Zinc oxide drying device

A drying device and zinc oxide technology, which is applied in the direction of heating device, drying solid materials, drying, etc., can solve the problems of poor drying effect, lower processing efficiency of zinc oxide production line, complex structure, etc., achieve good drying effect and improve output High speed and good drying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

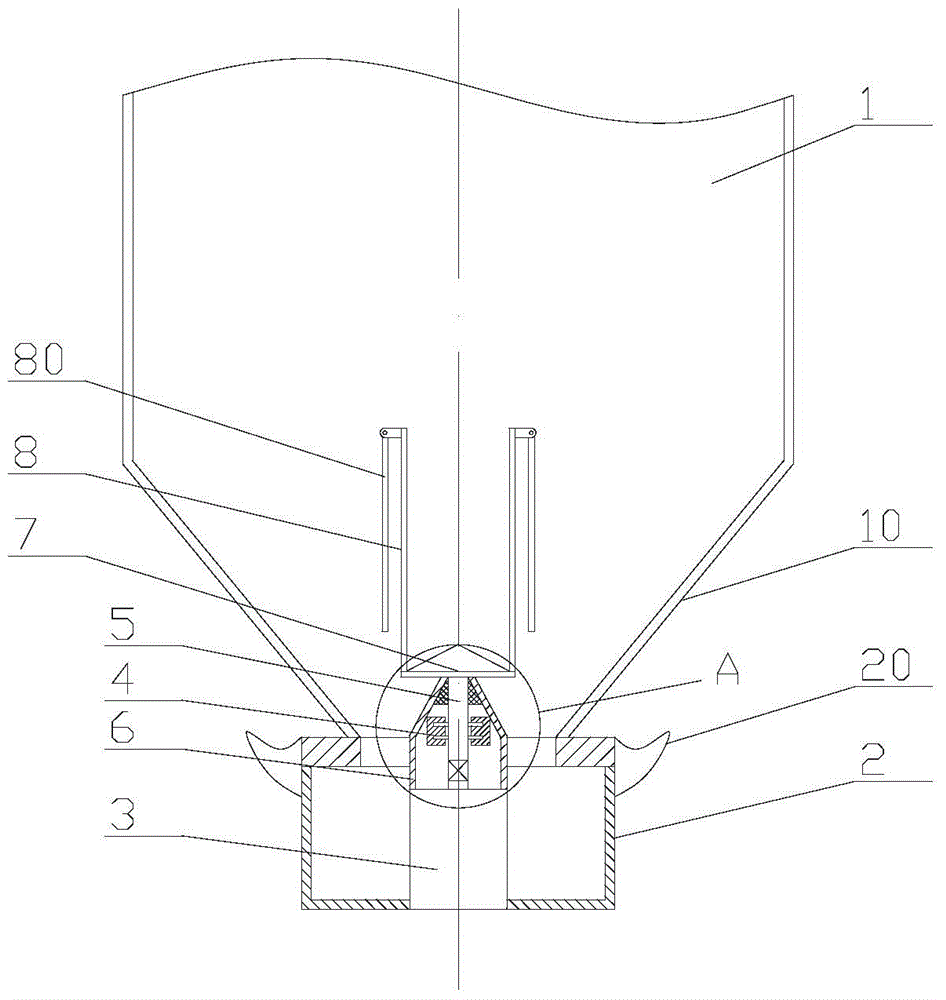

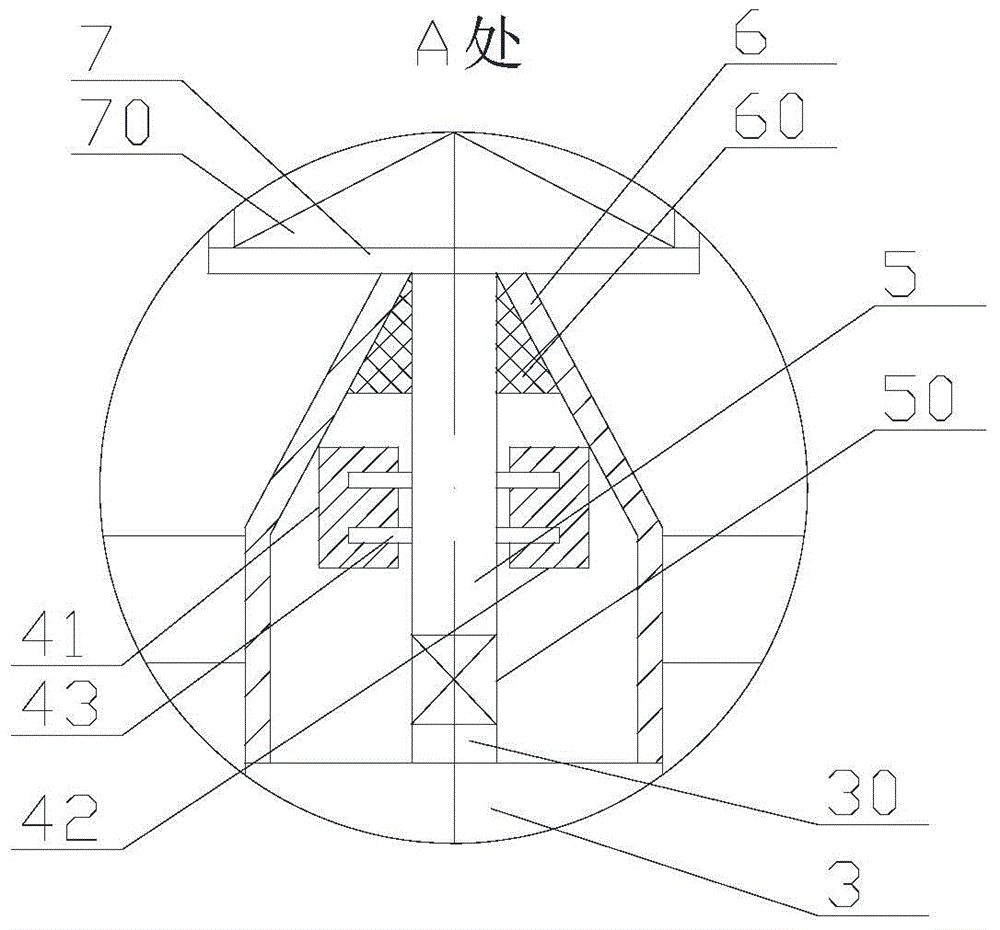

[0015] The present invention as Figure 1-2 As shown, it is connected below the pulverizing device 1, and the bottom of the pulverizing device 1 has a discharge hopper 10; Rotary table 7 and at least one pair of heating rods 8;

[0016] The support 2 is fixedly connected under the discharge hopper 10, the bottom of the rotary drive device 3 is fixedly connected with the support 2 and has an output shaft 30, and the transmission rod 5 passes through a coupling 50 made of insulating material. Connected to the top of the output shaft 30, the center of the rotary table 7 is fixedly connected to the top of the transmission rod 5, and the tapered sleeve 6 is free from the transmission rod 5, and the bottom edge of the tapered sleeve 6 is connected to the rotary drive The device 3 is fixedly connected, and the top edge is attached to the bottom surface of the rotary table 7; at least one pair of the heating rods 8 is vertically arranged, and the bottom end thereof is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com