Helicopter temperature regulation and oil tank explosion-proof system

A technology of temperature regulation and explosion-proof system, which is applied in the direction of fuel tank safety measures, aircraft parts, air treatment equipment, etc. It can solve the problems of hollow airborne fiber membrane inertization, large total system mass, and large compensatory load, etc., and achieve light weight , high coefficient of performance, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

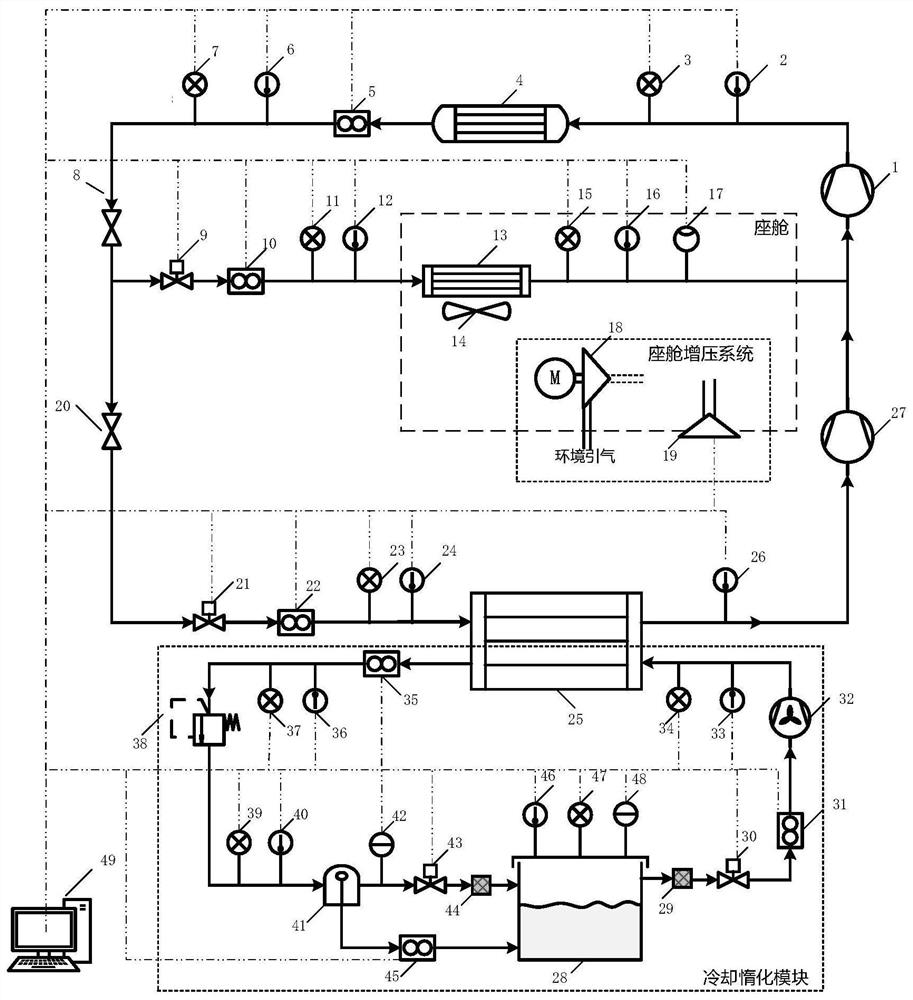

[0022] The invention adopts the coupling mode of two-stage airborne evaporative cycle refrigeration and inert gas phase space on the upper part of the cooling oil tank to realize the temperature adjustment of the helicopter and the explosion-proof of the oil tank. Such as figure 1 As shown, the two-stage evaporative refrigeration cycle system mainly includes a first-stage compressor 1, a second-stage compressor 27, a condenser 4, a first-stage expansion valve 8, a second-stage expansion valve 20, a first-stage evaporator 13 and The second-stage evaporator 25; the cooling oil-gas inertization module mainly includes an air extractor 32, a second-stage evaporator 25, a pressure regulating valve, an oil separator, an oil tank and two solenoid valves; the cockpit module includes a fan 14, an electric compressor 18 and exhaust valve 19. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com