Straw material particle processing equipment

A technology for processing equipment and materials, applied in the field of straw material granule processing equipment, can solve the problems of increased equipment cost, low granulation efficiency, and insufficient pulverization, so as to reduce equipment cost, improve efficiency and output, and improve cooling effect and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

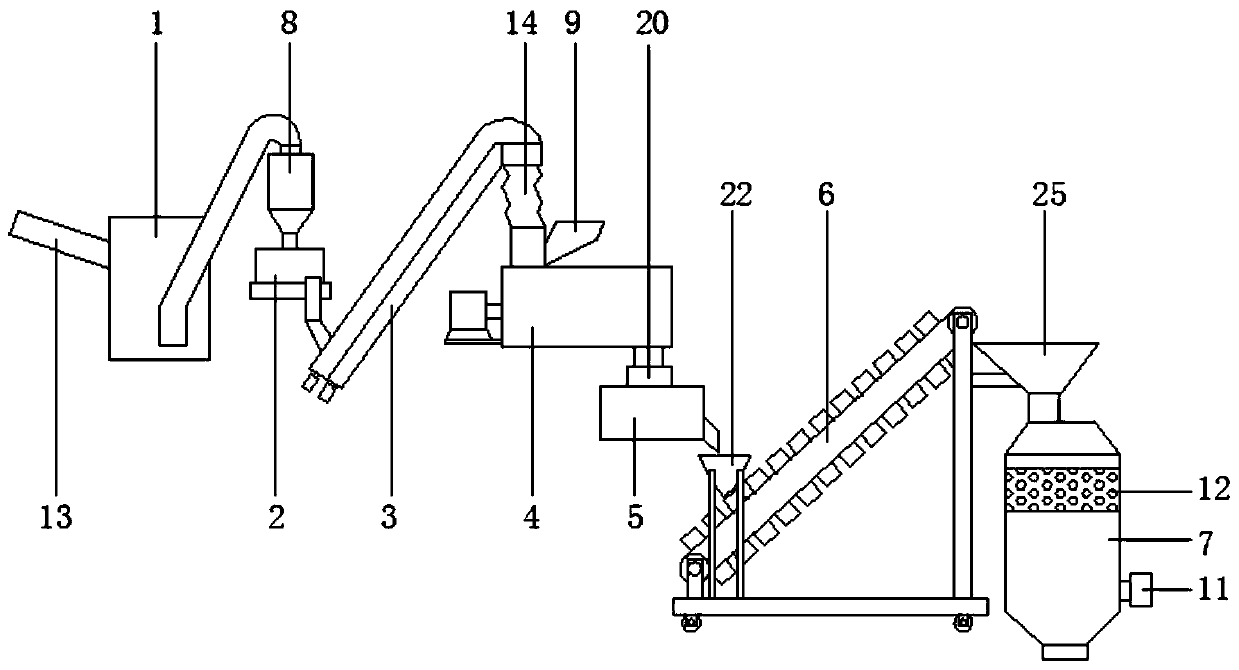

[0037] Such as Figure 1-Figure 7 As shown, the present invention provides a technical solution: a straw material particle processing equipment, including: a pulverizer 1, a secondary crushing device 2, a conveyor 3, a stirring buffer cylinder 4, a granulator 5, a hoist 6 and a cooling A screening tower 7, and the pulverizer 1, the secondary crushing device 2, the conveyor 3, the stirring buffer cylinder 4, the granulator 5, the hoist 6 and the cooling and screening tower 7 are arranged in sequence from left to right, forming a The integrated production line of crushing, mixing, granulation, cooling, and screening improves the overall work efficiency. The outlet of the pulverizer 1 is connected with a buffer hopper 8 through a pipeline, which can buffer the crushed material particles and has the function of preventing Dust effect, the bottom end of the buffer hopper 8 is connected to the top of the secondary crushing device 2, through the setting of the secondary crushing devi...

