Dissociation and recleaning technology for coking fine grain middling coal

A fine-grained and dissociated technology, used in flotation, solid separation, wet separation, etc., can solve the problem that resources cannot be recycled and reused, and achieve the effect of ensuring flotation selectivity, simple process flow, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

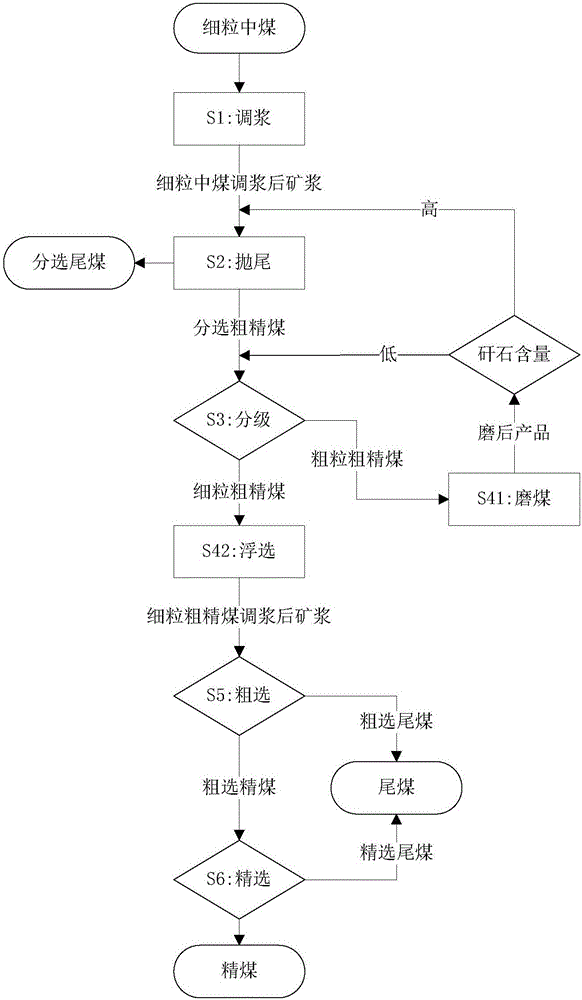

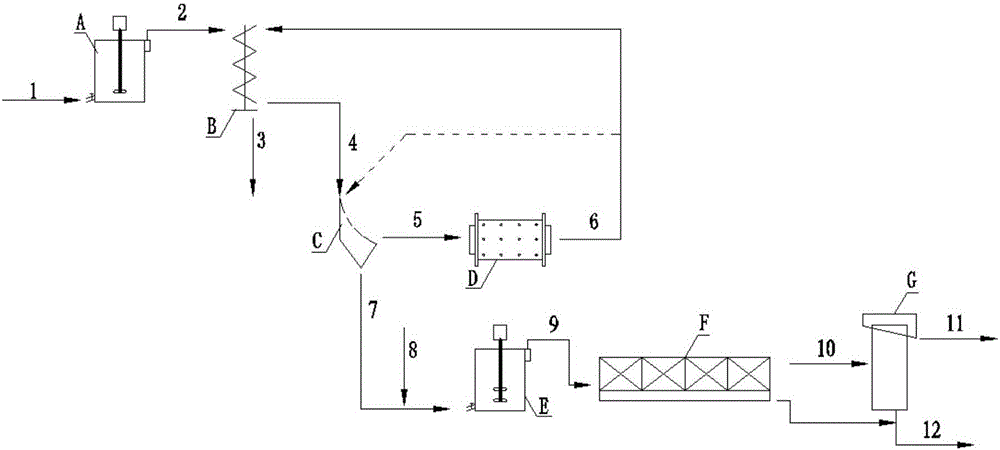

[0054] Such as figure 2 Shown, the concrete reselection technological process of the present invention is as follows

[0055] S1. Feed the fine-grained medium coal 1 (raw material) with a particle size below 3mm into the mixing tank A through a feed pump (not shown in the figure) for slurry mixing, and produce fine-grained medium coal slurry 2 after slurry adjustment.

[0056] S2. Feed the fine-grained medium coal slurry 2 into the spiral separator B for spiral tailing operation, and produce high-ash gangue particles as the sorted tailing coal 3, and simultaneously produce and retain the sorted coarse and clean coal 4; The ash content of the sorted tailing coal 3 can reach about 70%, which is treated as gangue.

[0057] S3. Put the sorted coarse and clean coal 4 into the vibrating curved screen C for grading operation. The sieve hole size of the vibrating curved screen is 0.5mm, and the grading particle size is about 0.25-1mm. Clean coal 5, and the undersieve is fine-graine...

Embodiment 2

[0064] Such as figure 2 Shown, the concrete reselection technological process of the present invention is as follows

[0065] S1. Feed the fine-grained medium coal 1 (raw material) with a particle size below 3mm into the mixing tank A through a feed pump (not shown in the figure) for slurry mixing, and produce fine-grained medium coal slurry 2 after slurry adjustment.

[0066] S2. Feed the fine-grained medium coal slurry 2 into the spiral separator B for spiral tailing operation, and produce high-ash gangue particles as the sorted tailing coal 3, and simultaneously produce and retain the sorted coarse and clean coal 4; Sorted tailing coal 3 is treated as gangue.

[0067] S3. Put the sorted coarse and clean coal 4 into the vibrating curved screen C for grading operation. The sieve hole size of the vibrating curved screen is 0.7mm, and the grading particle size is about 0.25-1mm. Clean coal 5, and the undersieve is fine-grained coarse clean coal 7.

[0068] S41. Feed the coa...

Embodiment 3

[0074] Such as figure 2 Shown, the concrete reselection technological process of the present invention is as follows

[0075] S1. Feed the fine-grained medium coal 1 (raw material) with a particle size below 3mm into the mixing tank A through a feed pump (not shown in the figure) for slurry mixing, and produce fine-grained medium coal slurry 2 after slurry adjustment.

[0076] S2. Feed the fine-grained medium coal slurry 2 into the spiral separator B for spiral tailing operation, and produce high-ash gangue particles as the sorted tailing coal 3, and simultaneously produce and retain the sorted coarse and clean coal 4; Sorted tailing coal 3 is treated as gangue.

[0077] S3. Put the sorted coarse and clean coal 4 into the vibrating curved screen C for grading operation. The sieve hole size of the vibrating curved screen is 1mm, and the grading particle size is about 0.25-1mm. Coal 5, and the undersieve is fine-grained coarse coal 7.

[0078] S41. Feed the coarse-grained co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com