Rotary dual-workbench cantilever type laser cutting machine

A technology of laser cutting machine and double workbench, which is applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of lower processing efficiency, strange shape, and insufficient attention, and achieve equipment manufacturing cost saving and comprehensive efficiency The effect of perfect lifting and nesting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

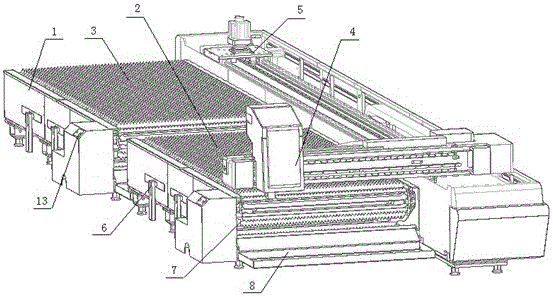

[0023] A rotary double table cantilever laser cutting machine, such as figure 1 , including frame 1, workbench one 2, workbench two 3, laser cutting assembly 4, host 5 for longitudinally moving laser cutting assembly 4, the side of host computer 5 is provided with workbench one 2, workbench two 3, working Table 1 2 and workbench 2 3 have the same structure and both adopt rotary workbench. Workbench 1 2 includes motor, driving roller, driven roller and chain plate conveyor belt. The chain plate conveyor belt surrounds the driving roller, driven roller, driving roller, The two ends of the driven roller are movably connected to the frame 1 through bearings respectively, the driving roller is connected to the rotating shaft of the motor, the frame 1 is provided with a limit switch 7, and the limit switch 7 is connected in series with the motor and the power supply in sequence. The sides of platform two 3 are provided with side storage boxes 6 respectively, and the ends of workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com