Patents

Literature

50results about How to "Control transmission speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

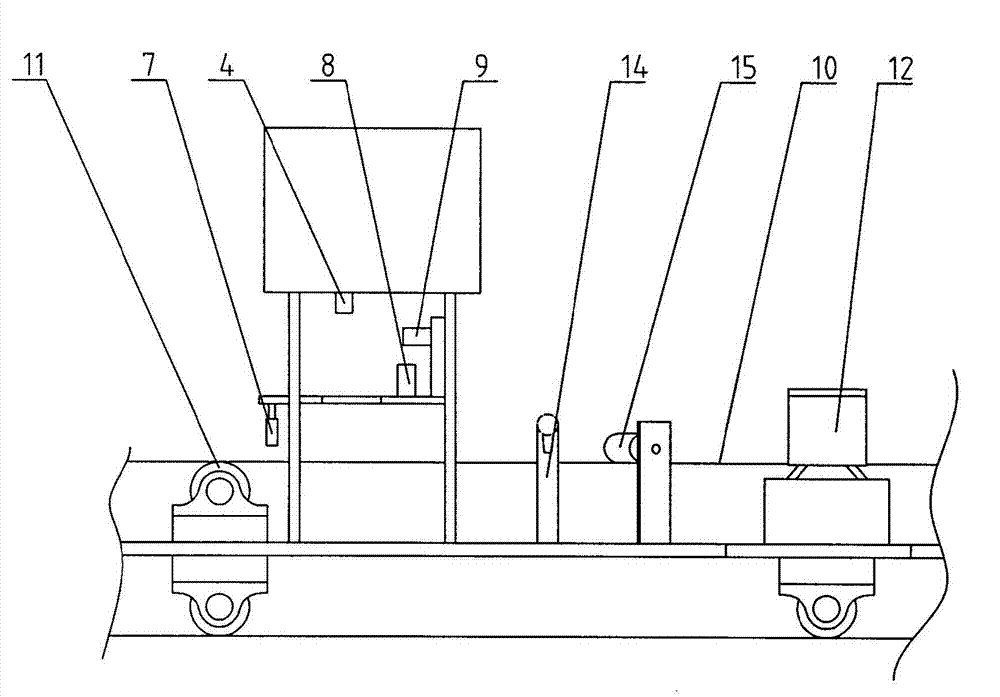

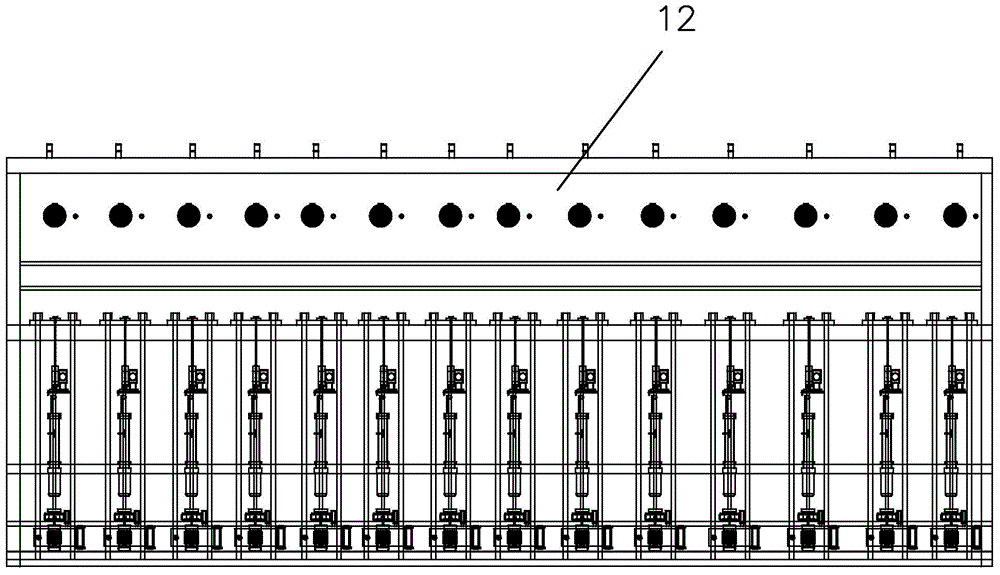

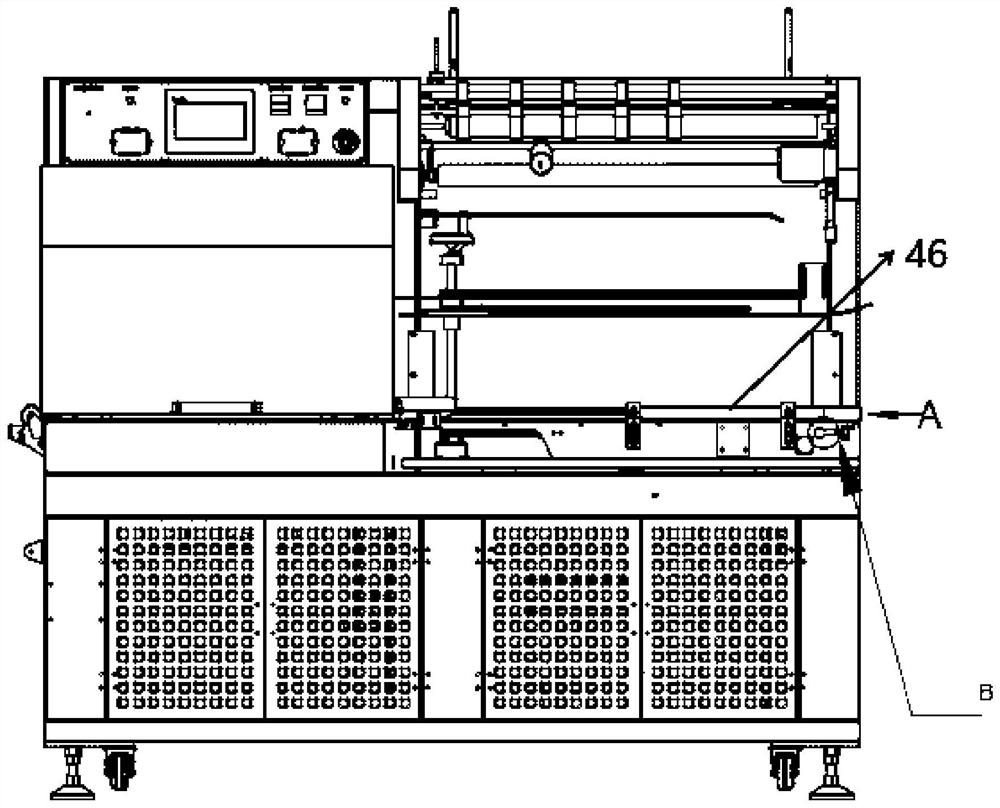

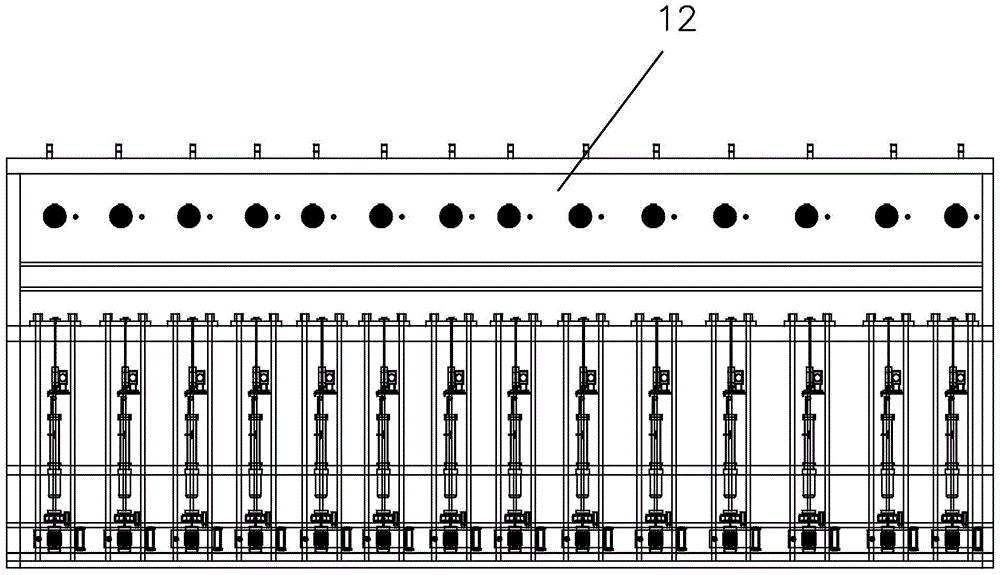

High-efficiency digital printing machine

InactiveCN102815092AAvoid confusionGuaranteed speedTypewritersOther printing apparatusControl systemPrinting ink

The invention discloses a high-efficiency digital printing machine comprising a frame, a cloth transportation device, an ink jet positioning and calibrating device and a printing ink jetting device. The cloth transportation device comprises a transportation control system, a cloth positioning mechanism, a power driving device and a transportation platform, wherein the cloth positioning mechanism is mounted on the frame and on two sides of the transportation platform, the power driving device is controlled by the transportation control system, and the transportation platform is driven by the power driving device. The printing ink jetting device is arranged above the transportation platform and comprises a jet nozzle assembly, an ink distribution assembly, an ink supply assembly and an ink control system. The high-efficiency digital printing machine is high in working efficiency, good in printing accuracy and capable of accurately printing complicated patterns.

Owner:CHANGZHOU YILIYASI TEXTILE +1

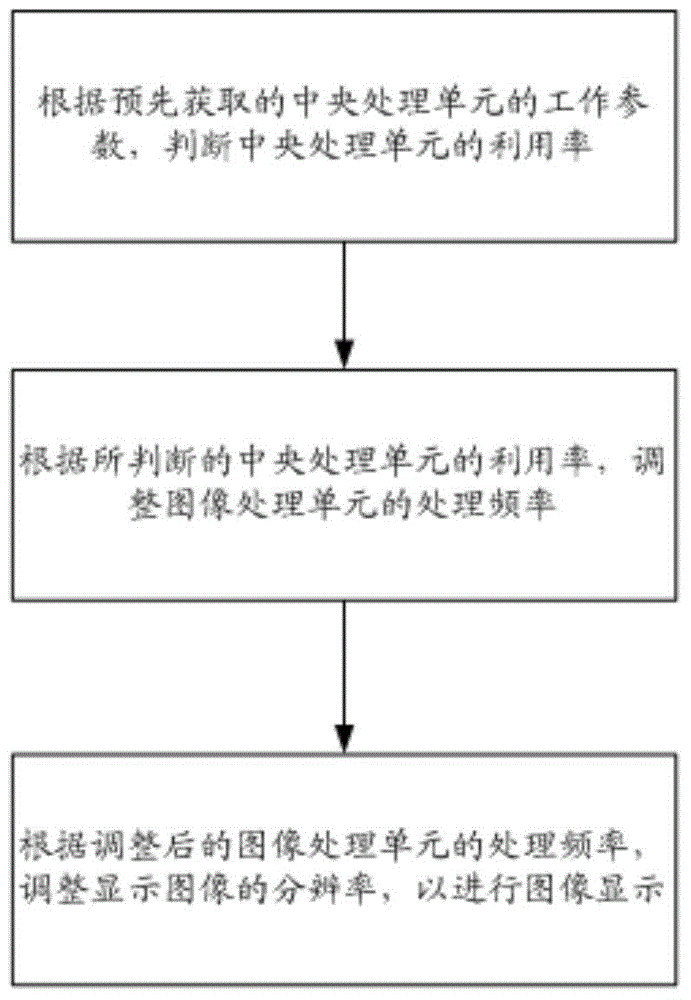

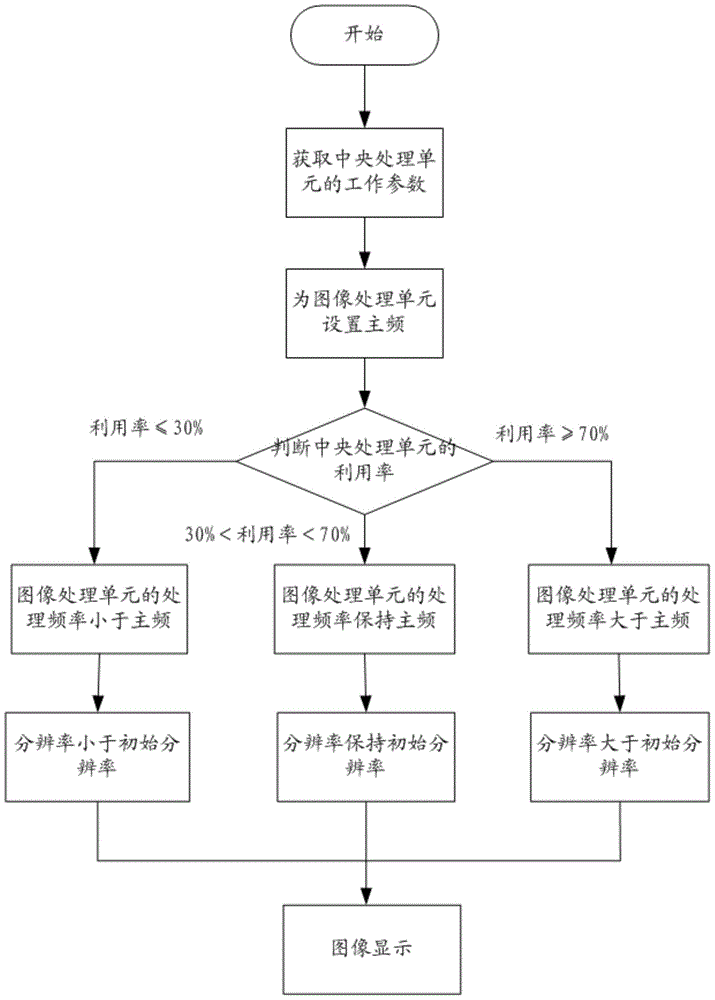

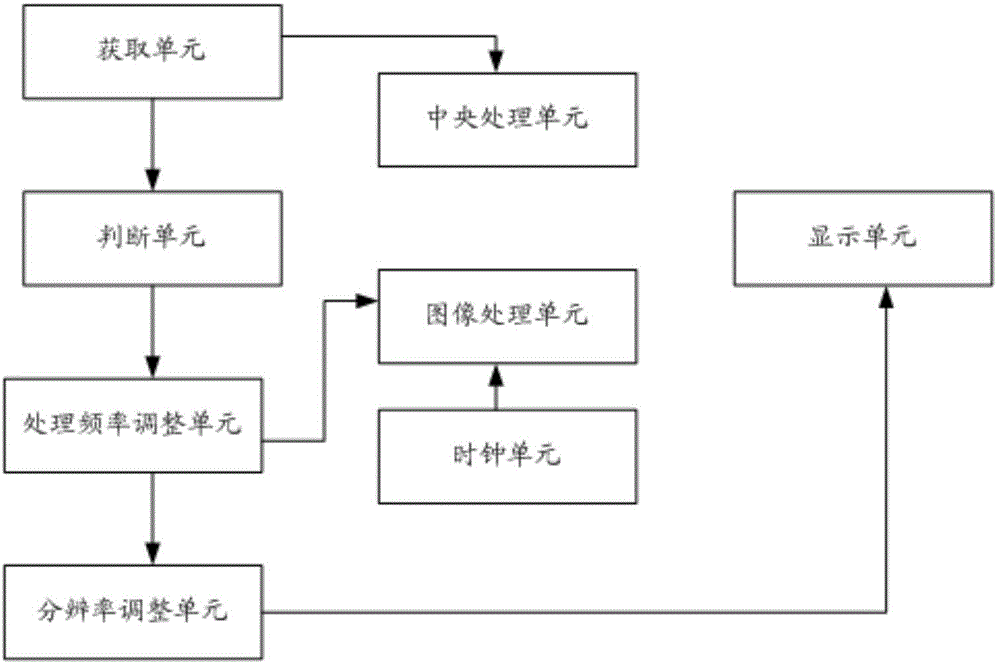

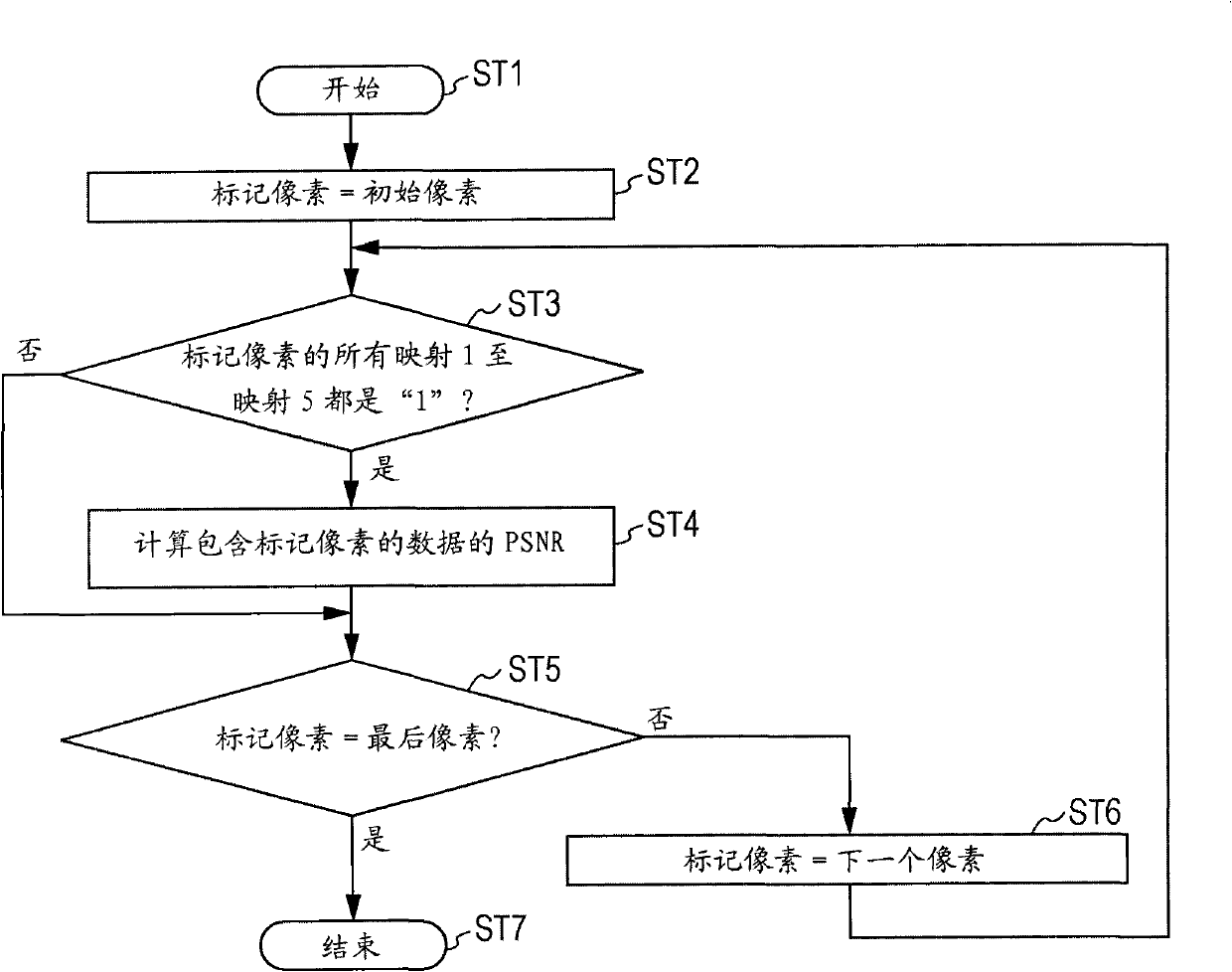

Image display method and display system

ActiveCN104932659AControl transmission speedReduce power consumptionImage memory managementCathode-ray tube indicatorsImaging processingComputer graphics (images)

The invention provides an image display method and display system, and belongs to the technical field of display. The problem that when an image is displayed through an existing image display method, power consumption is large can be solved. The image display method comprises the steps that the utilization rate of a center processing unit is judged according to pre-obtained work parameters of the center processing unit; the processing frequency of an image processing unit is adjusted according to a judgment result; the resolution of the displayed image is adjusted according to the adjusted processing frequency of the image processing unit to display the image.

