An easy-to-dissipate large-capacity power cable

A power cable and high load technology, applied in the field of power cables with easy heat dissipation and high current carrying capacity, can solve the problems of changes in the performance of the insulating layer, easy combustion, poor structural stability, etc. The effect of flame expansion burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

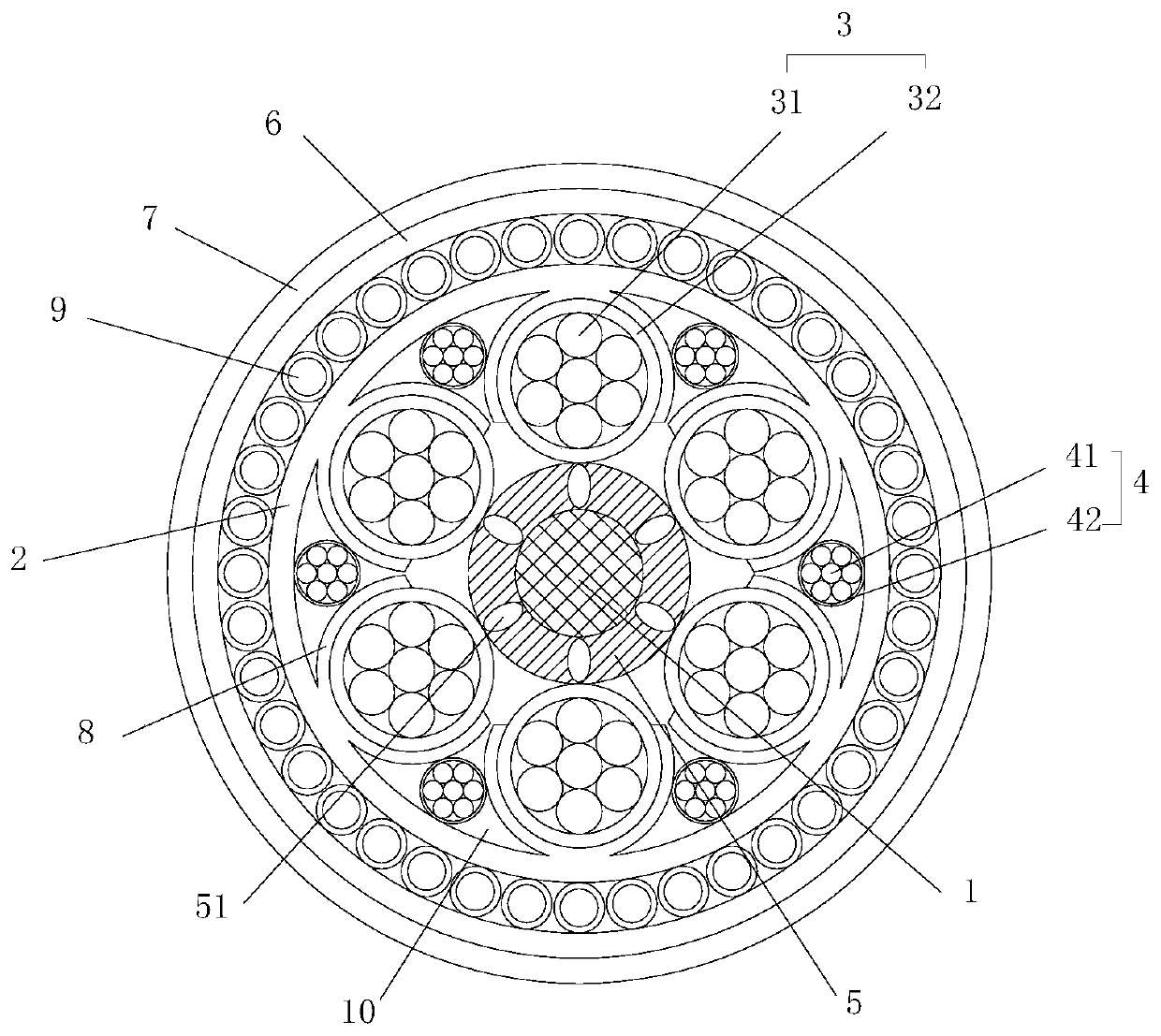

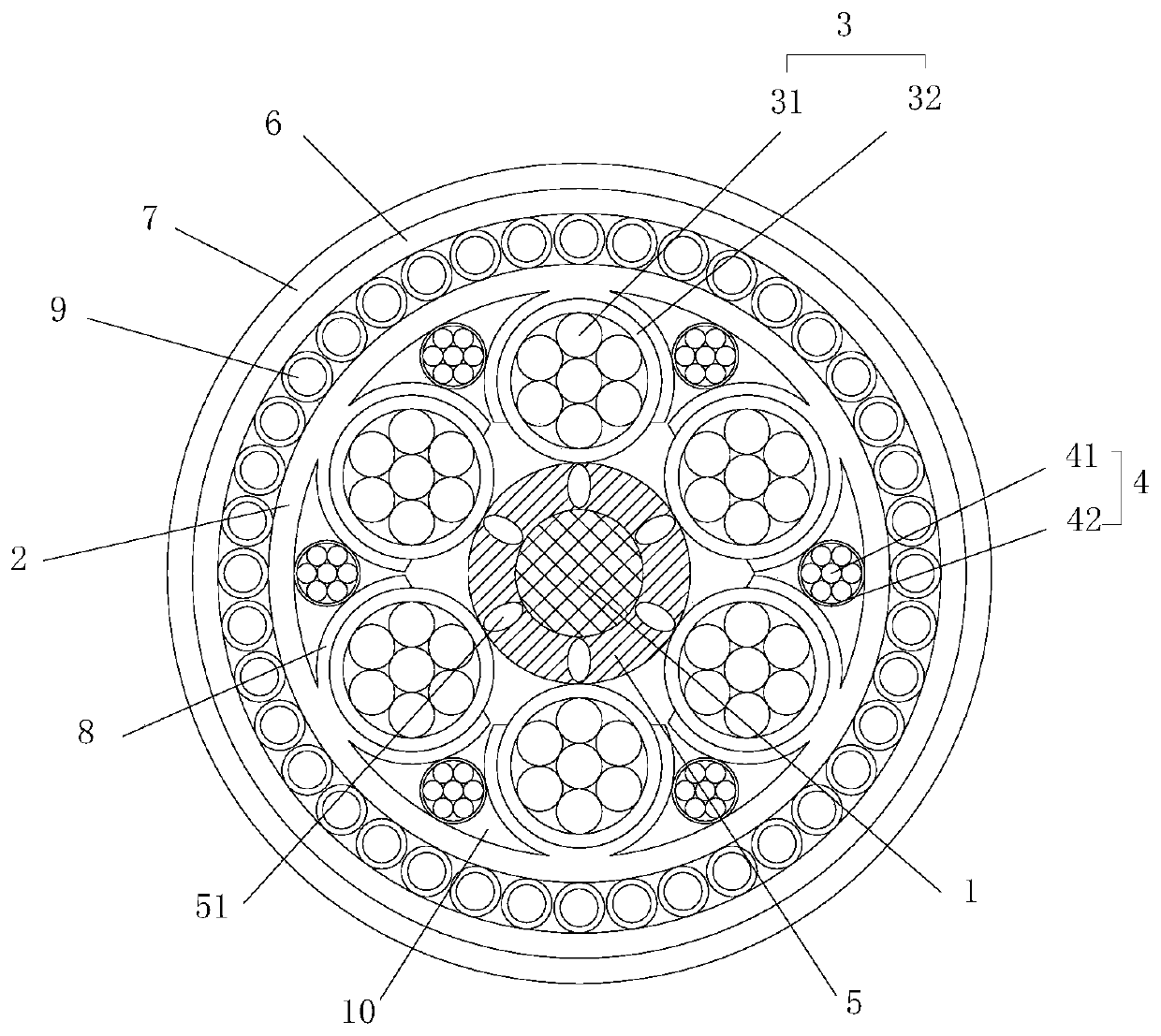

[0020] refer to figure 1 , the present invention proposes an easy-to-dissipate large-capacity power cable, including a central support core 1, an inner support tube 2, six first cores 3, and six second cores 4, wherein:

[0021] The central support core 1 is made of hard material, and the central support core 1 is located at the center of the cable. The central support core 1 is covered with a flame-retardant elastic tube 5, and inside the flame-retardant elastic tube 5 are distributed a plurality of cables extending axially. The cavity 51 has an elliptical cross-section and the long axis of the cavity 51 is arranged radially along the cable, and the cavity 51 is filled with coolant.

[0022] The inner support tube 2 is arranged on the outside of the central support core 1, and the outside of the inner support tube 2 is wrapped with a wrapping layer 6 and a sheath layer 7 in turn, and a plurality of hollow tubes 9 are arranged between the inner support tube 2 and the wrapping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com