Plastic hot melting device for plastic solidification

A hot-melt device and plastic technology, applied in the field of hot-melt devices, can solve the problems of lack of technical means and economic ability to handle and dispose of hazardous waste, damage to the ecological environment and human health, global environmental hazards, etc. Quick discharge, avoid oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Plastic hot-melt work for single raw materials:

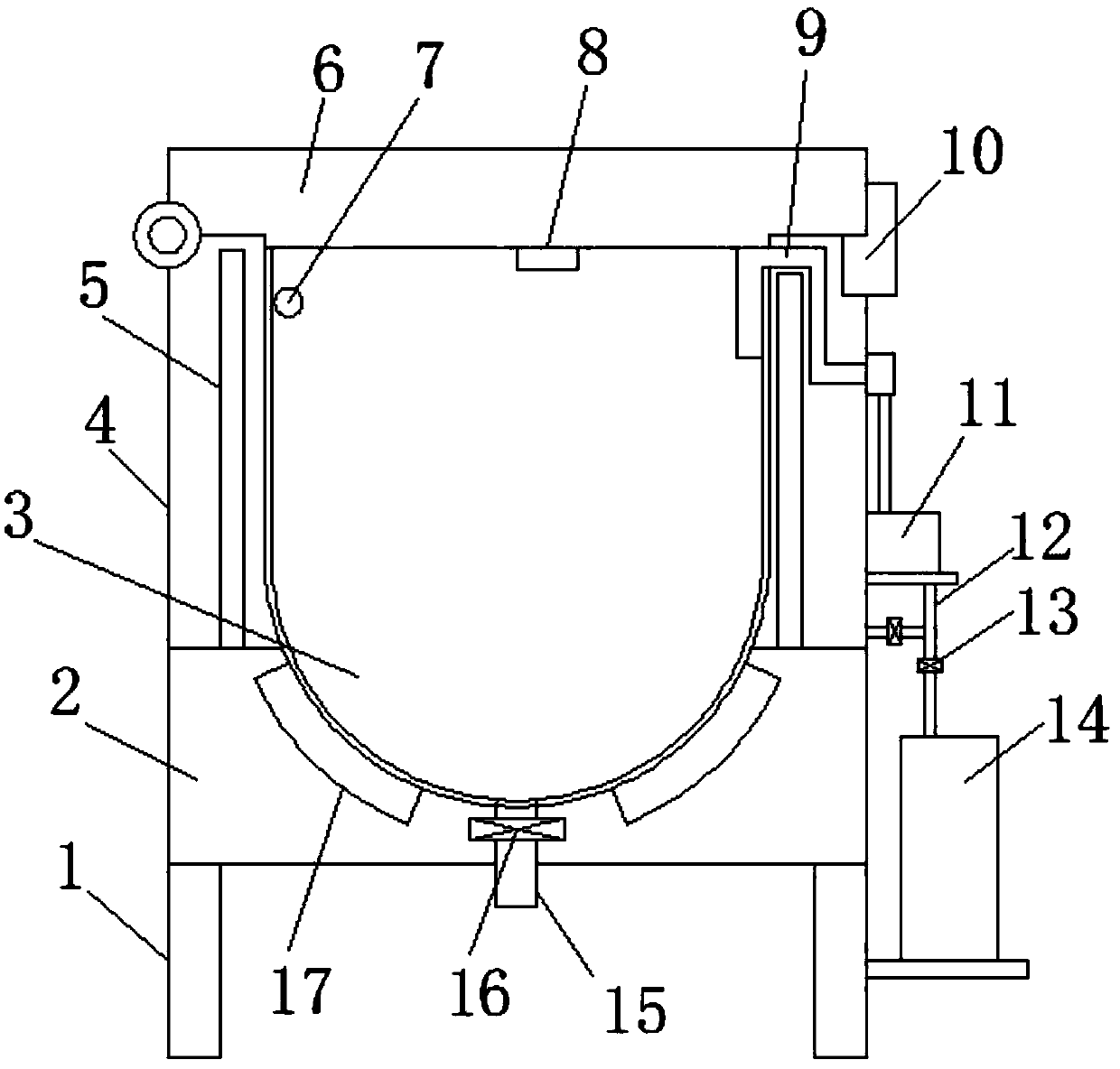

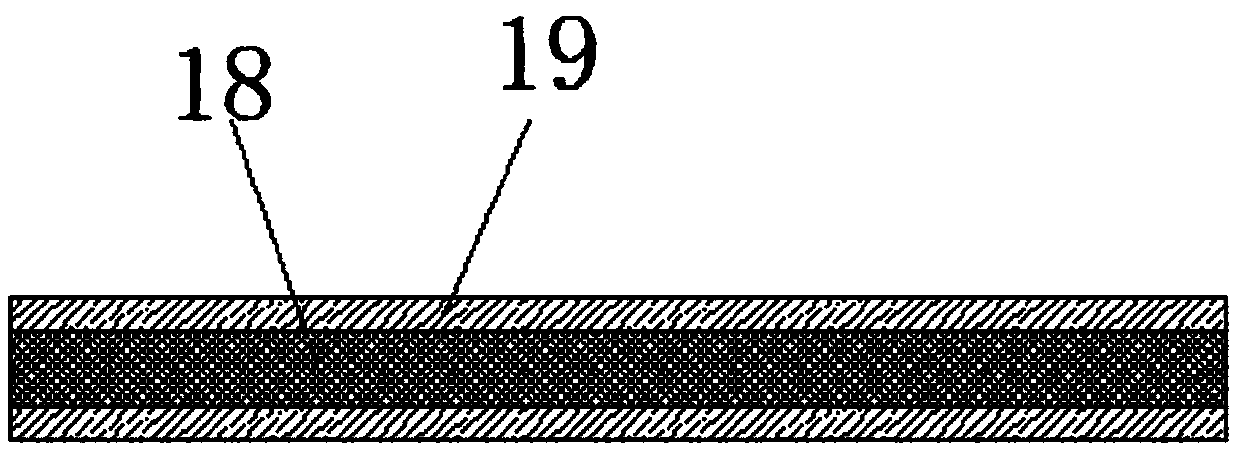

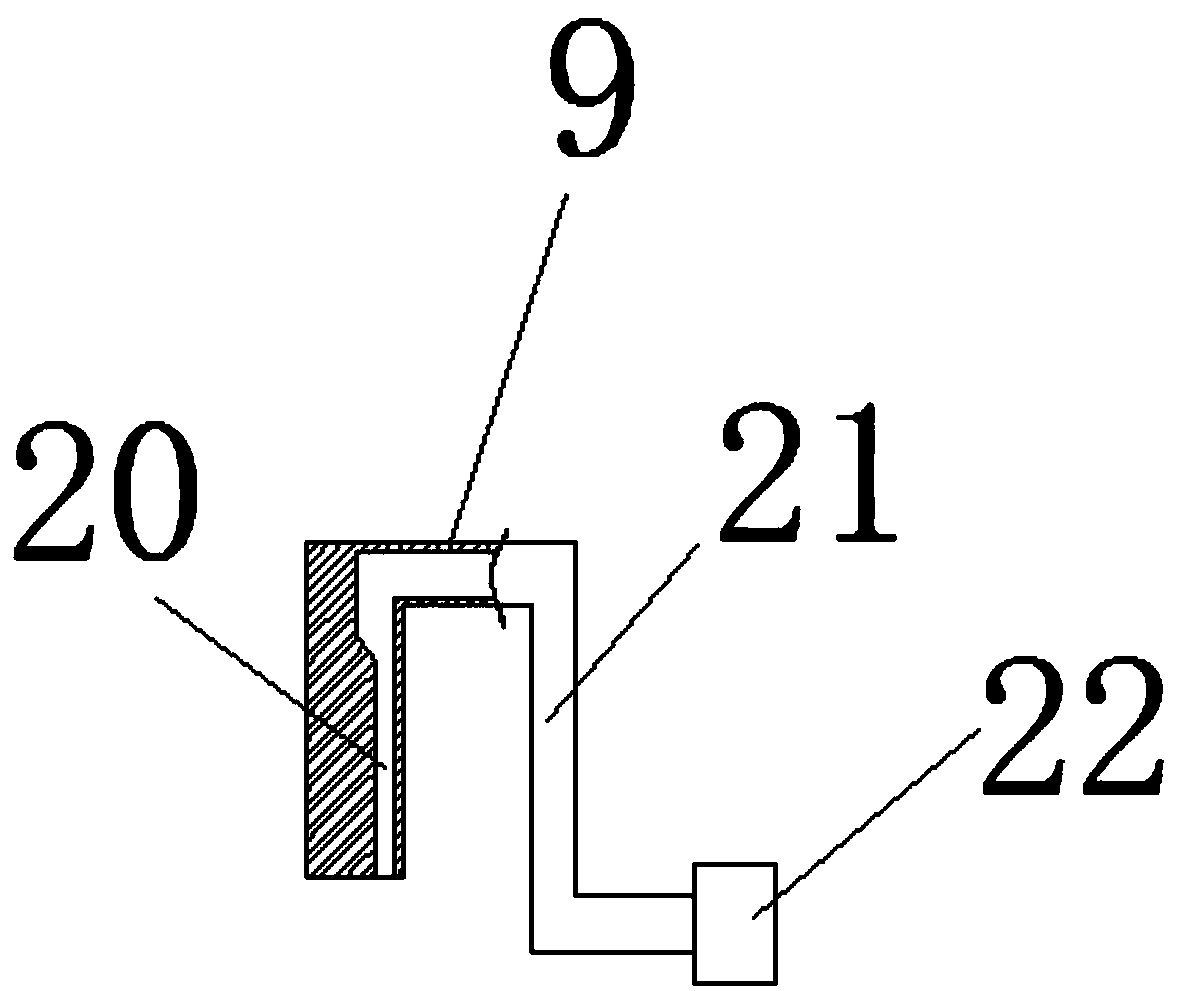

[0026] A plastic hot-melt device for plastic solidification, comprising a base 2 and an insulated box 4, the insulated box 4 is arranged on the base 2, a heat-melt kettle 3 is arranged inside the base 2 and the heat-insulated box 4, and the upper part of the hot-melt