Pressurization and dehumidification device for cabin of marine wind turbine generator system

A technology for wind turbines and nacelles, which is used in wind turbines, wind turbine monitoring, wind power generation, etc., can solve problems such as damage to metal parts, corrosion of metal parts, and reduction of service life, so as to reduce air humidity, increase internal pressure, The effect of preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

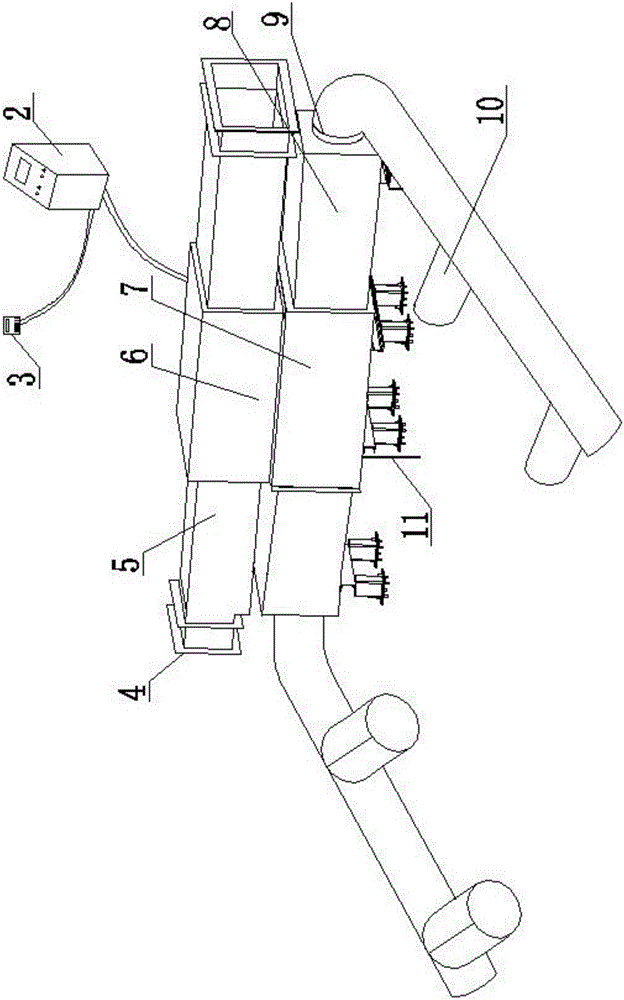

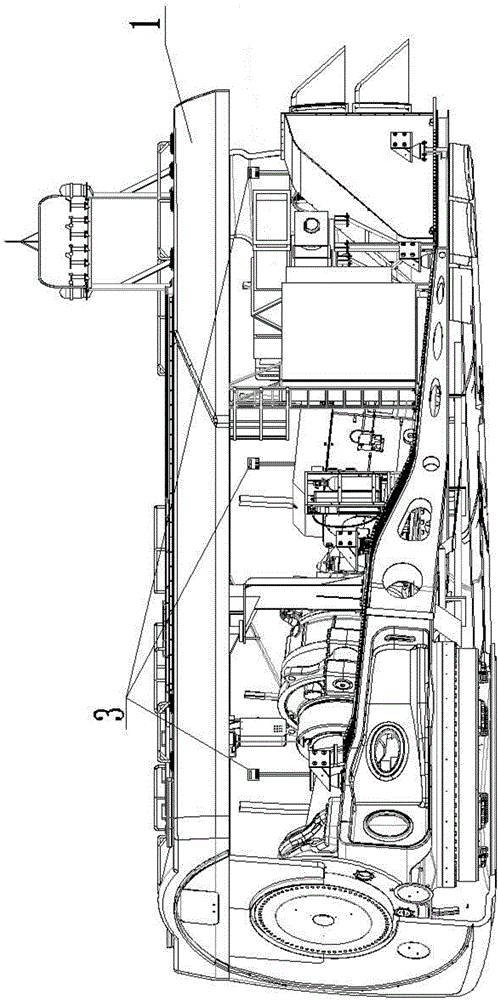

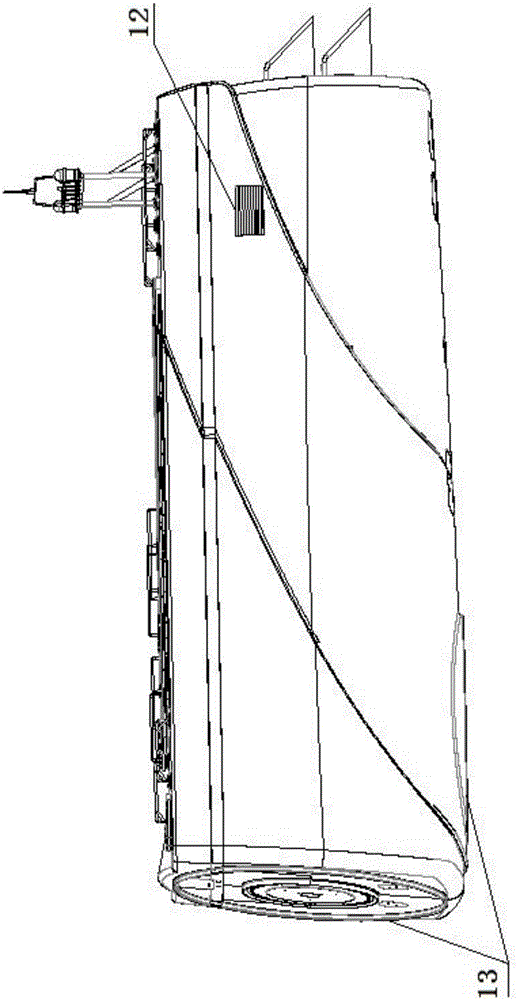

[0026] Embodiment 1, with reference to figure 1 , figure 2 and image 3 , a kind of pressurization and dehumidification device for the nacelle of an offshore wind power generating set is characterized in that it includes a booster pump 6 and a heat exchanger 7 arranged in the nacelle cover 1, a PLC 2 and a device for detecting and collecting pressure and humidity signals in the nacelle cover The sensor 3 of the booster pump is connected with the heat exchanger through the air pipeline, and a suction pipe 5 is arranged on the side of the booster pump, and the suction port 4 of the suction pipe is connected with the air intake port 4 provided on the outer wall of the nacelle cover. The tuyeres are connected, and an exhaust pipe 8 is arranged on the side of the heat exchanger. The exhaust port 9 of the exhaust pipe is arranged inside the nacelle cover, and a drain pipe 11 leading to the outside of the nacelle cover is arranged at the bottom of the heat exchanger. , the booster...

Embodiment 2

[0027] Embodiment 2, in the pressurization and dehumidification device for the nacelle of an offshore wind power generating set described in Embodiment 1: the suction pipes are arranged symmetrically on both sides of the booster pump, one on each side.

Embodiment 3

[0028] Embodiment 3, in the pressurization and dehumidification device for the nacelle of an offshore wind power generating set described in Embodiment 1 or 2: the exhaust pipes are arranged symmetrically on both sides of the heat exchanger, one on each side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com