas from the catalytic reactor can be used to regenerate an adsorption bed of the sulfur separator.

Owner:HONEYWELL INT INC

Hybrid fuel tank inerting system

A self-regulating system for reducing concentration of hydrocarbon vapor in a container may be performed by introducing air into the container and extracting a mixture of air and vapor from the container. The extracted mixture may be compressed with a compressor to produce a flow of compressed mixture of air and vapor. The compressed mixture may be passed through an oxidation reactor that may be either catalytic or thermal to produce a flow air and CO2. A turbine may be driven with the flow of air and CO2. The compressor may be driven with the turbine. Extraction from the container may continue until vapor concentration is low enough so that flow of CO2 and air from the reactor is insufficient to drive the turbine.

Owner:HONEYWELL INT INC

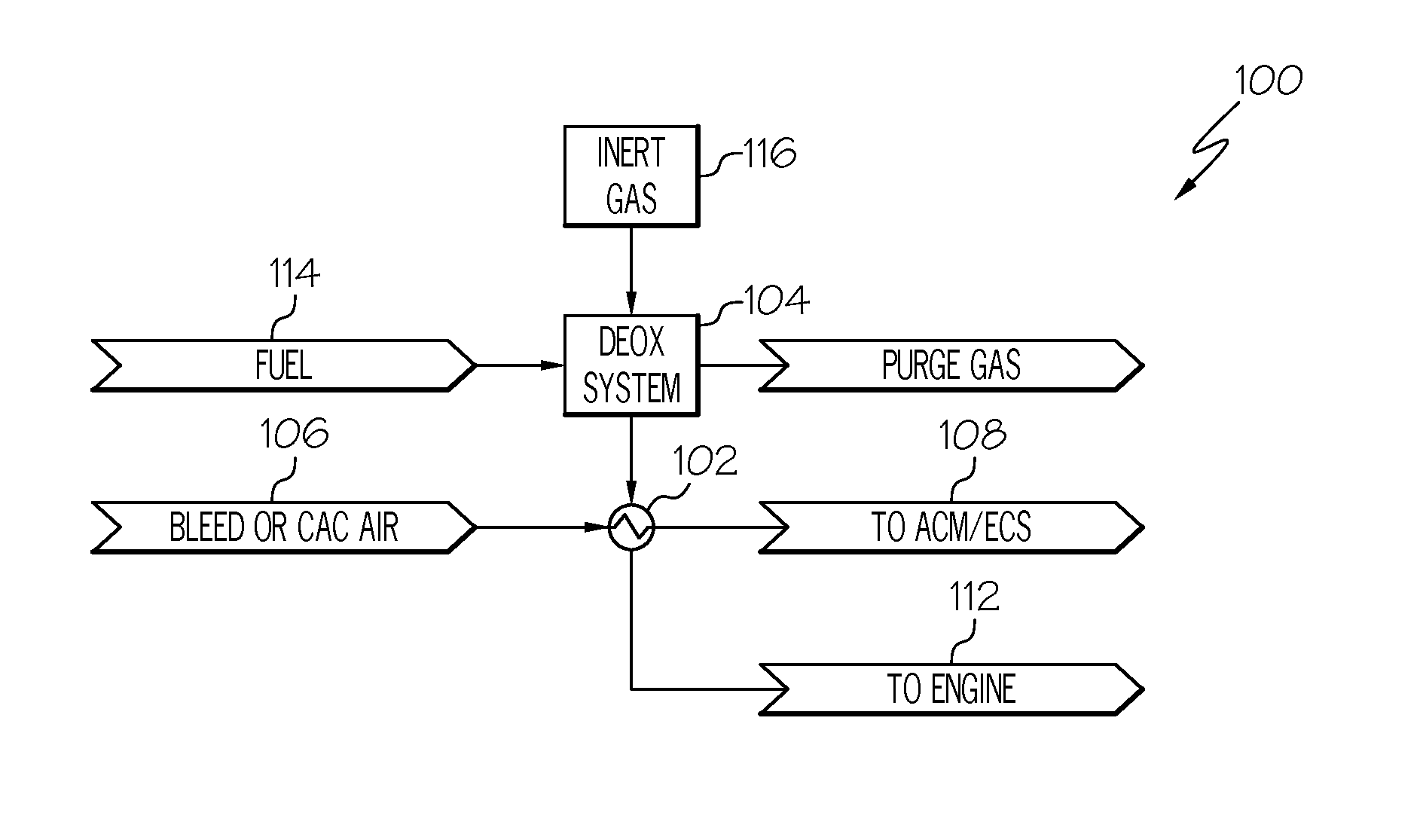

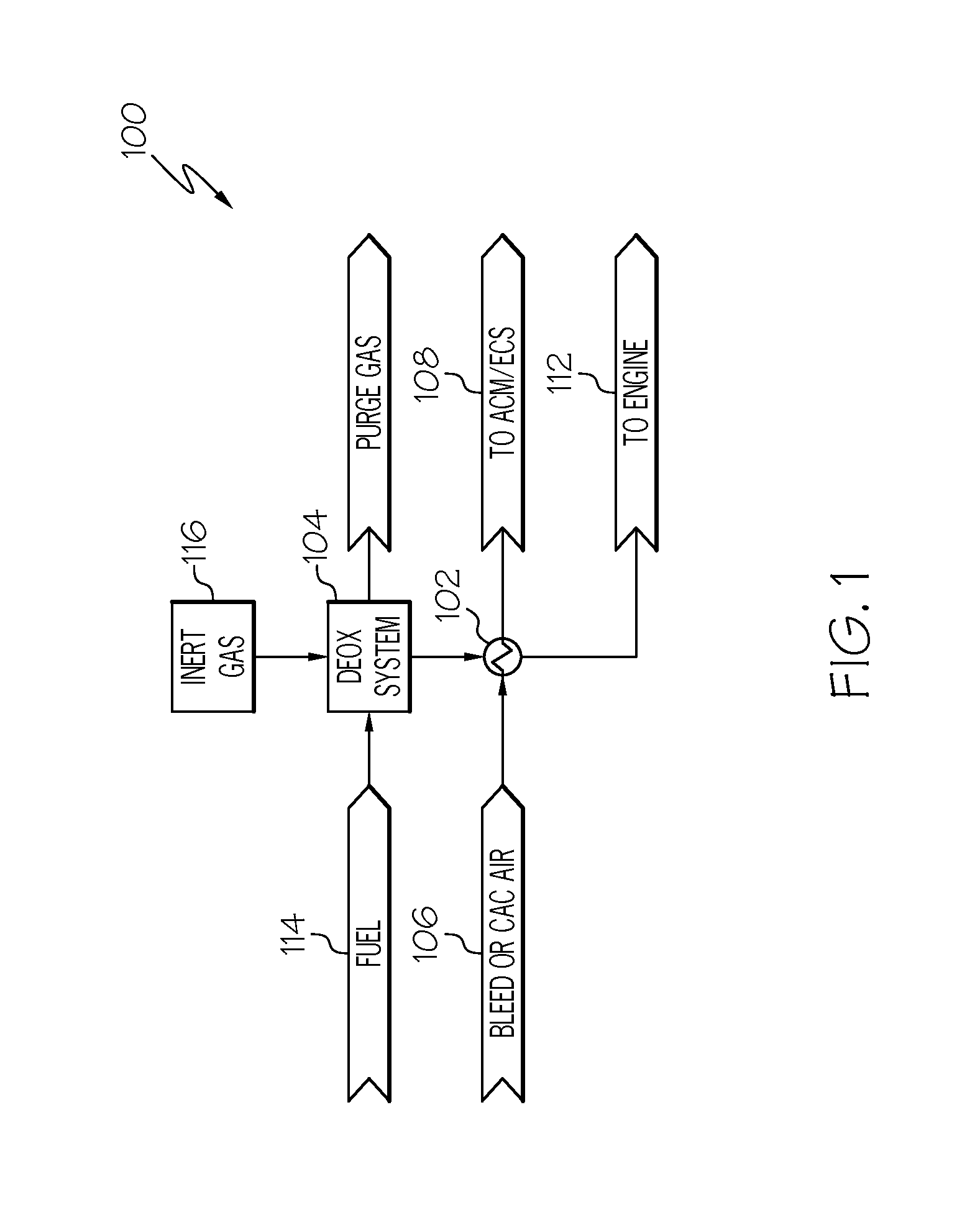

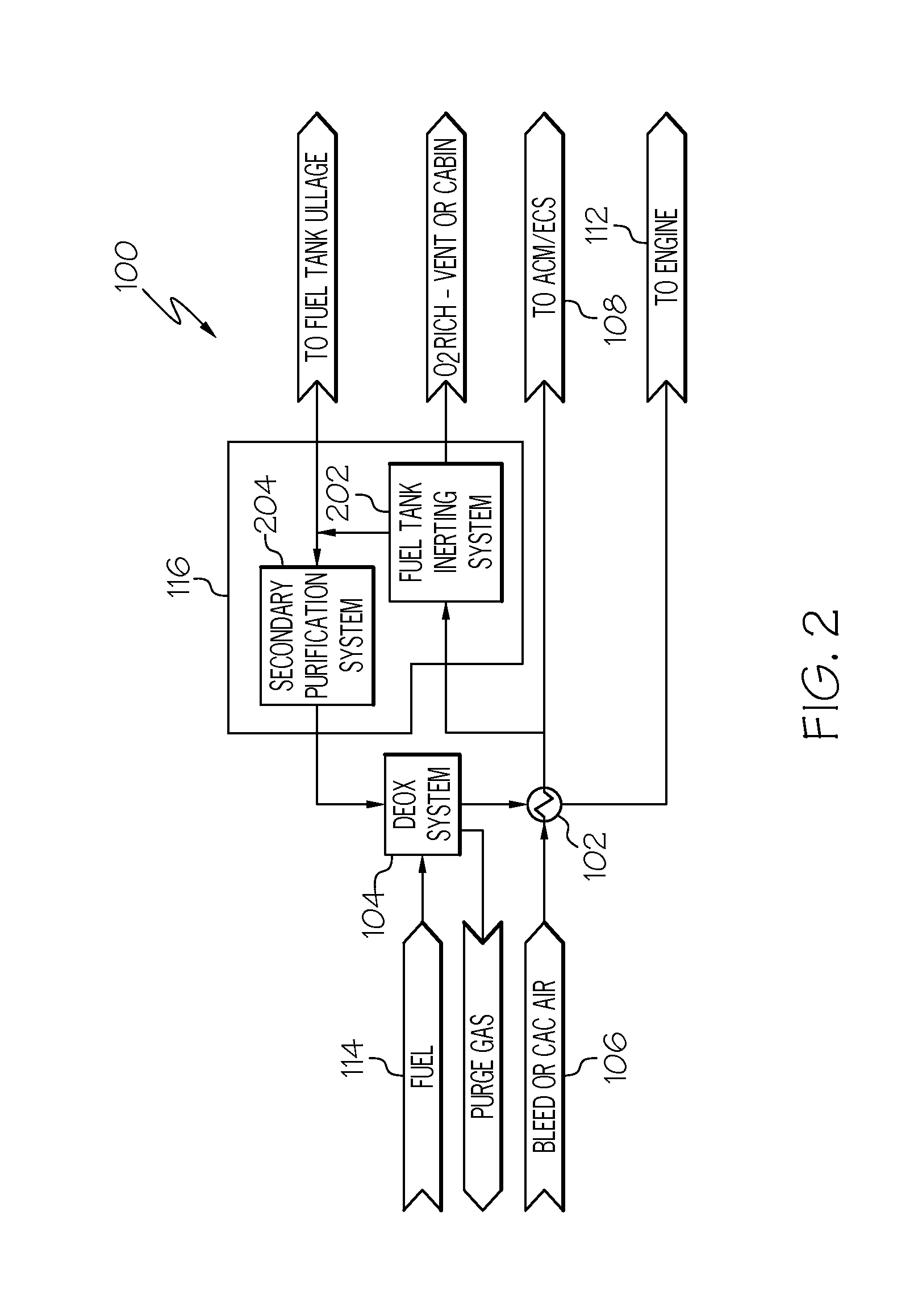

Fuel deoxygenation and fuel tank inerting system and method

ActiveUS9687773B2Gas treatmentLiquid degasification with auxillary substancesInerting systemEngineering