Owner:BOE TECH GRP CO LTD +1

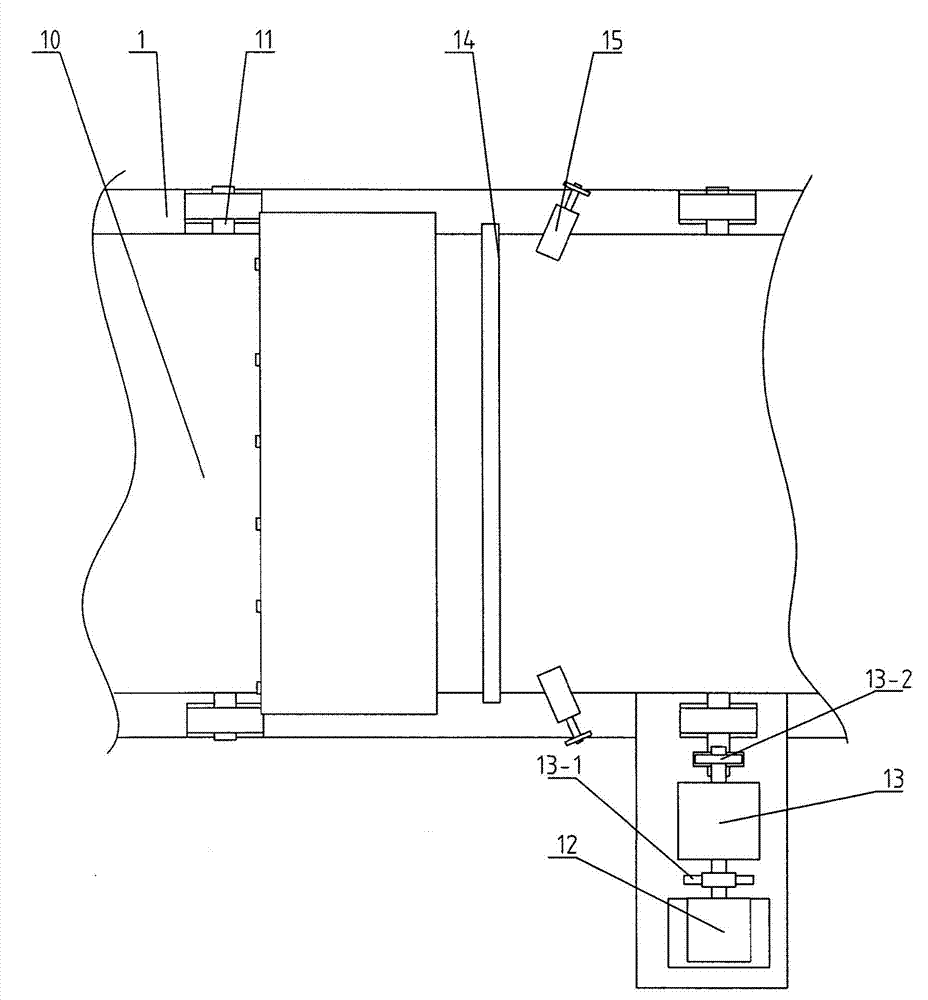

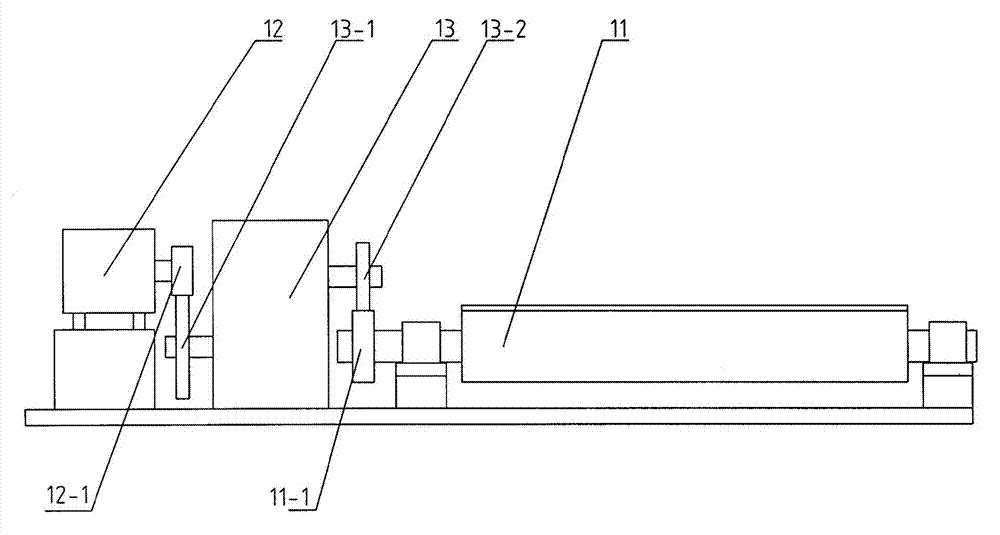

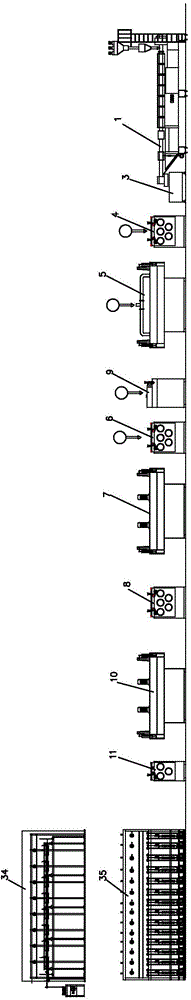

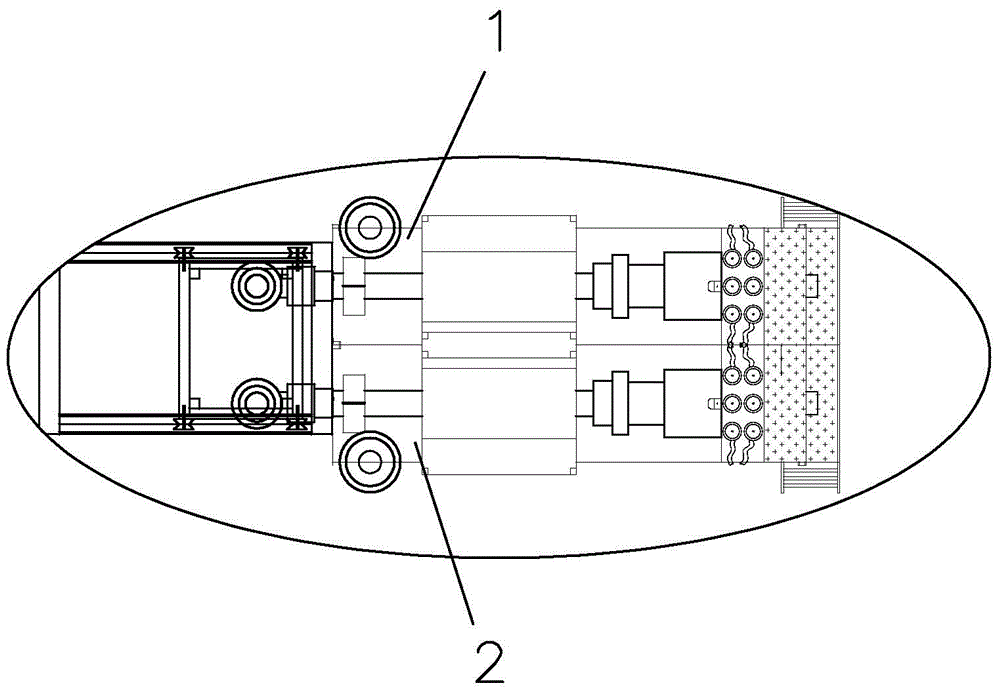

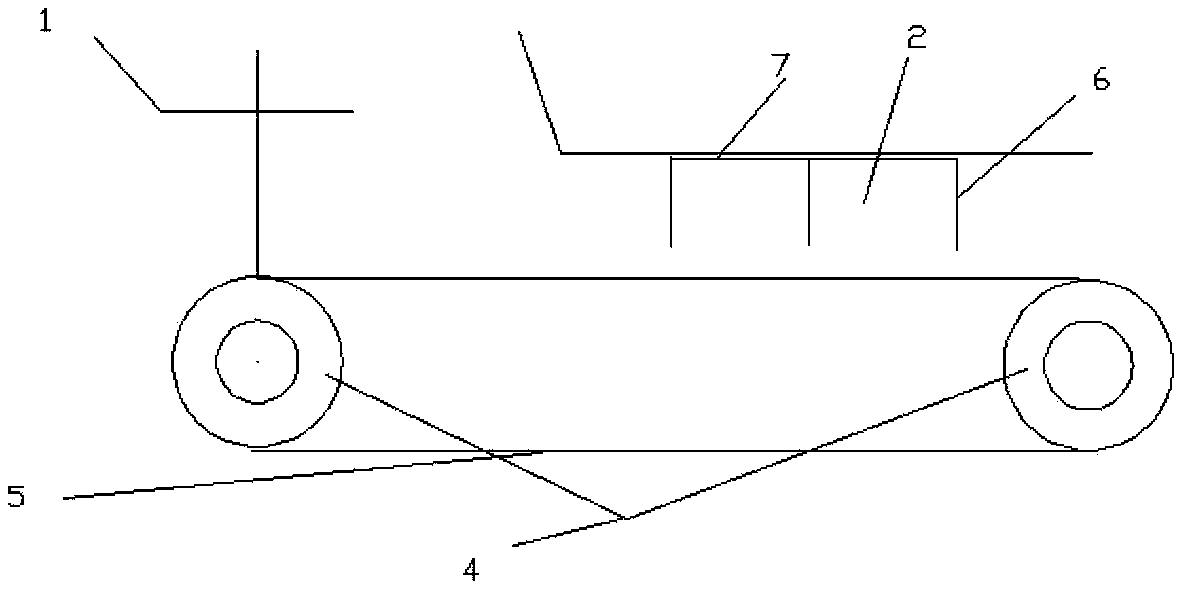

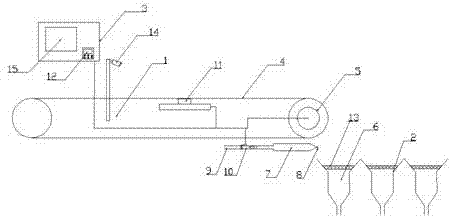

Lawn rayon production line and production method

ActiveCN104862792ASingle screw speed adjustment rangeRealize stepless speed regulationArtificial thread manufacturing machinesMelt spinning methodsProduction lineProcess time

The invention discloses a lawn rayon production line and production method. The lawn rayon production line comprises monofilament production equipment, after finishing equipment and a plying and twisting unit which are installed in sequence; two extruders of the monofilament production equipment of the lawn rayon production line are arranged in parallel and can produce monofilament with different colors and different types; the plying and twisting equipment conducts plying and twisting on the monofilament produced through the production line and monofilament which needs to be twisted, rewinding does not need to be conducted repeatedly, the process time and the workshop space are saved, requirements for plying and twisting production of two or more monofilament are met, and the production efficiency is greatly improved.

Owner:QINGDAO QINGHE ARTIFICIAL TURF

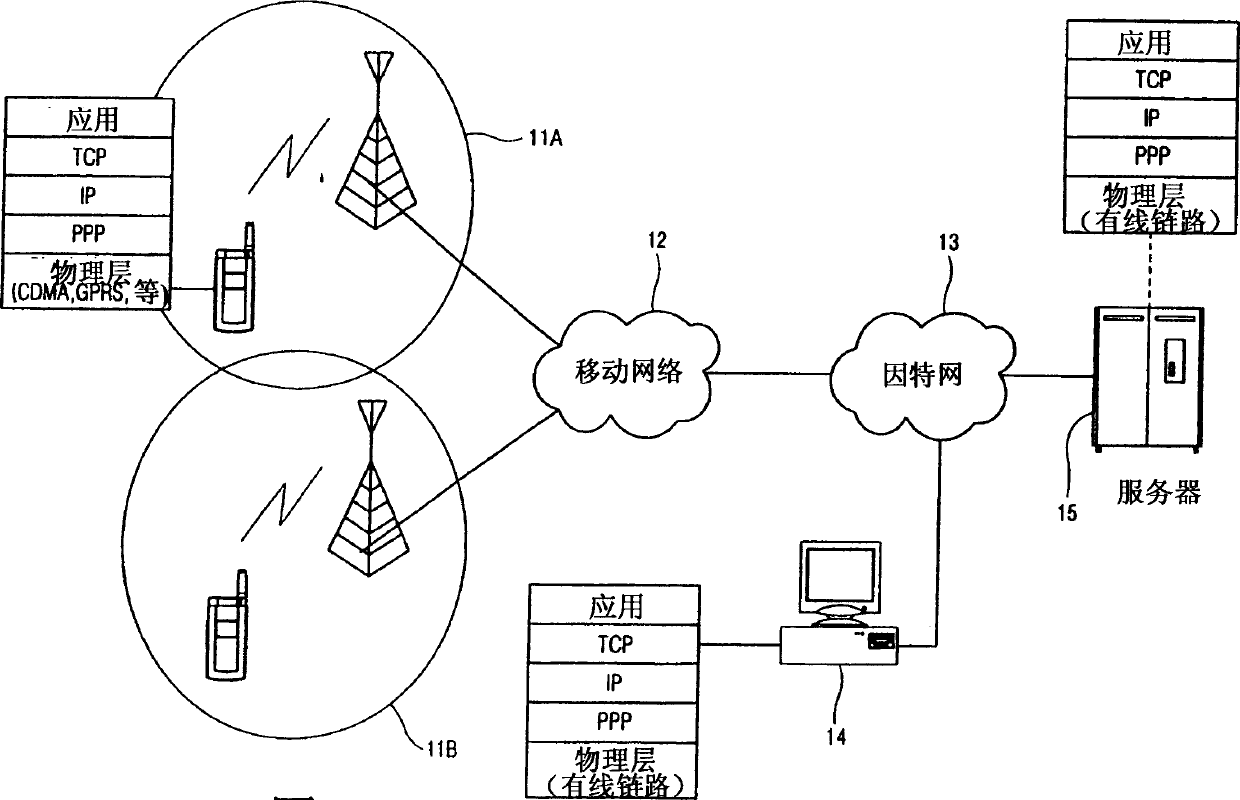

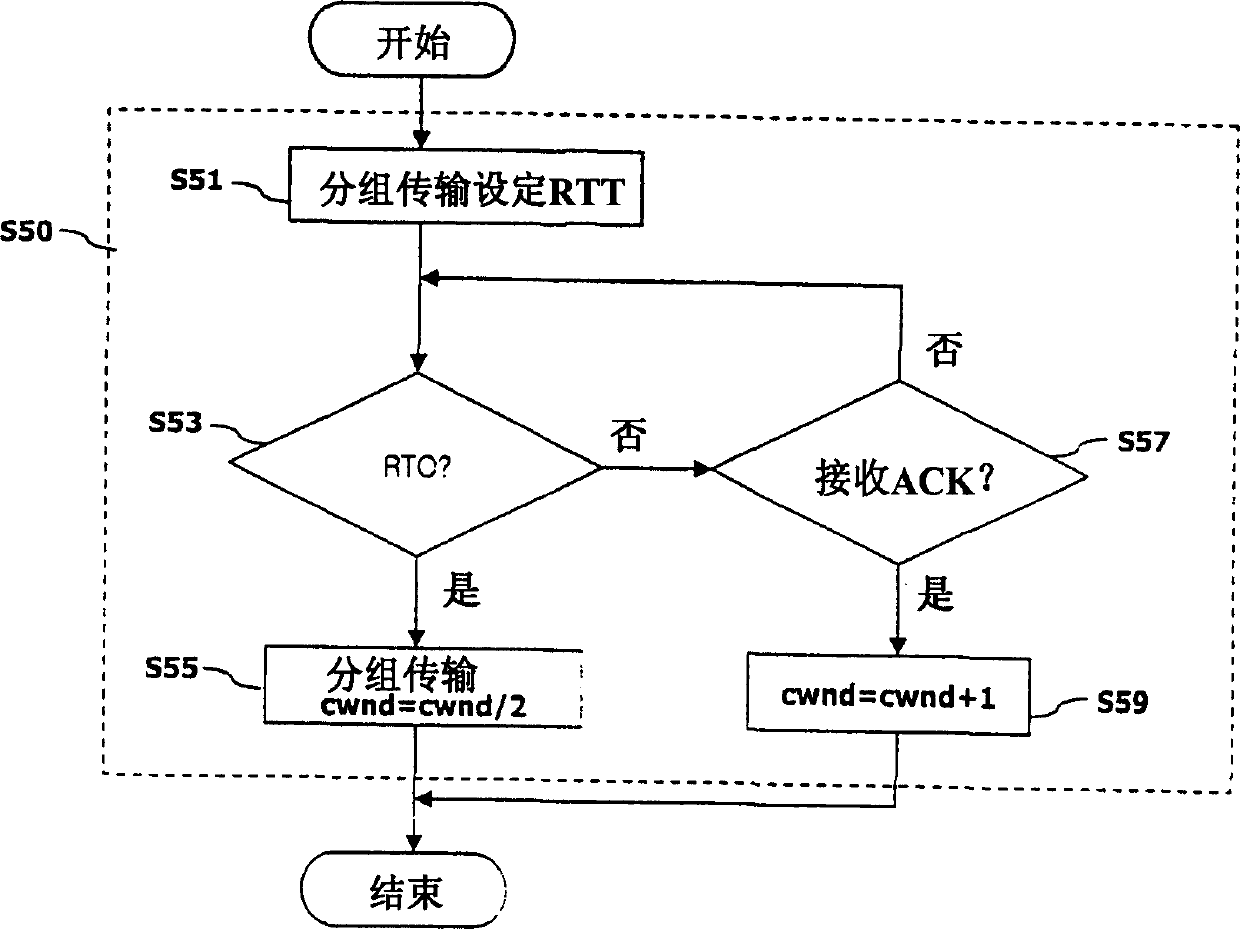

Tcp flow controlling method in high-speed mobile communications network

InactiveCN1767540AControl transmission speedError prevention/detection by using return channelNetwork traffic/resource managementData transmissionMobile communication network

Provides data transmission in mobile communication networks, and more specifically, a TCP flow control method for data transmission in high-speed mobile communication networks performing manual short-circuit / handover, which focuses on the following aspects, using mobile options of TCP packets The field identifies a mobile TCP packet, and the method includes determining which of a wired or mobile communication terminal is connected to the server, and controlling the transmission speed using different congestion avoidance schemes according to the determination.

