Forming method of polyvinyl chloride physical foam board

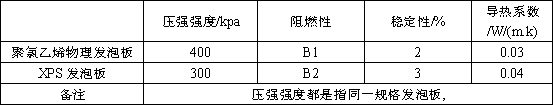

A polyvinyl chloride and physical foaming technology, applied in the field of plastic sheet manufacturing, can solve the problems of unstable product quality and difficulty in foaming, and achieve the effects of easy control of foaming ratio, low production cost, and fine and uniform cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

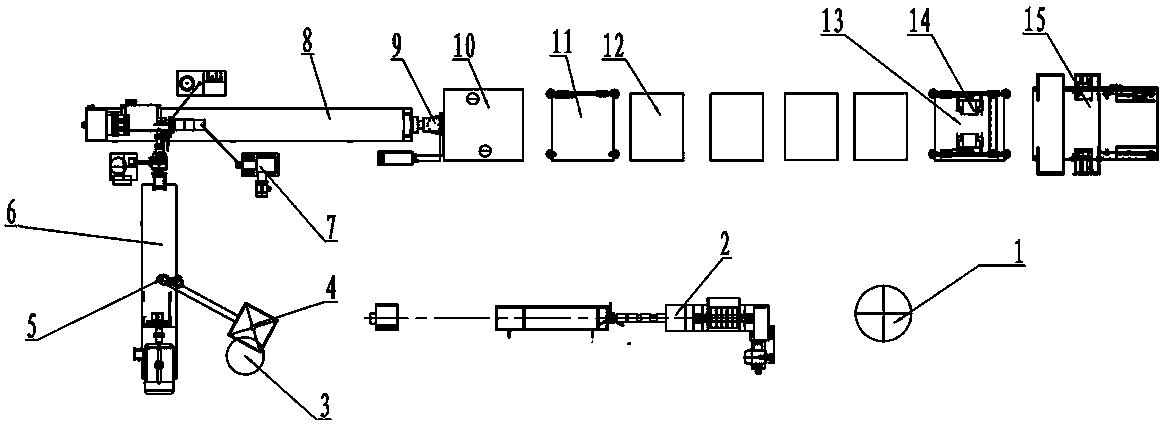

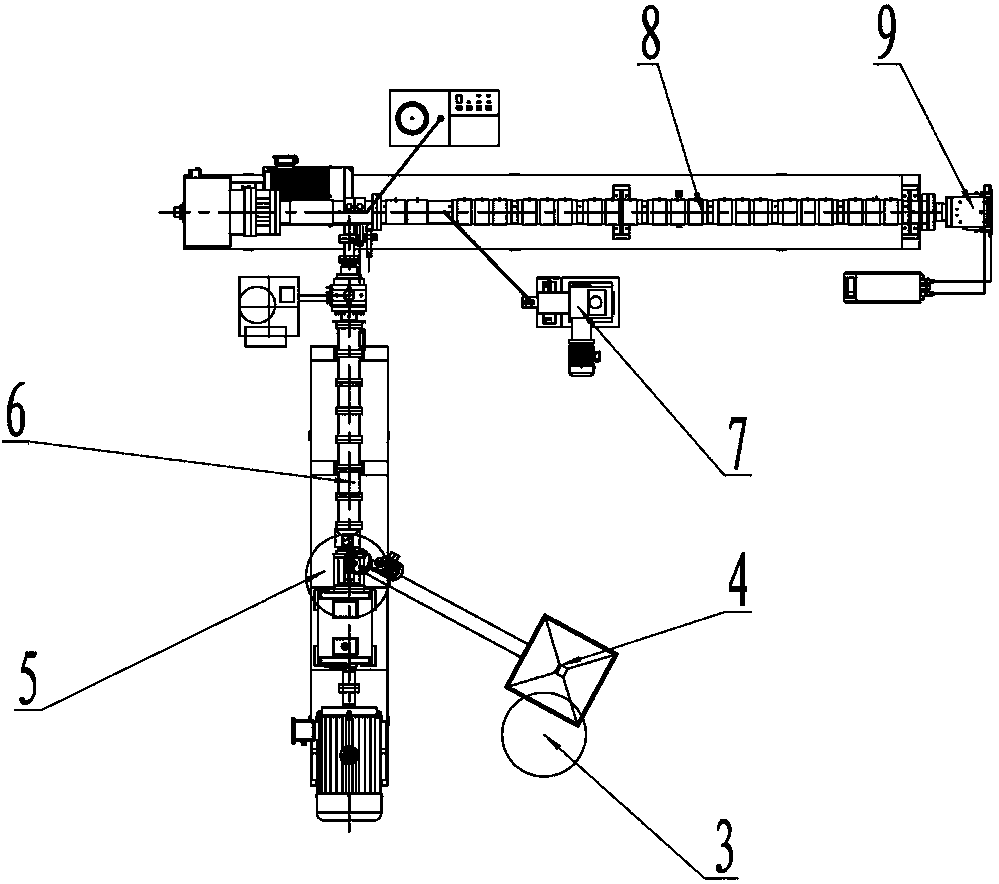

[0030] 1. Add 225 kg of polyvinyl chloride, 245 kg of polystyrene, 5 kg of copolymer of styrene and caprolactone, 25 kg of lead salt stabilizer to mixer 1 and mix evenly, then transfer the mixture to granulation Carry out granulation in machine 2;

[0031] 2. Put the material granules together with 2.5 kg of talcum powder, 1.5 kg of color masterbatch and 15 kg of hexabromocyclododecane flame retardant into the mixer 3 for mixing, and the mixture is automatically sent to the first stage through the feeder 4 Extruder 6 hopper 5;

[0032] 3. The mixed material in the hopper 5 is uniformly heated, melted and plasticized by the high-pressure screw in the primary extruder 6 through nine heating zones. The third zone is 180°C, the fourth zone is 180°C, the fifth zone is 170°C, the sixth zone is 170°C, the seventh zone is 170°C, the eighth zone is 170°C, and the ninth zone is 160°C. Inject 25 kg of environmentally friendly freon to fully mix it with the molten material, filter and r...

Embodiment 2

[0036] 1. Add 325 kg of polyvinyl chloride, 145 kg of polystyrene, copolymer of styrene and caprolactone, copolymer of benzene and methyl methacrylate, graft copolymer and embedded A total of 5 kg of the mixture of segment copolymers, a total of 25 kg of the mixture of lead salt stabilizer, organoolefin stabilizer, toughening agent ACR and antioxidant 1010 are mixed uniformly and then the mixture is transferred to the granulator 2 for making grain;