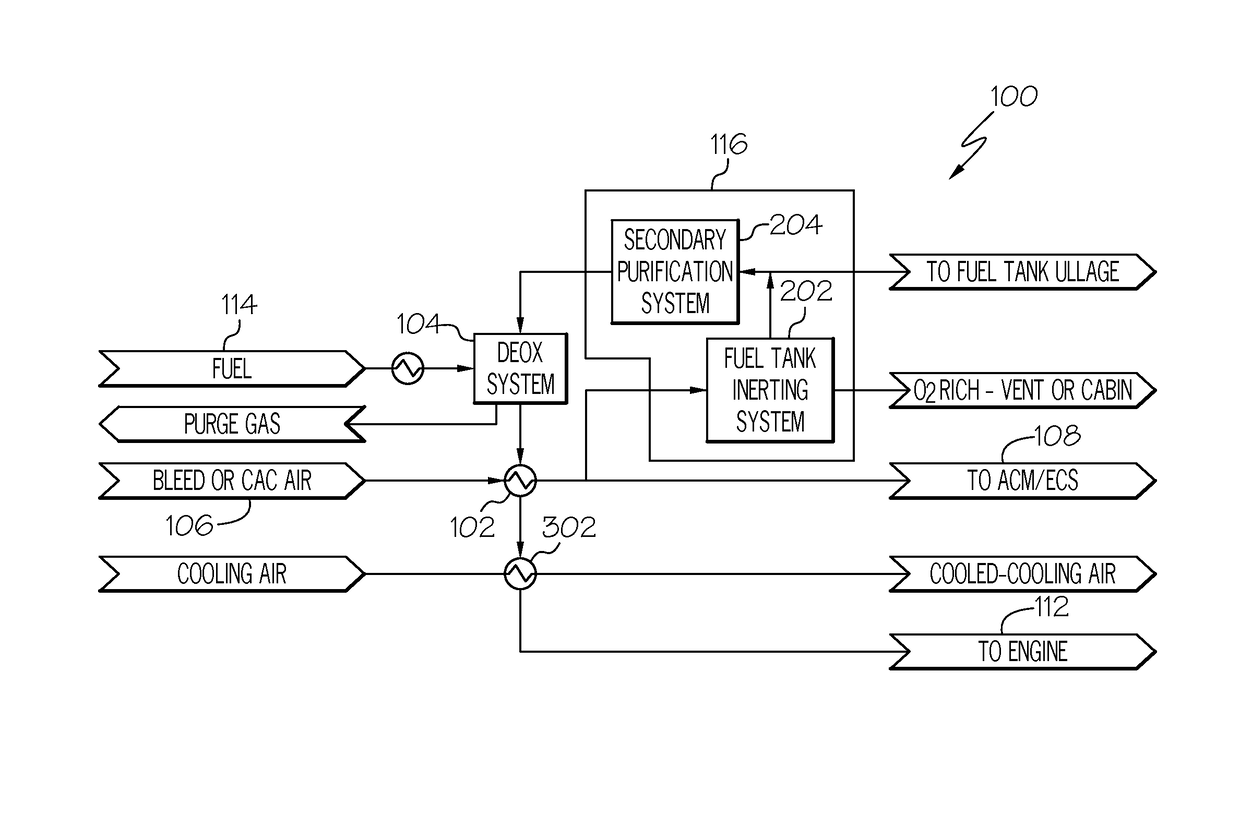

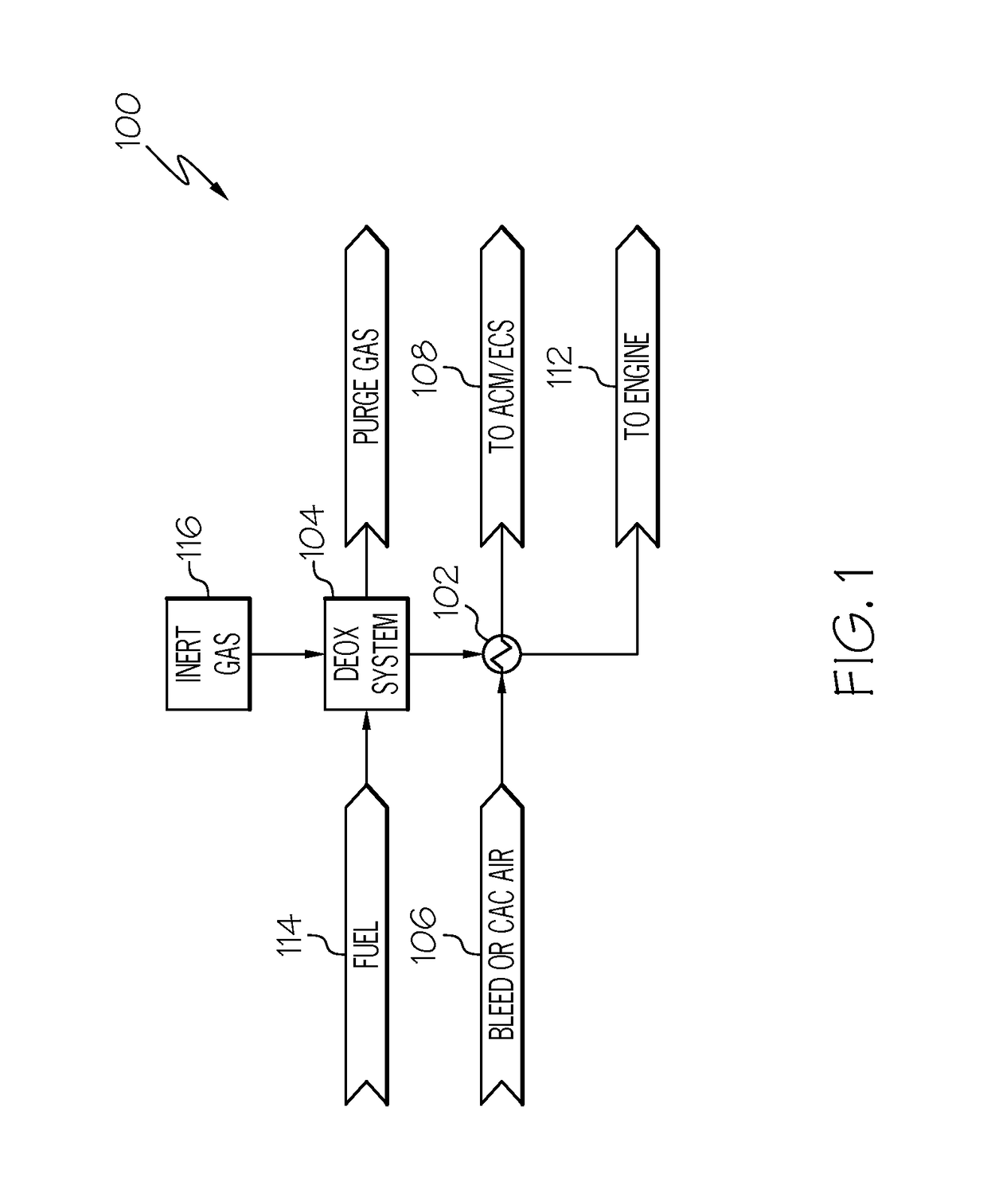

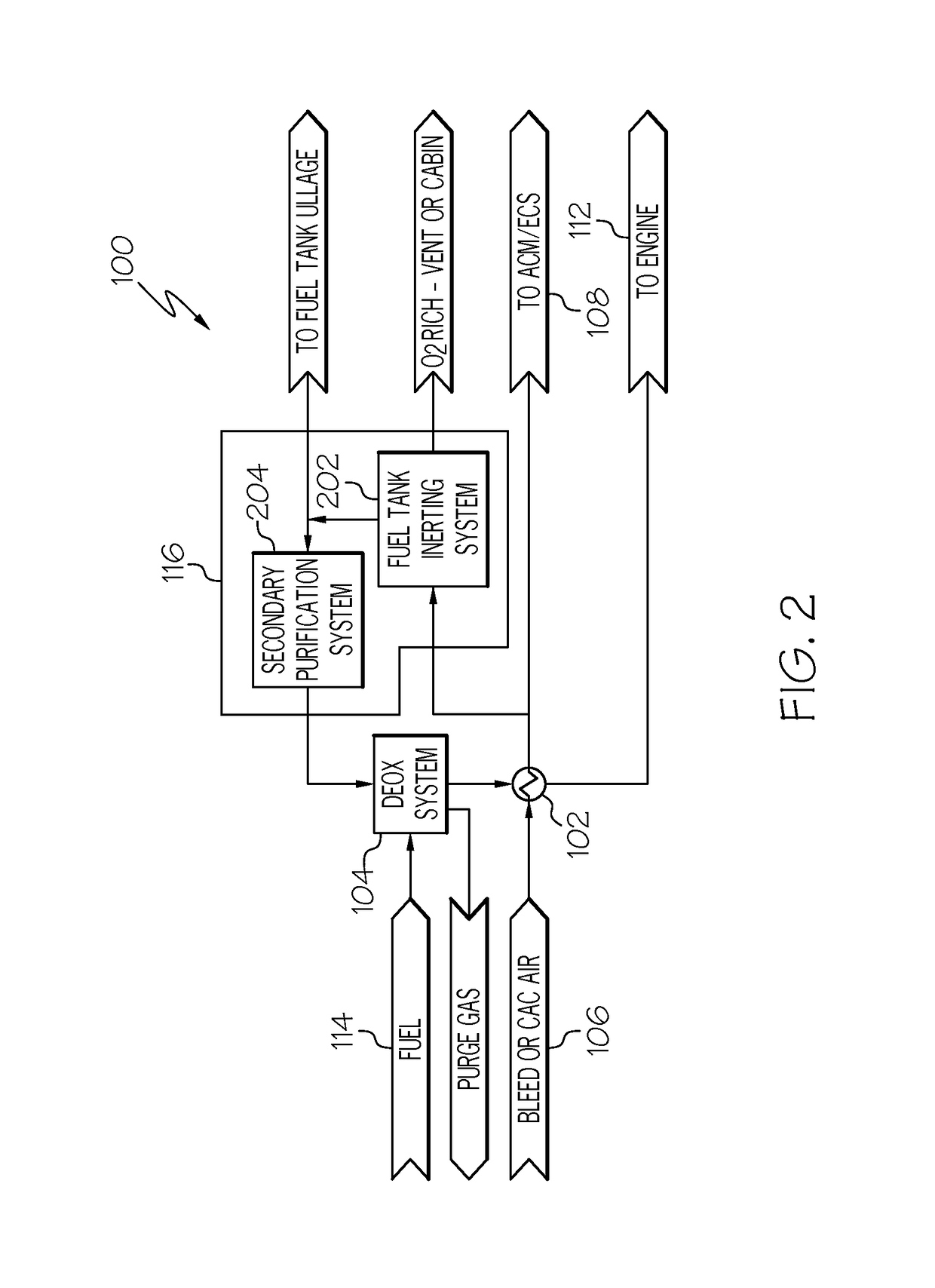

An aircraft fuel deoxygenation and tank inerting system includes an inert gas source, a fuel deoxygenation system, and an air / fuel heat exchanger. The inert gas source is configured to supply inert gas having an oxygen concentration of less than 3%. The fuel deoxygenation system is adapted to receive fuel from a fuel source and the inert gas from the inert gas source. The fuel deoxygenation system is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel and oxygen-rich purge gas. The air / fuel heat exchanger is adapted to receive compressed air from a compressed air source and the deoxygenated fuel from the fuel deoxygenation system. The air / fuel heat exchanger is configured to transfer heat from the compressed air to the deoxygenated fuel, to thereby supply cooled compressed air and heated deoxygenated fuel.

Owner:HONEYWELL INT INC

Advanced carbon dioxide fuel tank inerting system with desulfurization

A gas generating system comprises a catalytic reactor in fluid communication with a sulfur separator. The catalytic reactor oxidizes a fuel to provide a supply of carbon dioxide. The sulfur separator removes sulfur components from the stream before or after the fuel is oxidized. A portion of the hot exhaust gas from the catalytic reactor can be used to regenerate an adsorption bed of the sulfur separator.

Owner:HONEYWELL INT INC

On-board fuel inerting system

InactiveUS20030116679A1Effective monitoringExplosion is minimized and eliminatedPower plant fuel tanksPressure pumpsInerting systemCombustion

An inerting system is disclosed that is adaptable to inert the fuel tank of a vehicle, most typically an aircraft, that includes an oxygen detector to monitor the oxygen partial pressure of the vapors in the ullage (i.e., the overfuel) volume of the tank, a source of an inert gas (e.g., nitrogen) in valved communication with the ullage of the tank, and a detector for sensing the oxygen content in the ullage of the tank and controlling the flow of inert gas to the tillage to maintain that volume with a proportion oxygen that will not support combustion in the event of an ignition source or intrusion of another potentially explosive occurrence within said tank. A specific fiberoptic probe which enables monitoring oxygen content within the tank without introducing a source of electrical current within the tank is also disclosed.

Owner:SUSKO KENNETH

Oxygen sensor for aircraft fuel inerting systems

ActiveUS7352464B2Transmissivity measurementsColor/spectral properties measurementsOptical cavityInerting system

An apparatus and method for monitoring oxygen concentrations in fuel tank ullage comprising providing a sensor head comprising an optical cavity, exposing the optical cavity to an ambient gaseous environment of a fuel tank or air separation module, via a laser light source emitting wavelength modulated light through the cavity, and receiving the wavelength modulated light with a detector.

Owner:SOUTHWEST SCI

Fuel deoxygenation and fuel tank inerting system and method

ActiveUS20150314229A1Increase fuel consumptionGas treatmentLiquid degasification with auxillary substancesInerting systemDeoxygenation

An aircraft fuel deoxygenation and tank inerting system includes an inert gas source, a fuel deoxygenation system, and an air / fuel heat exchanger. The inert gas source is configured to supply inert gas having an oxygen concentration of less than 3%. The fuel deoxygenation system is adapted to receive fuel from a fuel source and the inert gas from the inert gas source. The fuel deoxygenation system is configured to remove oxygen from the fuel and thereby generate and supply deoxygenated fuel and oxygen-rich purge gas. The air / fuel heat exchanger is adapted to receive compressed air from a compressed air source and the deoxygenated fuel from the fuel deoxygenation system. The air / fuel heat exchanger is configured to transfer heat from the compressed air to the deoxygenated fuel, to thereby supply cooled compressed air and heated deoxygenated fuel.

Owner:HONEYWELL INT INC

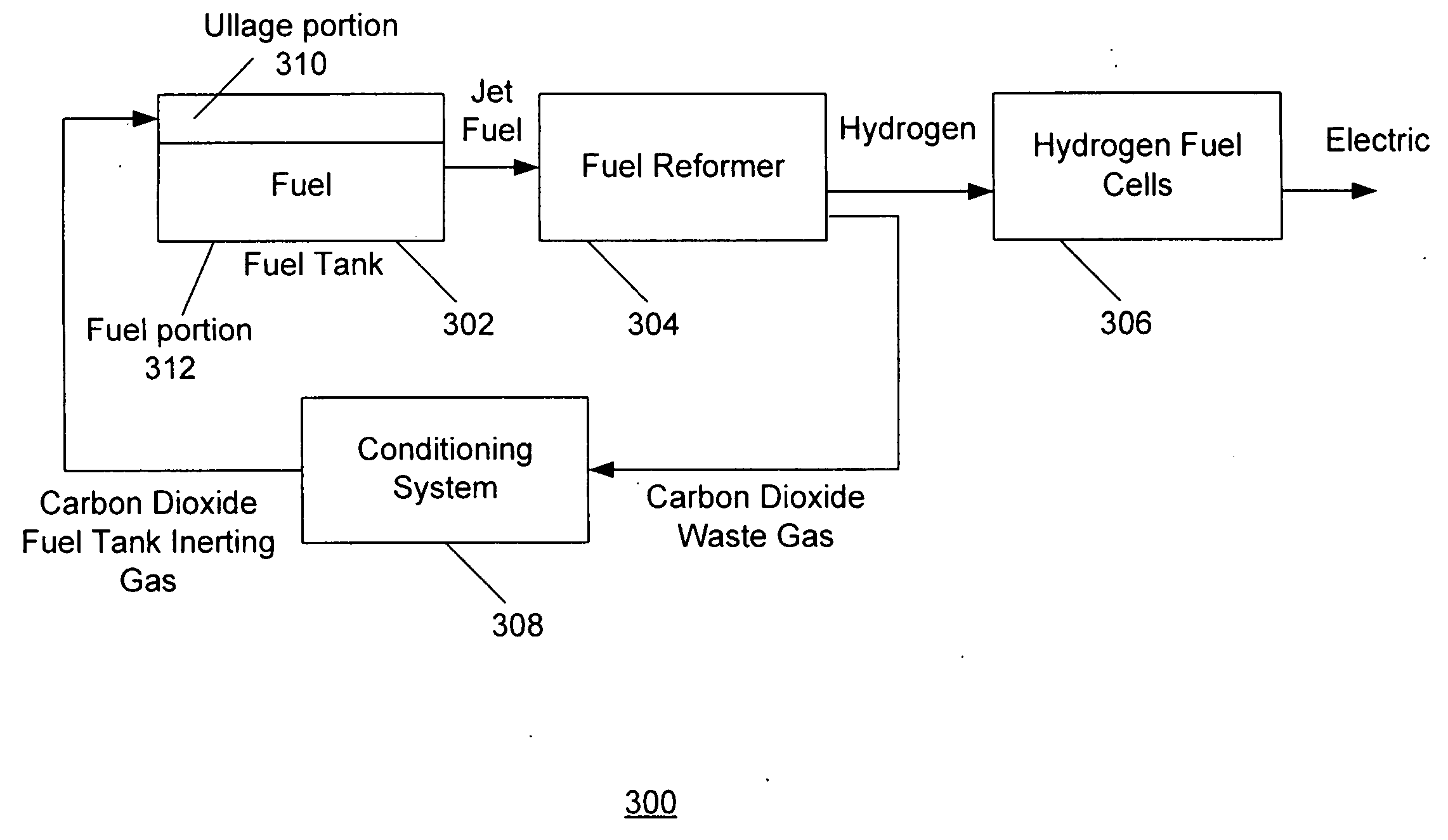

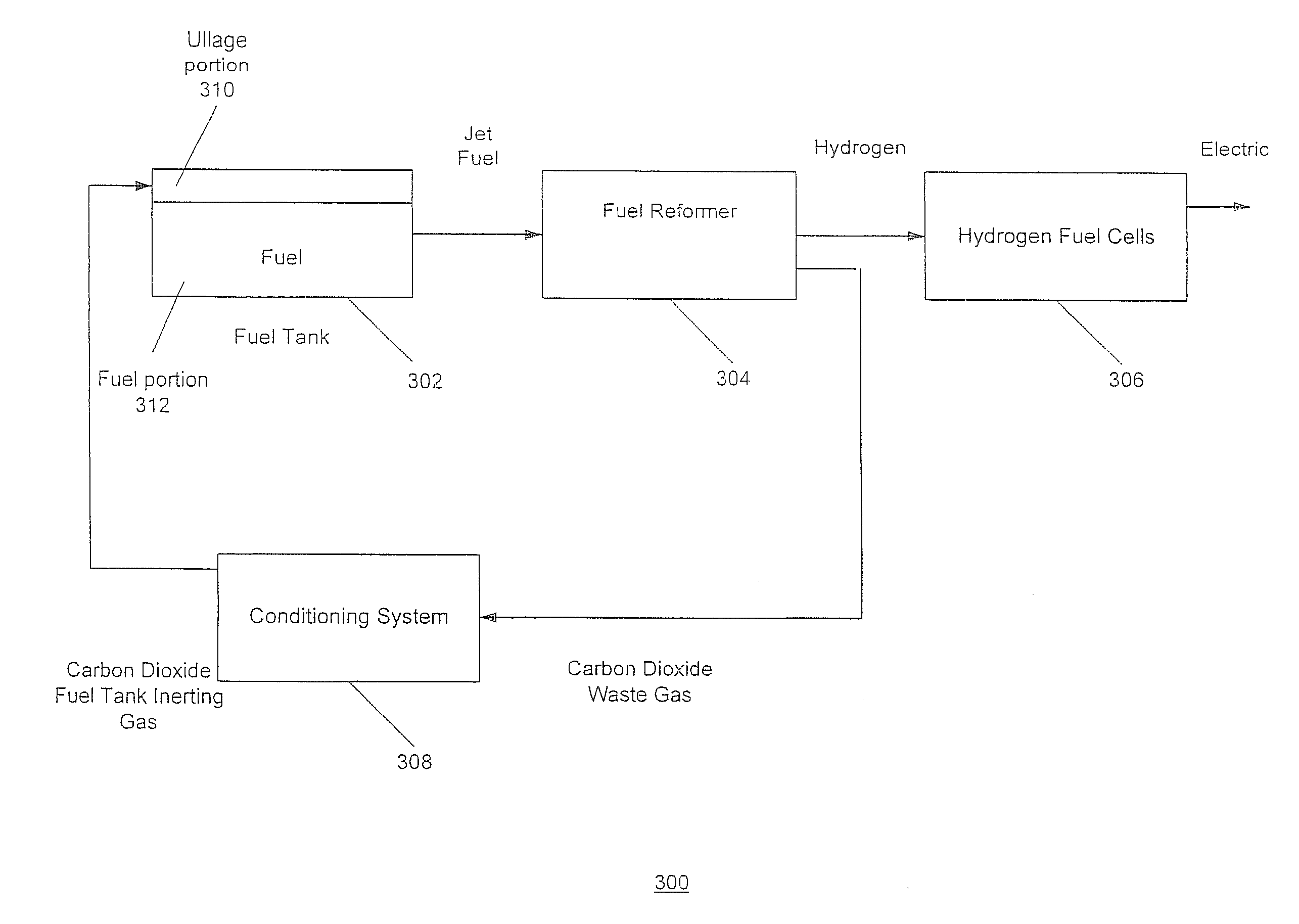

Fuel system for an aircraft including a fuel tank inerting system

A fuel system for an aircraft is disclosed. The fuel system comprises a fuel tank and a fuel reformer for receiving fuel from the fuel tank. The system includes a hydrogen fuel cell array for receiving hydrogen from the fuel reformer. The system further includes mechanism for providing an inerting gas from the fuel system to the fuel tank.

Owner:THE BOEING CO

Air separation system and method with modulated warming flow

An inerting system and method characterized by a primary air separation module configured to communicate with an upstream source of pressurized air at elevated temperature for production of a primary downstream flow of nitrogen-enriched air to be delivered to a space to be inerted; a secondary air separation module configured to communicate with the upstream source of pressurized air at elevated temperature for production of a supplemental downstream flow of nitrogen-enriched air to be delivered to a space to be inerted when high nitrogen-enriched airflow is desired during a high flow period; and a flow controller configured to provide a warming flow through the secondary air separation module to heat the secondary air separation module to above ambient temperature during a warming period other than the high flow period.

Owner:PARKER INTANGIBLES LLC

Hybrid fuel tank inerting system

A self-regulating system for reducing concentration of hydrocarbon vapor in a container may be performed by introducing air into the container and extracting a mixture of air and vapor from the container. The extracted mixture may be compressed with a compressor to produce a flow of compressed mixture of air and vapor. The compressed mixture may be passed through an oxidation reactor that may be either catalytic or thermal to produce a flow air and CO2. A turbine may be driven with the flow of air and CO2. The compressor may be driven with the turbine. Extraction from the container may continue until vapor concentration is low enough so that flow of CO2 and air from the reactor is insufficient to drive the turbine.

