Liquid cosmetic semi-finished product filtering device

A technology for liquid cosmetics and filter devices, which is applied in filtration separation, dispersed particle filtration, chemical/physical processes, etc., can solve problems such as inability to stir liquid cosmetics, uneven cosmetics, and reduced stirring effect, and improve mixing efficiency and stirring effect. Good, improve the effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

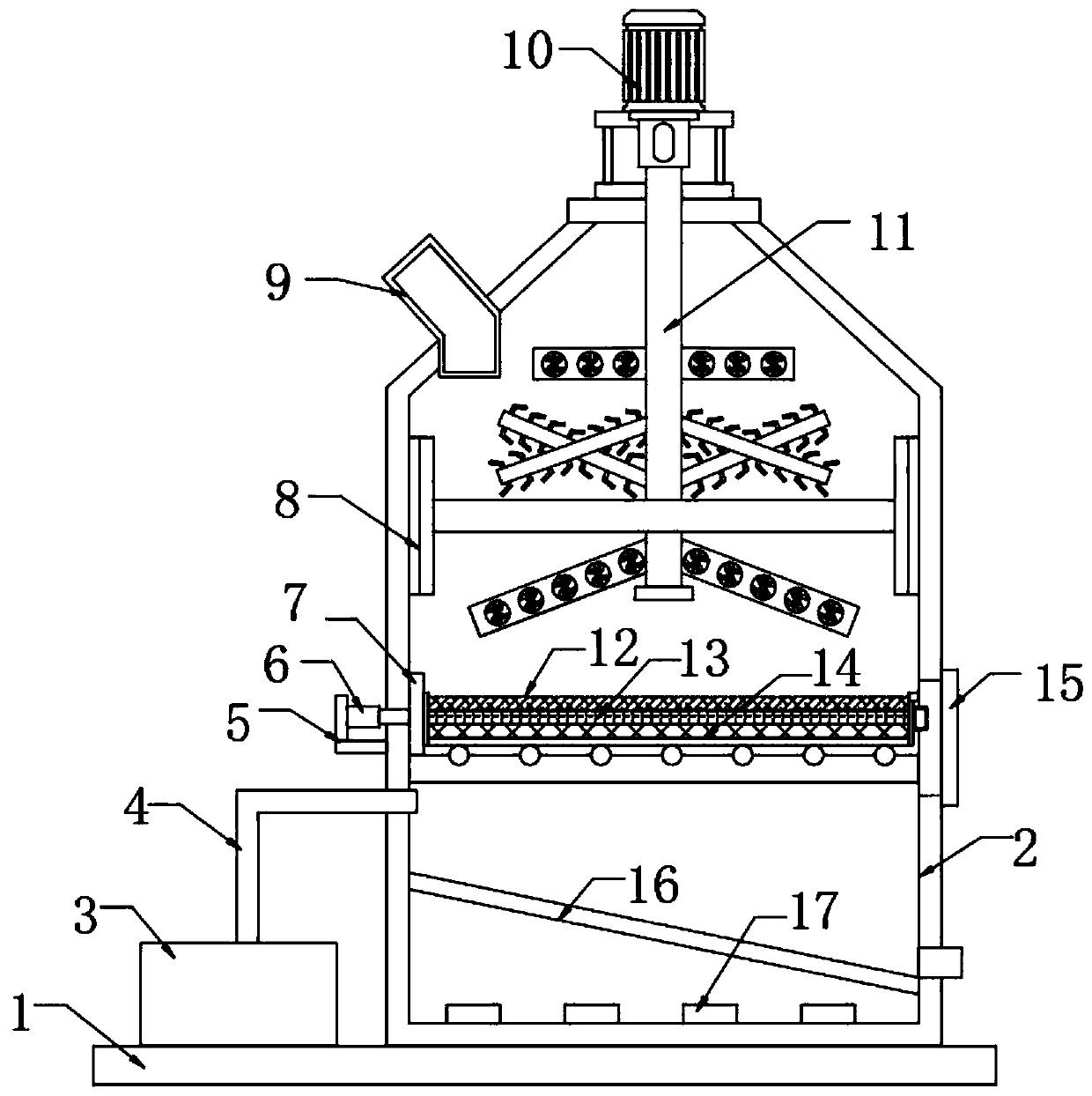

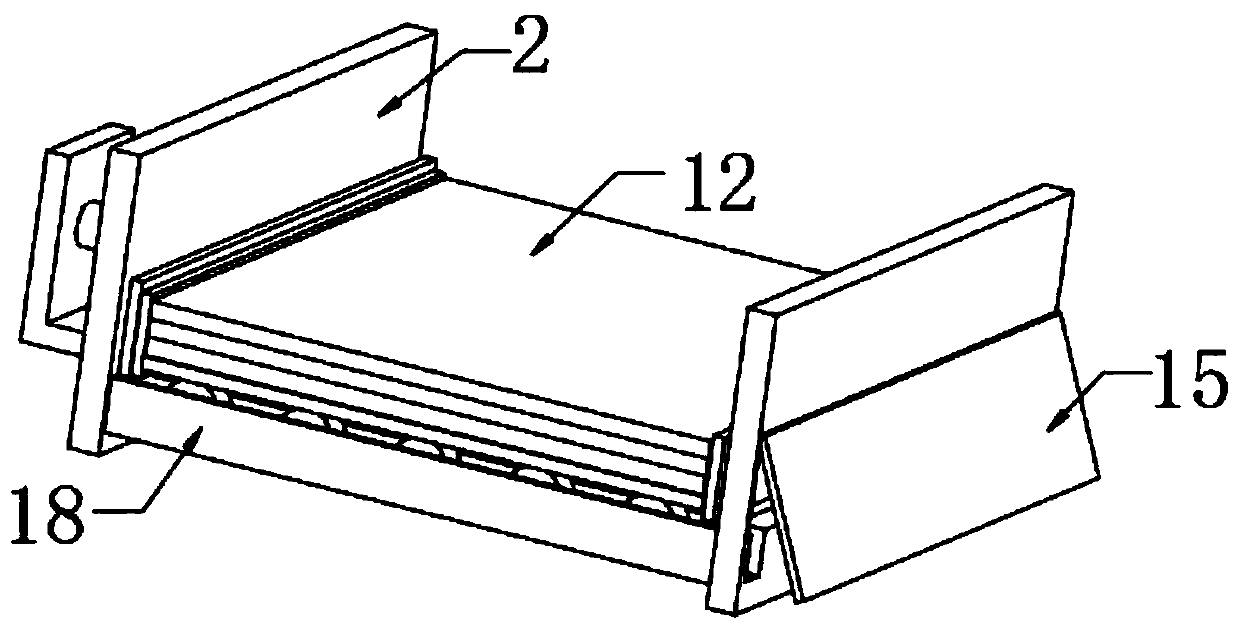

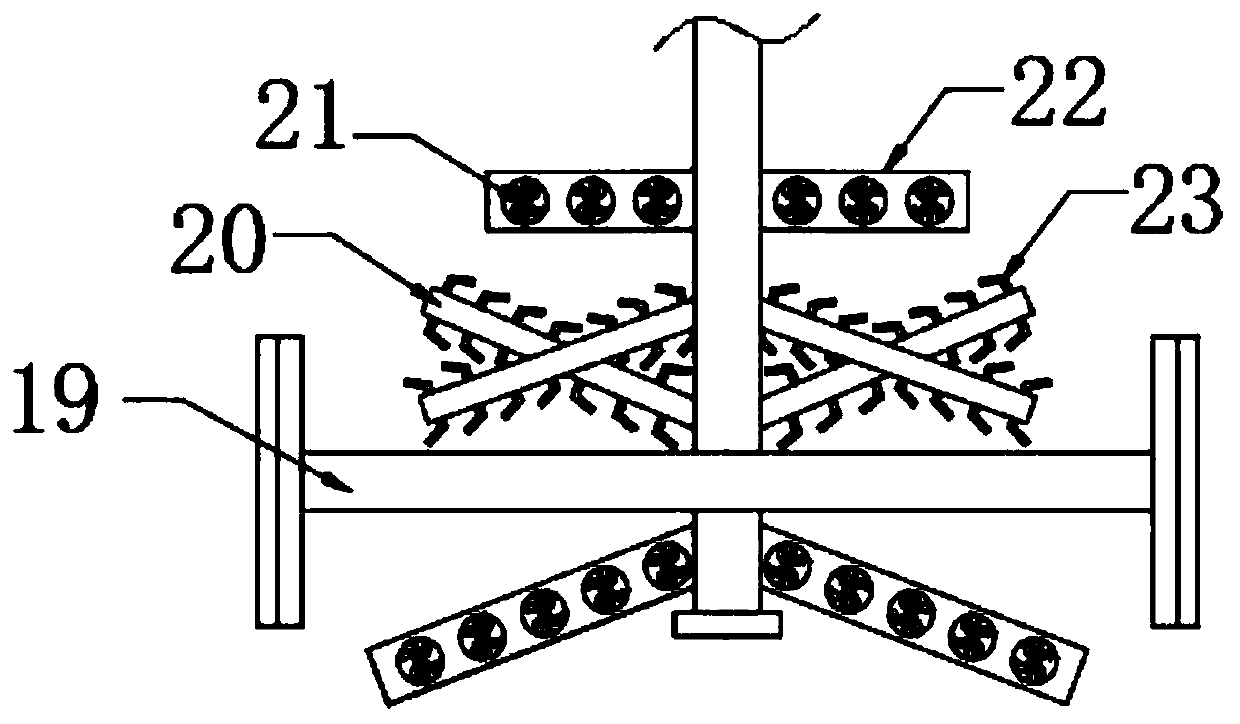

[0032] refer to Figure 1-5 , a semi-finished product filter device for liquid cosmetics, comprising a bottom plate 1, the top outer wall of the bottom plate 1 is fixed with a filter box 2 by screws, and an L-shaped fixing plate 5 is welded on one side of the filter box 2, and the top outer wall