Rice impurity removing device for processing rice flour

A technology for rice and rice flour, which is applied in the field of rice impurity removal devices for rice flour processing, can solve problems such as discharge of impurities, and achieve the effects of rapid discharge, strong practicability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

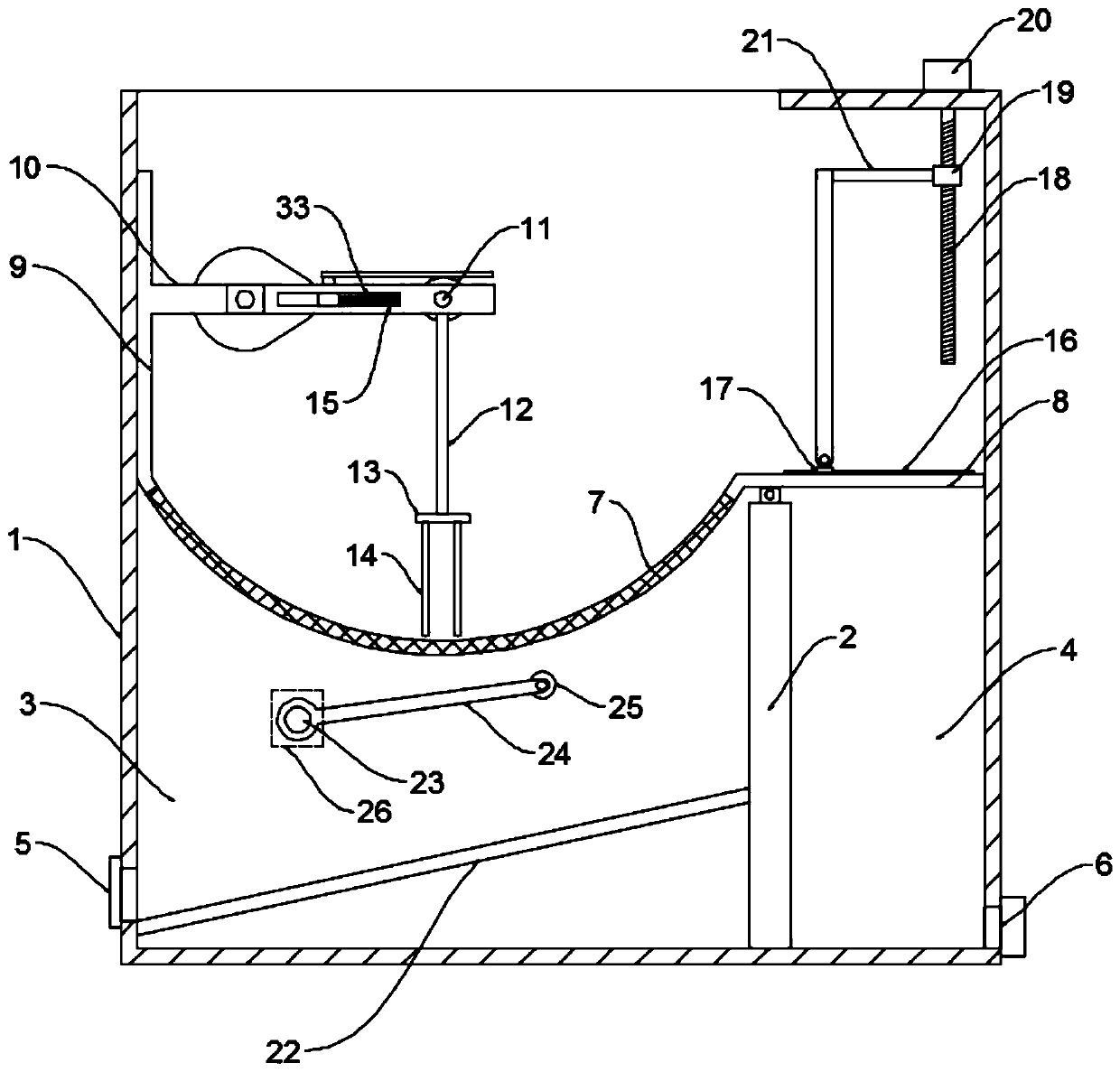

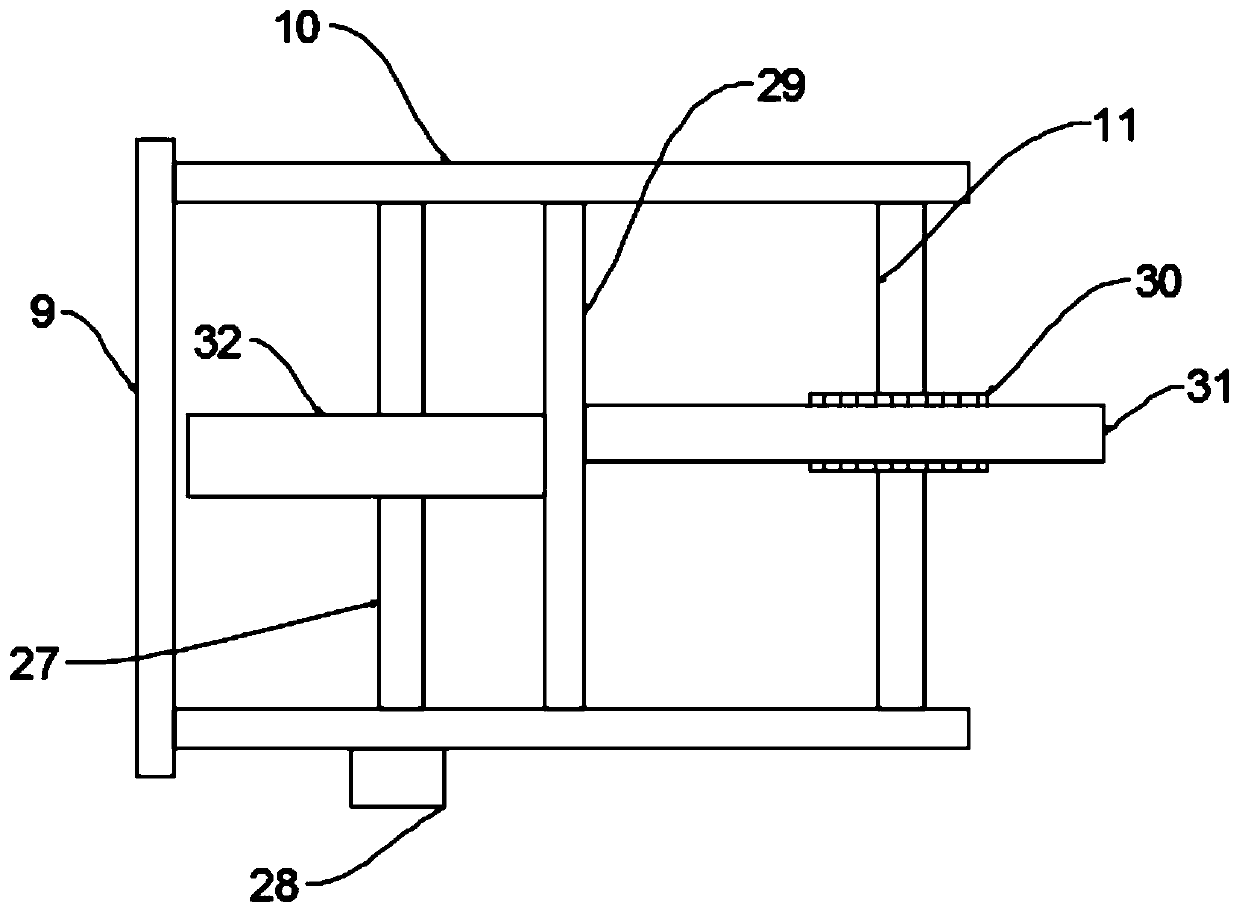

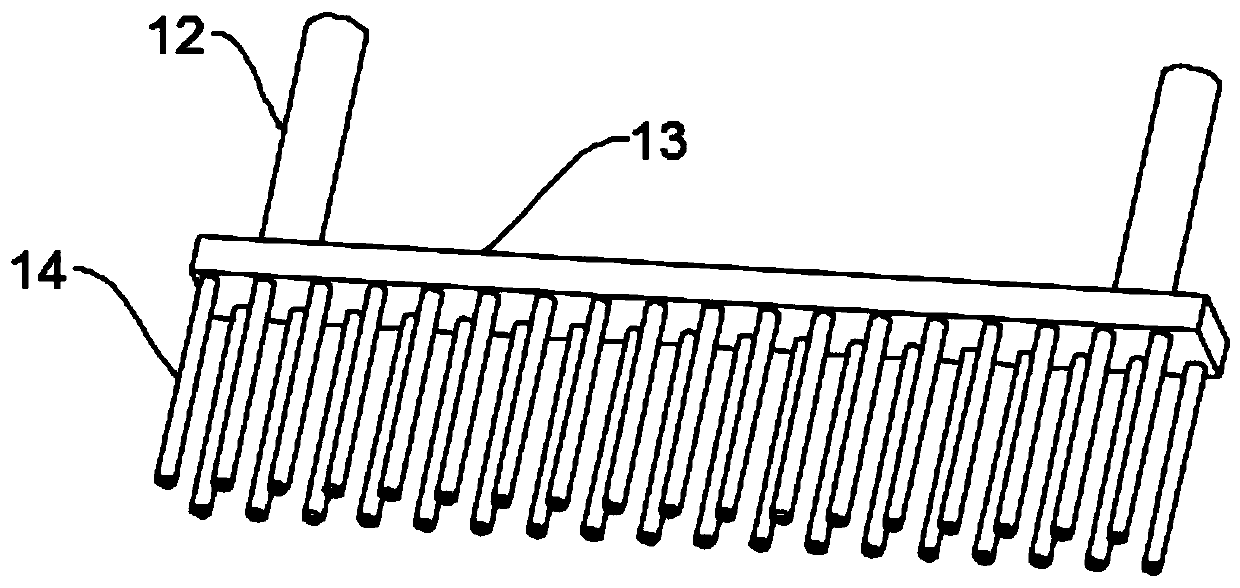

[0023] see Figure 1~3 , in an embodiment of the present invention, a rice cleaning device for rice flour processing, comprising a cleaning box 1, the inside of the cleaning box 1 is provided with a baffle 2 and the baffle 2 divides the inside of the cleaning box 1 into Collecting trough 3 and