Owner:HONEYWELL INT INC

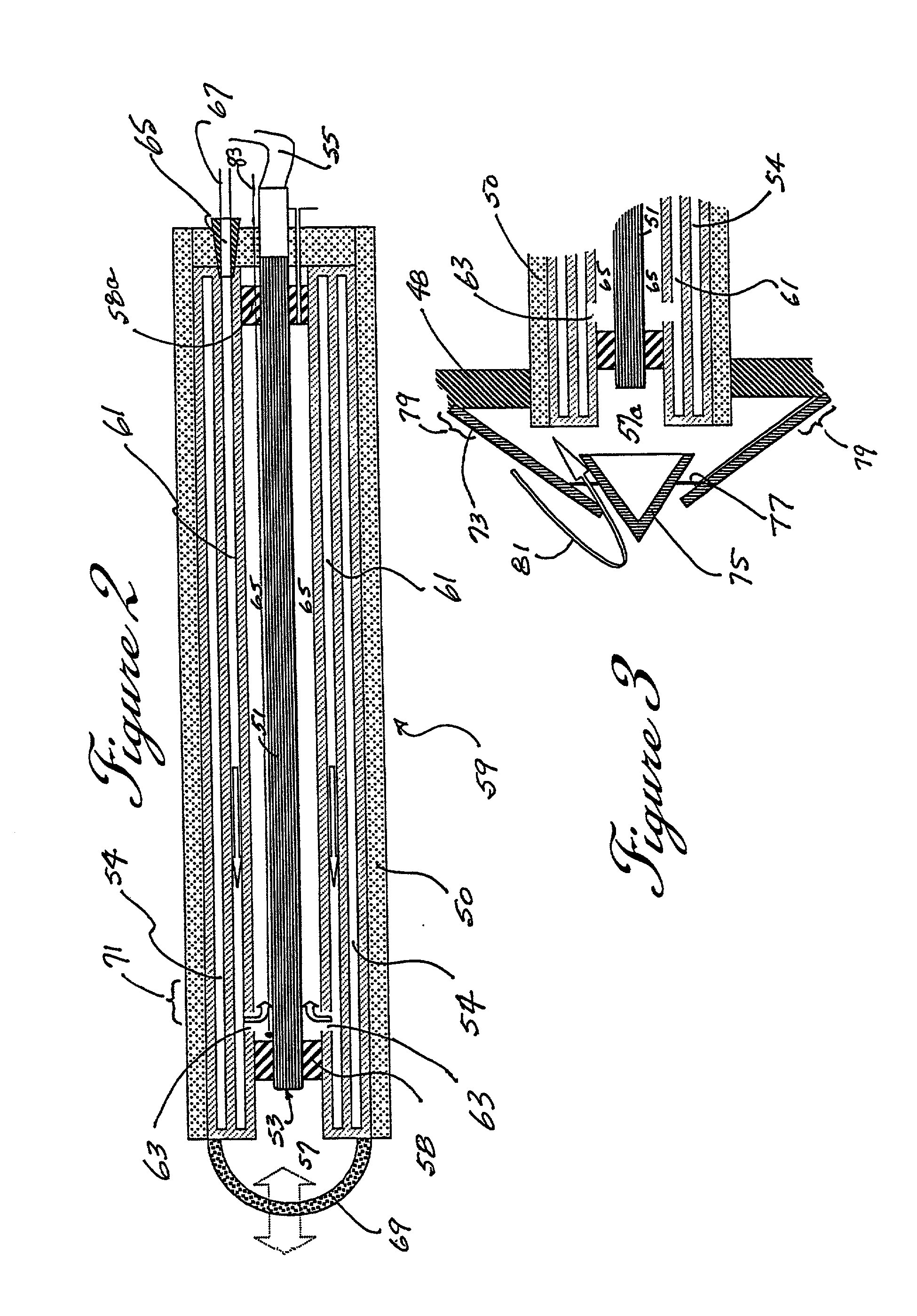

Nitrogen inerting system for explosion prevention in aircraft fuel tank & oxygenating system for improving combustion efficiency of aerospace rockets/ aircraft engines

InactiveUS20090166358A1Increase speedIncrease rotation speedCombination devicesGas treatmentAviationGas passing

Compressed Air from an aircraft rocket engine's compressed air line to its air-conditioning system, or an Auxiliary Air Compressor out-put is used, for energizing a high-speed gas turbine. The very high-speed convoluting air discharge into a vortex cone causes a first separation of the Air gas components, by stratifying into heavier (Argon), medium (Oxygen) and lighter (Nitrogen) components, where in the heavier and lighter components are non-combustible, inert gases and the medium is a combustible gas. The lighter non-combustible component (Nitrogen) exits from the turbine in one direction for storage in the Inert gas tank. The heavier (Argon) and medium (Oxygen) components together move in the opposite direction for having a second stratifying separation downstream in the vortex tube, to separate non-combustible, heavier (Argon) gas from combustible medium (Oxygen) gas components. The combustible, medium (Oxygen) component exits the vortex tube open end, to flow into an Oxygenating storage tank; whereas, the heavier, non-combustible(Argon) gas is piped into the Inert gas storage tank. Both gas storage tank in-flow lines are fitted with non-return valves. The out flow lines from the Inert tank to either Fuel Tank “Ullage” or “OBGIS” areas are fitted with electronic control valves, operated by signals received from fibre-optic Temperature / Pressure / Oxygen concentration Sensors in the Fuel tank “Ullage” or “OBGIS: areas. Likewise, the outflow lines from the Oxygenating tank are fitted with electronc control valves activated by engine “takeoff” or Passenger cabin low oxygen signals, respectively.

