Building material processing device

A technology for processing equipment and building materials, which is applied in the direction of unloading equipment, clay preparation equipment, cement mixing equipment, etc., can solve the problems of low concrete mixing efficiency, concrete cannot be discharged quickly, etc., to reduce ineffective mixing time and reduce mixing costs , the effect of fast mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

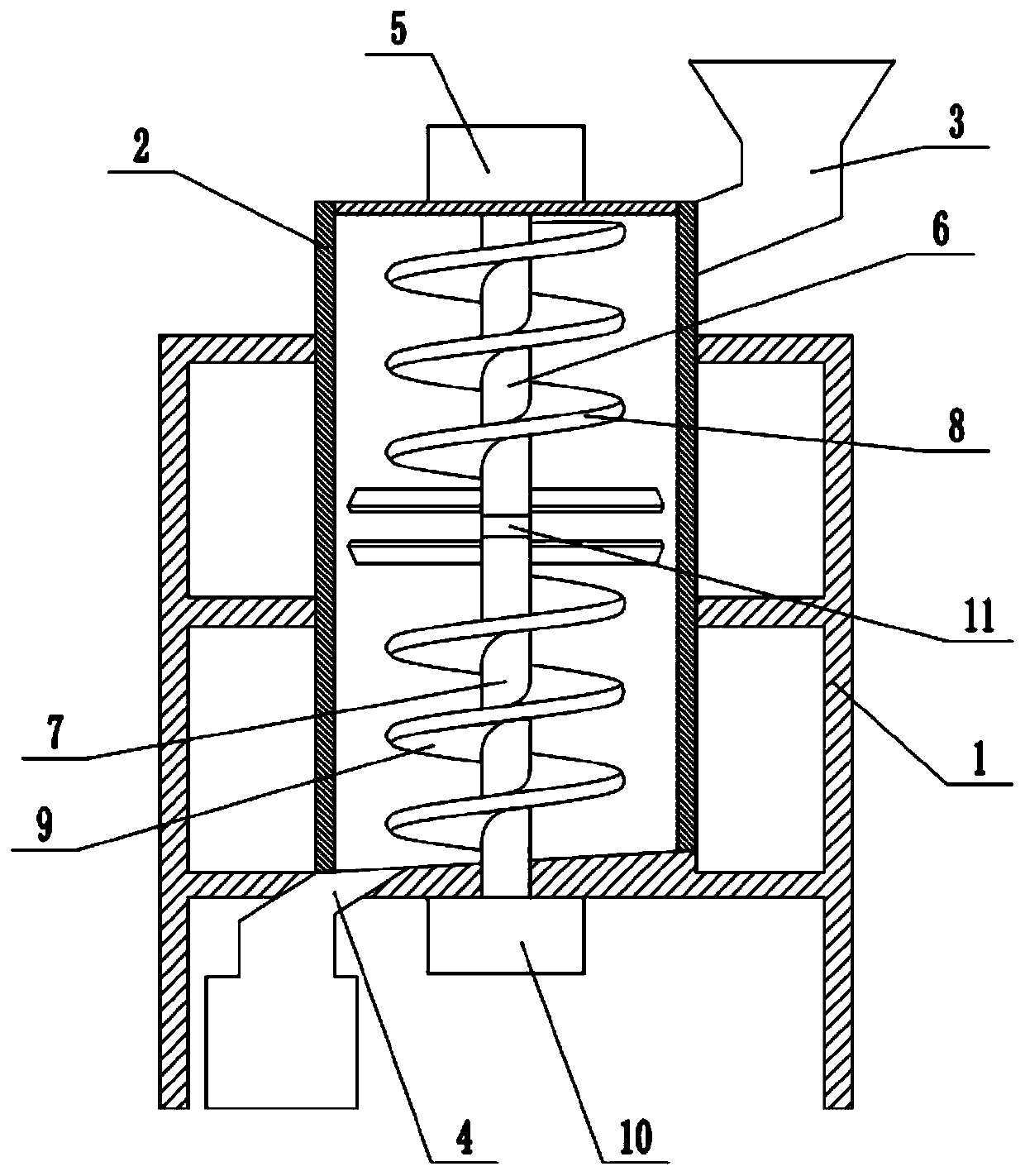

[0037] Embodiment one is basically as figure 1 and figure 2 As shown, a building material processing device includes a support frame 1, a vertically arranged mixing drum 2 is fixedly connected to the supporting frame 1, the upper right side of the mixing drum 2 is provided with a feed port 3, and the bottom of the mixing drum 2 is provided There is a discharge port 4, a rotating shaft is coaxial with the mixing drum 2 in the mixing drum 2, and the top of the mixing drum 2 is fixedly connected with a drive unit that drives the rotating shaft to rotate through bolts. In this embodiment, the driving unit includes an output shaft that is set downward. The first motor 5, the top of the rotating shaft is fixedly connected with the output shaft of the first motor 5 through a shaft coupling.

[0038] like figure 1 As shown, the rotating shaft includes an upper rotating shaft 6 and a lower rotating shaft 7 linked to each other. The lower rotating shaft 7 is close to the discharge po...

