Method for preparing high-temperature-rusistance water-expansible rubber

A water-swellable rubber and high-temperature-resistant technology, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor temperature resistance, and achieve the effects of low equipment requirements, simple process, and controllable expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

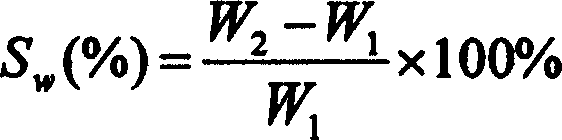

Embodiment 1

[0022] Add 2 g of acrylic acid, 4 g of sodium acrylate, 2 g of acrylamide, 2 g of 2-acrylamido-2-methylpropanesulfonic acid, 0.2 g of diethylene glycol diacrylate, 50 ml of toluene, and 1 g of Span-80 In the reactor, the temperature was raised to 75°C under constant stirring, and the initiator potassium persulfate was added dropwise for copolymerization reaction for 3 hours, filtered, washed and dried with methanol to obtain water-absorbent resin powder, and then 100 parts of nitrile rubber, 30 parts of water-absorbent resin powder , 5 parts of zinc oxide, 2 parts of sulfur, 1 part of anti-aging agent, 20 parts of carbon black, and 2.5 parts of accelerator are blended and vulcanized on an open mill to obtain water-swellable rubber in the range of 25°C to 150°C. Weigh 8 grams of the water-swellable rubber and 80 grams of deionized water, put them into an autoclave, seal it, heat the autoclave to 150°C and keep it warm for 3 days, then quickly lower it to room temperature, take o...

Embodiment 2

[0024] 2.5 g of acrylic acid, 3 g of sodium acrylate, 3 g of acrylamide, 1.5 g of 3-acrylamidopropyltrimethylammonium chloride (APTAC), 0.1 g of N,N'-methylenebisacrylamide, 50 mL of solvent Add cyclohexane and 1 gram of Span-60 into the reactor, raise the temperature to 60°C under constant stirring, add the initiator potassium persulfate dropwise for 4 hours of copolymerization reaction, filter, wash and dry with methanol to obtain water-absorbent resin powder, and then 100 parts Nitrile rubber, 30 parts of water-absorbing resin powder, 5 parts of zinc oxide, 2 parts of sulfur, 1 part of anti-aging agent, 20 parts of carbon black, 2.5 parts of accelerator are blended on an open mill and vulcanized at 25°C to 150°C Water-swellable rubber within the range. Weigh 8 grams of the water-swellable rubber and 80 grams of deionized water, put them into an autoclave, seal it, heat the autoclave to 150°C and keep it warm for 3 days, then quickly lower it to room temperature, take out th...

Embodiment 3

[0026] 3 g of acrylic acid, 3.5 g of sodium acrylate, 1.5 g of acrylamide, 2 g of methacrylamidopropyltrimethylammonium chloride (MPTMA), 0.3 g of N,N'-methylenebisacrylamide, 50 mL of solvent Cyclohexane and 1 gram of Span-60 were added to the reactor, and the temperature was raised to 85°C under constant stirring, and the initiator ammonium persulfate was added dropwise for a copolymerization reaction for 4 hours, filtered, washed and dried with methanol to obtain a water-absorbent resin powder, and then 100 parts Neoprene, 30 parts of water-absorbing resin powder, 1 part of stearic acid, 5 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of anti-aging agent, 30 parts of pottery clay are blended on an open mill and vulcanized at 25 ° C to 150 Rubber that can expand with water in the temperature range. Weigh 8 grams of the water-swellable rubber and 80 grams of deionized water, put them into an autoclave, seal it, heat the autoclave to 150°C and keep it warm for 3 days...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com