Owner:BOSE RANENDRA K

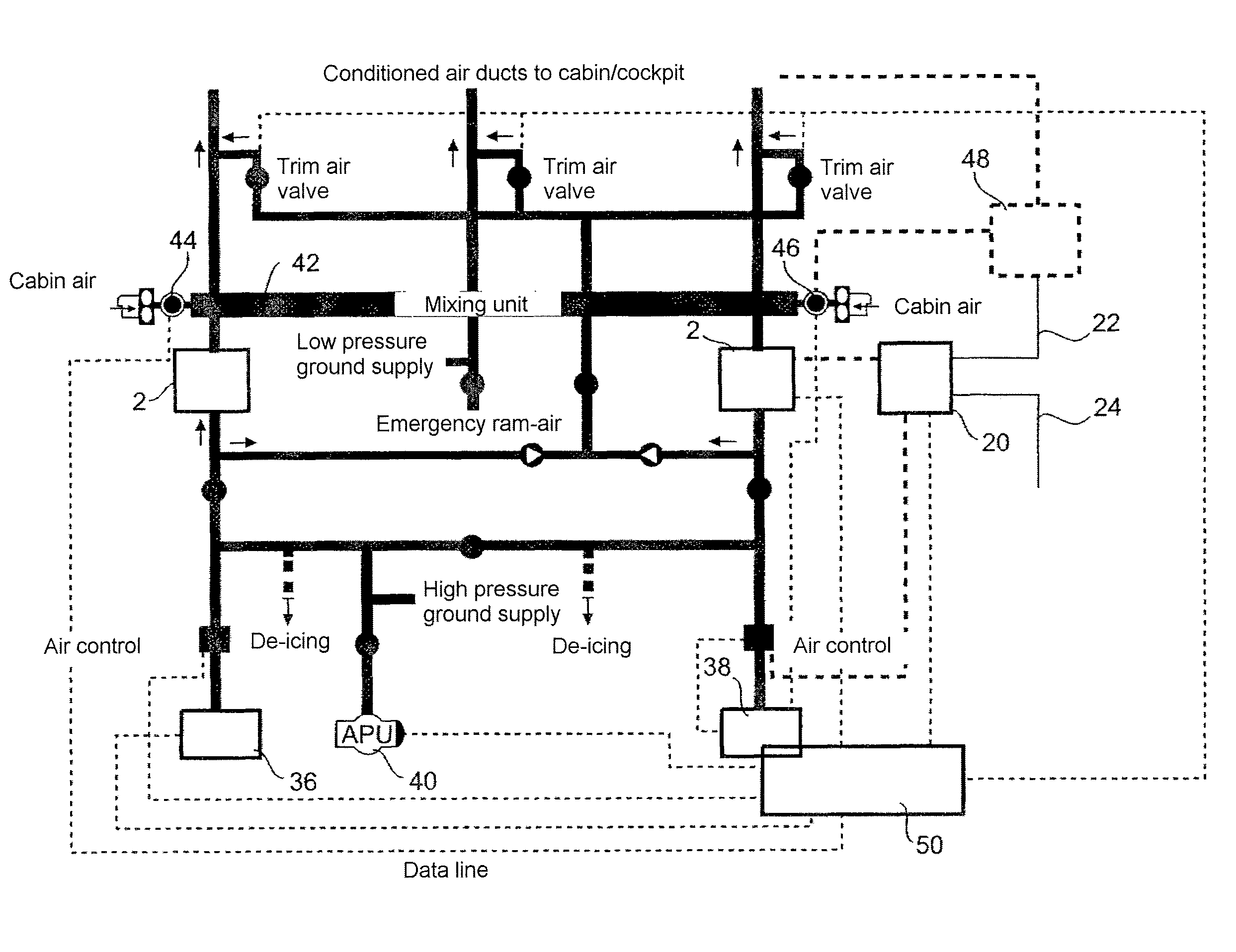

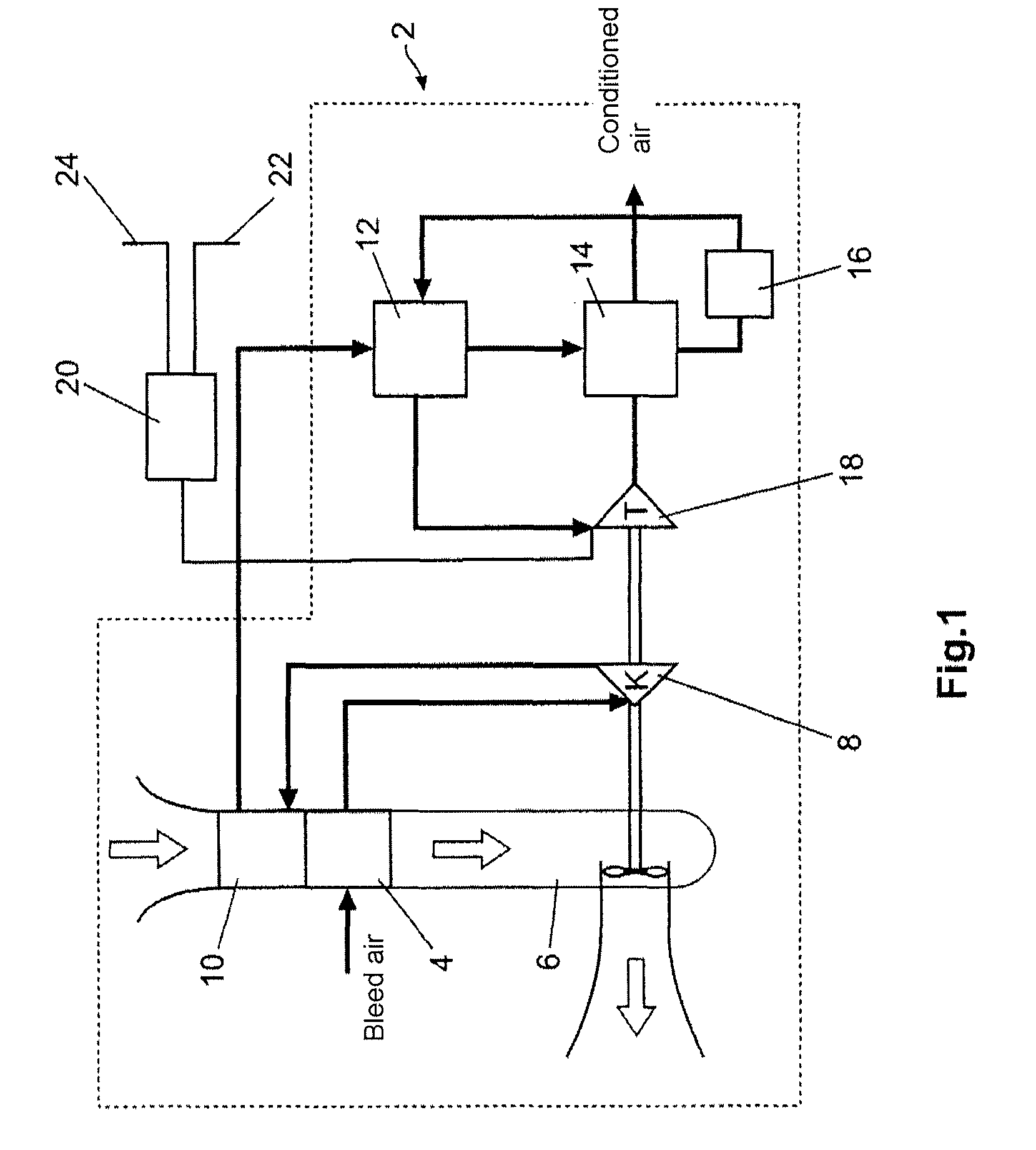

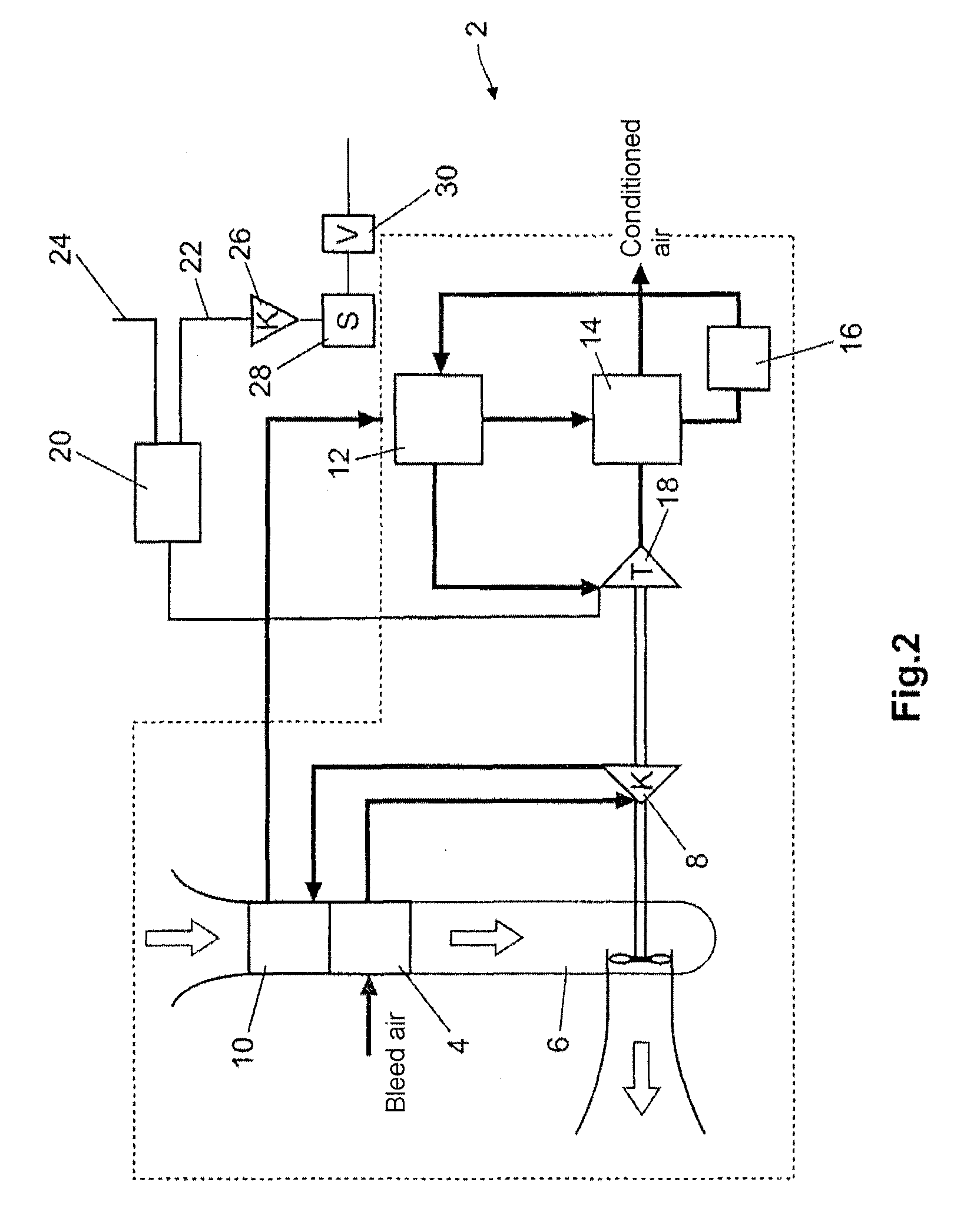

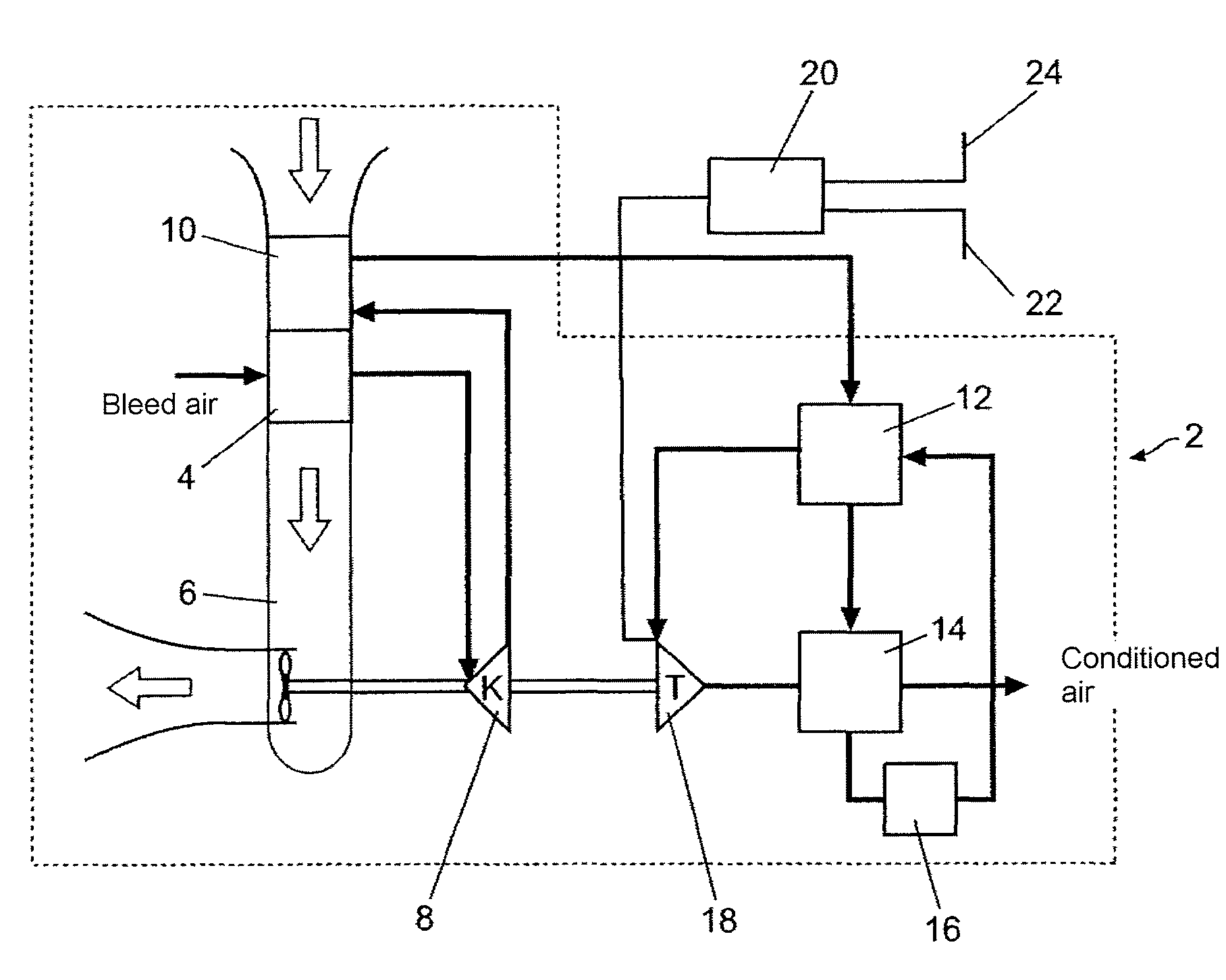

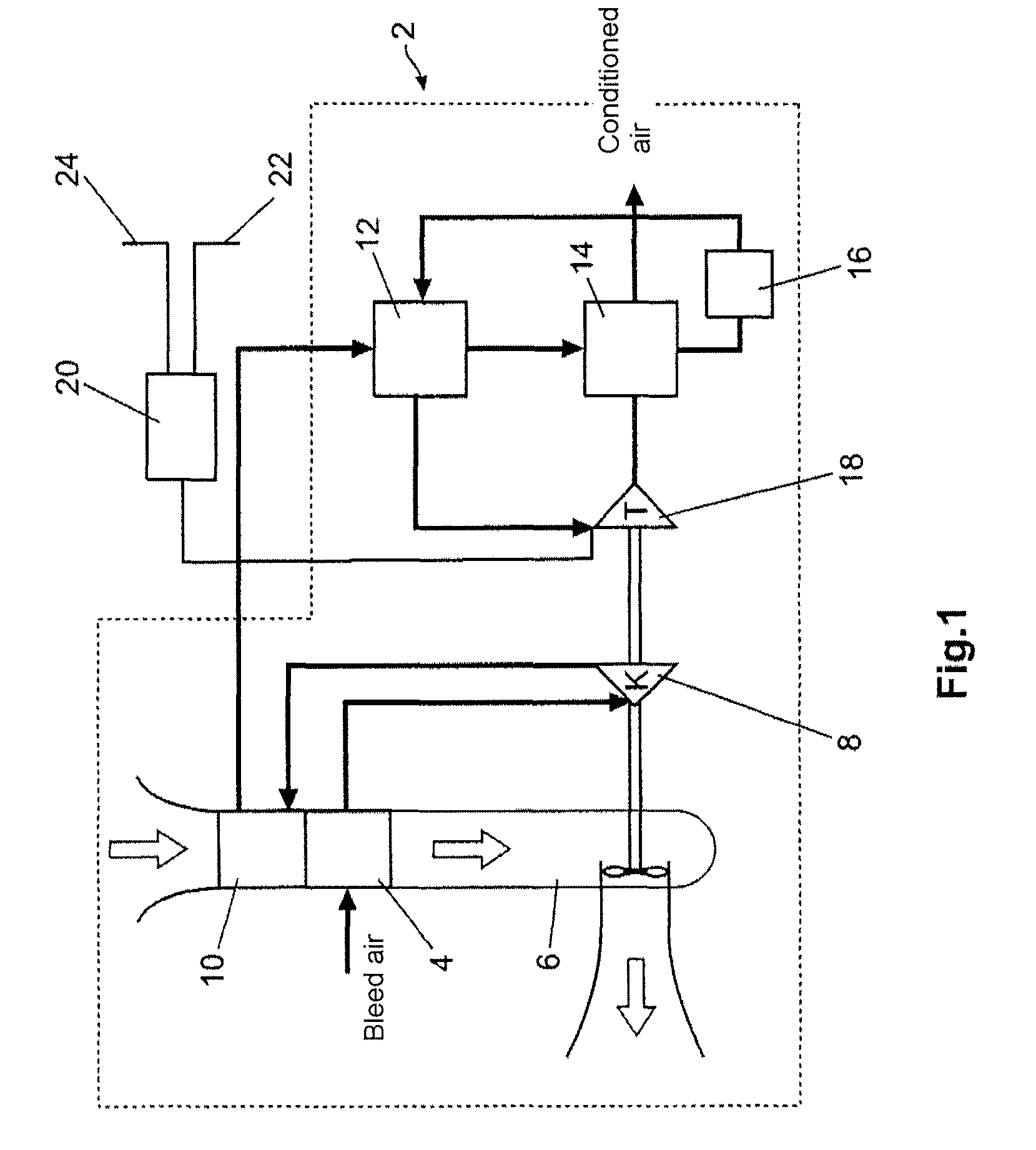

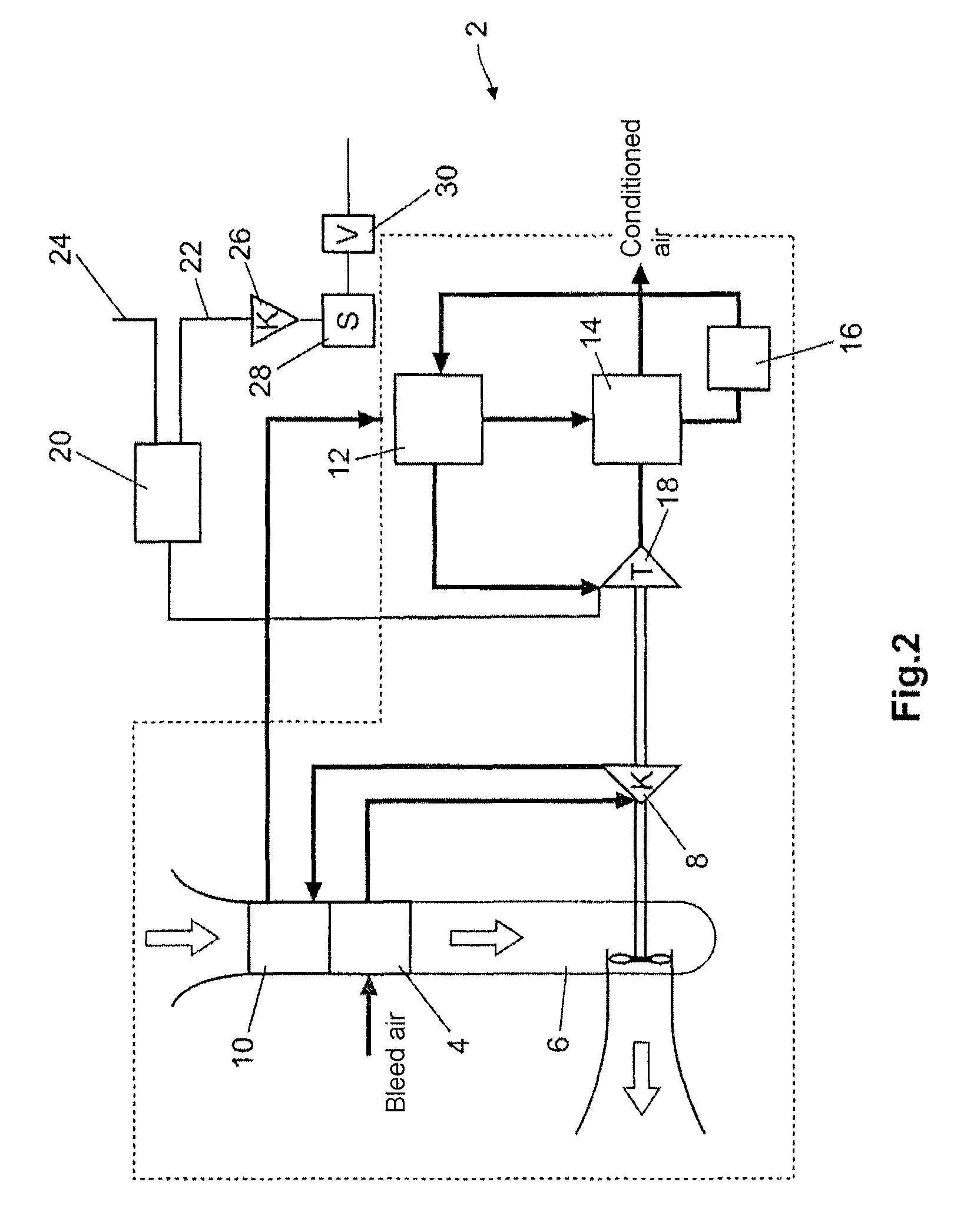

Inerting system for an aircraft

ActiveUS20110062288A1Reduce weightEliminate needPower plant fuel tanksDispersed particle filtrationInerting systemAir separation

The invention pertains to an inerting system for an aircraft featuring at least one air separation module with at least one air inlet, a first air outlet and a second air outlet. The air separation module is designed for splitting an input air flow into a first air flow and a second air flow, wherein the first air flow is enriched with oxygen in comparison with the input air flow and discharged at the first air outlet and the second air flow is enriched with nitrogen in comparison with the input air flow and discharged at the second air outlet. In comparison with known inerting systems, the inerting system according to the invention is characterized in that the air inlet can be connected to an air extraction point in an air processing system and the inerting system is designed for routing the first air flow into a cabin to be air-conditioned.

Owner:AIRBUS OPERATIONS GMBH

Fuel system for an aircraft including a fuel tank inerting system

A fuel system for an aircraft is disclosed. The fuel system comprises a fuel tank and a fuel reformer for receiving fuel from the fuel tank. The system includes a hydrogen fuel cell array for receiving hydrogen from the fuel reformer. The system further includes mechanism for providing an inerting gas from the fuel system to the fuel tank.

Owner:THE BOEING CO

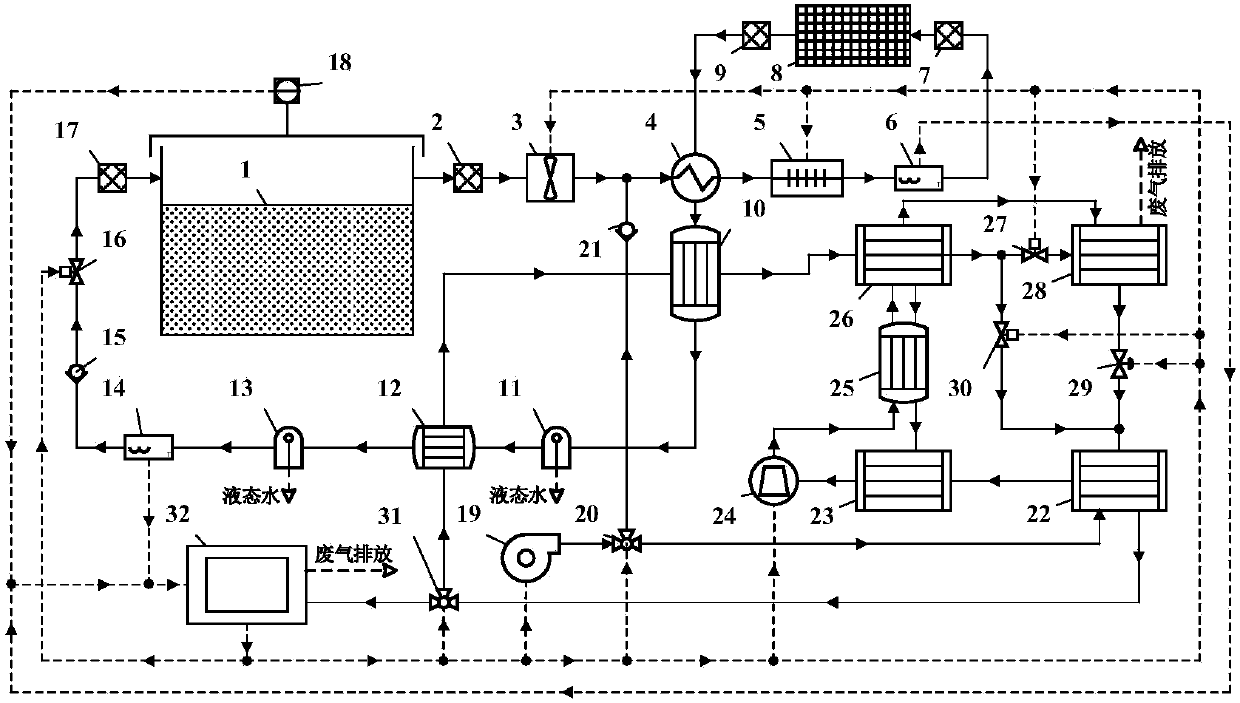

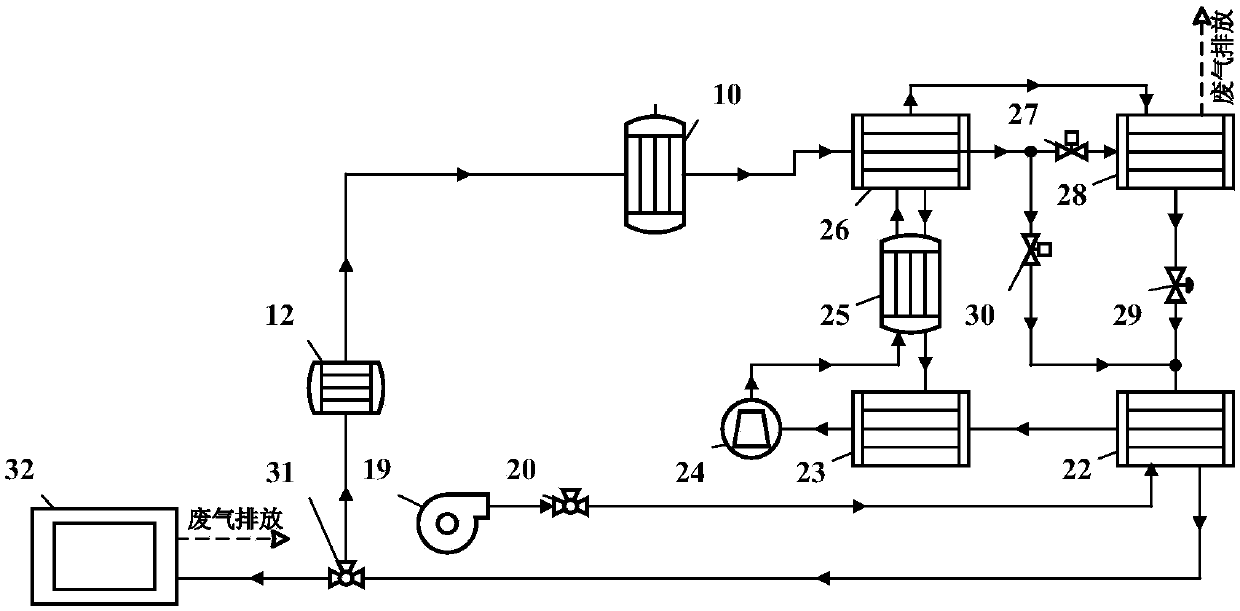

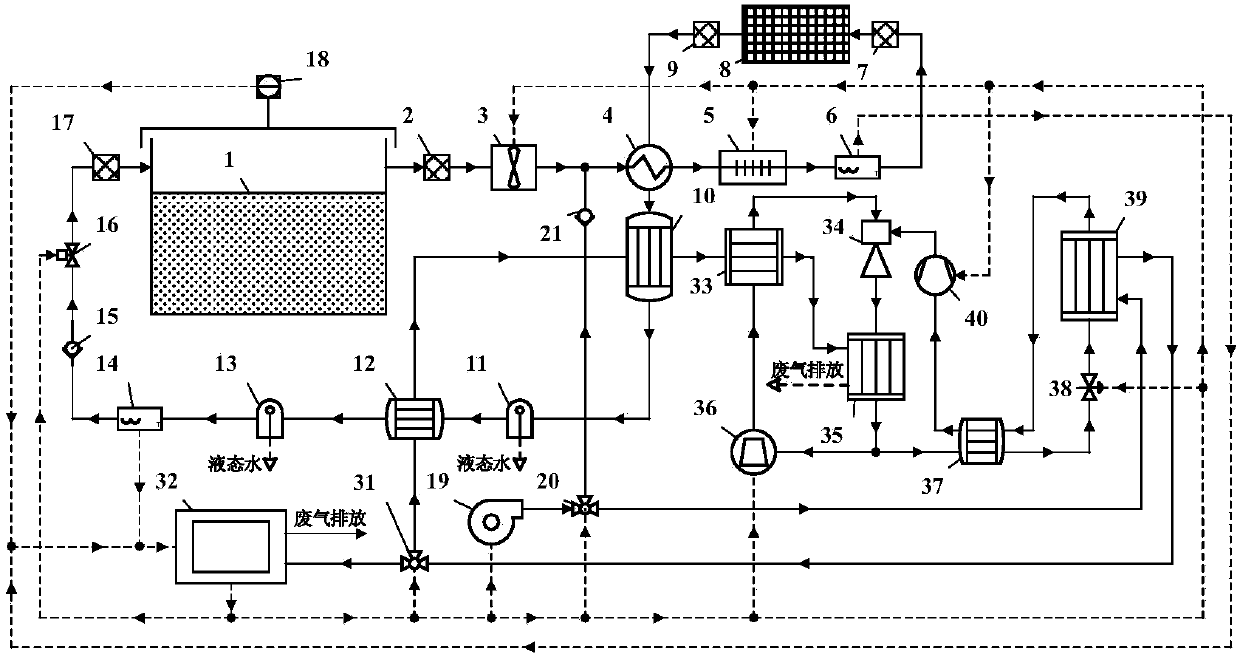

Airplane environment control and fuel tank inerting coupled system and method based on membrane separation method