Owner:LG ELECTRONICS INC

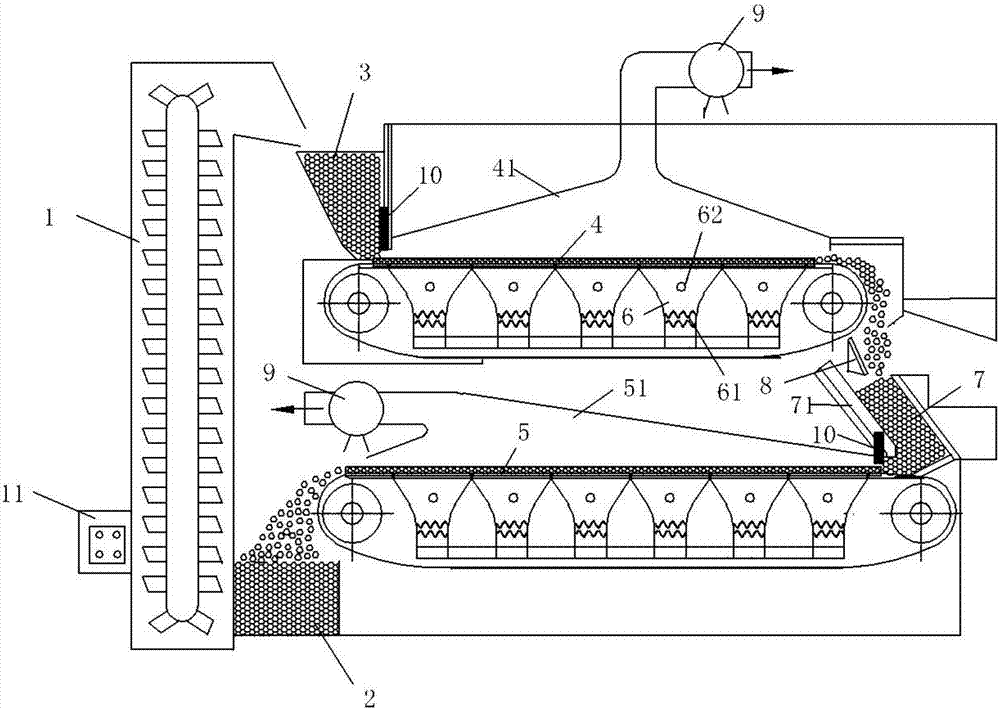

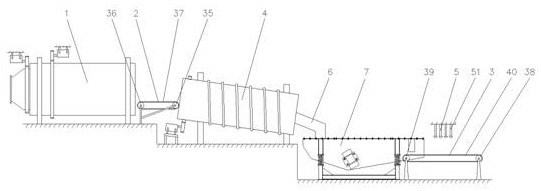

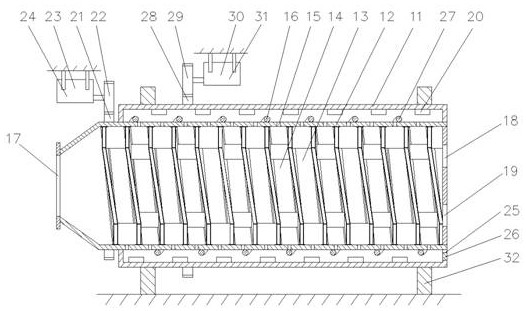

Composite electric heating grain dryer

InactiveCN106942367ACompact structureReduce cost inputSeed preservation by dryingHot blastElectric heating

The invention discloses a composite electric heating grain dryer. The composite electric heating grain dryer comprises an elevator, a bin and a drying device, wherein the drying device is arranged above the bin; the outlet of the elevator is connected with the inlet of the drying device. The composite electric heating grain dryer is characterized in that the drying device comprises an upper drying chamber and a lower drying chamber; an independent hot-air-room is arranged under a conveying belt; a tempering bin is arranged between the upper drying chamber and the lower drying chamber; therefore, the drying process can be automatically controlled by combining the design of a control terminal. Compared with the prior art, the composite electric heating grain dryer has the advantages that cost and environmental pollution can be reduced due to no hot-blast stove; an independent air chamber is adopted to supply heat, the drying hot-air temperature can be randomly adjusted, and the grain has high drying quality; the drying efficiency is improved since stage drying cannot cause interference; the design of the tempering bin is well matched with the grain drying characteristics, and the grain drying efficiency is high; the grain drying mode can be adjusted for different grain types by combining the control terminal, and a relatively high drying efficiency can be realized under a relatively low energy consumption condition.

Owner:HEFEI UNIV OF TECH

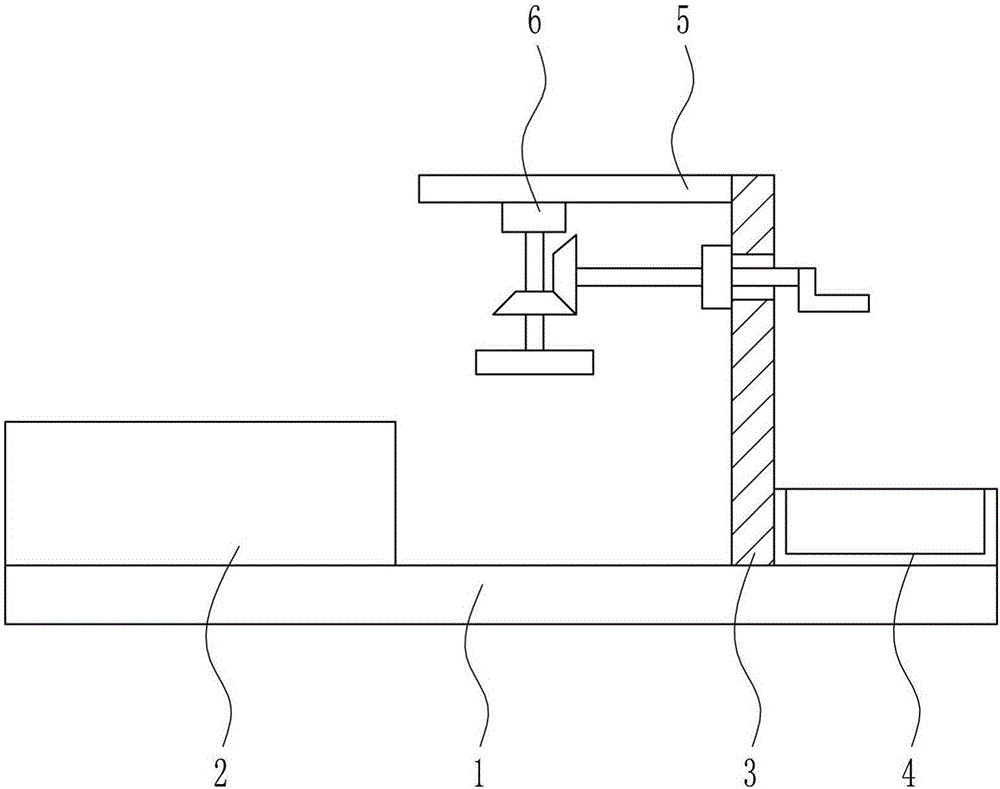

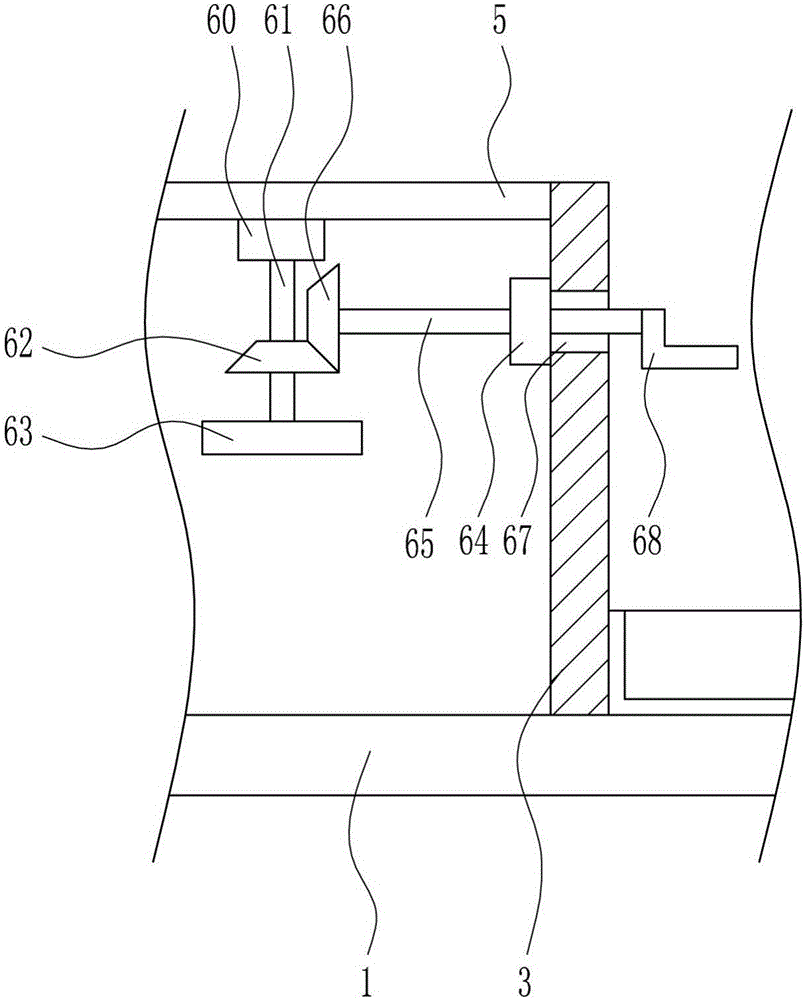

Polishing and grinding device for shoe sole

InactiveCN106723671AEasy accessFreely control transmission speedShoemaking devicesPlane surface grinding machinesEngineeringMulti dimensional

The invention relates to a grinding device, in particular to a polishing and grinding device for a shoe sole. The technical purpose for providing the polishing and grinding device for the shoe sole is achieved. In order to solve the technical problem, the polishing and grinding device for the shoe sole comprises a base plate, a conveying device, a third support, a collection box, a first support rod, a grinding device and the like; the conveying device, the third support and the collection box are arranged on the top of the base plate in sequence from left to right, the first support rod is arranged on the upper portion of the left side of the third support, and the grinding device is arranged at the bottom of the first support rod. Accordingly, the effects of diverse grinding directions and easy operation are achieved, a worker can fetch the shoe sole in the grinding process conveniently, the shoe sole is ground to be more precise and proper, and the worker can grind the shoe sole in a multi-dimensional mode.

