Epoxy polyester powder coating production equipment and production process thereof

A technology for powder coatings and production equipment, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of inconvenient adjustment of powder coating particle size and high production costs, and achieve improved production discharge effect and reasonable structure , Improve the effect of production nesting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

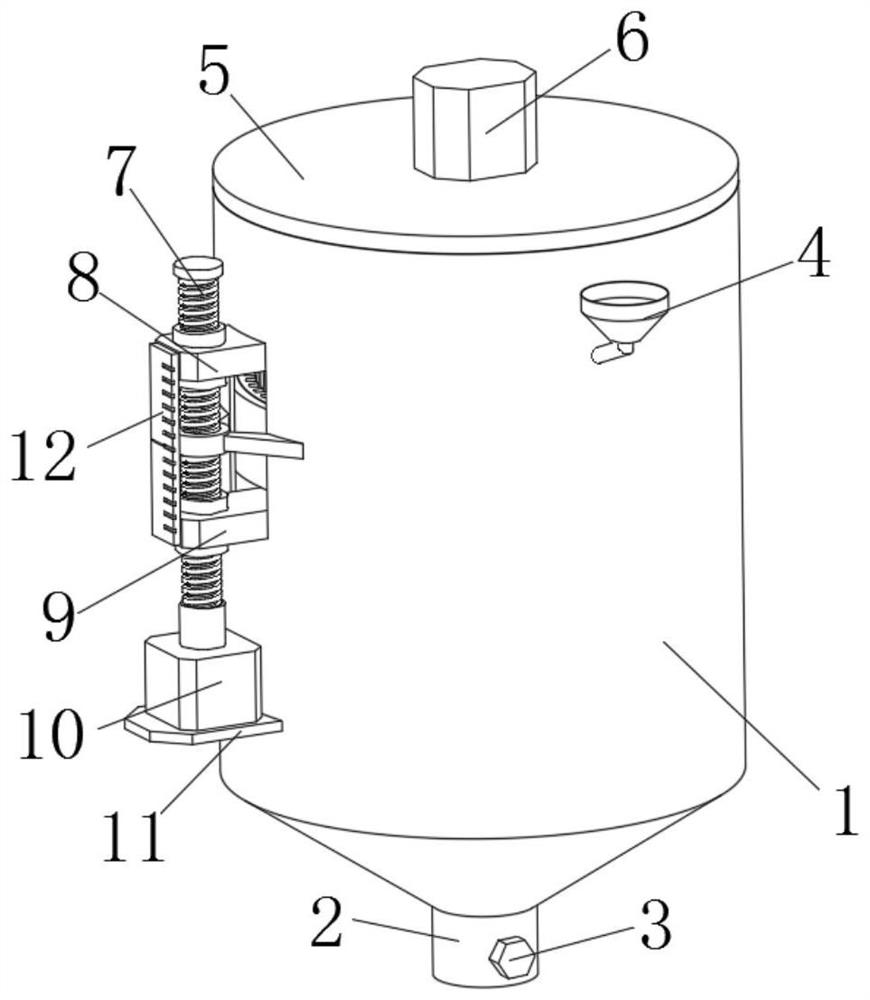

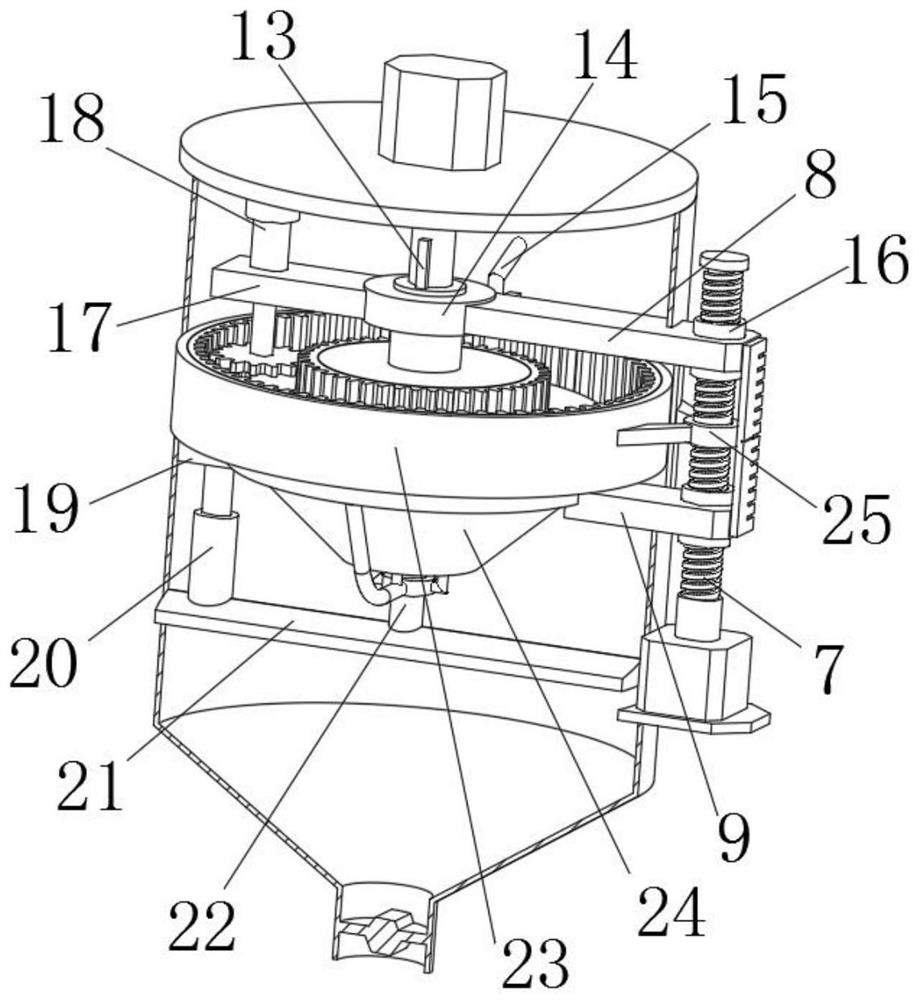

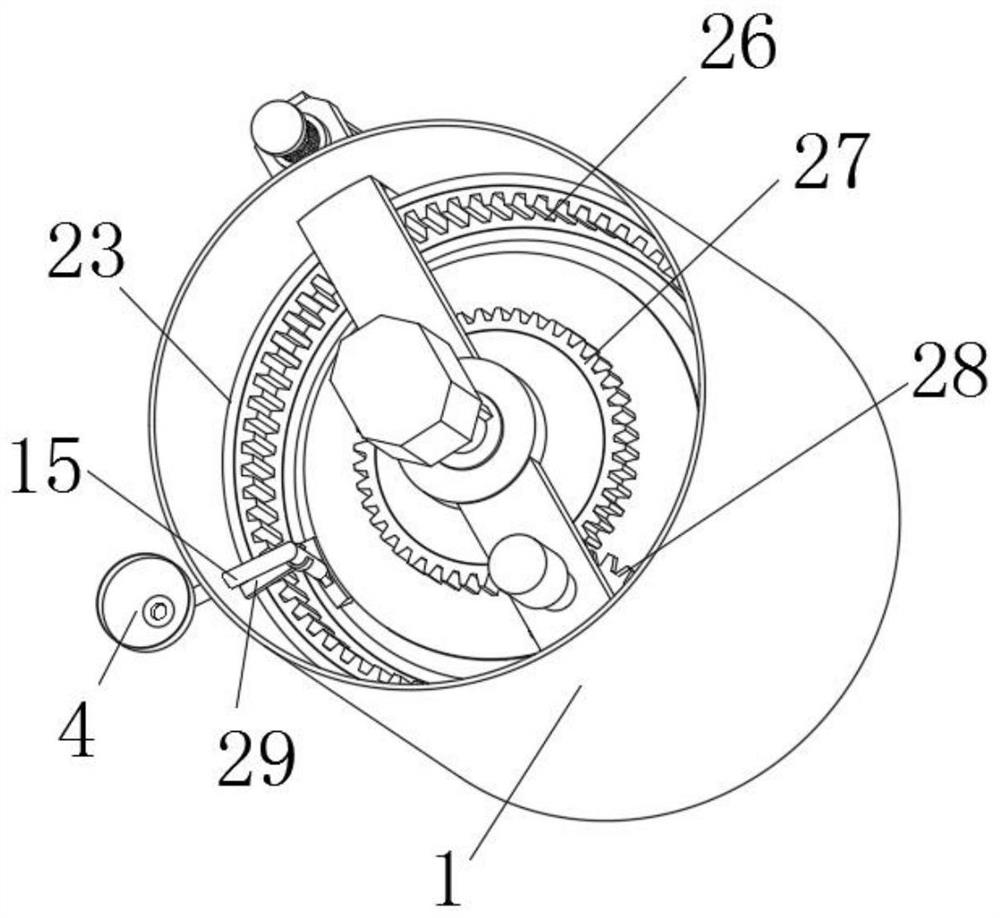

[0044] Example: Reference Figure 1-11 A kind of epoxy polyester powder coating production equipment shown, comprises cabinet 1, the box cover 5 that is installed on the top of cabinet 1, and the bottom of cabinet 1 is fixedly connected with discharge pipe 2, and valve 3 is arranged on discharge pipe 2 , a discharge part is installed in the chassis 1, and the discharge part is connected with the box cover 5; a discharge gap adjustment unit is installed on the discharge part, and the discharge gap adjustment unit is connected with the chassis 1, and a power is installed on the discharge part. Transfer unit; one side of the cabinet 1 is fixedly connected with a feeding unit, and the feeding unit is located at one side of the discharge part.

[0045] With the above structure, by setting the discharge part, it is convenient to discharge the epoxy polyester powder coating, and by setting the discharge gap adjustment unit, the distance between the discharge parts can be adjusted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com