Owner:BEIHANG UNIV

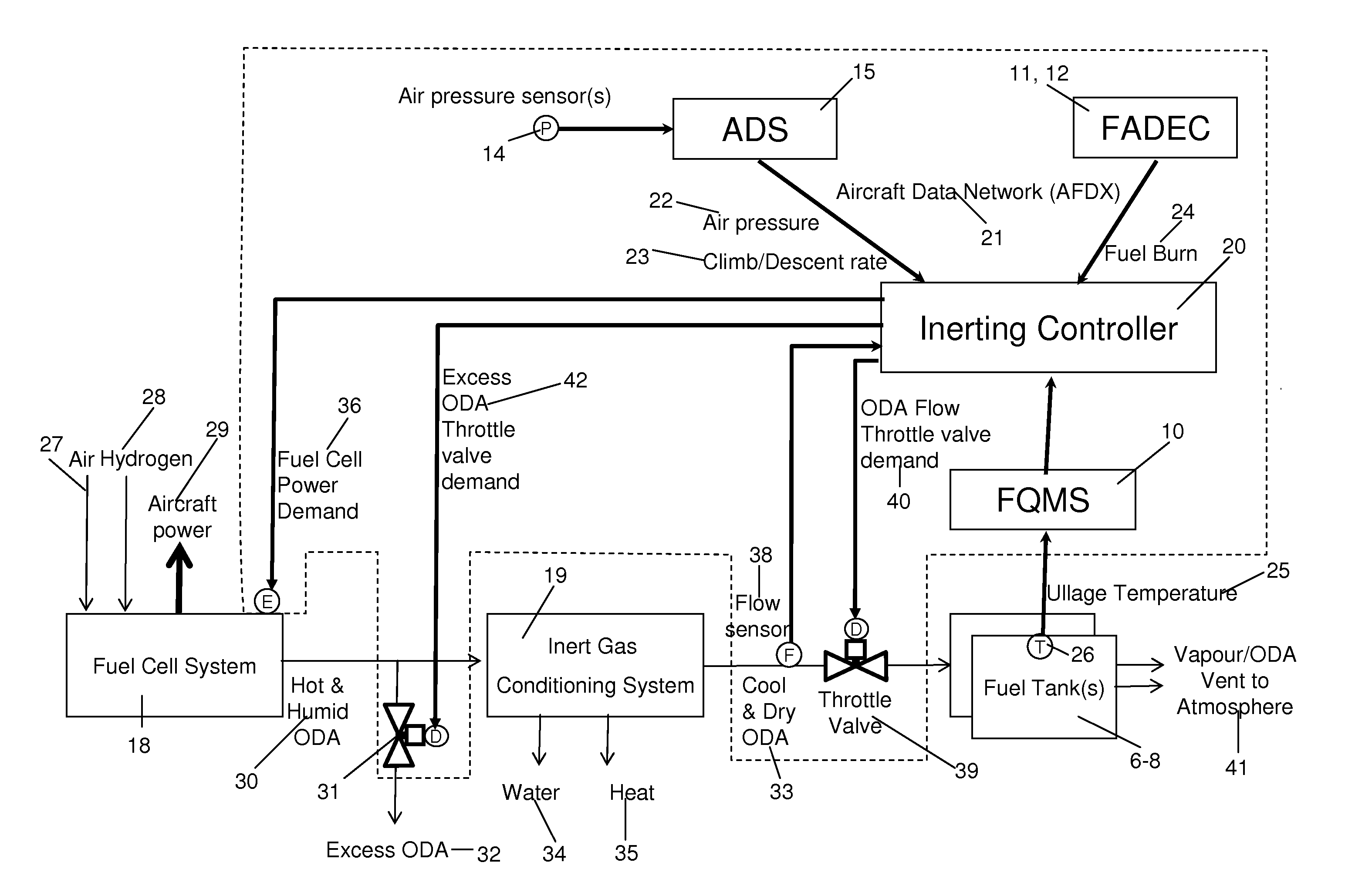

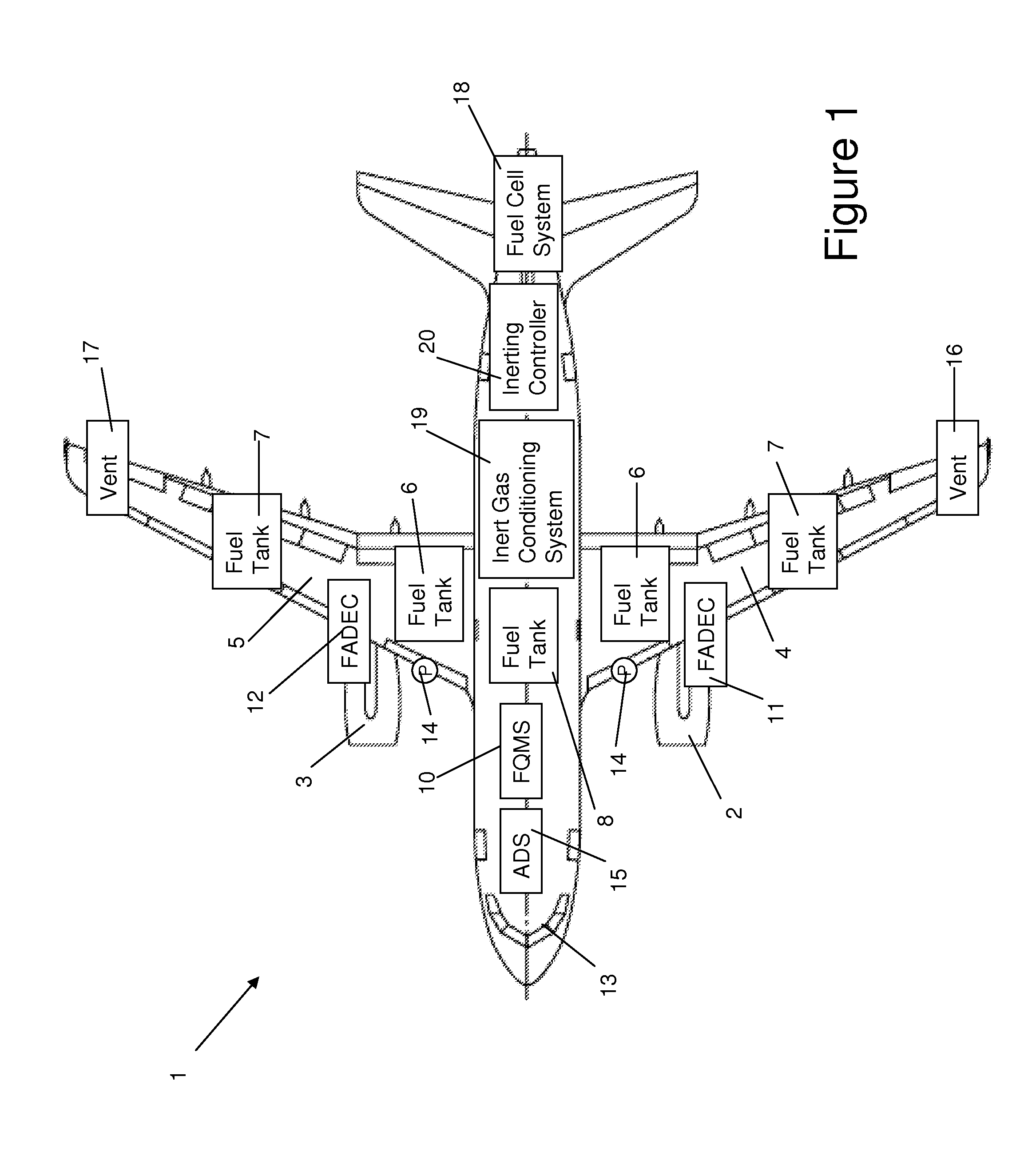

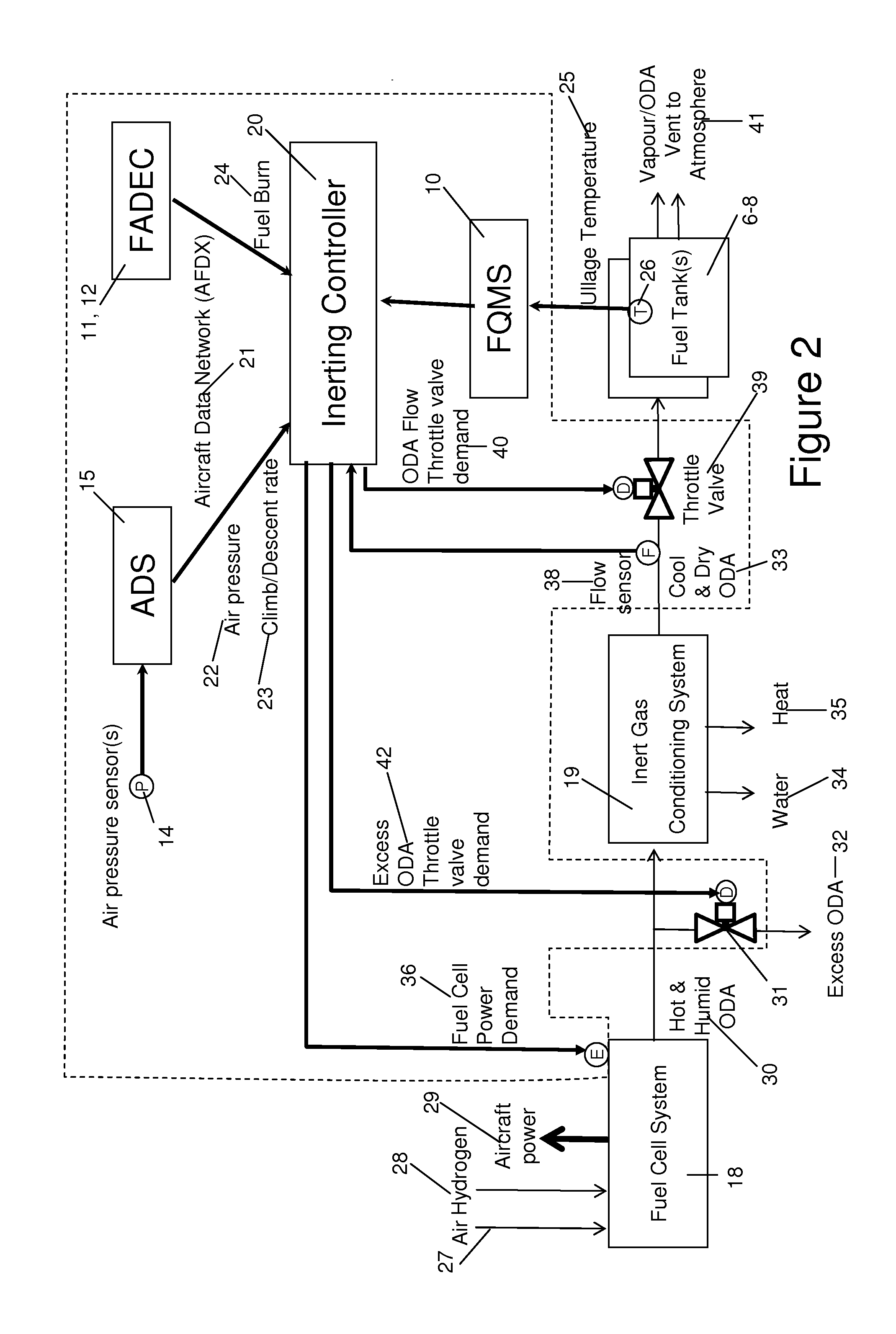

Aircraft inerting system

ActiveUS20140238501A1Lower the volumeEasy to usePower installationsPower plant fuel tanksInerting systemEngineering

A method of controlling a flow rate of inerting gas introduced into a vented aircraft fuel tank, the method comprising: monitoring changes in a quantity of a fuel in the aircraft fuel tank; monitoring changes in the ambient air pressure external to the aircraft fuel tank; and actively controlling a flow rate of inerting gas, {dot over (m)}(I), introduced into the aircraft fuel tank based upon changes in the quantity of fuel in the fuel tank and changes in the ambient air pressure, p. Also, an aircraft including a vented fuel tank, a supply of inerting gas for rendering inert the fuel tank ullage, and a controller for performing the method.

Owner:AIRBUS OPERATIONS LTD +1

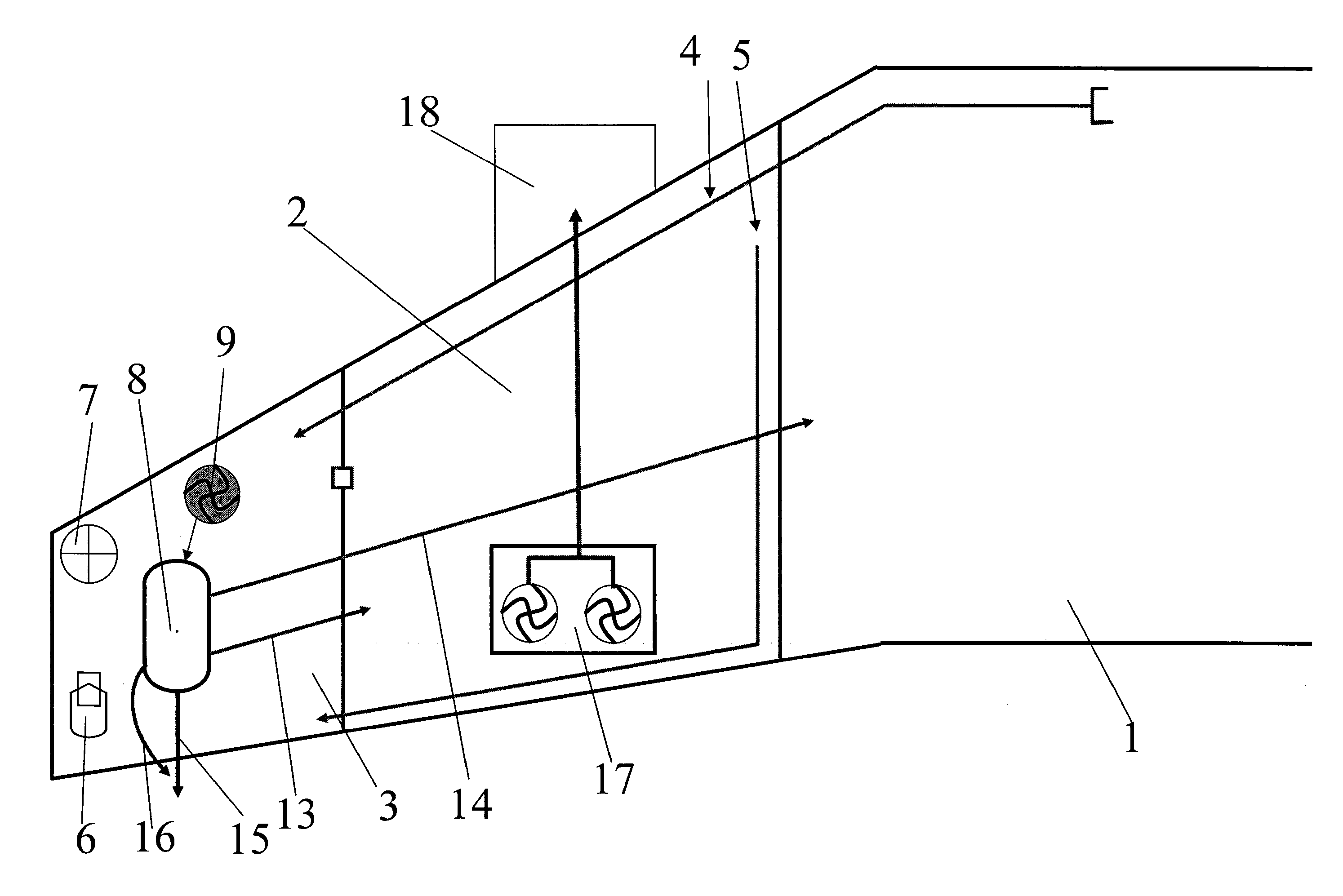

Fuel system and method

ActiveUS20130000142A1Reduce installation costsSaving weightDrying using combination processesGas treatmentInerting systemProcess engineering

A fuel system comprising a fuel tank, a vent tank having a duct open to the ambient atmosphere, a first vent line fluidically connecting the fuel tank ullage to the vent tank, a gas drying system including a pump and a dehumidifying device disposed within the vent tank, and a second vent line fluidically connecting a dry gas outlet of the dehumidifying device to the ullage, wherein the pump is operable to maintain a higher pressure within the ullage than in the vent tank so as to drive vapour rich gas from the ullage into the vent tank via the first vent line. Also, a method of operating the fuel system and a method of retro-fitting the gas drying system in an existing fuel system. The gas drying system may optionally be a gas drying / inerting system.

Owner:AIRBUS OPERATIONS LTD

Fuel system and method

ActiveUS8904669B2Lower levelAccelerate evaporationLiquid degasificationDrying solid materials with heatInerting systemEngineering

A fuel system comprising a fuel tank, a vent tank having a duct open to the ambient atmosphere, a first vent line fluidically connecting the fuel tank ullage to the vent tank, a gas drying system including a pump and a dehumidifying device disposed within the vent tank, and a second vent line fluidically connecting a dry gas outlet of the dehumidifying device to the ullage, wherein the pump is operable to maintain a higher pressure within the ullage than in the vent tank so as to drive vapor rich gas from the ullage into the vent tank via the first vent line. Also, a method of operating the fuel system and a method of retro-fitting the gas drying system in an existing fuel system. The gas drying system may optionally be a gas drying / inerting system.

Owner:AIRBUS OPERATIONS LTD

Inerting system for an aircraft

ActiveUS8500878B2Reduce weightEliminate needPower plant fuel tanksAir-treatment apparatus arrangementsInerting systemEngineering