Owner:林永远

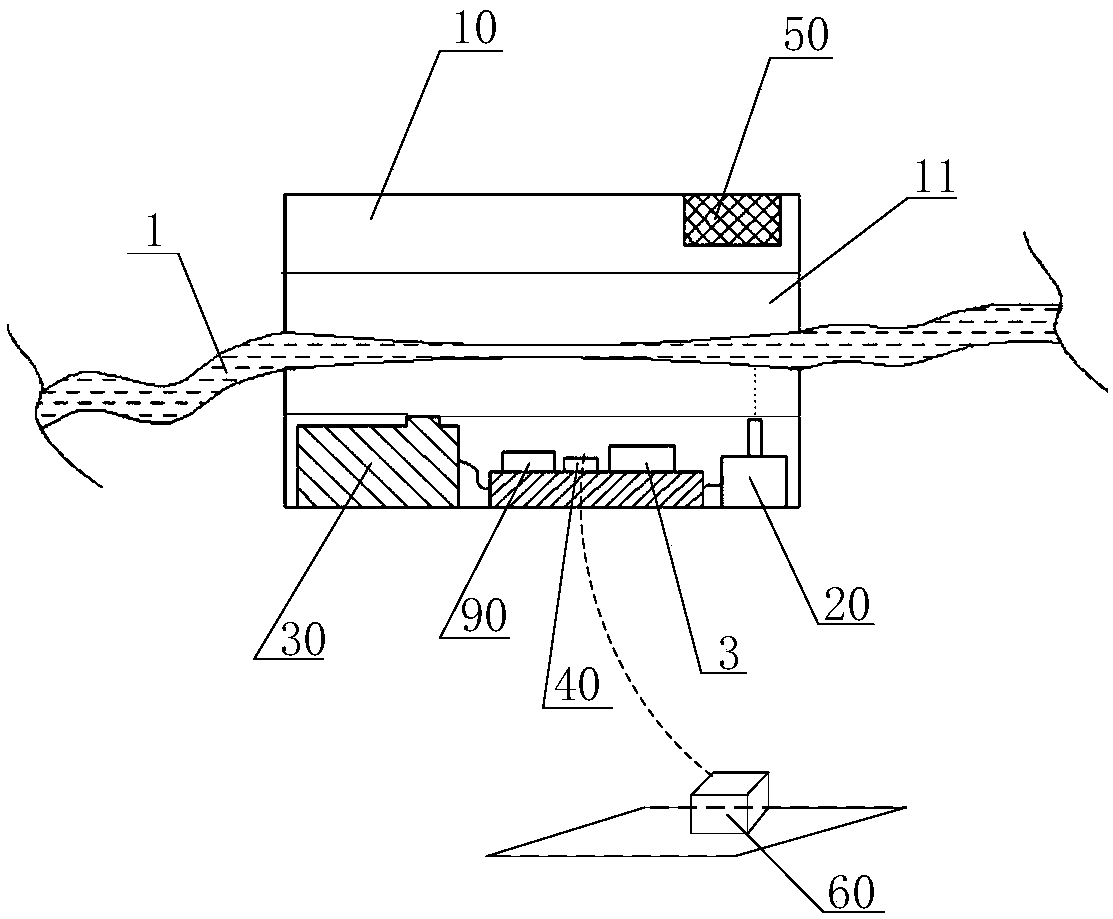

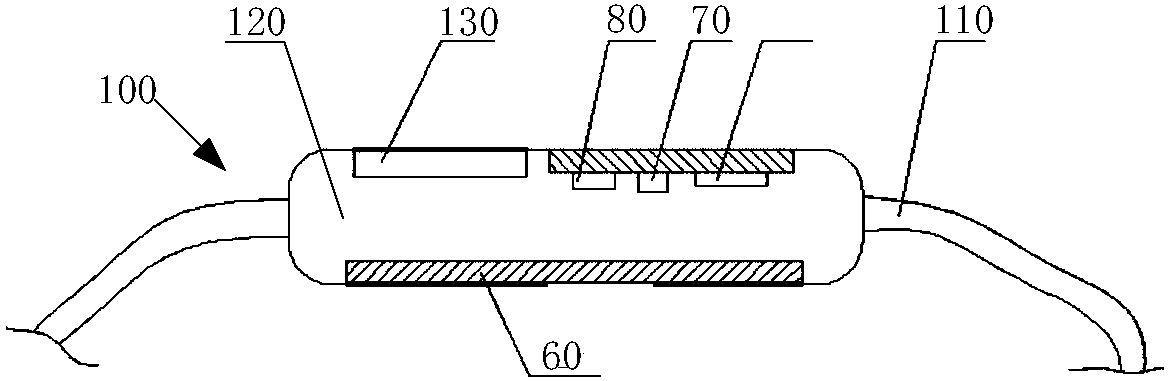

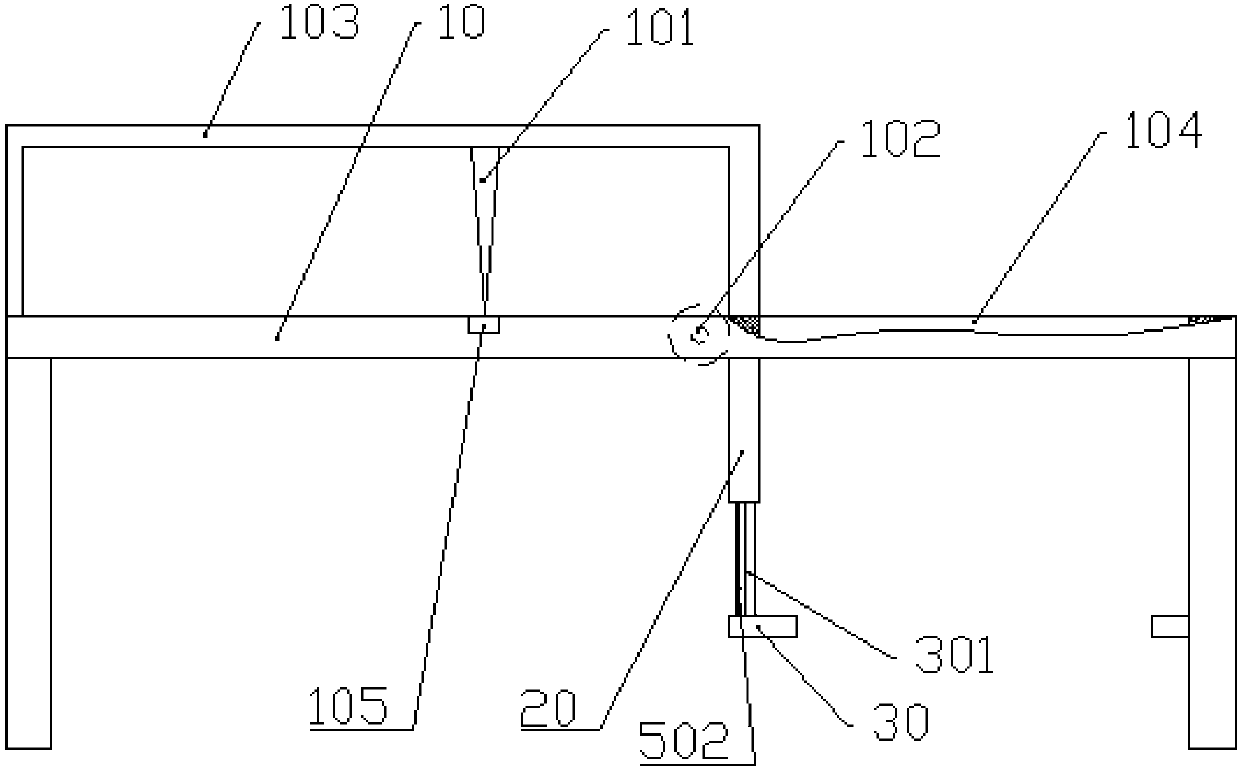

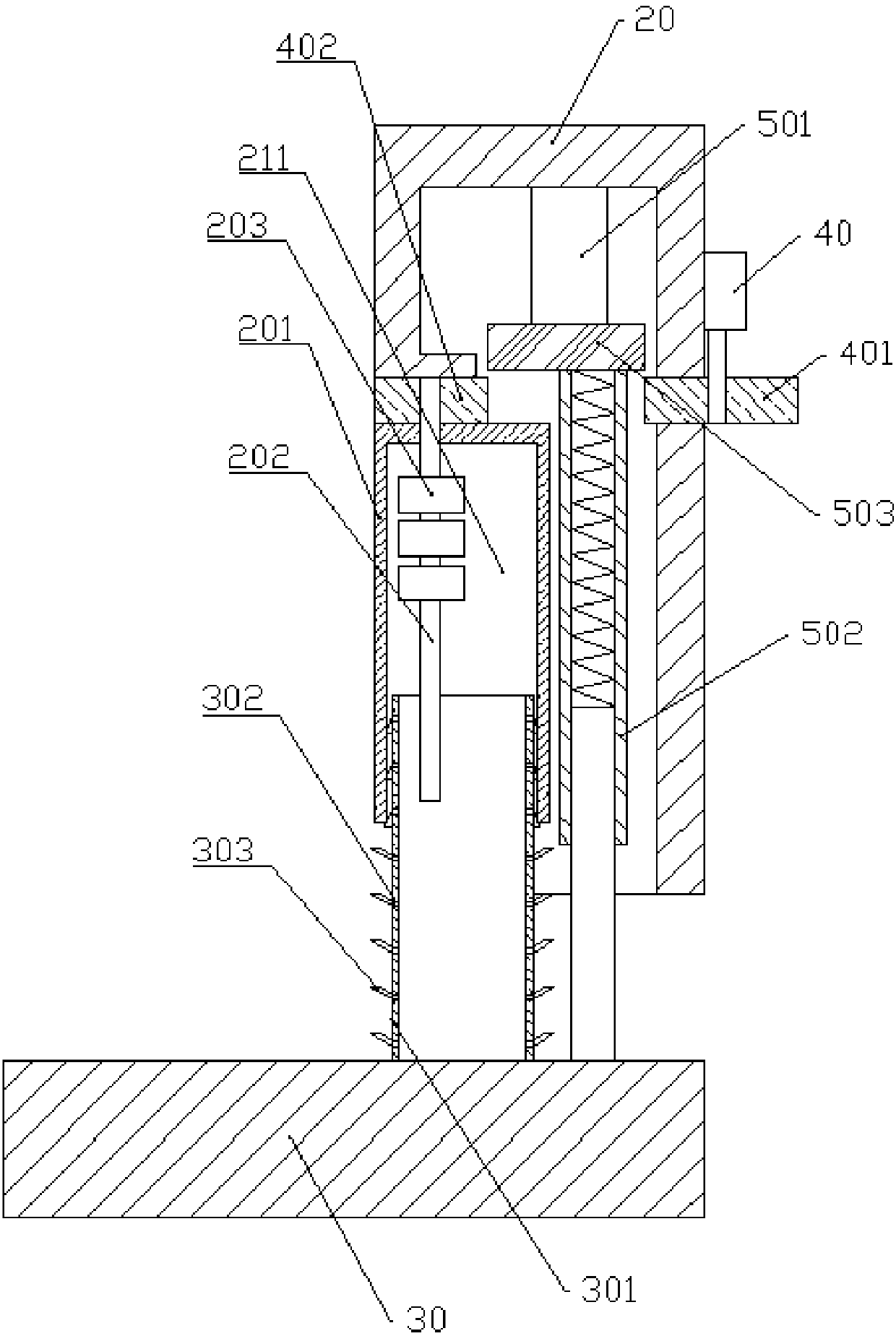

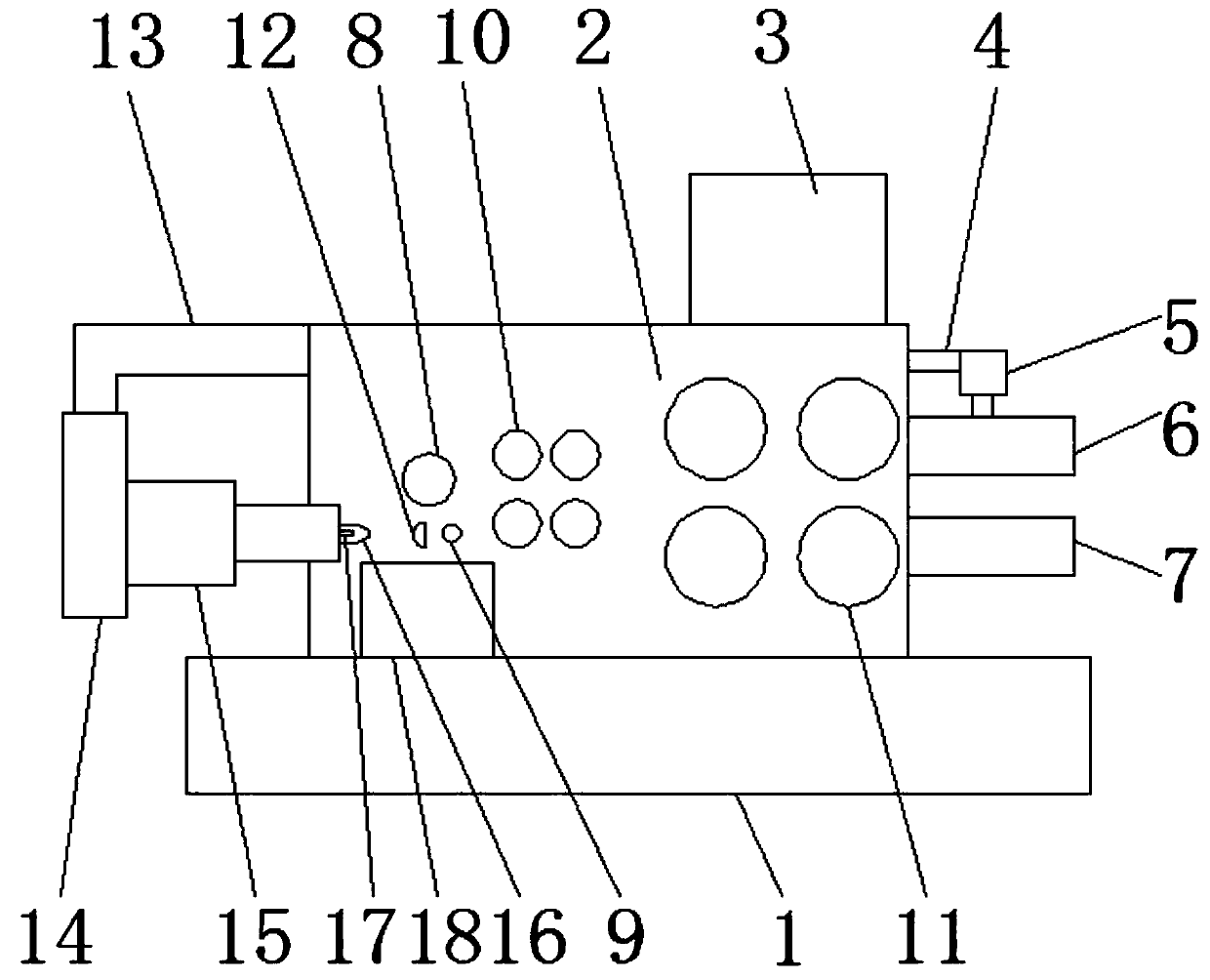

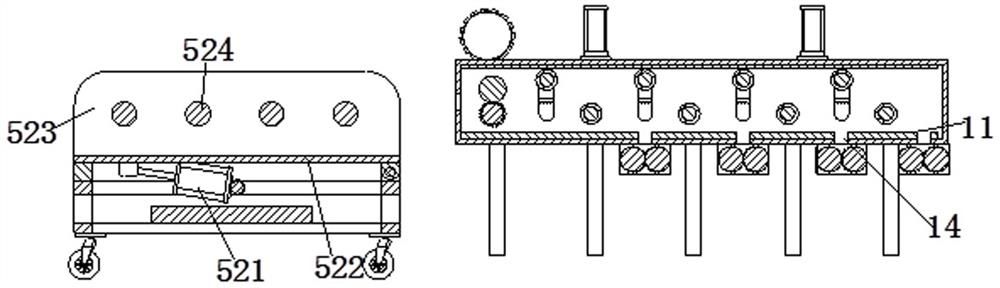

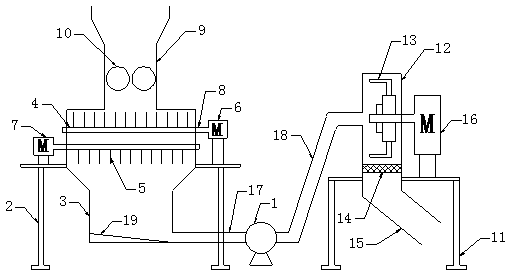

Liquid transmission control device and liquid transmission system

PendingCN110292679AAvoid abnormal flow ratesControl transmission speedElectrocardiographyMedical devicesTransmission systemLiquid transfer

The invention provides a liquid transmission control device and a liquid transmission system. The device comprises a pipeline bearing member, a flow rate sensor, an adjustment structure and a controller. The pipeline bearing member is designed to allow pipelines made from soft materials and used for liquid transfer to be arranged therein, the pipeline bearing member includes an accommodating space, and the accommodating space is used for accommodating at least one part of the pipelines; the flow rate sensor is used for detecting the flow rate of liquid transmission in the pipelines; the adjustment structure is used for adjusting the cross-sectional areas of the pipelines arranged in the accommodating space so as to adjust the flow rate of liquid transmission in the pipelines; the controller is used for outputting a control signal to the adjustment structure according to the flow rate detected by the flow rate sensor, so that the adjustment structure adjusts the cross-sectional areas ofthe pipelines arranged in the accommodating space. The device can monitor the condition of in-vitro and in-vivo liquid transmission and control the liquid transmission speed timely to avoid medical accidents caused by abnormal flow rates.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