miscellaneous trough 4, said collecting trough 3 is provided with screening arc-shaped net plate 7 and the two ends of screening arc-shaped net plate 7 are respectively provided with side plate 9 and cover plate 8, said cover The plate 8 covers the top port of the miscellaneous tank 4 and the miscellaneous tank 4 is hinged near the end of the screening arc screen plate 7 and the top of the baffle plate 2. The top of the side plate 9 is provided with a toggle frame 10 and the toggle frame 10 A toggle lever shaft 11 coaxial with the screening arc-shaped net plate 7 is arranged on the top, and a dialing assembly for stirring the rice in the screening arc-shaped net plate 7 is fixed on the t...

Embodiment 2

[0028] The difference between this embodiment of the present invention and Embodiment 1 is that: a swing rod shaft 23 is arranged inside the collecting tank 3 and a knock rod 24 is fixed on the swing rod shaft 23, and the knock rod 24 is far away from the swing rod shaft 23 The end of the swing rod shaft 23 is provided with a knocking ball 25, and the end of the swing rod shaft 23 is connected to the output end of the vibration motor 26 arranged on the outer wall of the miscellaneous removal box 1. The vibration motor 26 can drive the swing rod shaft 23 to rotate positively and negatively so that The knock bar 24 swings and utilizes the knocking ball 25 to knock the screen curved screen 7 to vibrate, so as to prevent the rice from blocking the screen holes of the screen curved screen 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com