Owner:AIRBUS OPERATIONS GMBH

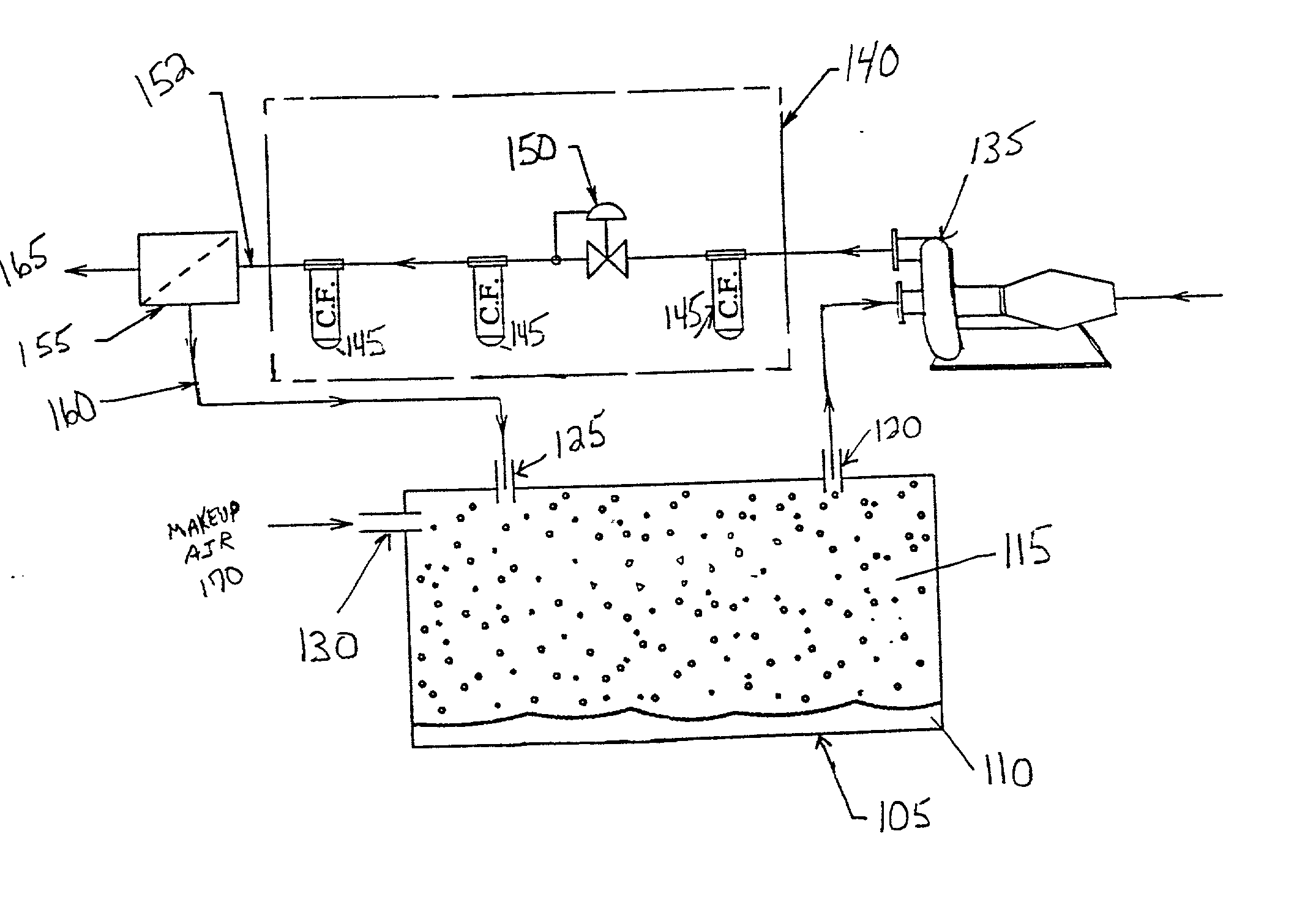

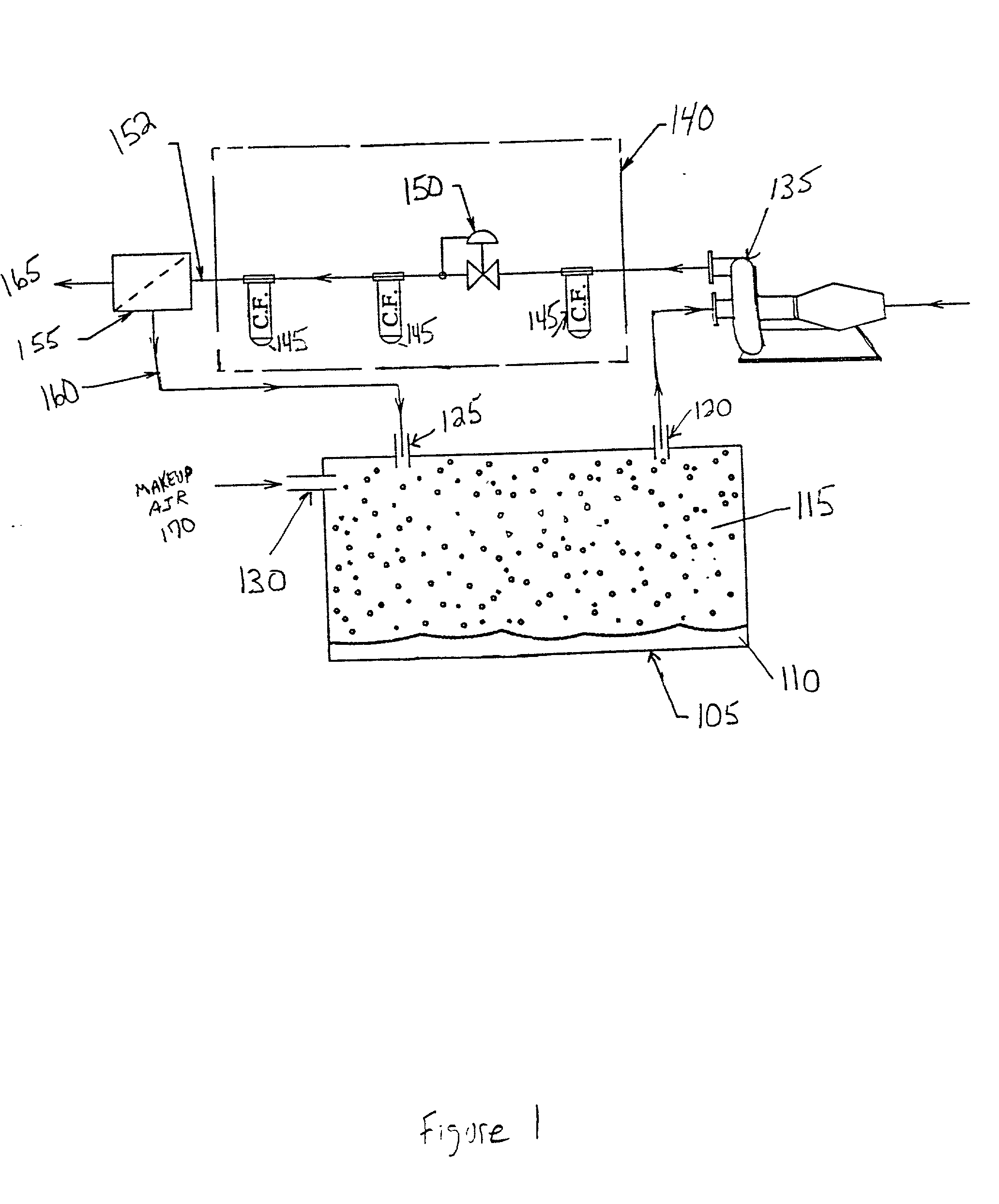

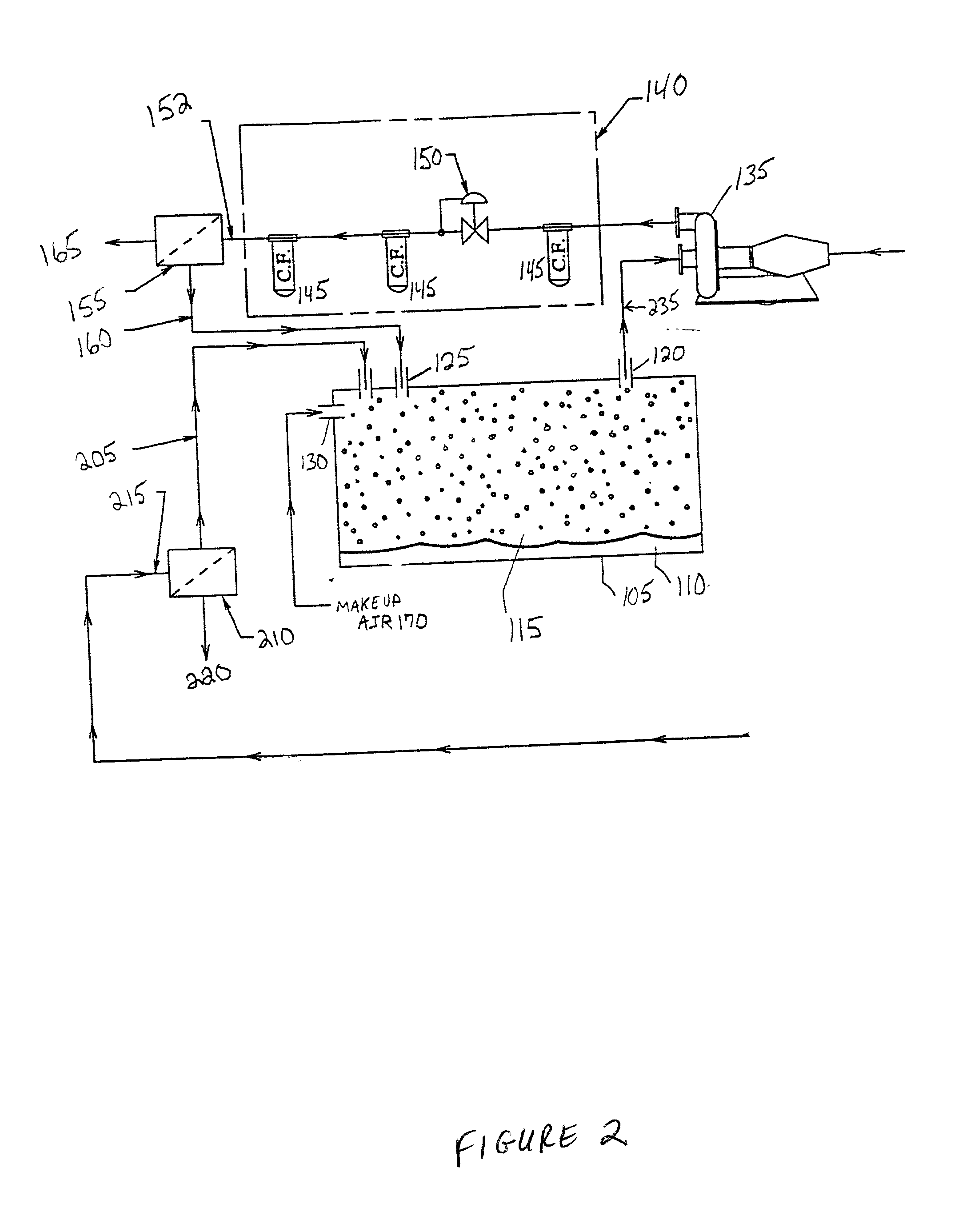

Vented compartment inerting system

InactiveUS20020117052A1Combination devicesLiquid handling installationsInerting systemProcess engineering

1. An inerting system for a vented controlled atmosphere container, for inerting a flammable gas comprising a flammable vapor and oxygen, comprising: (i) a container; (ii) an outlet in the container for the flammable gas; (iii) a compressor, in fluid communication with the outlet, which compresses the flammable gas from the container; (iv) a separator, in fluid communication with the compressor, for removing oxygen from the flammable gas to produce an oxygen-depleted flammable gas; (v) an inlet in the container, which is in fluid communication with the separator; through which the oxygen-depleted flammable gas is fed into the container.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

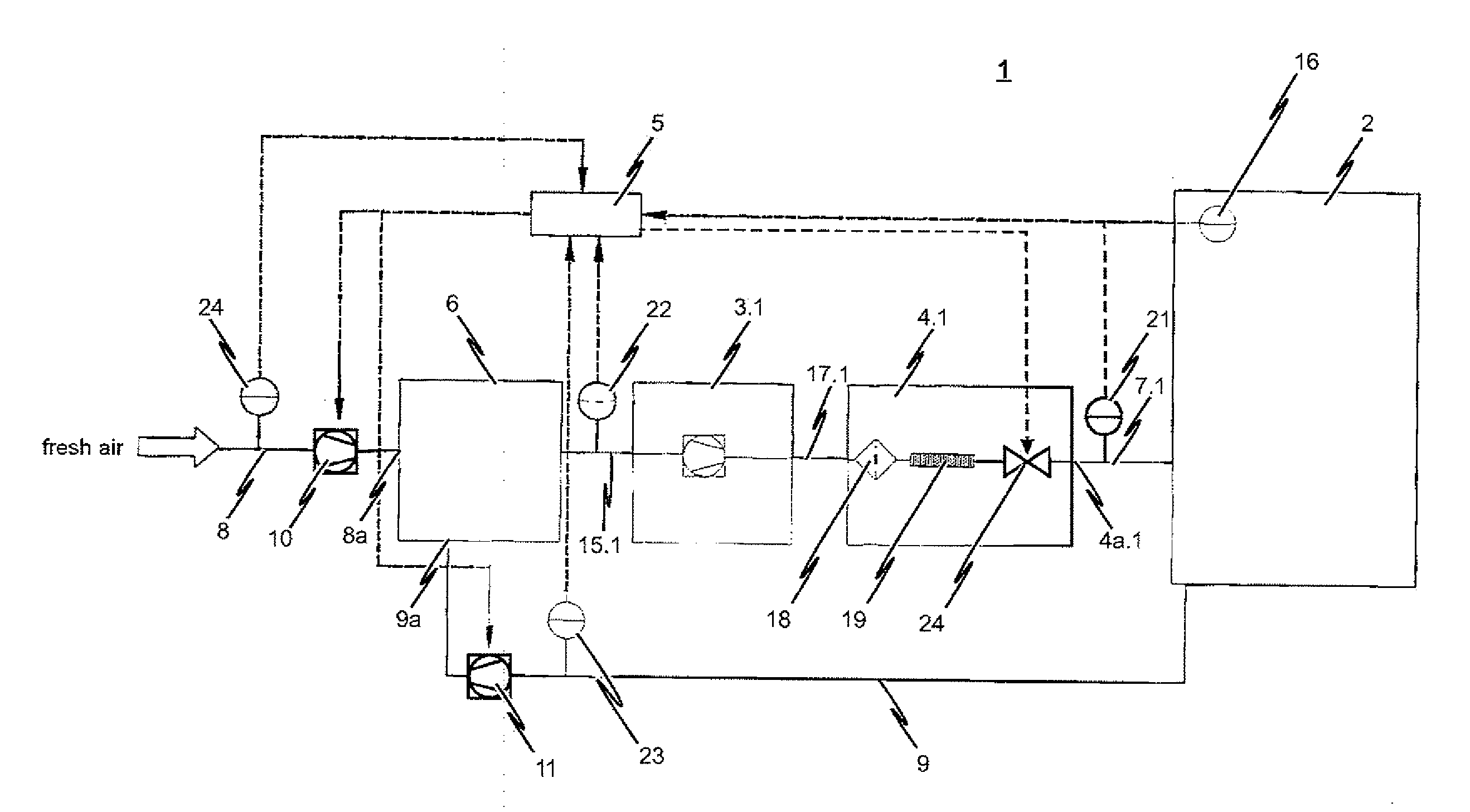

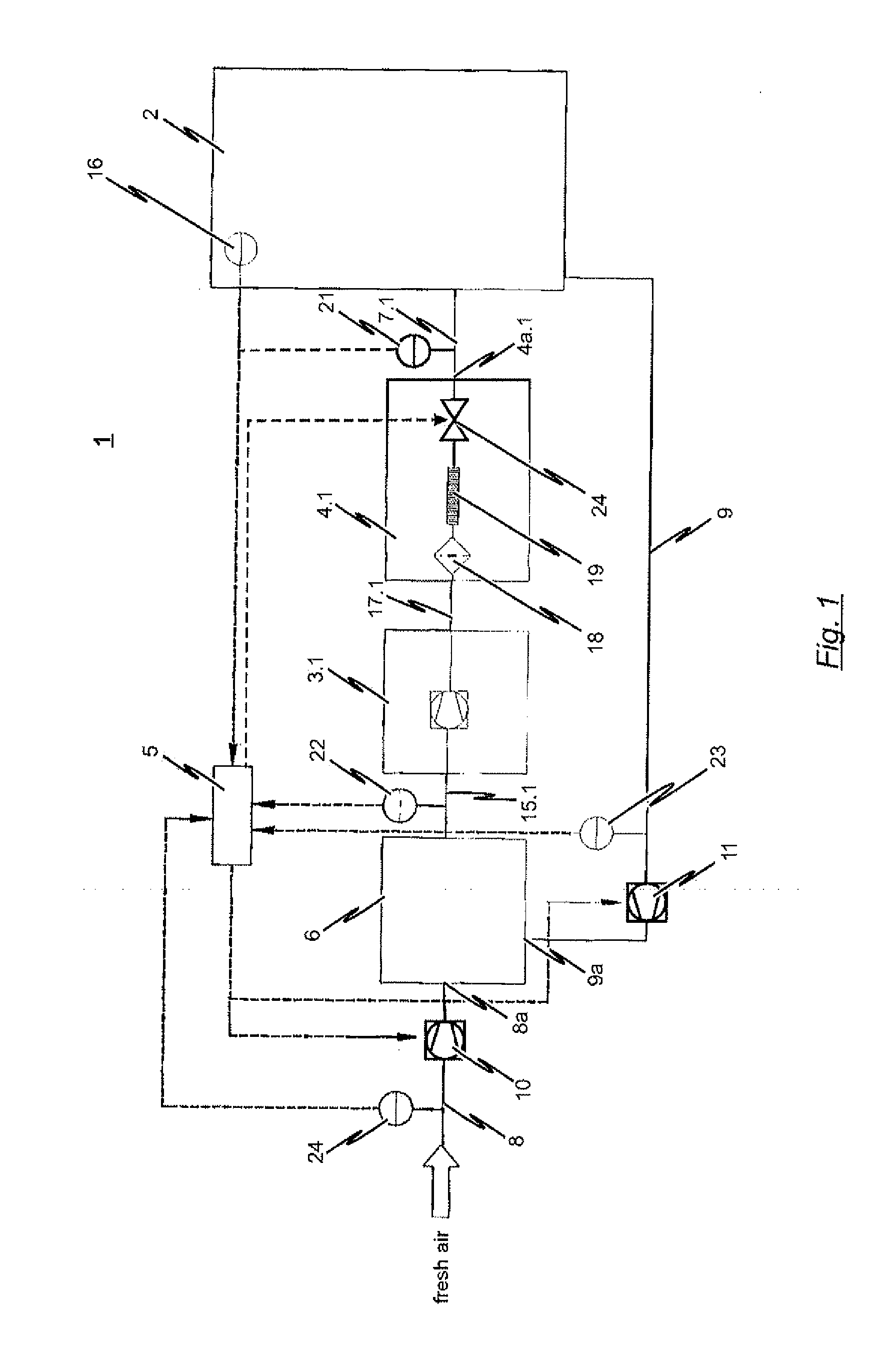

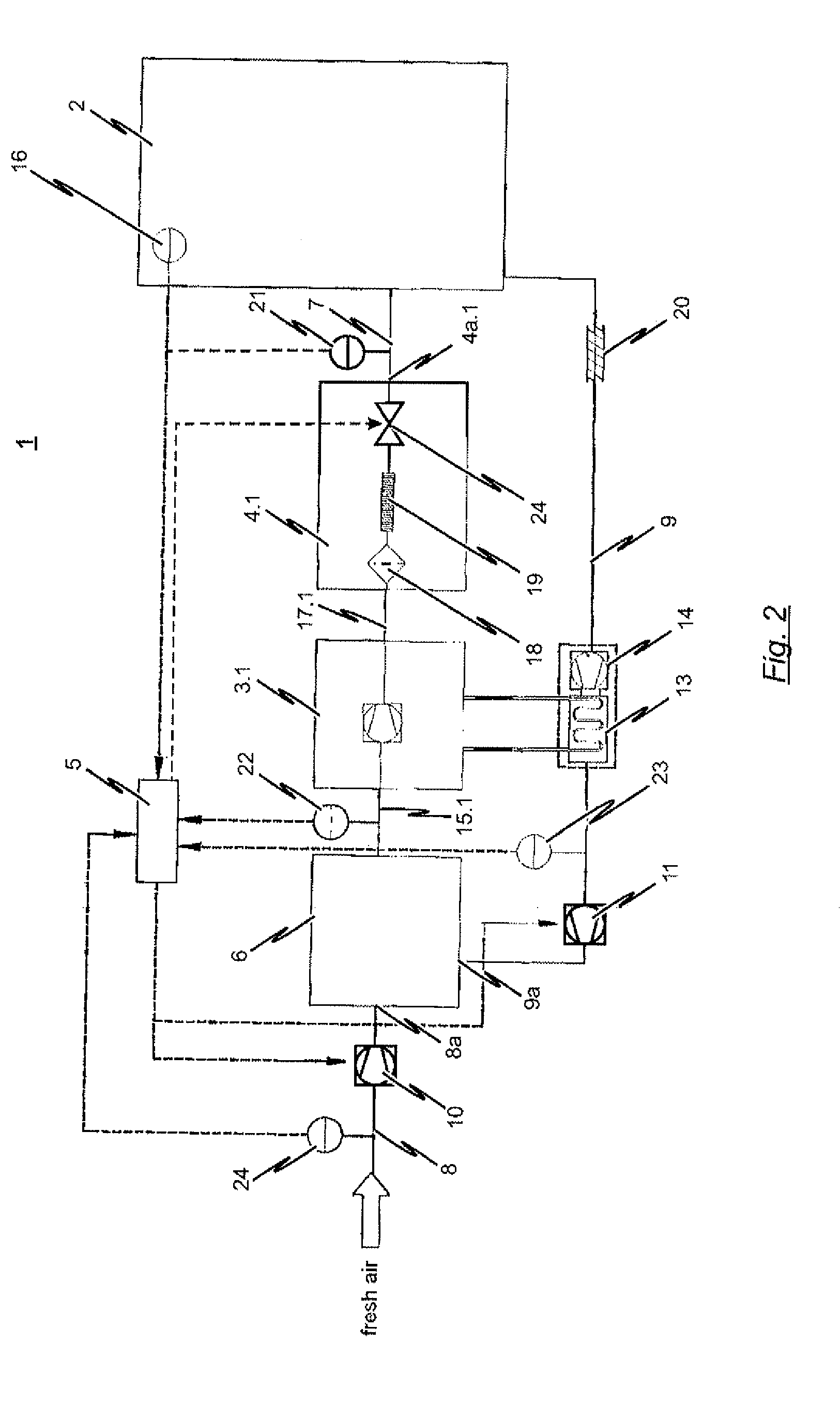

Inerting method for preventing and/or extinguishing fire as well as inerting system to realize the method