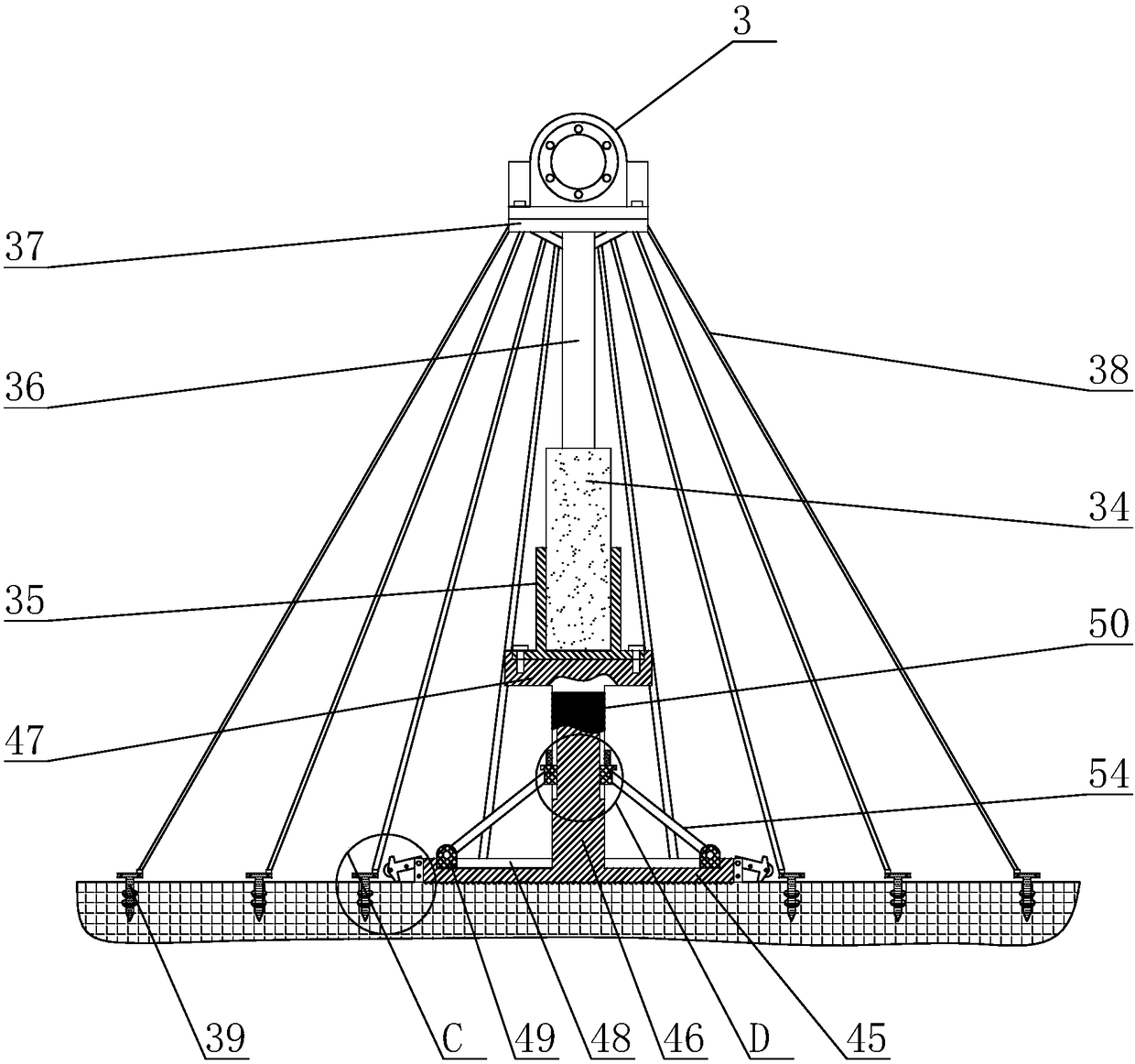

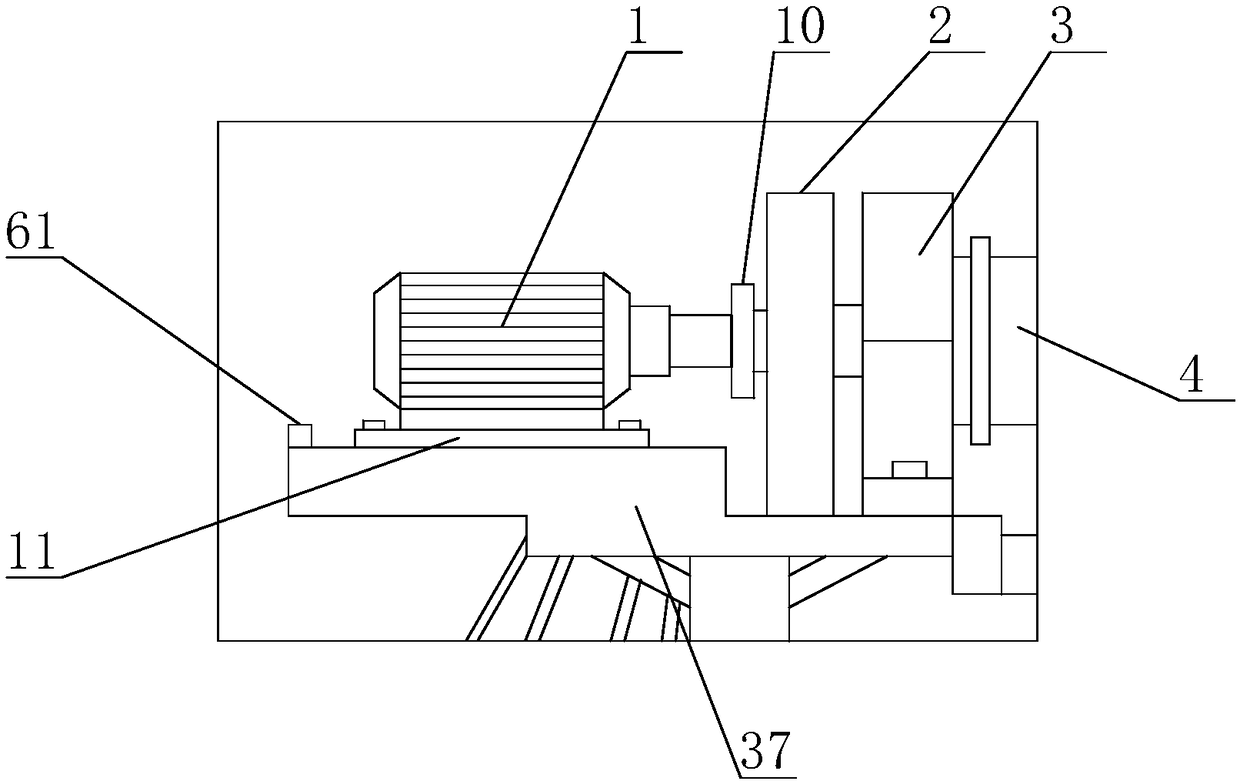

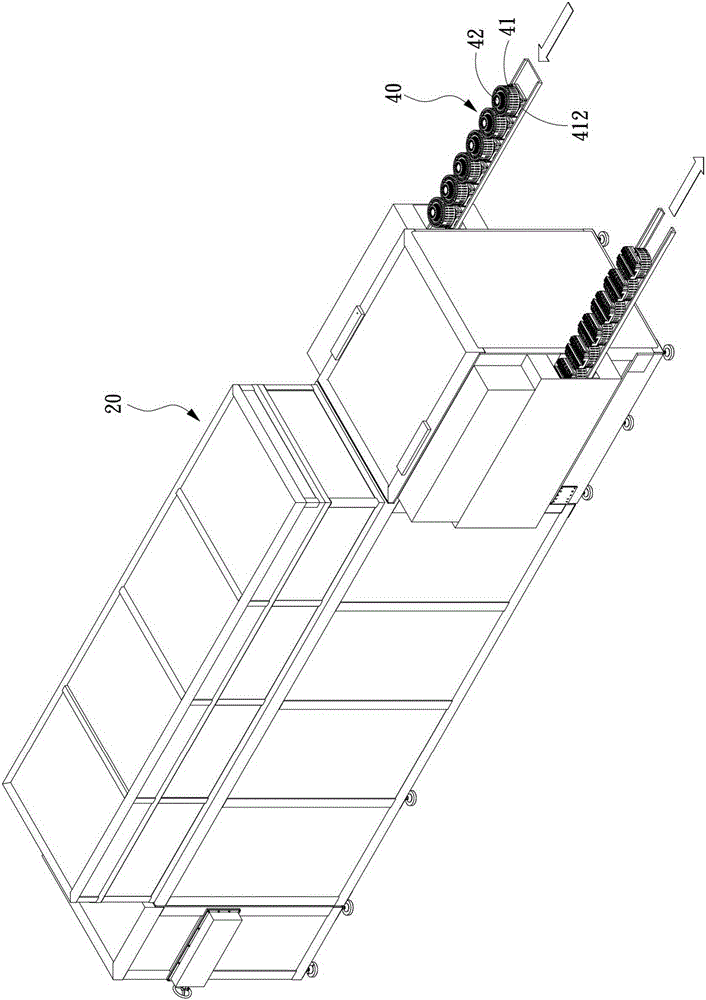

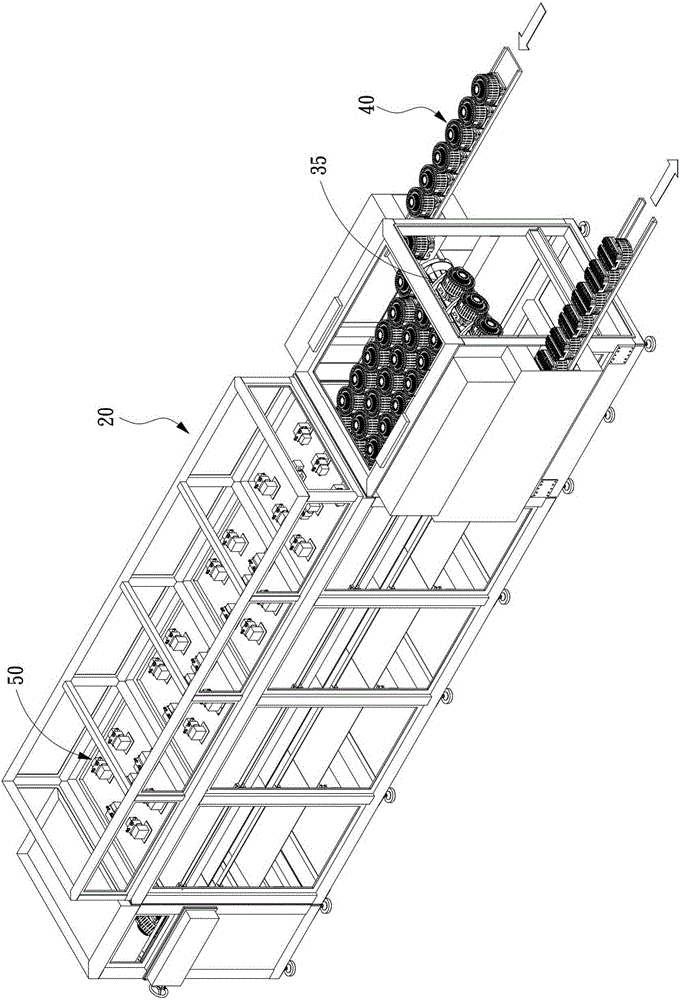

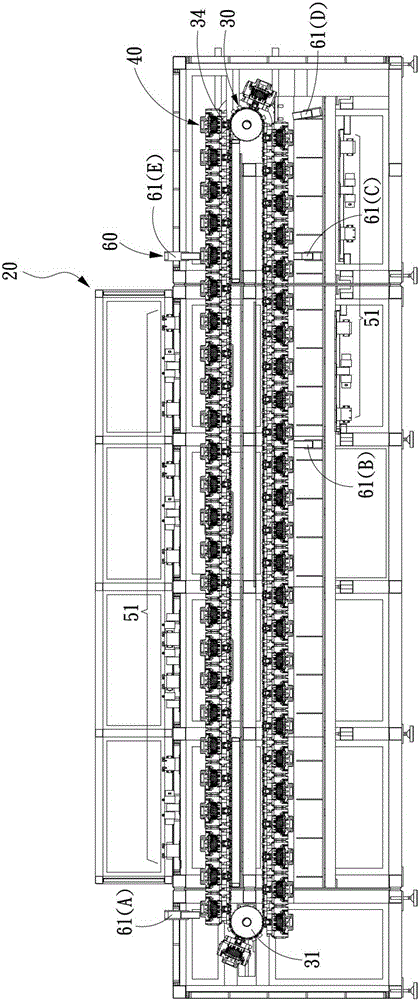

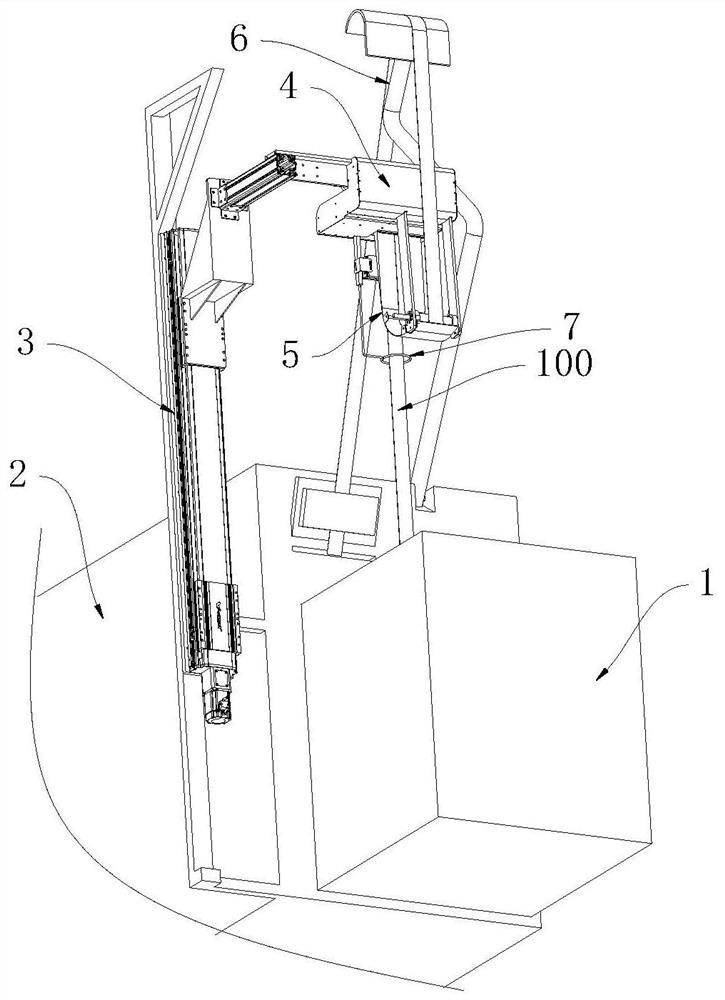

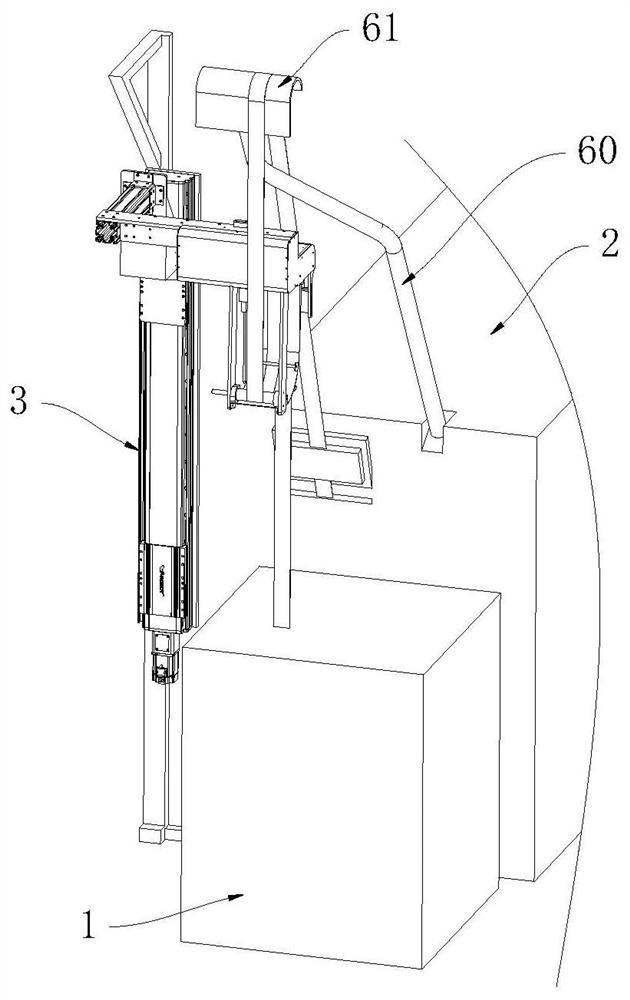

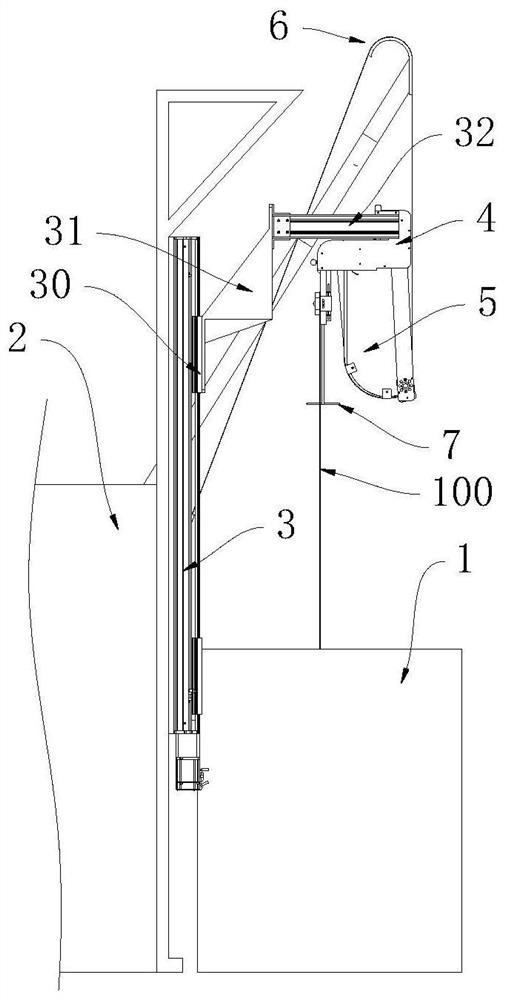

Construction material conveying apparatus

PendingCN108313882AEasy to operate and controlImprove construction efficiencyBase supporting structuresBraking devices for hoisting equipmentsDrive motorEngineering

The invention discloses a construction material conveying apparatus, and mainly relates to the field of construction equipment. The construction material conveying apparatus comprises two adjustable support frames, a driving mechanism, and a material conveying mechanism. The driving mechanism comprises a driving motor, a decelerator, a top bearing pedestal, and a driving main shaft. A driving gearis arranged on the driving main shaft. The material conveying mechanism comprises a conveying toothed belt, a bottom bearing pedestal arranged on the ground, and a driven gear. The conveying toothedbelt is tightened and is arranged between the driving gear and the driven gear. The rotation shafts of two ends of the driven gear are arranged on the bottom bearing pedestal. The external surface ofthe conveying toothed belt is provided with a plurality of material hanging devices. The conveying apparatus is suitable for transporting construction materials in a low building, is convenient to operate and control, can convey construction materials automatically and mechanically, and is capable of delivering materials to construction workers in all positions; the construction efficiency is largely improved, the labor cost is reduced, and furthermore, the conveying apparatus is convenient to assemble, disassemble, and transport, and promotes the development of construction in rural areas.

Owner:岳晓楠

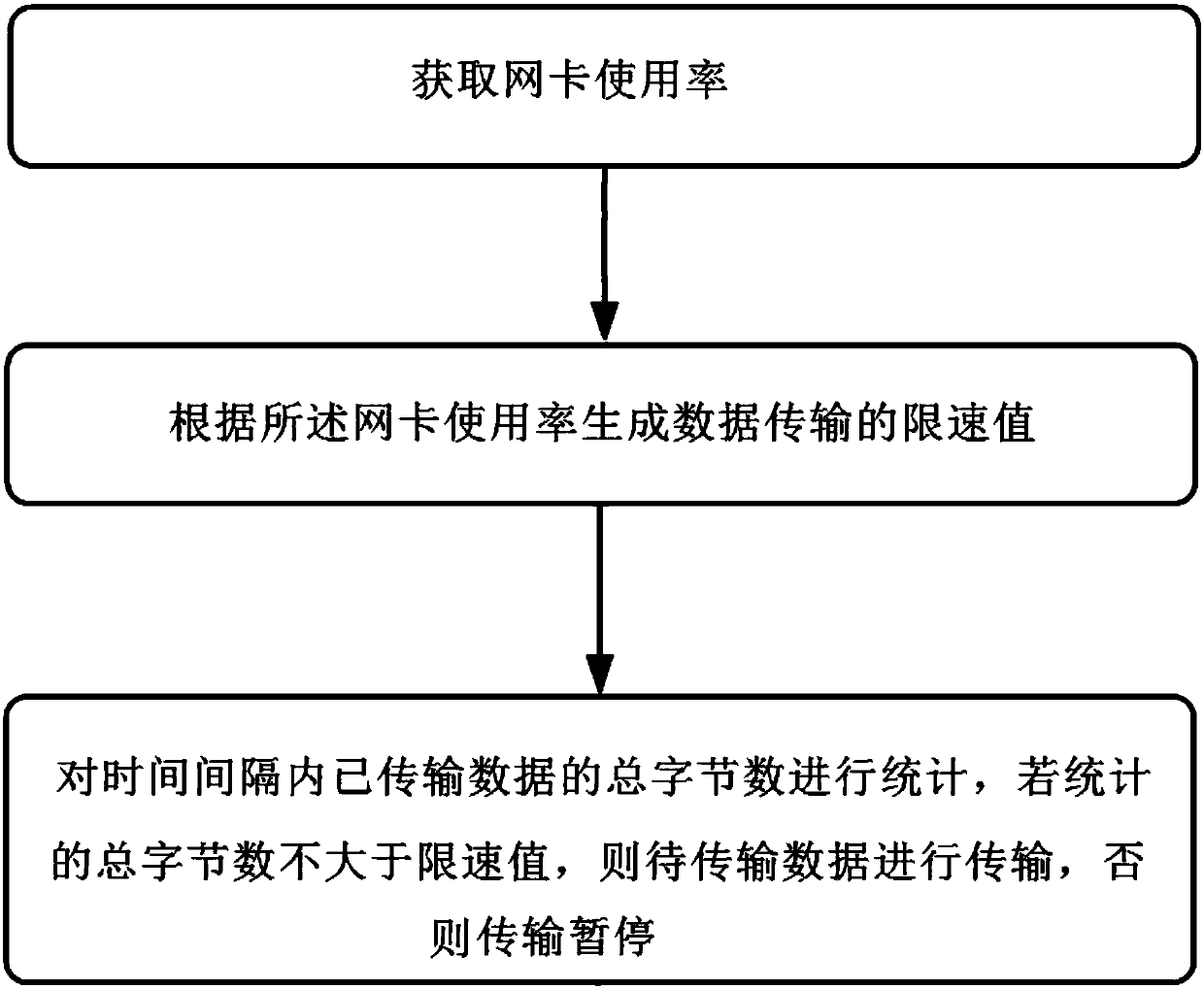

Speed limiting method and system for data transmission, equipment and computer readable storage medium

InactiveCN109547277ASolve the problem of fullFlexible control data transfer rateData switching networksControl dataBroadband

The invention relates to a speed limiting method and system for data transmission, equipment and a computer readable storage medium. The speed limiting method for data transmission comprises the following steps of acquiring a network card usage rate; generating a speed limit value of data transmission according to the network card usage rate; and counting the total number of bytes of data transmitted in a time interval, if the counted total number of bytes is not larger than the speed limit value, transmitting data to be transmitted, otherwise stopping transmission. According to the speed limiting method and system for data transmission, the equipment and the computer readable storage medium, a problem that broadband resources are occupied due to the fact that the broadband resources are used in an unlimited manner in a data transmission process is effectively solved, the speed limit value of data transmission is dynamically updated according to the network card usage rate, and the data transmission rate is controlled flexibly. Speed limit control is carried out by comparing the counted total number of bytes of the transmission data and the speed limit value, so that the time precision is high, and the ms level can be achieved.

Owner:SF TECH

Corn thresher

Owner:TIANJIN BAOTIAN AGRI MACHINERY SALES

Microwave heating system

InactiveCN106488602AAdjust heating temperatureAdjust heating timeMicrowave heatingSystems designClosed loop

The invention relates to a microwave heating system. The microwave heating system is used for heating and processing a sealing box loaded with a heated substance, a microwave pressure module is used for wrapping and pressurizing the sealing box, the microwave heating system is fixed on a transfer device moving in a cycle way, a microwave heating device is used for generating microwave, heating the sealing box and heating and stirring when the transfer device carries the sealing box to move, a temperature measurement module is used for detecting a temperature of the sealing box or the heated substance, high heat and high voltage can be stood when the sealing box is heated, no leak is generated in the heated substance due to internal expansion or hot steam, and heating is more uniform since the stirring strength of the heated substance can be set in advance and the moving speed can be dynamically controlled; and meanwhile, during system design, appropriate stirring frequency and repeated heating frequency of the heated substance can be set, parameters such as output power and heating time of the microwave heating device and a rotational speed of the transfer device can be dynamically adjusted during system running, a closed-loop temperature control system is formed, and the demand of an industrial heating program is satisfied.

Owner:BOTTLE TOP DEV

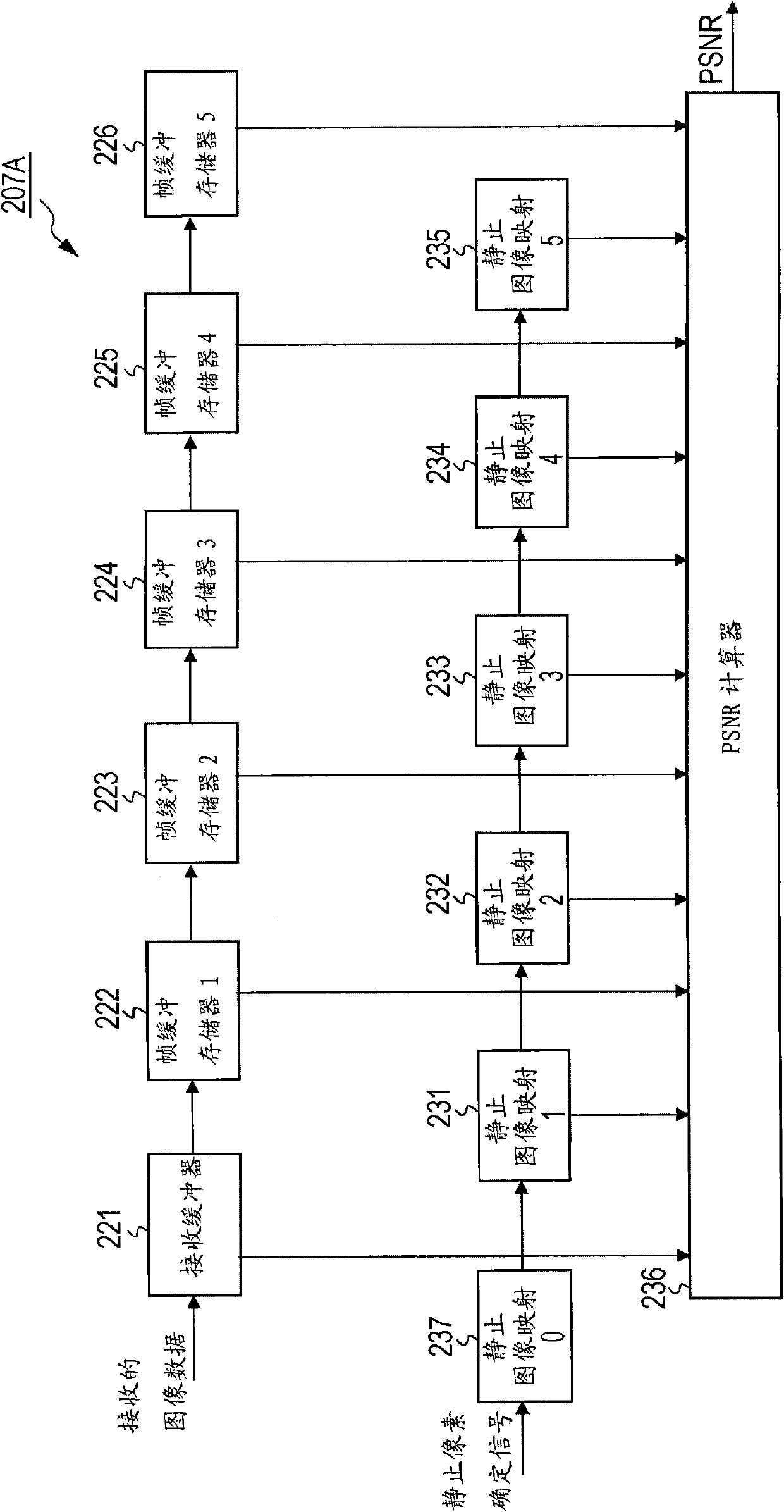

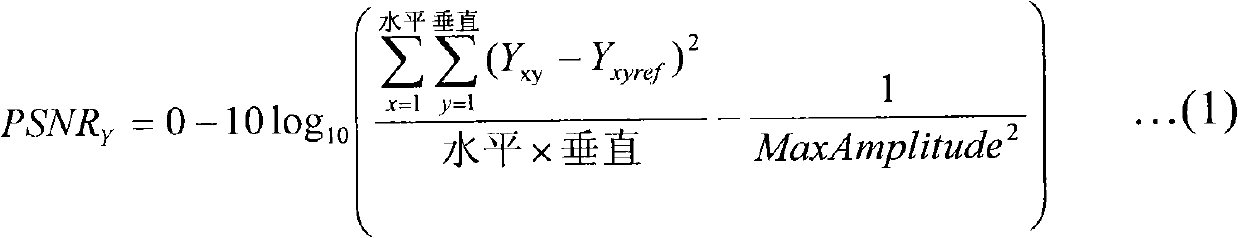

Image receiving apparatus, image receiving method, and image transmitting apparatus

InactiveCN101951503AControl transmission speedControl transmission powerTelevision system detailsPulse modulation television signal transmissionWireless transmissionImaging data

An image receiving apparatus includes: an image data receiver which receives image data wirelessly transmitted from an external apparatus; and a transmission path state detector which detects a state of a wireless transmission path on the basis of a degree of deviation from an average value of pixel data of pixels in a time direction in a still image region of the image data received by the imagedata receiver.

Owner:SONY CORP

Copper clad plate cutting method

ActiveCN107931697AEasy to GrindImprove grinding efficiencyShearing machinesShearing machine accessoriesCopper

The invention relates to the field of circuit boards, and particularly discloses a copper clad plate cutting method. In the cutting method, a cutting device is adopted, the cutting device can conductgrinding treatment on the four cut corners of a copper clad plate at the same time in the using process, and the grinding efficiency of the corners of the copper clad plate is improved; and meanwhile,ground copper clad plates are stacked on a receiving plate and can be centralizedly collected conveniently, and the stacked copper clad plates do not need to be arranged again. Through the scheme, the grinding efficiency of the corners of the copper clad plate can be improved.

