Discharge gate structure

A technology at the discharge port and outlet, which is applied in the field of discharge port structure, can solve the problems of difficult accurate measurement, precision exceeding the error value, and large fluctuations in the output of the discharge port, so as to improve the discharge speed and feed rate. The effect of material accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

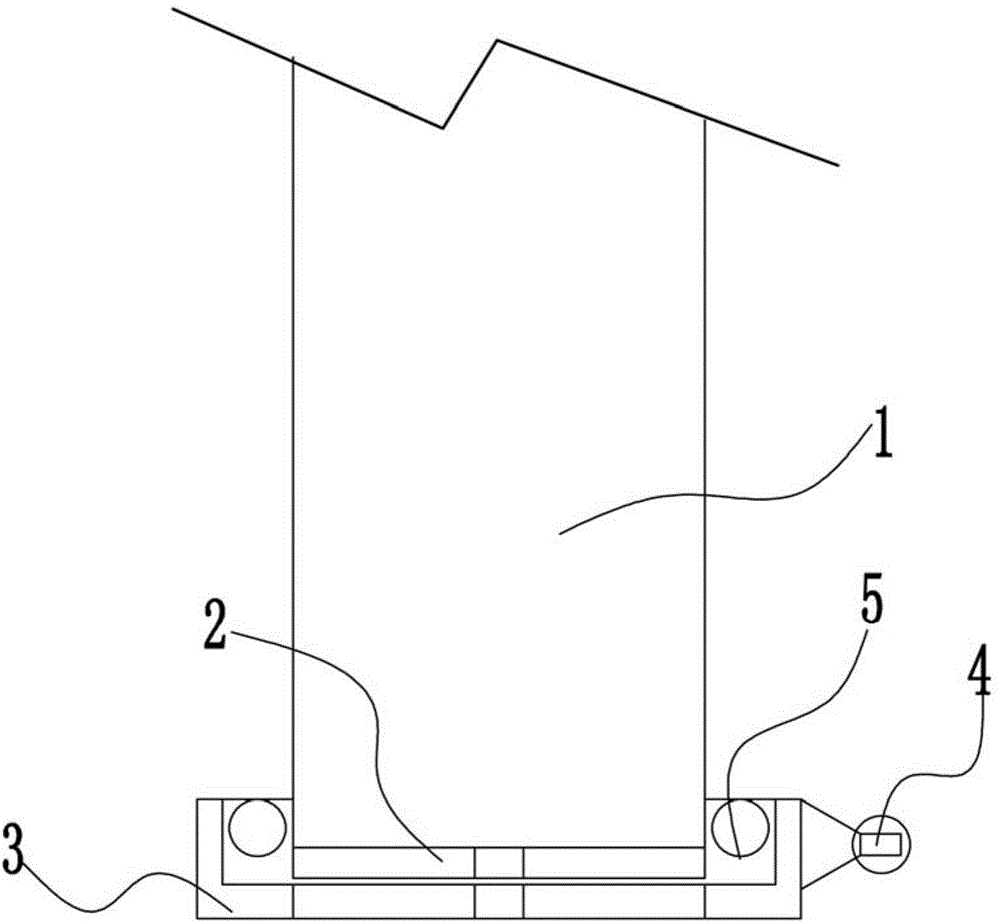

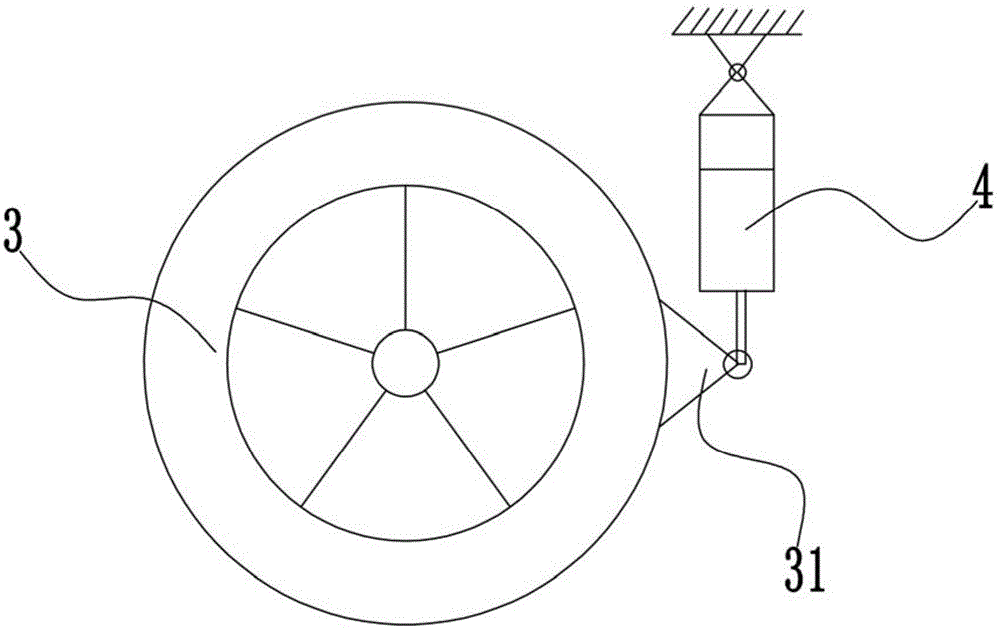

[0017] Figure 1 to Figure 6 A discharge port structure according to an embodiment of the present invention is schematically shown.

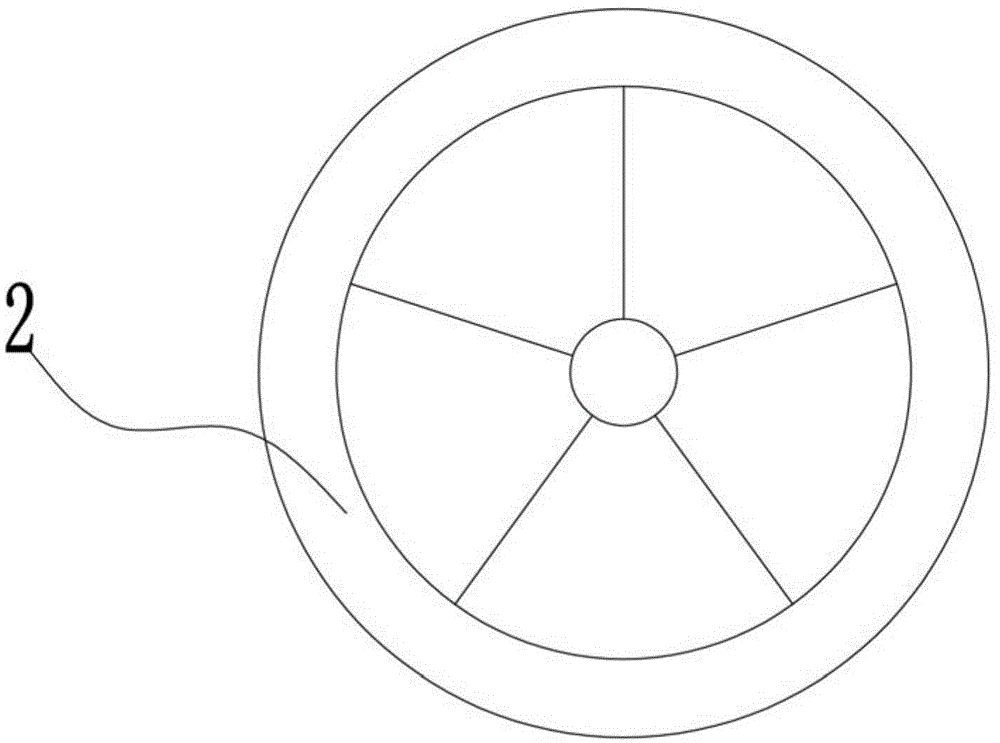

[0018] like figure 1 and figure 2 , This kind of discharge port structure includes a discharge port main body 1, the discharge port main body 1 is a cylindrical discharge port; the outlet of the discharge port main body 1 is provided with an inner grid 2 and an outer grid 3 in sequence in the axial direction.

[0019] like image 3 , the inner grid 2 is a circular block; the radius of the inner grid 2 is the same as the inner radius of the discharge opening main body 1, so that the inner grid 2 can be axially fixed in the discharge opening main body 1; the inner grid 2 and the discharge opening main body 1 The main body 1 of the material opening can be riveted or clamped to fix the inner grid 2 and the main body of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com