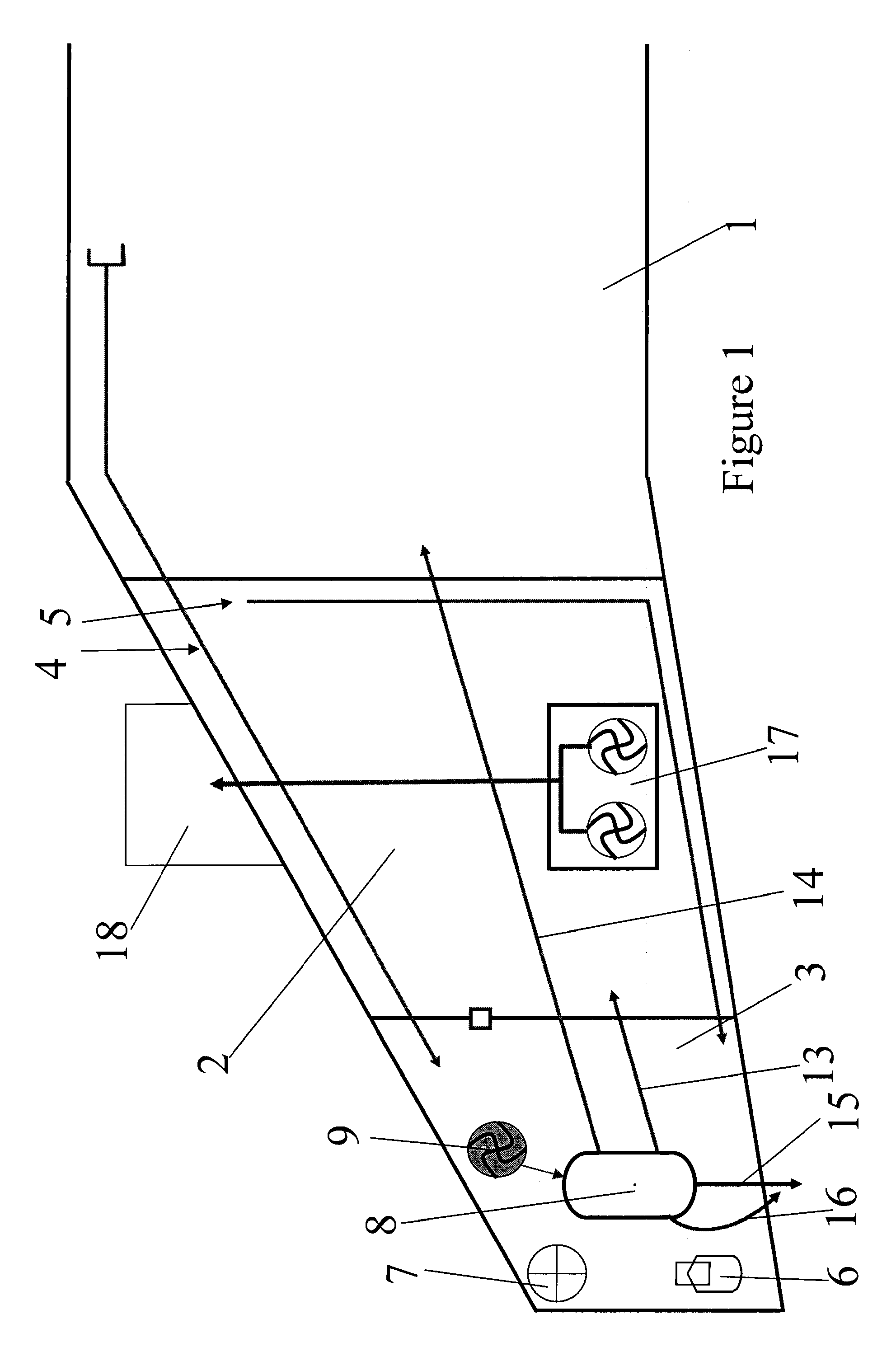

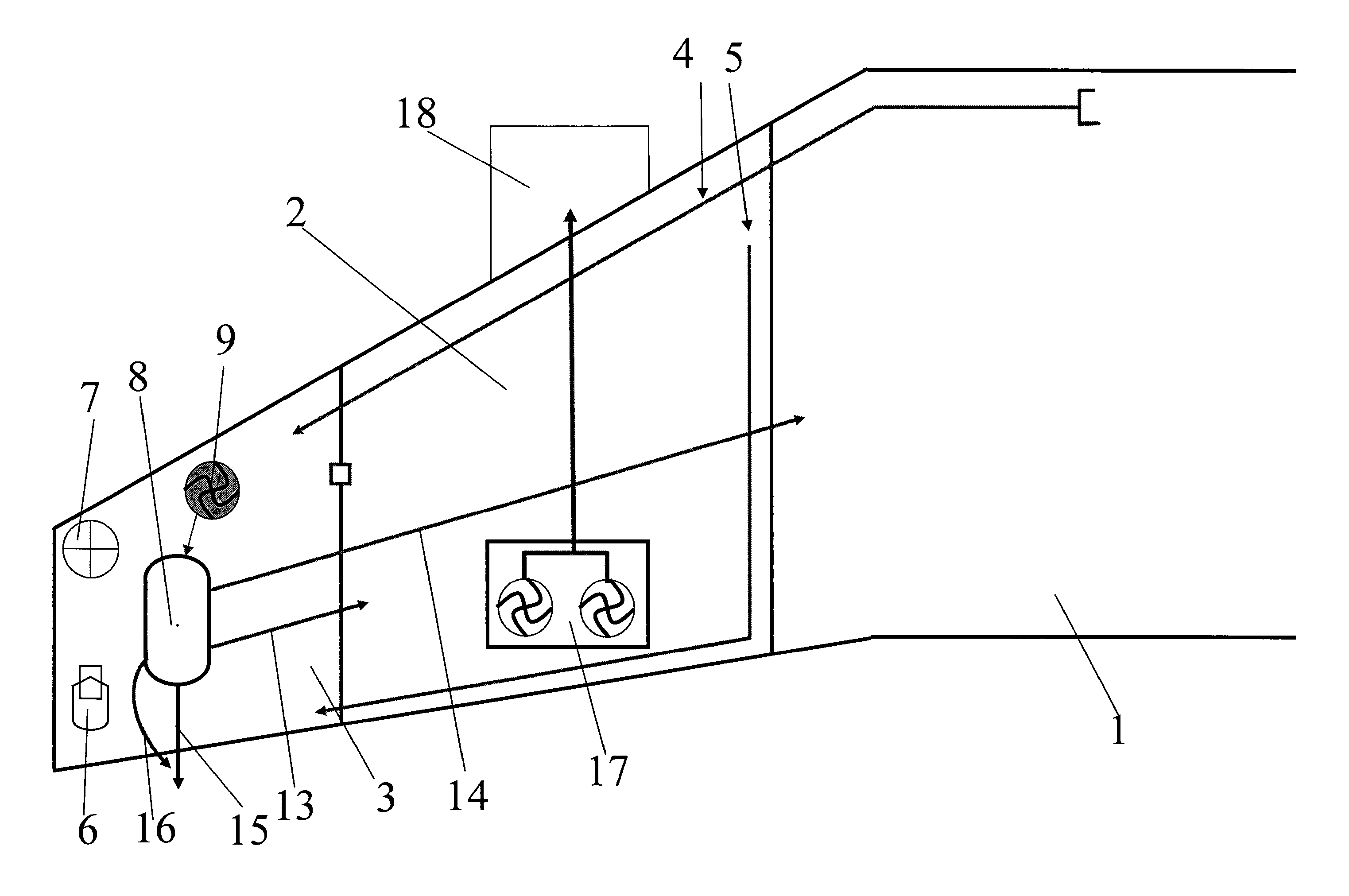

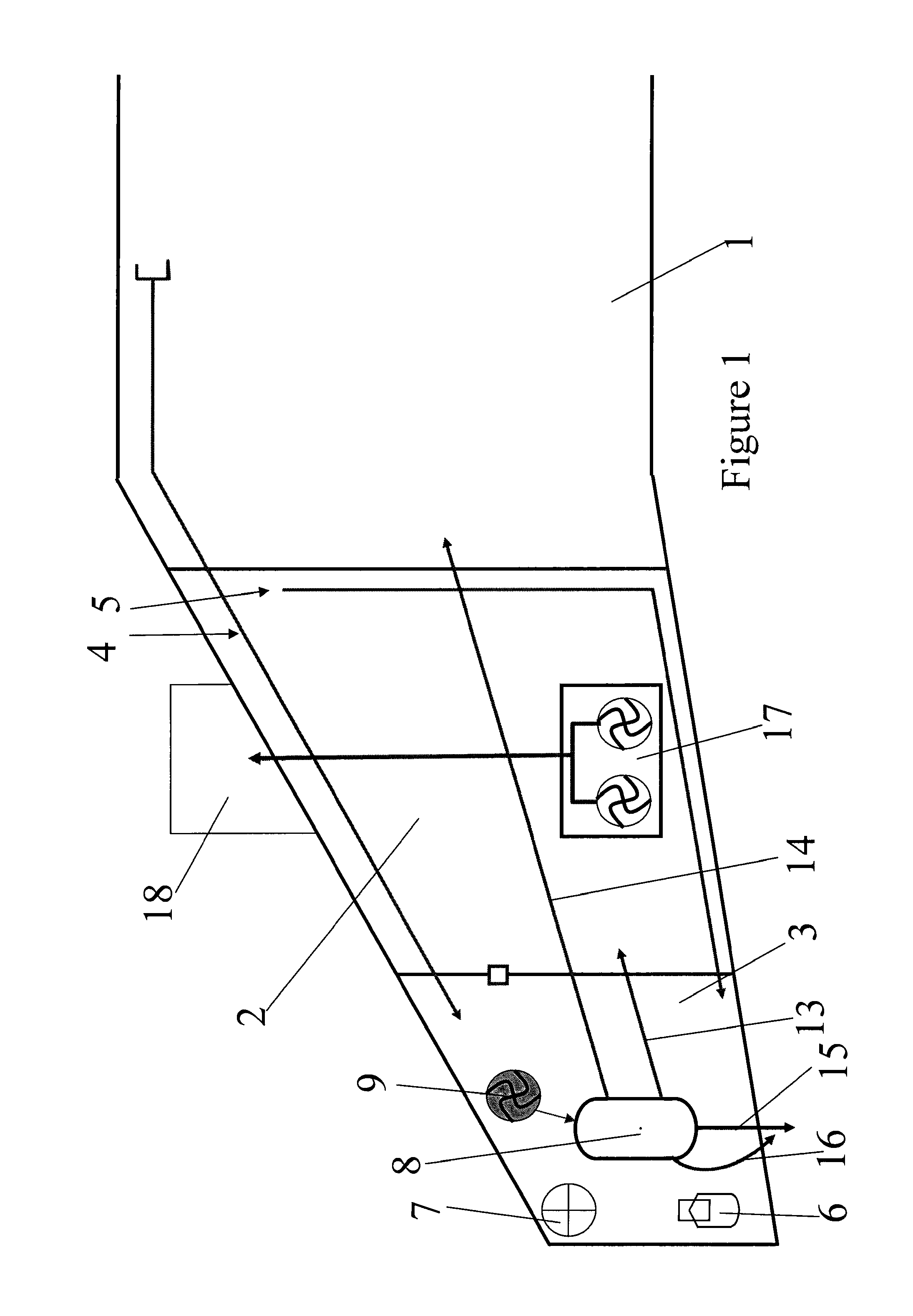

The invention relates to an inerting method as well as an inerting system (1) to set and / or maintain a reduced oxygen content in an enclosed room (2), wherein a gas separation system (3.1, 4.1; 3.2, 4.2; 3.3, 4.3) is provided which separates off at least a portion of the oxygen from an initial gas mixture provided in a mixing chamber (6) and by so doing, provides a nitrogen-enriched gas mixture. In order to optimize the operation of the inerting system (1), the invention provides for a portion of the air to be withdrawn from the enclosed room (2) and admixed with fresh air in the mixing chamber (6).

Owner:AMRONA

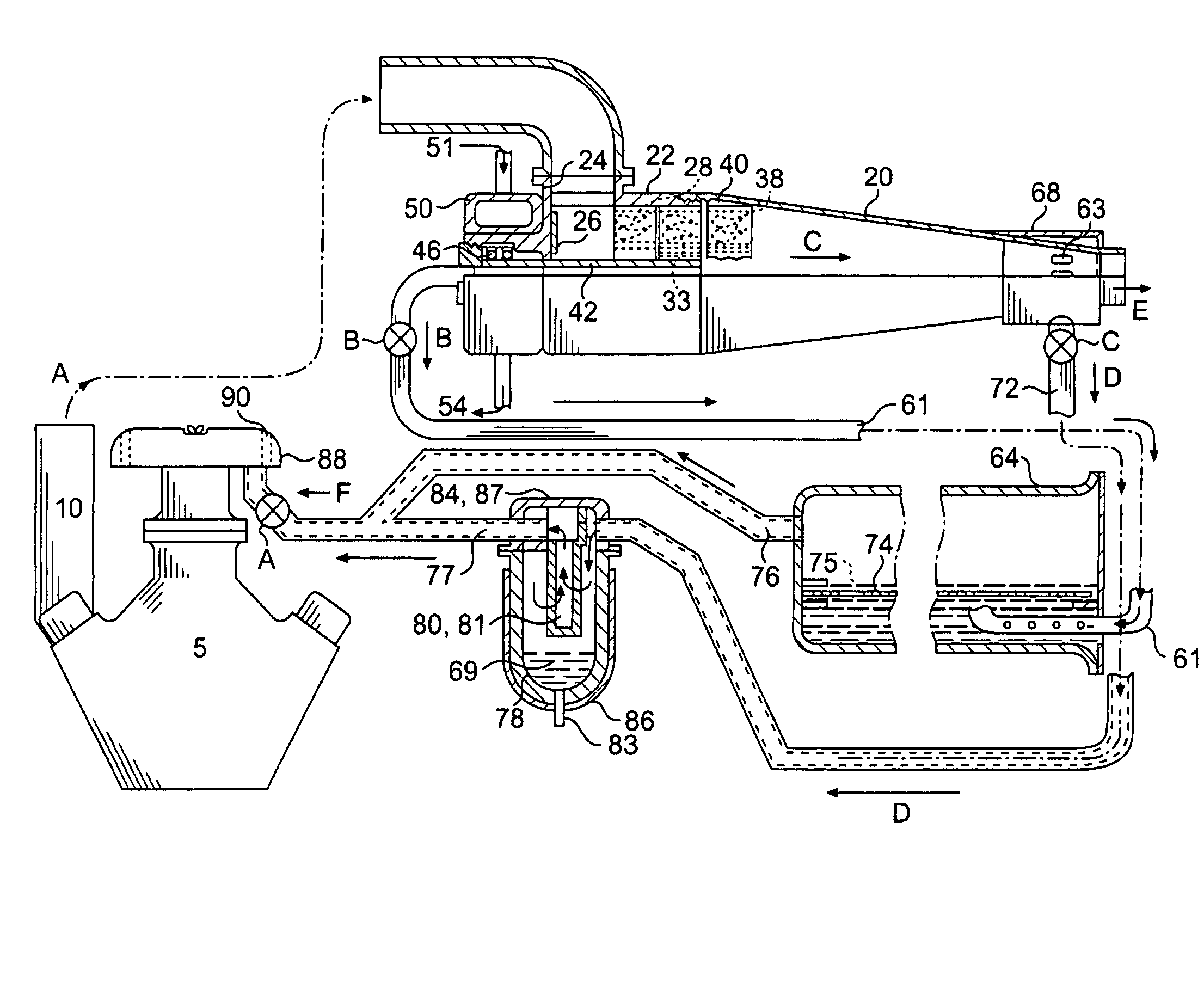

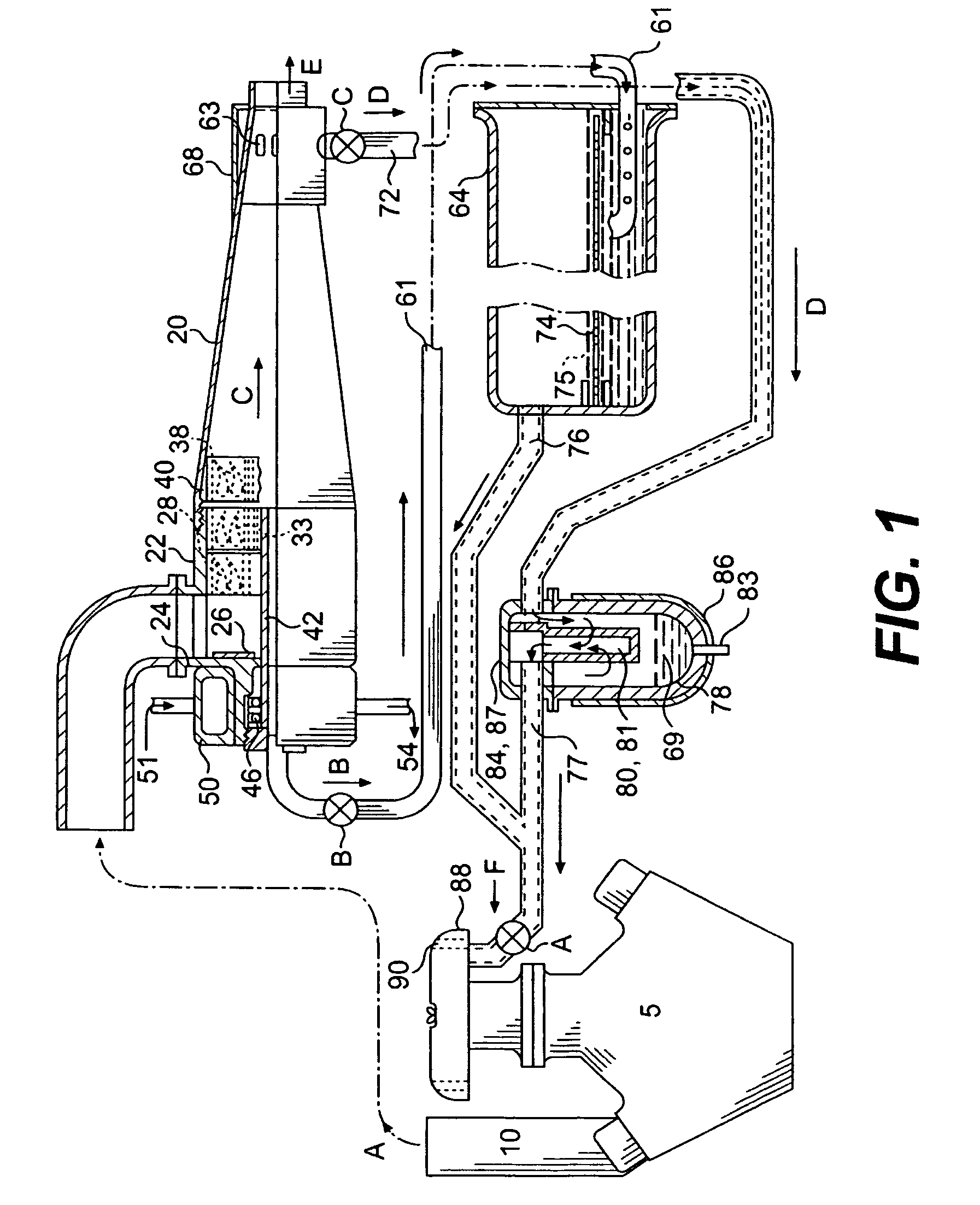

Nitrogen inerting system for explosion prevention in aircraft fuel tank and oxygenating system for improving combustion efficiency of aerospace rockets/ aircraft engines