kettle 3 is Open structure, the lower part of the hot-melt kettle 3 is a hemispherical structure, the base 2 is provided with a hemispherical placement groove matching the lower part of the hot-melt kettle 3, and a heating device 17 is arranged in the placement groove, and the shape of the heating device 17 is the same as that of the lower part of the hot-melt kettle. Matching and close to the hot-melt kettle, the inner wall of the upper end of the hot-melt kettle 3 is provided with an air injection pipe 9, the air injection pipe 9 is connected to the air pump 11, and the air pump 11 is arranged on the outside of the insulation box 4, and the upper end of the...

Embodiment 2

[0029] Plastic hot-melt work for a variety of raw materials:

[0030]A plastic hot-melt device for plastic solidification, comprising a base 2 and an insulated box 4, the insulated box 4 is arranged on the base 2, a heat-melt kettle 3 is arranged inside the base 2 and the heat-insulated box 4, and the upper part of the hot-melt kettle 3 is Open structure, the lower part of the hot-melt kettle 3 is a hemispherical structure, the base 2 is provided with a hemispherical placement groove matching the lower part of the hot-melt kettle 3, and a heating device 17 is arranged in the placement groove, and the shape of the heating device 17 is the same as that of the lower part of the hot-melt kettle. Matching and close to the hot-melt kettle, the inner wall of the upper end of the hot-melt kettle 3 is provided with an air injection pipe 9, the air injection pipe 9 is connected to the air pump 11, and the air pump 11 is arranged on the outside of the insulation box 4, and the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com