[0037] 2. Add a total of 20 kg of material granules, talcum powder, calcium carbonate, zinc stearate, 10 kg of color masterbatch and 50 kg of hydroxide flame retardant into the mixer 3 and mix them. The feeder 4 is automatically sent into the primary extruder 6 hopper 5;

[0038] 3. The mixed material in the hopper 5 is uniformly heated, melted and plasticized by the high-pressure screw in the primary extruder 6 through nine heating zones. The third zone is 180°C, the fourth zone is 180°C, the fifth zone is 170°C, the sixth zone...

Embodiment 3

[0042] 1. Add 275 kg of polyvinyl chloride, 195 kg of polystyrene, 5 kg of graft copolymer and block copolymer mixture, 25 kg of lead salt stabilizer and organic vinyl stabilizer mixture in mixer 1 and mix After being uniform, the mixture is transferred to the granulator 2 for granulation;

[0043] 2. Add 10 kg of material granules together with the mixture of calcium carbonate and zinc stearate, 5 kg of color masterbatch and 30 kg of hexabromocyclododecane flame retardant into the mixer 3 and mix them. The machine 4 is automatically sent into the first-level extruder 6 hopper 5;

[0044] 3. The mixed material in the hopper 5 is uniformly heated, melted and plasticized by the high-pressure screw in the primary extruder 6 through nine heating zones. The third zone is 180°C, the fourth zone is 180°C, the fifth zone is 170°C, the sixth zone is 170°C, the seventh zone is 170°C, the eighth zone is 170°C, and the ninth zone is 160°C. Inject a total of 75 kg of carbon dioxide and b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com