Owner:高唐融知融智科技服务有限公司

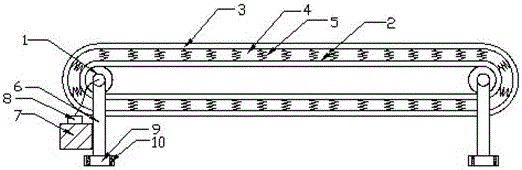

Conveying device

InactiveCN105947675AReduce exposureReduce Fragmentation RateCharge manipulationConveyor partsBreakage rateEngineering

The invention provides a conveying device. The conveying device comprises a conveying body support, a supporting unit used for supporting a to-be-conveyed object and conveying units. The supporting unit comprises a plurality of supporting rods used for being supported on the two opposite sides of the to-be-conveyed object. The conveying units are arranged on the conveying body support and connected with the supporting unit and can move on the conveying body support to drive the supporting unit to move so that the to-be-conveyed object can be conveyed. The conveying units are arranged on the two sides of the conveying body support and are used for supporting and conveying the to-be-conveyed object. Compared with the prior art, contact between the to-be-conveyed object and the conveying device in the conveying process is reduced, the breakage rate in the carrying process is reduced, and the production yield is increased. When to-be-conveyed objects with patterns on the back side are encountered, the locality and possibility of scratching of the back side patterns can be greatly reduced, the quality is guaranteed, and the conveying speed is more easily controlled. Compared with a traditional conveying device, the number of wheels is reduced, and the equipment purchasing and installing and maintaining cost is saved.

Owner:BOE TECH GRP CO LTD +1

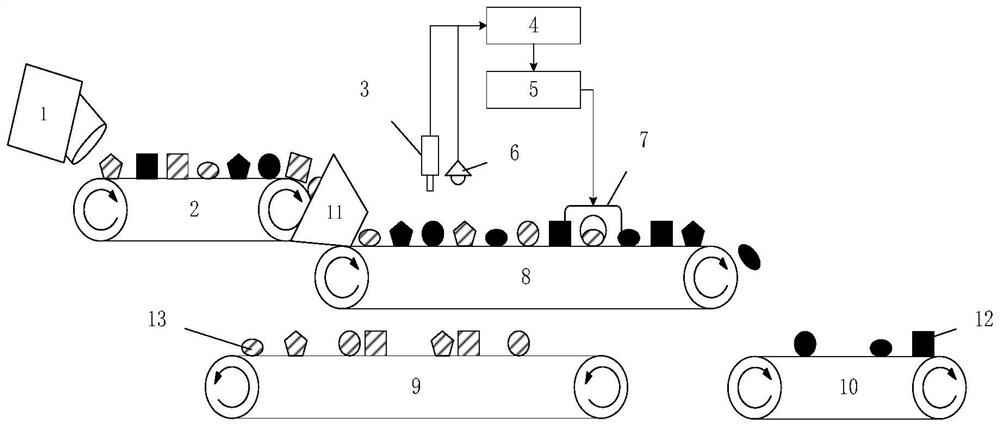

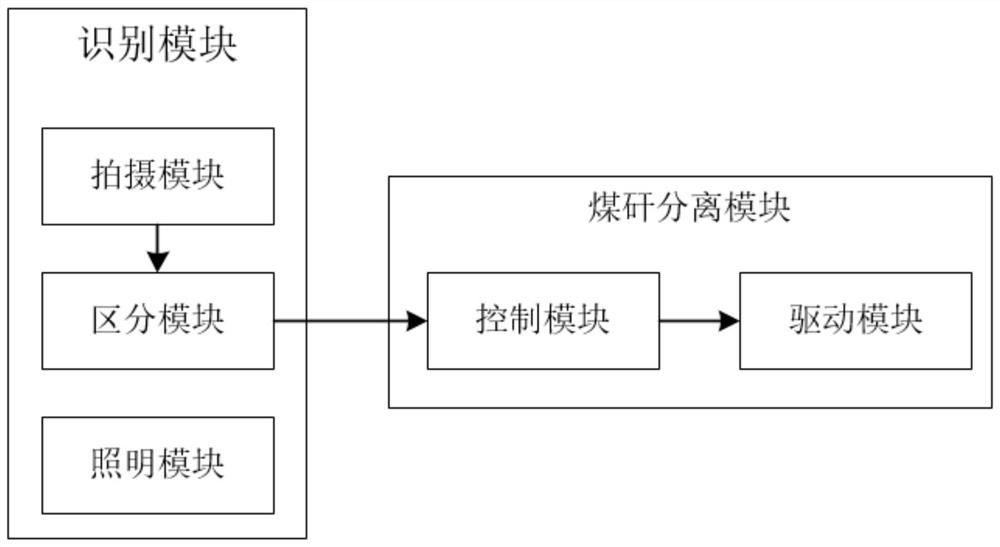

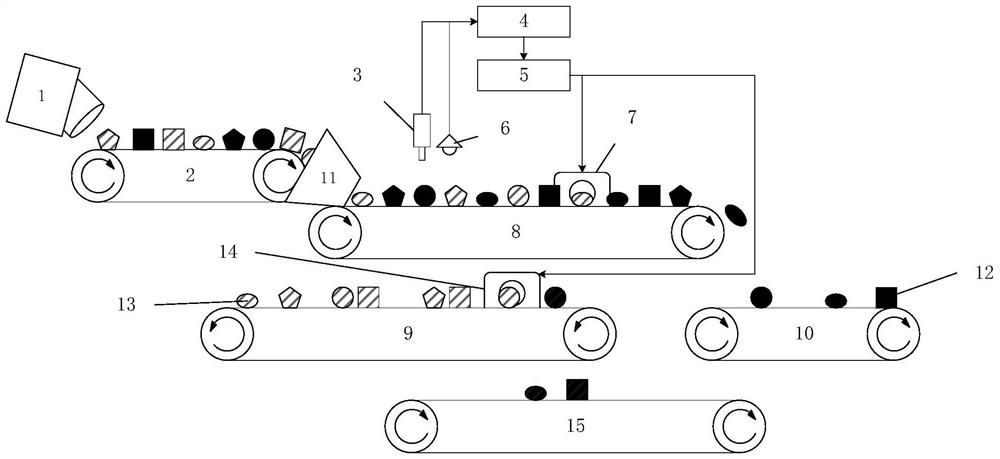

Coal and gangue separation system and identification method

PendingCN113680709ASeparation, environmental protection and safetyLow costSortingThermodynamicsProcess engineering

The invention belongs to the technical field of coal and gangue separation, and discloses a coal and gangue separation system and an identification method. The coal and gangue separation system comprises a vibration coal feeder, a main conveyor belt, an identification module and a coal and gangue separation device, wherein the vibration coal feeder is located at the conveying starting end of the main conveyor belt and used for conveying a coal and gangue mixture to the main conveyor belt, and the coal and gangue mixture comprises coal and gangue; the main conveyor belt is used for conveying the coal and gangue mixture; the identification module is located right above the main conveyor belt and used for shooting a coal and gangue mixture image, putting the shot coal and gangue image into a gangue model, identifying gangue in the image and obtaining position information of the gangue; and the coal and gangue separation device is located at one side of the main conveyor belt and used for screening out gangue according to a confidence coefficient, obtaining the position information of the gangue and separating out the gangue before the coal and gangue mixture reaches the tail end of the main conveyor belt, so that the problems that in the prior art, a gangue identification method is harmful, equipment is complex, the equipment cost is high, and maintenance is difficult are solved.

Owner:重庆科华安全设备有限责任公司 +1

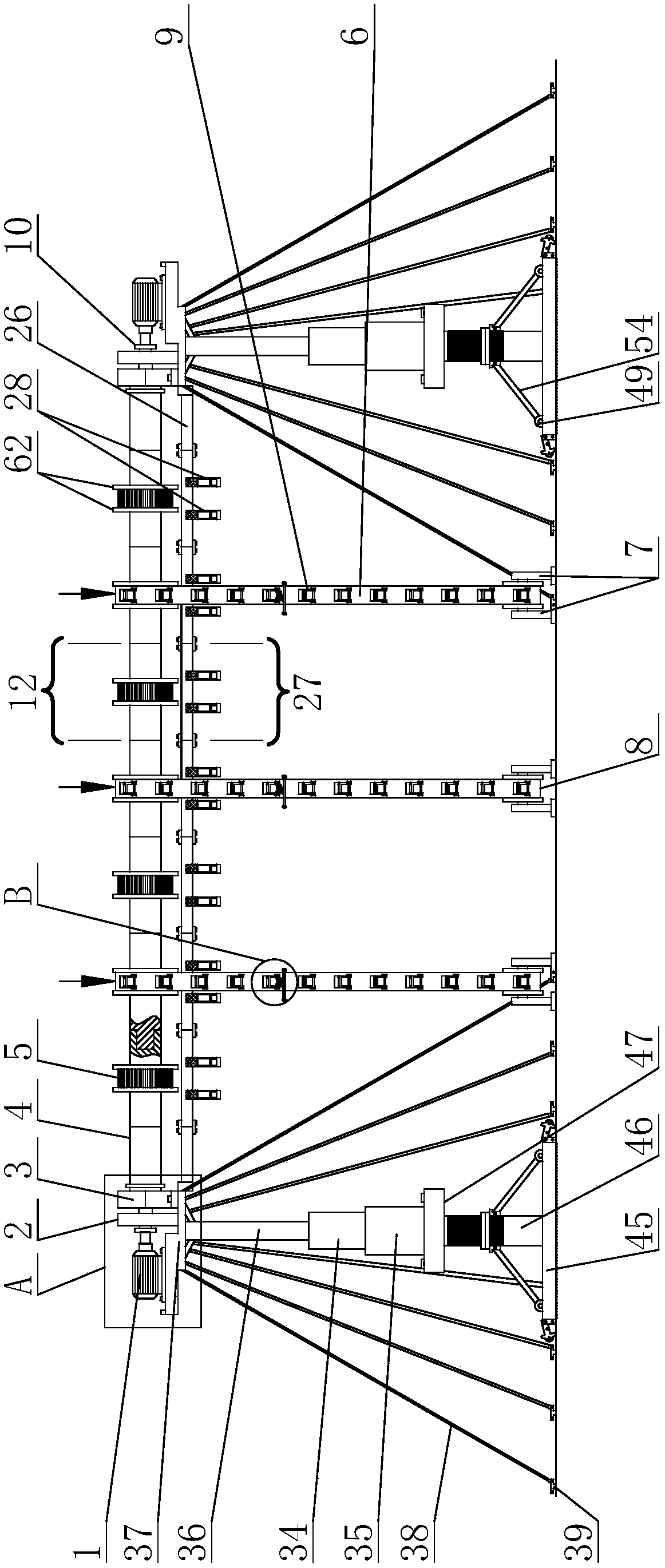

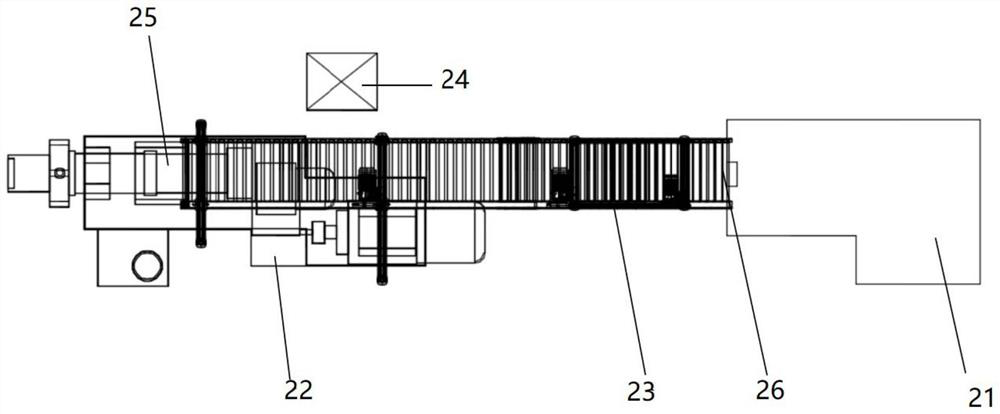

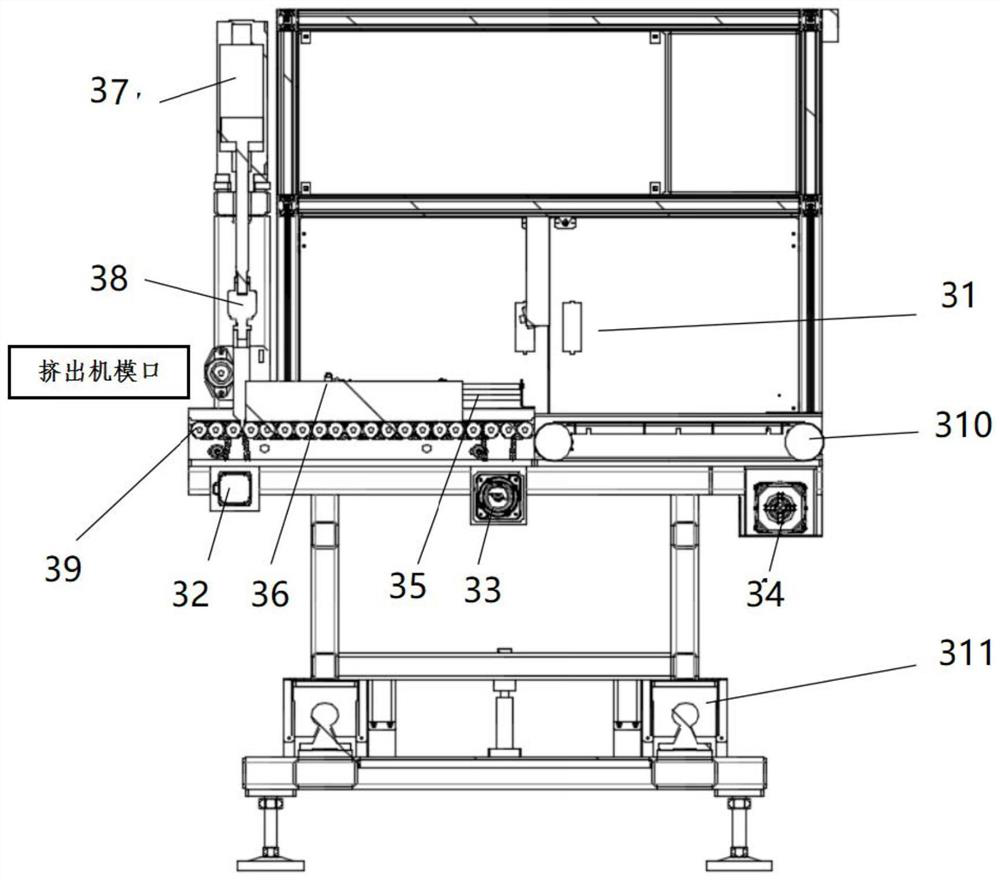

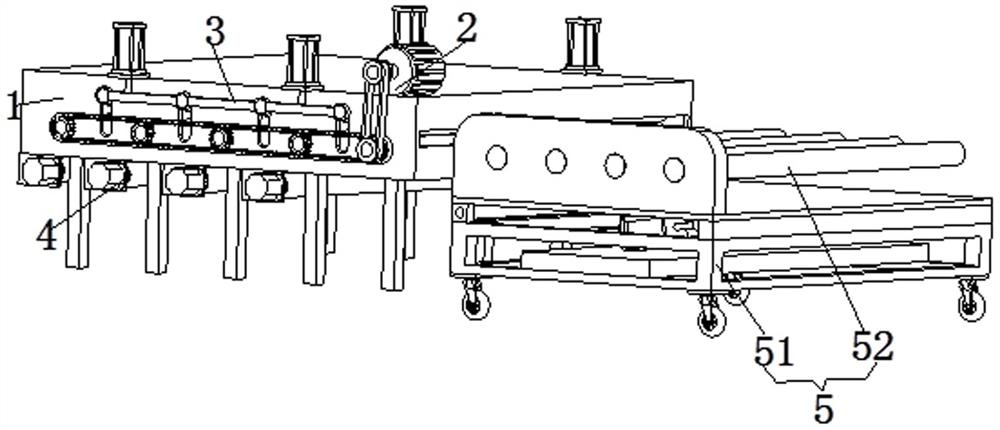

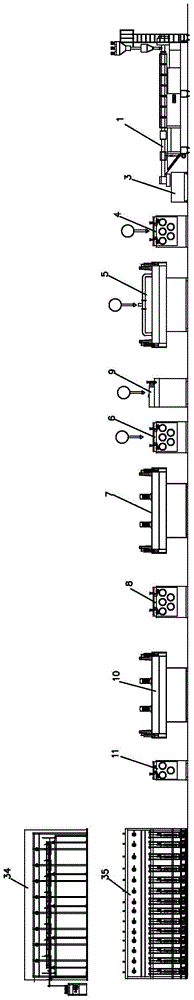

Silicone rubber automatic conveying, extruding and packaging production equipment and production method

The invention discloses silicone rubber automatic conveying, extruding and packaging production equipment and a production method. The silicone rubber automatic conveying, extruding and packaging production equipment comprises a plurality of extruding and packaging production line branch lines, a high-altitude roller conveying line and a stacking main line, the extruding and packaging production line branch lines are located on one side of the high-altitude roller conveying line, and the stacking main line is located at the output end of the high-altitude roller conveying line; each extruding and packaging production line branch line is sequentially provided with a silicon rubber cutting automatic conveying mechanism, an automatic fixed-length cutting mechanism, a weighing conveying mechanism, a film covering packaging mechanism, a shaping, boxing and labeling mechanism, a first two-way conveying lifting device and a carton opening mechanism; and the stacking main line comprises a second two-way conveying lifting device, a carton sealing mechanism and a mechanical arm stacking mechanism. The production line equipment is simple in structure and easy to maintain, the equipment maintenance time is shortened, and the production efficiency is effectively improved.

Owner:XINAN TIANYU SILICONE CO LTD

Efficient food processing and sorting machine

InactiveCN106862088AControl forward speedHigh degree of automationSortingAutomatic controlEngineering

The invention belongs to the technical field of agricultural machinery and discloses an efficient food processing and sorting machine, which includes a transmission device, a sorting device and a control device, the sorting device is located at the front end of the transmission device, and the transmission device and the sorting device are Connected with the control device, the transmission device includes a transmission belt, the front end of the transmission belt is provided with a transmission motor, the sorting device includes at least two collection boxes, and an air blowing device is arranged on the collection box, and the air blowing device The device includes an air blowing port and an air intake pipe connected to the air blowing port, the air intake pipe is provided with a flow control device, the transmission belt is provided with a quality sensor, and the transmission motor, the flow control device and the quality sensor are all connected with the control The device is connected, and the control device is provided with a motion control device. The high-efficiency food processing and sorting machine of the present invention has high automatic control, high sorting efficiency and high sorting precision.