Embodiment 2

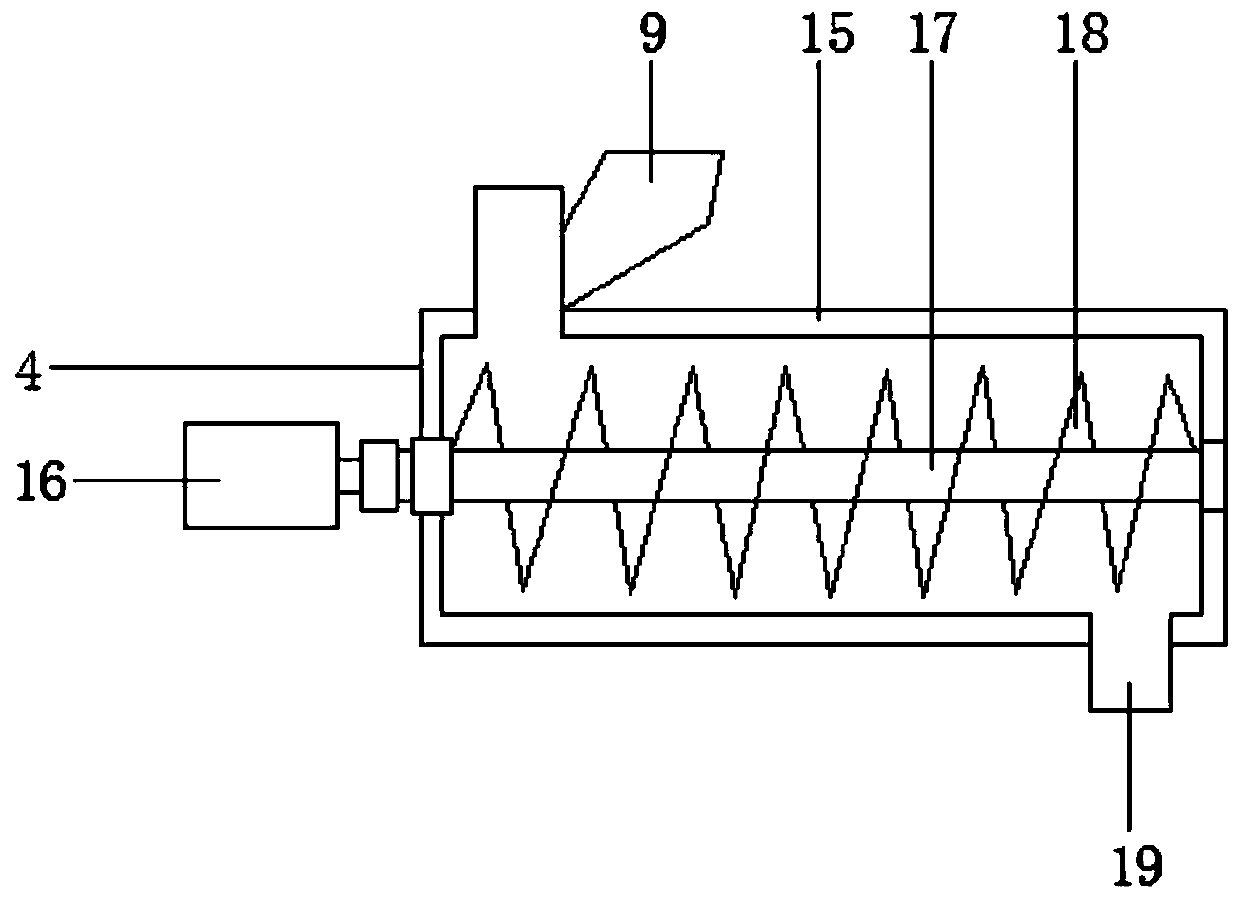

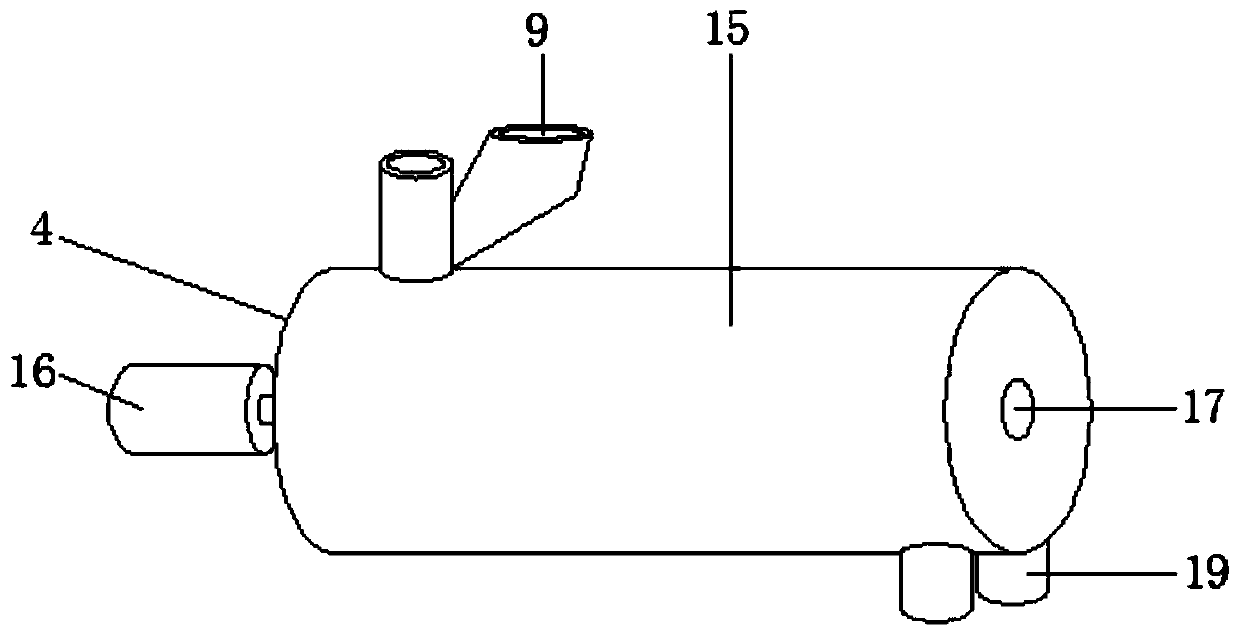

[0044] Such as figure 2 with image 3 As shown, the horizontal cylinder 15 is set as a cylinder, and the two ends of the stirring shaft 17 are rotatably connected to the center of the two ends of the horizontal cylinder 15 through bearings, so that the rotation is stable, which is beneficial to the mixing of the mixture by the spiral stirring blade 18. Stir evenly, and the additive inlet 9 is obliquely connected to the feeding inlet side of the stirring buffer cylinder 4, which is convenient for adding additives.

Embodiment 3

[0046] Such as Figure 6-Figure 8 As shown, the bottom end of the outlet of the cooling and screening tower 7 is connected with a discharge plate 23, and the discharge plate 23 is connected to the bottom of the guide sieve plate 10 at the bottom of the cooling and screening tower 7, so as to facilitate Discharge the cooled and sieved finished granules for easy collection. Triangular through holes 24 are evenly distributed on the surface of the guide sieve plate 10 to prevent the finished granules from clogging the sieve holes. There are gaps between the inner walls of the sub-towers 7, which is convenient for the finished granules to slide down from the material guide sieve plate 10 in turn, so as to quickly complete cooling and screening.

[0047] Working principle and use process: When this kind of straw material particle processing equipment is in use, the straw material is firstly crushed through the pulverizer 1, temporarily stored and buffered through the buffer hopper 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com