Fluorosilicone membrane for high-salt wastewater treatment and preparation method thereof

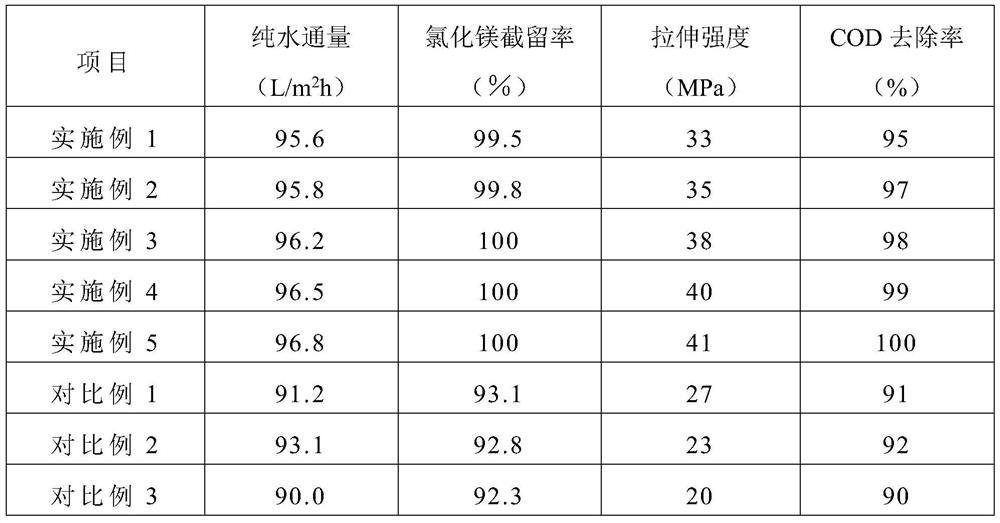

A high-salt wastewater, fluorosilicon technology, applied in permeation/dialysis water/sewage treatment, chemical instruments and methods, membranes, etc., can solve the problem of low water flux and salt removal rate, poor corrosion resistance, complex preparation process, etc. To achieve the effect of improving the salt removal rate, stable membrane performance and excellent mechanical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a fluorosilicon membrane for high-salt wastewater treatment, comprising the steps of:

[0029] Ⅰ Preparation of fluorosilicone polymer: Bis(4-aminophenoxy)dimethylsilane 18.8g, 2,2-bis(4-carboxyphenyl)hexafluoropropane 10g, 1-ethyl-(3- Dimethylaminopropyl) carbodiimide hydrochloride 3g, 2g of 4-dimethylaminopyridine are dissolved in dimethyl sulfoxide 100g to form a solution, then the solution is added in the reaction kettle, and the air in the kettle is replaced with nitrogen, usually Press down at 75°C for 2 hours, then raise the temperature to 110°C for 2 hours, then raise the temperature to 220°C, conduct the primary polycondensation reaction for 4 hours, then evacuate to 500Pa, heat to 235°C, then conduct the polycondensation reaction for 8 hours, and then cool to room temperature , adjusted to normal pressure, precipitated in water, washed the precipitated polymer three times with ethanol, and then dried in a vacuum oven at 70°C for 10 hours...

Embodiment 2

[0034]A method for preparing a fluorosilicon membrane for high-salt wastewater treatment, comprising the steps of:

[0035] Ⅰ Preparation of fluorosilicone polymer: Bis(4-aminophenoxy)dimethylsilane 18.8g, 2,2-bis(4-carboxyphenyl)hexafluoropropane 10g, 1-ethyl-(3- 4g of dimethylaminopropyl) carbodiimide hydrochloride, 2.3g of 4-dimethylaminopyridine are dissolved in 110g of N,N-dimethylformamide to form a solution, then the solution is added to the reaction kettle, and the Replace the air in the kettle with air, react at 79°C under normal pressure for 2.3 hours, then raise the temperature to 113°C for 2.3 hours, then raise the temperature to 223°C, perform the primary polycondensation reaction for 4.5 hours, then vacuumize to 500Pa, heat to 237°C, and then conduct the polycondensation reaction After 8.5 hours, cool to room temperature, adjust to normal pressure, precipitate in water, wash the precipitated polymer with ethanol 4 times, and then dry in a vacuum oven at 73°C for ...

Embodiment 3

[0040] A method for preparing a fluorosilicon membrane for high-salt wastewater treatment, comprising the steps of:

[0041] Ⅰ Preparation of fluorosilicone polymer: Bis(4-aminophenoxy)dimethylsilane 18.8g, 2,2-bis(4-carboxyphenyl)hexafluoropropane 10g, 1-ethyl-(3- 5 g of dimethylaminopropyl) carbodiimide hydrochloride, 2.5 g of 4-dimethylaminopyridine are dissolved in 130 g of N-methylpyrrolidone to form a solution, then the solution is added to the reactor, and the reactor is replaced with neon gas Air, react at 80°C for 2.6 hours under normal pressure, then raise the temperature to 115°C for 2.6 hours, then raise the temperature to 225°C, perform the primary polycondensation reaction for 5 hours, then vacuumize to 500Pa, heat to 241°C, and then polycondense for 9 hours, then Cool to room temperature, adjust to normal pressure, precipitate in water, wash the precipitated polymer with ethanol 4 times, and then dry in a vacuum oven at 76°C for 13 hours to obtain a fluorosilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com