Embodiment 2

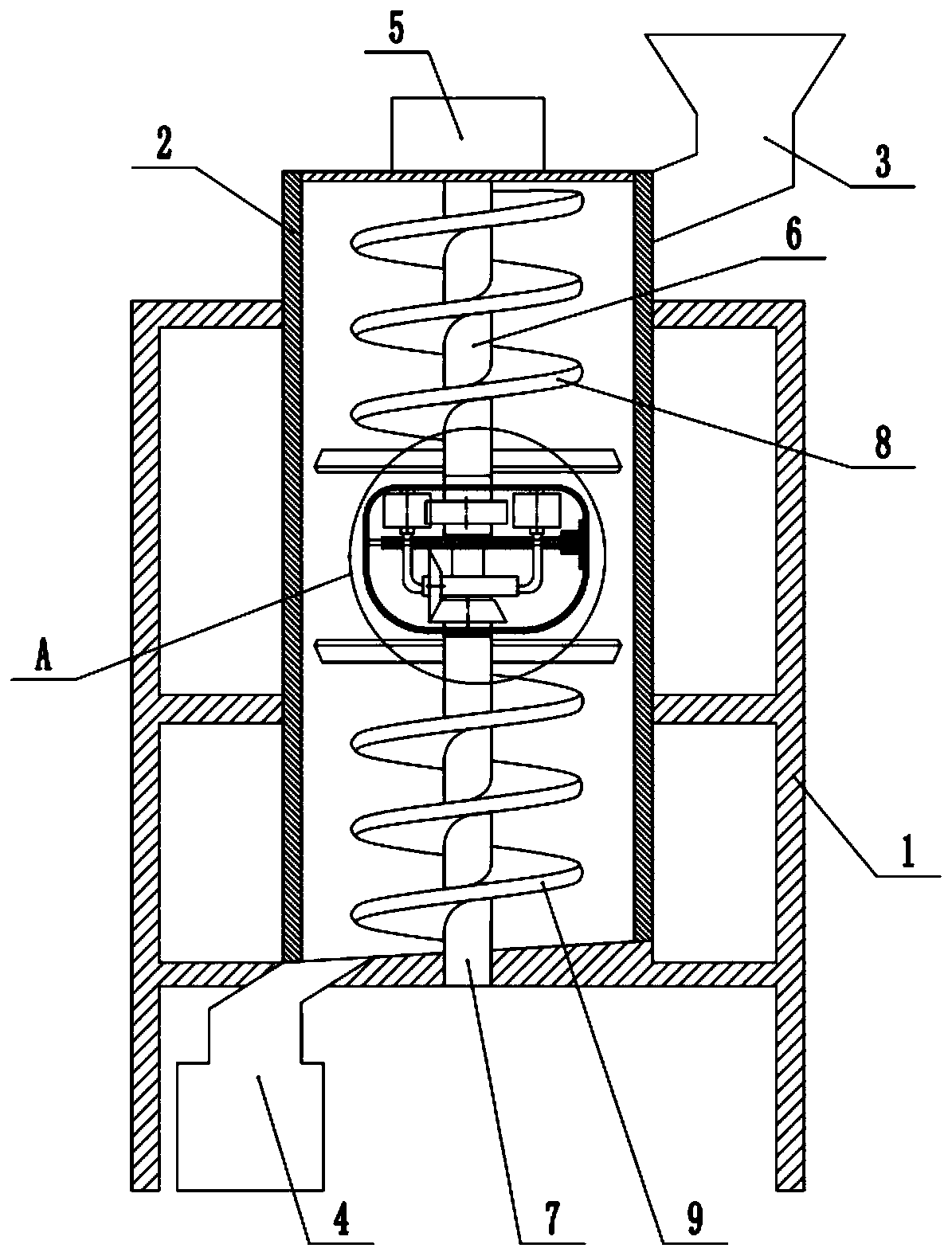

[0049] The difference between the second embodiment and the first embodiment is that the reversing mechanism is improved.

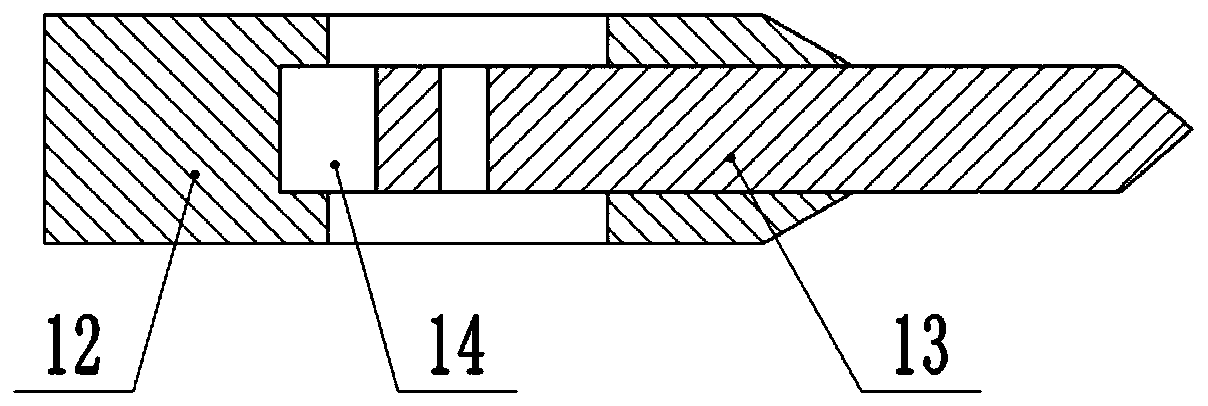

[0050] to combine image 3 and Figure 4 As shown, a reversing mechanism is provided between the upper rotating shaft 6 and the lower rotating shaft 7, and the reversing mechanism includes a driving wheel 15, a first spur gear 16, a second spur gear 17, a first bevel gear 18, a second bevel gear 19, Driven shaft 20 and switcher.

[0051] Switcher comprises fixed plate 21, slide plate 22, electromagnet and protective cover 23, and the outer wall of protective cover 23 is connected smoothly, is all connected by bearing between upper rotating shaft 6 and lower rotating shaft 7 and protective cover 23, and driving wheel 15, the first The spur gear 16 , the second spur gear 17 , the first bevel gear 18 , the second bevel gear 19 , the driven shaft 20 and the switch are all located in the protective cover 23 . like Figure 4 As shown, the driving wheel 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com