Owner:SHAANXI SHANZE AGRI SCI & TECH

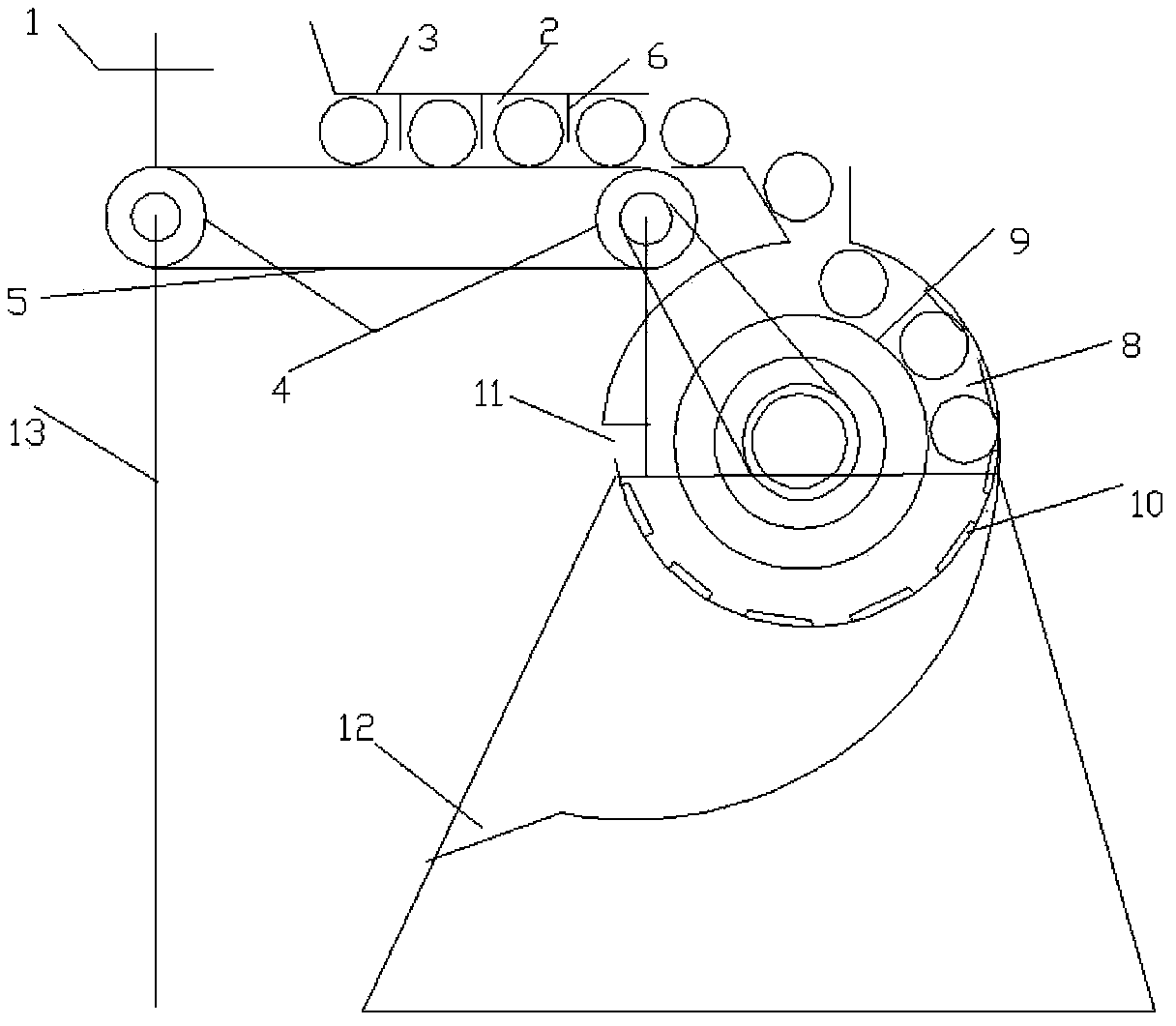

Novel looping machine with machining precision

InactiveCN109822019APrecise processingControl transmission speedWire ringsHydraulic cylinderSteering wheel

The invention discloses a novel looping machine with machining precision. The machine comprises a base; a machine body is fixedly mounted at the top of the base; a console is fixedly mounted at the top of the machine body; a connecting rod is fixedly mounted on the right side surface of the machine body; a first hydraulic cylinder is fixedly mounted at the right end of the connecting rod; a movable pressing plate is fixedly mounted at the bottom of the first hydraulic cylinder; a base plate is arranged on the right side surface of the machine body; a steering wheel, a support wheel, a feedingwheel and a pressing wheel are rotationally mounted on the front surface of the machine body; a guide block is fixedly mounted on the front surface of the machine body; an L-shaped rod is fixedly mounted on the right side surface of the machine body; the end, far from the machine body, of the L-shaped rod is fixedly connected with the mounting plate; a second hydraulic cylinder is fixedly mountedon the right side surface of the mounting plate; a cutter is arranged at the end, far from the mounting plate, of the second hydraulic cylinder; and a light eye is arranged on the front surface of thecutter. The novel looping machine with machining precision can control the moving speed of steel coils through the pressing wheel and the feeding wheel, and can timely cut off the steel coils throughcooperation of the light eye with the second hydraulic cylinder and the cutter to guarantee the size precision of steel rings.

Owner:安徽安康塑业有限公司

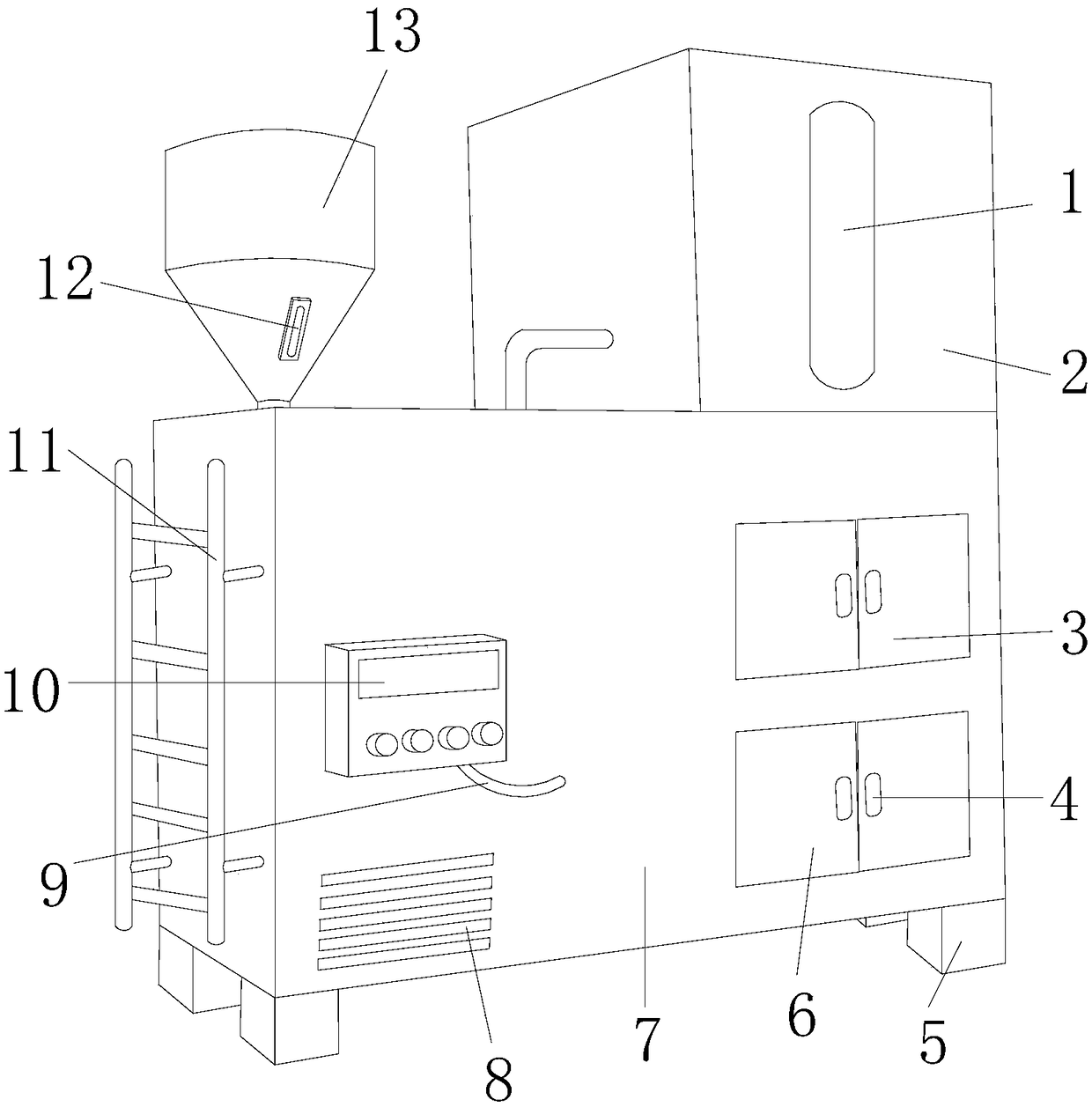

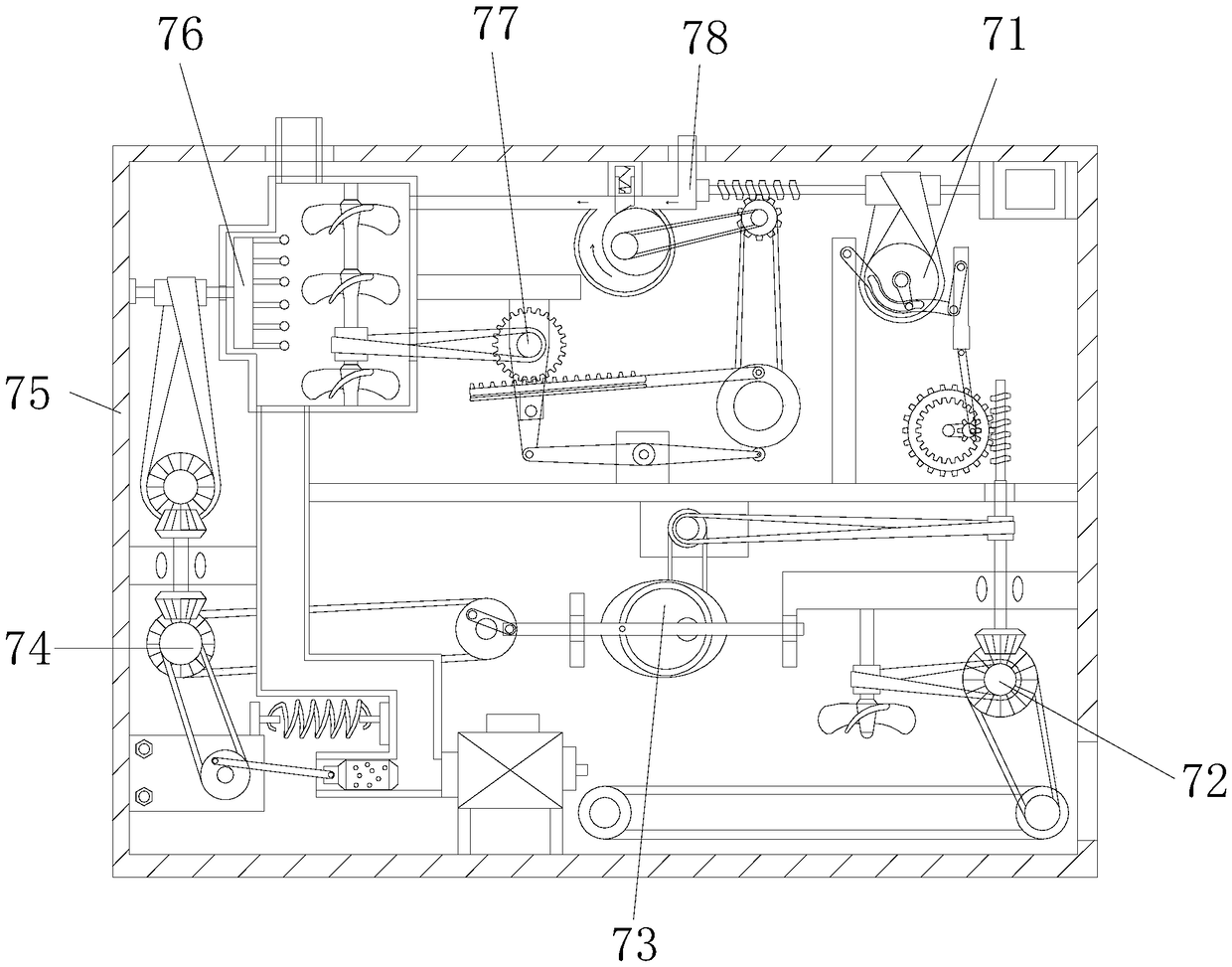

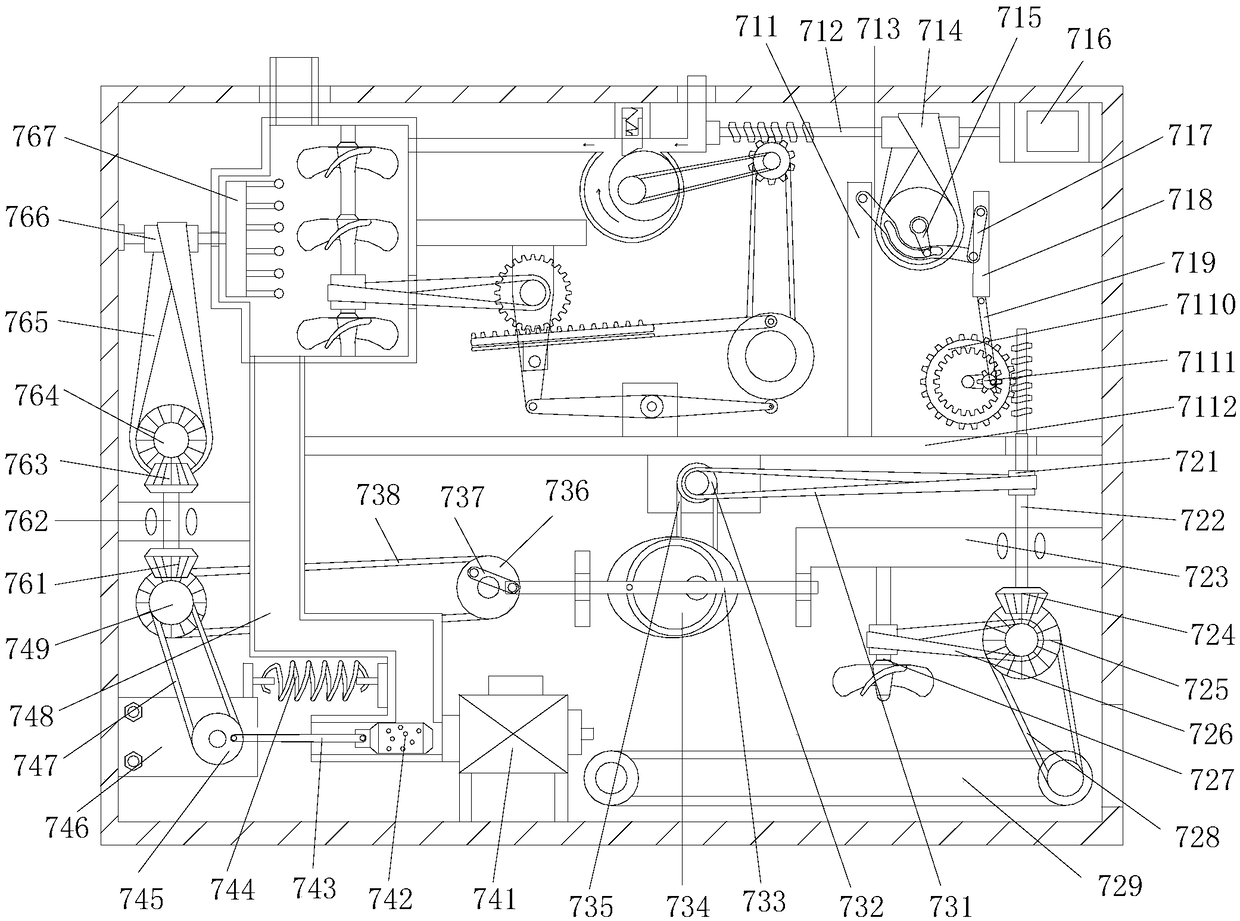

Biodegradable membrane producing equipment

The invention discloses biodegradable membrane producing equipment which structurally comprises transparent glass, a plasticizer box, an upper opening and closing door, a plastic groove, a cushion block, a lower opening and closing door, a degradation membrane anti-breakage device, a ventilation opening, a power line, a control panel, a ladder, an observation port and a large funnel. The plasticizer box is welded to the right end of the upper surface of the degradation membrane anti-breakage device, the transparent glass is embedded in the front surface of the plasticizer box, the large funnelis embedded into the left end of the upper surface of the degradation membrane anti-breakage device, the observation port is attached to the front surface of the large funnel, and the ladder is welded to the left surface of the degradation membrane anti-breakage device. The degradation membrane anti-breakage device is arranged to control the extrusion speed of thermoplastic and the transmission speed of a membrane conveying belt, the tensile force borne by the thin membrane can be within a bearable range, and the membrane is prevented from being broken by pulling due to excessive tension; anda plasticizer is added into raw materials, so that the toughness of the membrane is further improved, and the quality of products is ensured.

Owner:谢彬彬

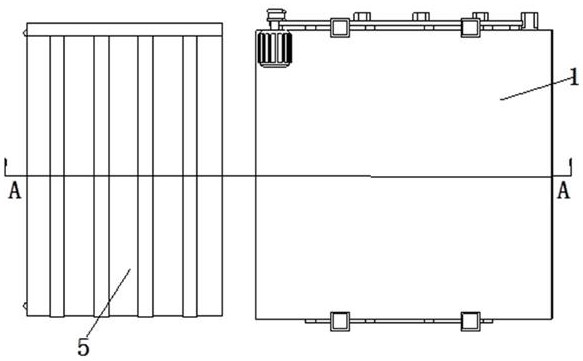

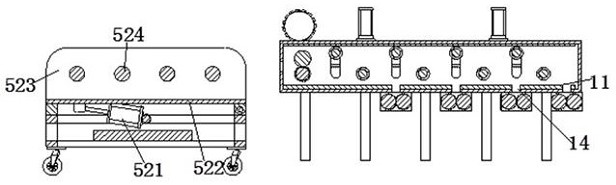

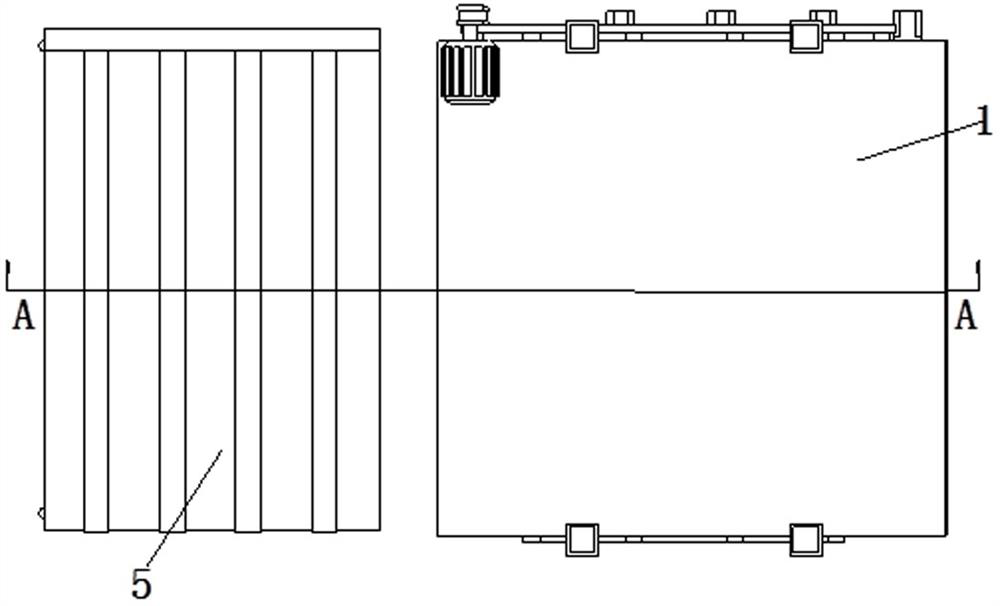

A cloth drying device

ActiveCN112899945BExtended drying timeImprove drying effectLiquid/gas/vapor removalTextile treatment carriersEngineeringMechanical engineering

The invention discloses a cloth drying device, which relates to the technical field of cloth drying, and comprises a drying box body, a transmission assembly, a lifting assembly, a material unloading assembly and a material loading assembly. The drying box body is fixedly arranged on the ground, The lifting assembly is arranged above the drying box, and the working end of the lifting assembly is movably arranged in the drying box, the transmission assembly is arranged in the drying box, and the unloading assembly is provided with several groups, Several groups of the unloading components are arranged on the drying box, and the feeding components are set on the side of the drying box, and through the cooperation between the components of the present invention, various cloths can be dried at the same time According to the different drying degrees of different fabrics, the materials are cut separately.