InactiveUS7806966B2Increase speedIncrease rotation speedCombination devicesGas treatmentAir conditioningCheck valve

Compressed Air from an aircraft / rocket engine's compressed air line to its air-conditioning system, or an Auxiliary Air Compressor out-put is used, for energizing a high-speed gas turbine. The very high-speed convoluting air discharge into a vortex cone causes a first separation of the Air gas components, by stratifying into heavier (Argon), medium (Oxygen) and lighter (Nitrogen) components, where in the heavier and lighter components are non-combustible, inert gases and the medium is a combustible gas. The lighter non-combustible component (Nitrogen) exits from the turbine in one direction for storage in the Inert gas tank. The heavier (Argon) and medium (Oxygen) components together move in the opposite direction for having a second stratifying separation downstream in the vortex tube, to separate non-combustible, heavier (Argon) gas from combustible medium (Oxygen) gas components. The combustible, medium (Oxygen) component exits the vortex tube open end, to flow into an Oxygenating storage tank; whereas, the heavier, non-combustible(Argon) gas is piped into the Inert gas storage tank. Both gas storage tank in-flow lines are fitted with non-return valves. The out flow lines from the Inert tank to either Fuel Tank “Ullage” or “OBGIS” areas are fitted with electronic control valves, operated by signals received from fiber-optic Temperature / Pressure / Oxygen concentration Sensors in the Fuel tank “Ullage” or “OBGIS: areas. Likewise, the outflow lines from the Oxygenating tank are fitted with electronc control valves activated by engine “takeoff” or Passenger cabin low oxygen signals, respectively.

Owner:BOSE RANENDRA K

Environment-friendly inerting waste heat utilization system for fuel tank

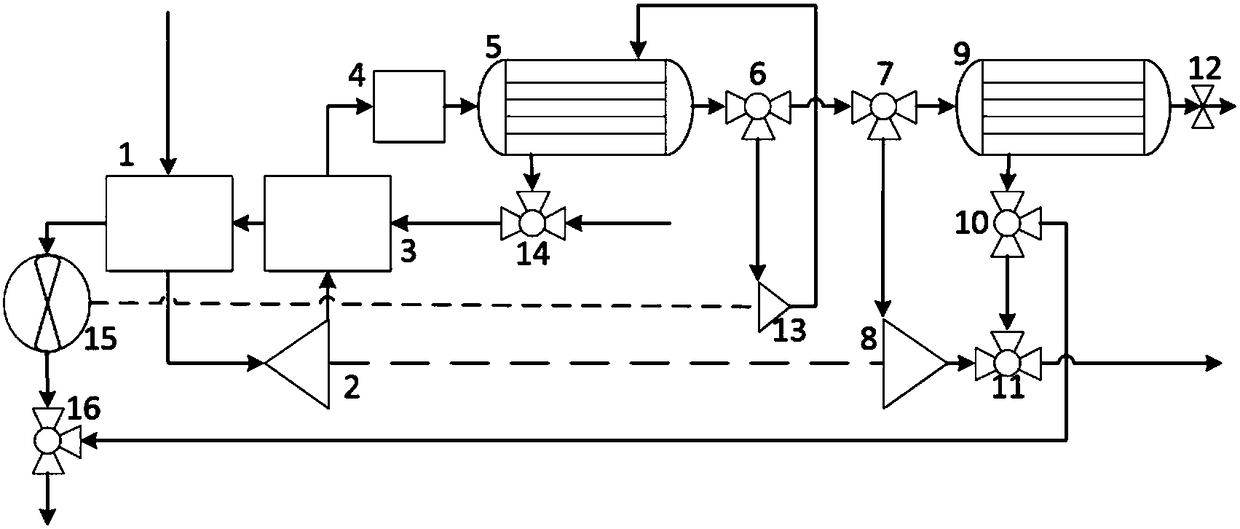

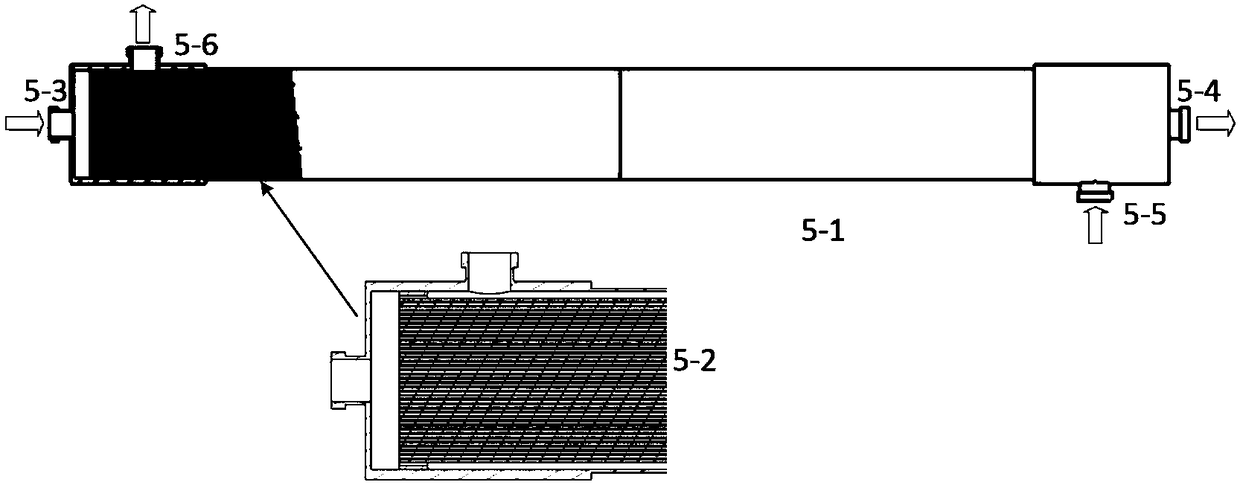

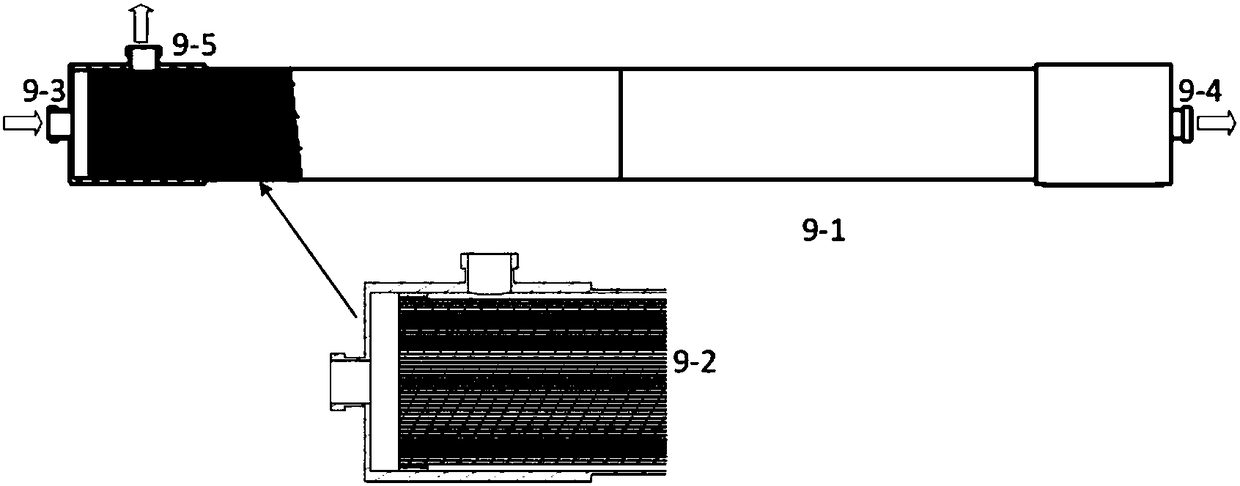

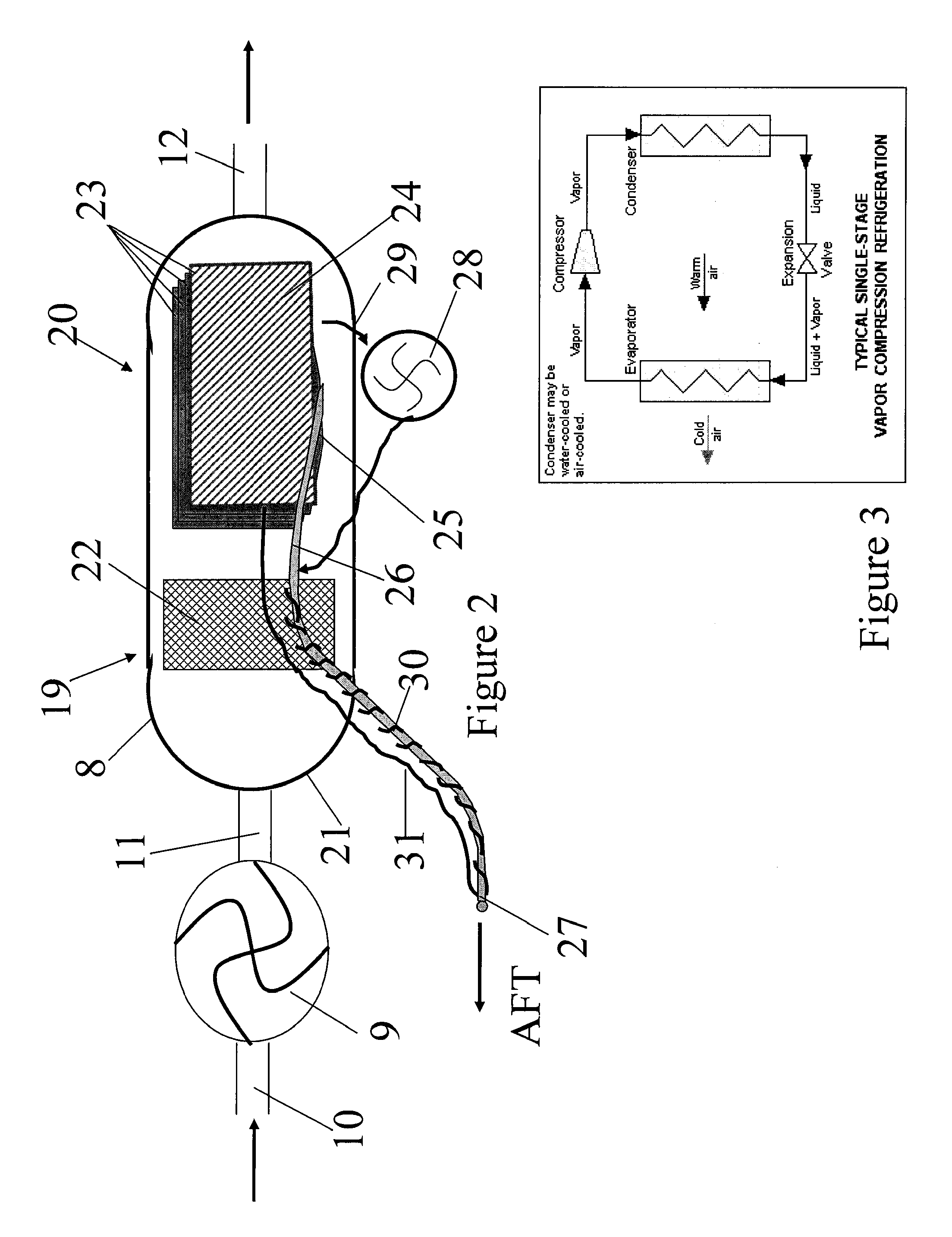

ActiveCN108033027ANo pollution in the processImprove energy utilizationFuel tank safety measuresConditioning fuel arrangementsGas phaseCatalytic oxidation

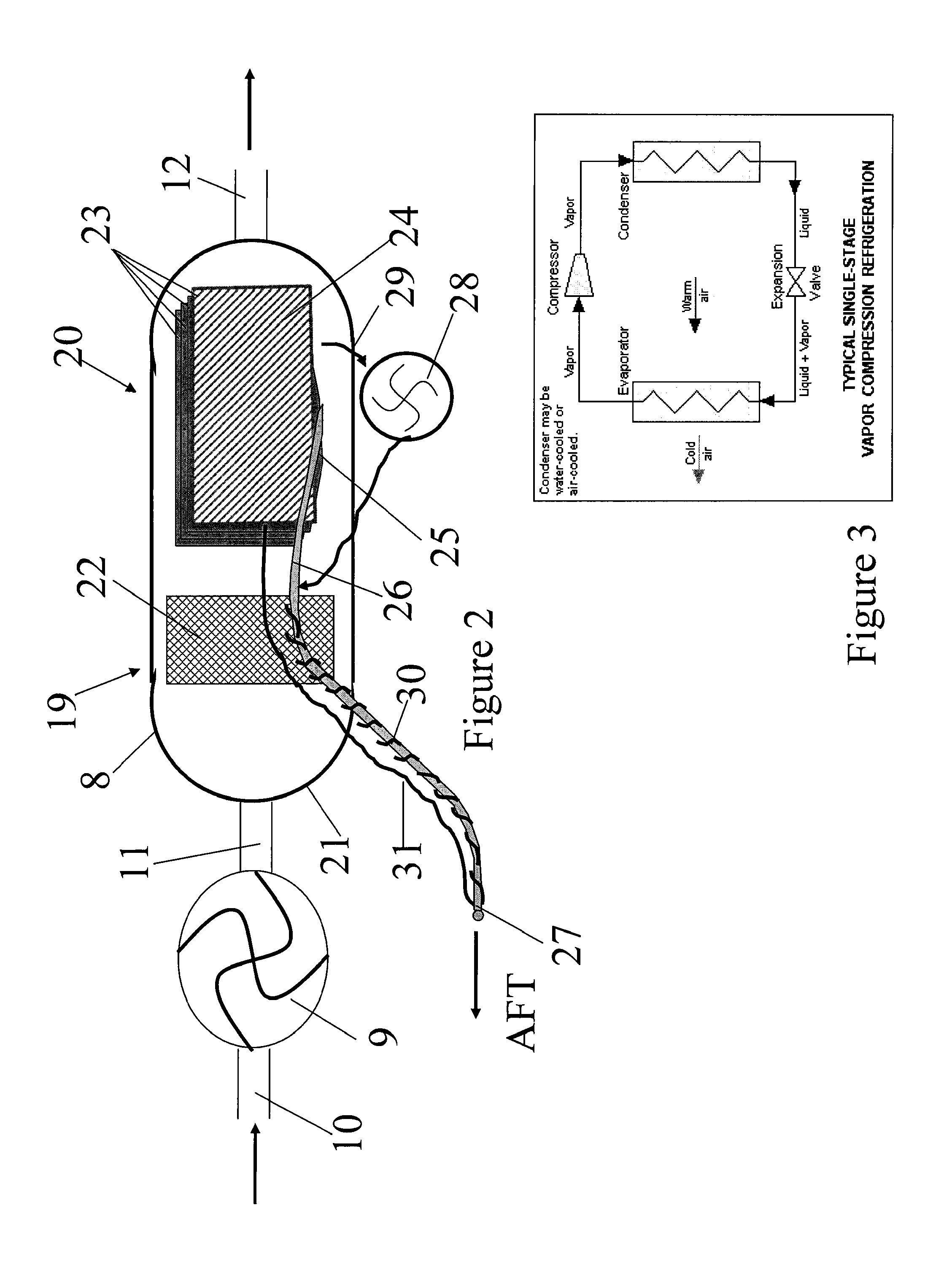

The invention discloses an environment-friendly inerting waste heat utilization system for a fuel tank. According to the principle, fuel vapor of an air-phase space of the upper portion of the fuel tank and an air mixture are subjected to flameless catalytic combustion in a catalytic oxidation reactor, carbon dioxide is generated, nitrogen which is not involved in reaction and carbon dioxide whichis generated during the reaction are used as mixed inert gas for inerting the fuel tank, and the fire-proof and explosion-proof aim is achieved. Gas waste heat is used for driving a refrigeration system, a low-temperature cooling medium is obtained and can be used for further cooling gas after the reaction, water is separated out as much as possible, and the medium can also cool a control subsystem. The environment-friendly inerting waste heat utilization system for the fuel tank has the advantages of being high in energy utilization rate, short in inerting time, capable of optimizing the performance of an inerting system and causing no environmental pollution and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com