Inorganic-filler-filled high-temperature-resistant foam material and preparation method thereof

A technology of foam materials and inorganic fillers, which is applied in the field of flame-retardant polymer foam materials and heat resistance, and can solve the problems of destroying the ozone layer of the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

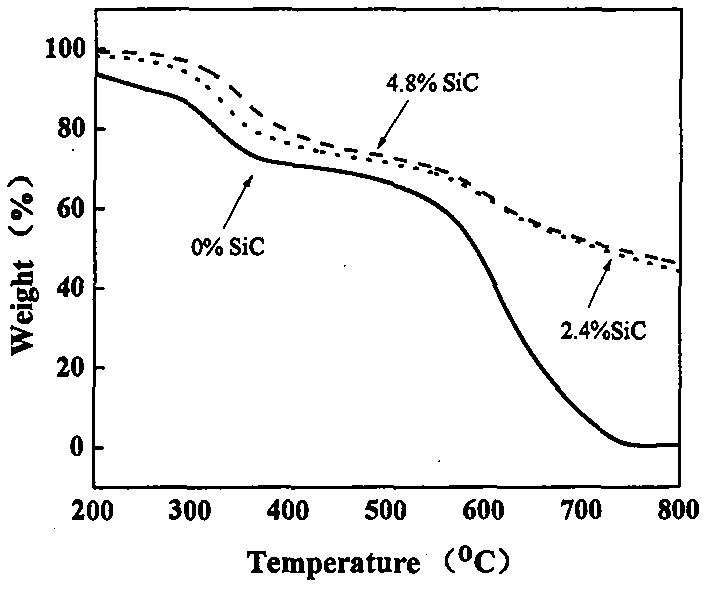

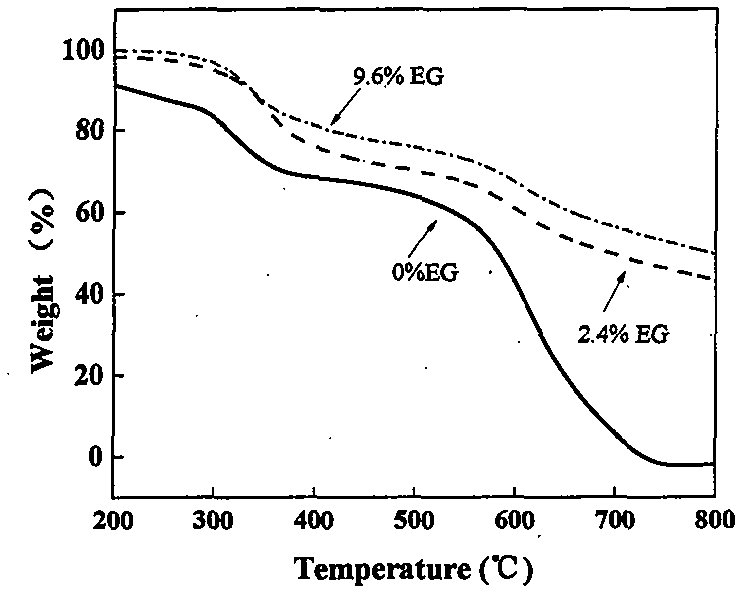

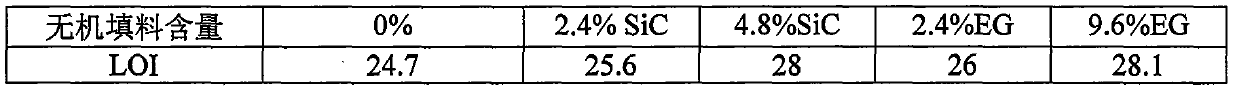

[0020] First, mix 30 parts of pyromellitic anhydride, 30 parts of dimethylformamide, 1 part of catalyst and 90 parts of isocyanate to obtain solution A. Put 17 parts of polyether polyol, 3 parts of water, 3 parts of silicone surfactant, and 5 parts of silicon carbide (about 2.4% of the whole) into the reaction vessel and stir at high speed to obtain solution B at a stirring speed of 2000r / min; The time is 2 minutes. Mix solution A and solution B and stir at high speed until uniform and free foaming. The stirring speed is 2000r / min. The stirring time was 30 seconds. The resulting material is placed in an oven for heat treatment. The heat treatment temperature is 250° C., and the heat treatment time is 2 hours to obtain a high temperature resistant composite foam filled with inorganic particles.

Embodiment 2

[0022] First, mix 30 parts of pyromellitic anhydride, 30 parts of dimethylformamide, 1 part of catalyst and 90 parts of isocyanate to obtain solution A. Put 17 parts of polyether polyol, 3 parts of water, 3 parts of silicone surfactant, and 10 parts of silicon carbide (about 4.8% of the whole) into a reaction vessel and stir at a high speed to obtain solution B. The stirring speed is 2000r / min and the stirring time is for 2 minutes. Mix solution A and solution B and stir at high speed until uniform and free foaming. The stirring speed is 2000r / min. The stirring time was 30 seconds. The resulting material is placed in an oven for heat treatment. The heat treatment temperature is 250° C., and the heat treatment time is 2 hours to obtain a high temperature resistant composite foam filled with inorganic particles.

Embodiment 3

[0024] First, mix 30 parts of pyromellitic anhydride, 30 parts of dimethylformamide, 1 part of catalyst and 90 parts of isocyanate to obtain solution A. Put 17 parts of polyether polyol, 3 parts of water, 3 parts of silicone surfactant, and 15 parts of silicon carbide (accounting for about 7.2% of the whole) into a reaction vessel and stir at high speed to obtain solution B at a stirring speed of 2000r / min; The time is 2 minutes. Mix solution A and solution B and stir at high speed until uniform and free foaming. The stirring speed is 2000r / min. The stirring time was 30 seconds. The resulting material is placed in an oven for heat treatment. The heat treatment temperature is 250° C., and the heat treatment time is 2 hours to obtain a high temperature resistant composite foam filled with inorganic particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com