of the filter box 2 is screwed The motor 10 is fixed, and the output shaft of the motor 10 is connected to the rotating rod 11 through a coupling, and the outer wall of one side of the rotating rod 11 is welded with a stirring frame 22, and the inner wall of the stirring frame 22 is connected with equidistantly distributed stirring blades through bearings 21. X-shaped stirring rods 20 are welded on both sides of the outer wall of the rotating rod 11, and the outer wall of the X-shaped stirring rod 20 is welded with crushing knives 23 distributed equidistantly. The crushing knives 23 have an L-shaped structure. The same transparent sloping plate 16 is welded on the side.

[0033] In th...

Embodiment 2

[0036] refer to Image 6 , a liquid cosmetic semi-finished product filter device, also includes a support column 27 welded to the top outer wall of the filter box 2, the top outer wall of the support column 27 is fixed with a treatment box 28 by screws, and the inner wall of the treatment box 28 is equipped with a fourth filter screen 29 The same conduit 26 is connected with the activated carbon adsorption layer 30, one side inner wall of the filter box 2 and the bottom inner wall of the treatment box 28 through a flange.

[0037]Connect the device to the power supply, add liquid cosmetics from the feed port 9 to the filter box 2, turn on the motor 10, and the motor 10 drives the rotating rod 11 to rotate, and then the X-shaped stirring rod 20 and the stirring frame 22 can fully stir the cosmetics, The stirring blade 21 can rotate under the flow of the liquid during stirring, the crushing knife 23 crushes the agglomerated cosmetics, the scraper 8 can effectively prevent the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com