Owner:温州市豪维顿服饰有限公司

Feeding device for industrial manufacturing

InactiveCN106044050ASimple structureLow costConveyorsControl devices for conveyorsDrive shaftManufacturing systems

Owner:吴建平

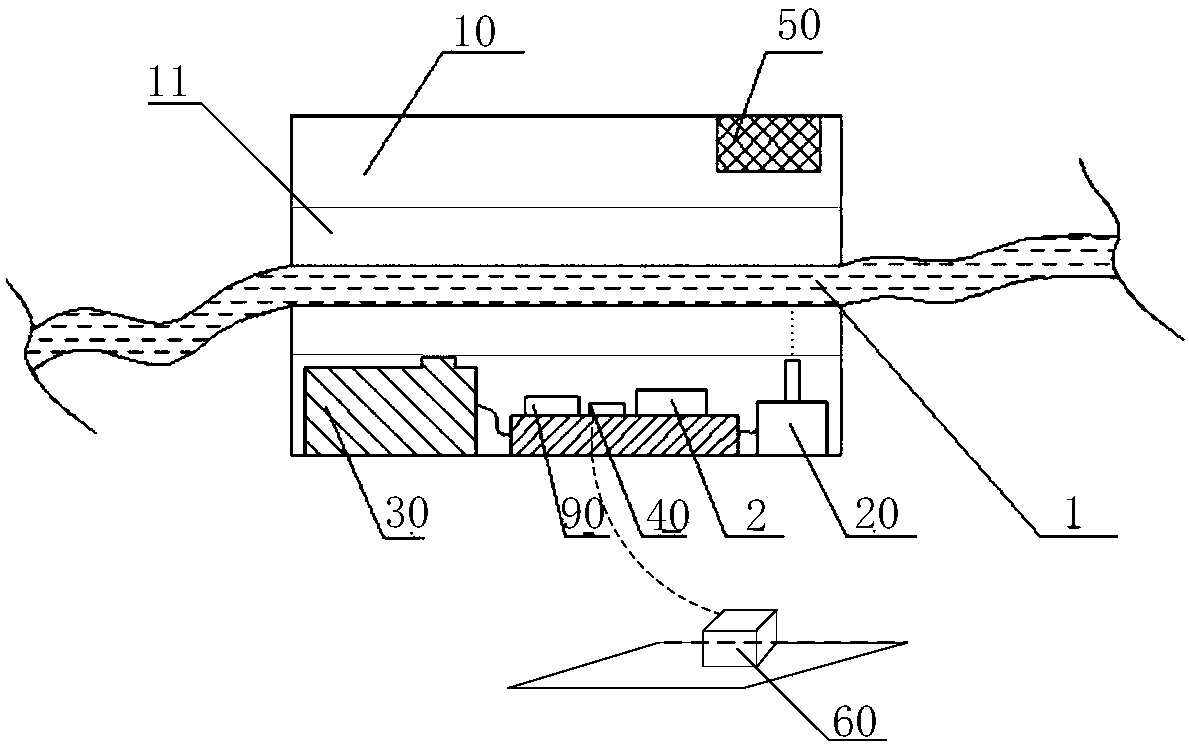

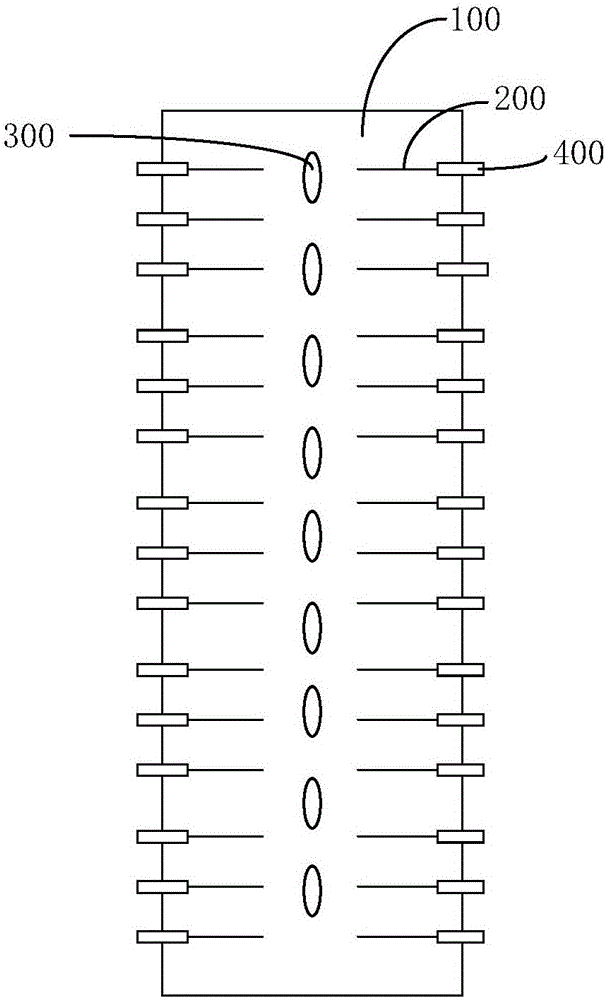

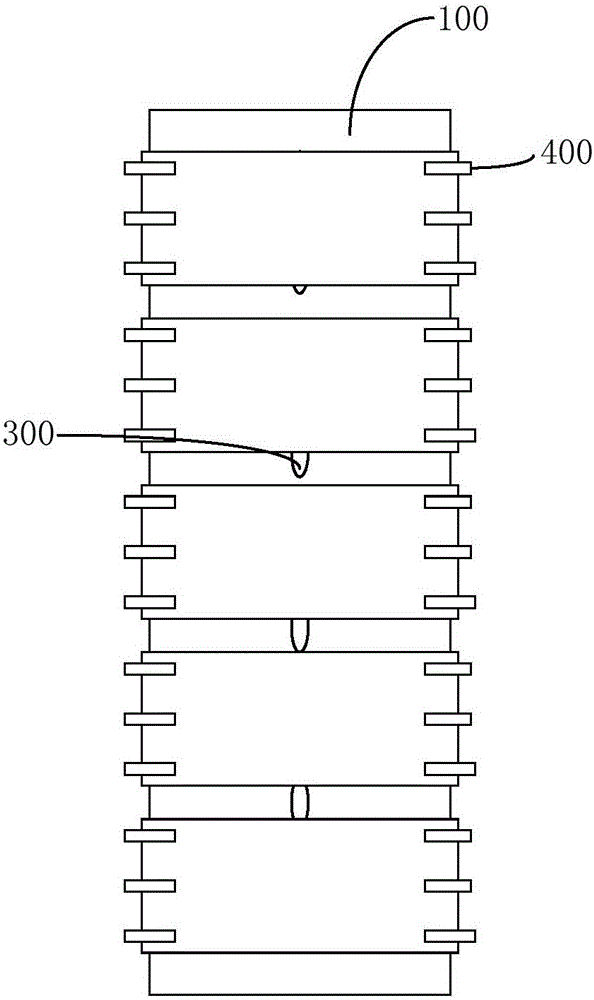

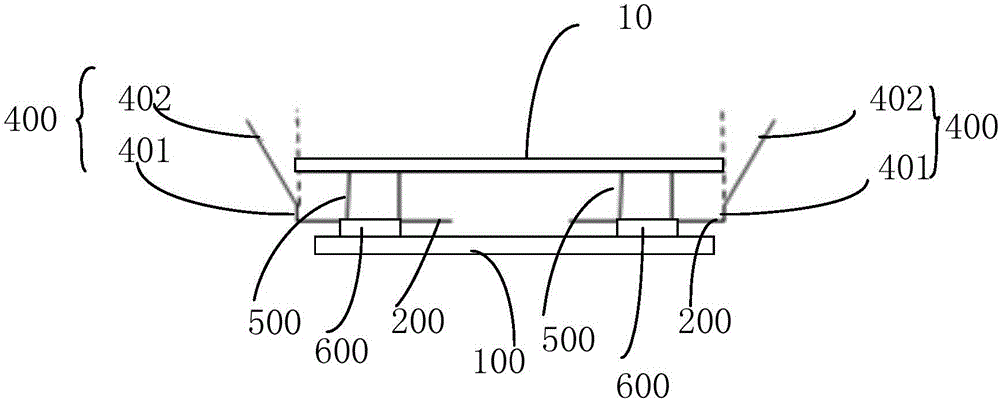

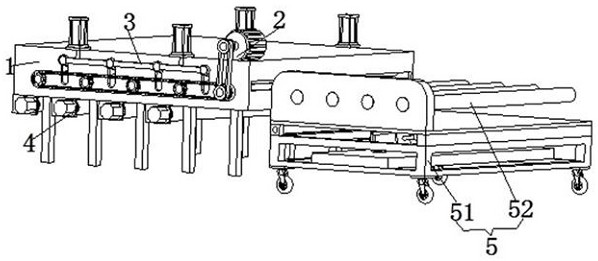

Cloth drying device

ActiveCN112899945AExtended drying timeImprove drying effectLiquid/gas/vapor removalTextile treatment carriersEngineeringMechanical engineering

The invention discloses a cloth drying device, and relates to the technical field of cloth drying. The cloth drying device comprises a drying box body, a conveying assembly, a lifting assembly, a discharging assemblies and a feeding assembly; the drying box body is fixedly arranged on the ground; the lifting assembly is arranged above the drying box body, and the working end of the lifting assembly is movably arranged in the drying box body; the conveying assembly is arranged in the drying box body; the multiple sets of discharging assemblies are arranged on the drying box body; and the feeding assembly is arranged beside the drying box body. Through cooperation of all the components, multiple kinds of cloth can be dried at the same time; and discharging is carried out according to different drying degrees of different fabrics.

Owner:温州市豪维顿服饰有限公司

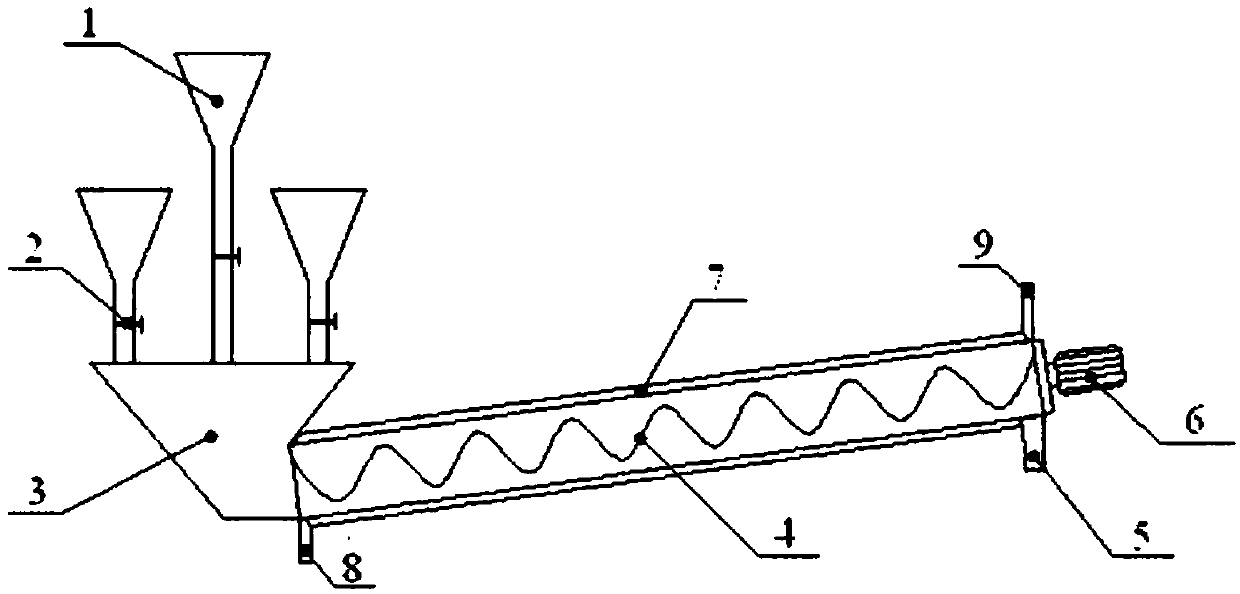

Multifunctional chemical raw material conveying and packaging device

The invention discloses a multifunctional chemical raw material conveying and packaging device. The multifunctional chemical raw material conveying and packaging device comprises a feeding bin set (1), a main bin (3), a conveyor (4), a conveyor material outlet (5) and a motor (6), and the conveyor is also sleeved with a conveyor jacket (7). Compared with the prior art, the multifunctional chemicalraw material conveying and packaging device adopts a mode that the plurality of feeding bins are communicated with the main bin through adjusting valves and then are mutually matched with a screw conveyor for use, so that the mixing efficiency is obviously improved in the material conveying process, and materials can be fully mixed; meanwhile, the conveyor jacket capable of circulating cooling water sleeves the conveyor, so that the materials are cooled while conveying; and a frequency modulation motor is used for driving the conveyor to work, the conveying speed of the conveyor and the rotating speed of threads can thus be controlled, and the speed requirement of the subsequent packaging process can be met. In conclusion, the multifunctional chemical raw material conveying and packagingdevice has the advantages that the production efficiency is remarkably improved, and a large amount of production cost is saved.

Owner:西安玖诚玖谊实业有限公司

A kind of stir-frying processing device and processing method thereof

ActiveCN109793022BRealize automated productionSolve the technical problems of "large amount of manual labor"Charging/discharging ovensBiotechnologyEngineering

The invention relates to a stir-frying processing device and a processing method thereof. The method comprises: feeding the roast into the stir-frying device for stir-frying; On the belt A of the device A, the powder runs with the belt A. When the powder runs to the right end of the belt A, the powder falls into the drying device for drying, and the dried powder falls into the screening device through the feeding pipe. , the screening device will sieve out the dust mixed in the bag, and discharge the dust from the discharge port to the belt B of the conveyor B. The bag will run with the belt B. The sterilizing device above sterilizes the meat, thereby completing the whole process of meat processing; the purpose of this invention is to solve the problem of the large amount of manual labor in the current artificial fried rice processing process, the poor quality of fried rice, easy to produce bacteria, and the The generation of smoke and dust endangers the health of operators and other issues.

Owner:烟台兴捷智能科技有限公司

Novel multistage crushing device

The invention discloses a novel multistage crushing device. The device comprises a first crushing mechanism, a powder delivery pump and a second crushing mechanism, the first crushing mechanism comprises a support and a discharging chamber arranged on the support, a first chopping cutter group and a second chopping cutter group are arranged in the discharging chamber, a first driving motor and a second driving motor are arranged at two sides of the discharging chamber, the upper part of the discharging chamber is connected with a feeding chamber, a pair of rollers is arranged in the feeding chamber, the second crushing mechanism comprises a frame, a crushing shell arranged on the frame, a crushing cutter hammer, a screen and a discharging hopper arranged below the screen, and a third driving motor is arranged outside the crushing shell. The crushing device is designed to have the above structure, the pair of rollers, chopping cutters and the crushing cutter hammer are integrates, and the powder delivery pump is used to transport a material, so the crushing precision is greatly improved, thereby the device has the advantages of high crushing precision, realization of multi-mode simultaneous crushing, and simplicity in operation.

Owner:重庆市易特杰机械制造有限公司

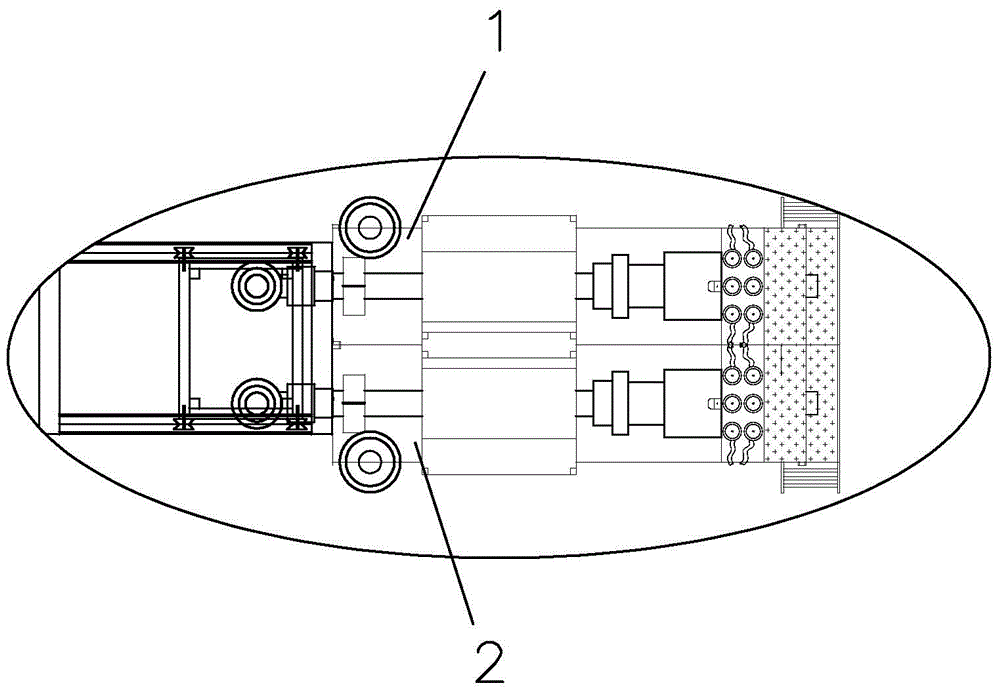

A production control system and method for a filter rod suction resistance stabilizing device

ActiveCN111134356BIncrease productivityImprove processing qualityTobacco smoke filtersLoop controlControl system

The invention discloses a production control system of a filter stick suction resistance stabilizing device, which comprises a speed acquisition device, a servo driver, a man-machine interaction device and a main controller, wherein the speed acquisition device is used for acquiring the conveying speed of tows; the servo driver is used for driving a tow traction device to operate; the man-machineinteraction device is used for displaying data and typing a control instruction; the speed acquisition device, the servo driver, the tow traction device, the tension sensor and the man-machine interaction device are respectively in communication with the main controller, and the main controller is used for processing an instruction input by the man-machine interaction device, data acquired by thespeed acquisition device and data acquired by the tension sensor, and sending driving parameters to the servo driver according to a processing result; the servo driver drives the tow traction device to operate and drives the lifting device to execute ascending or descending actions according to the driving parameters, and then the tow conveying speed and the tow tensioning degree are controlled. Automatic closed-loop control can be achieved, and the requirement for intelligent production can be met.

Owner:深圳市联君科技股份有限公司

A kind of lawn rayon production line and production method

ActiveCN104862792BSingle screw speed adjustment rangeRealize stepless speed regulationArtificial thread manufacturing machinesMelt spinning methodsProduction lineProcess time

The invention discloses a lawn rayon production line and production method. The lawn rayon production line comprises monofilament production equipment, after finishing equipment and a plying and twisting unit which are installed in sequence; two extruders of the monofilament production equipment of the lawn rayon production line are arranged in parallel and can produce monofilament with different colors and different types; the plying and twisting equipment conducts plying and twisting on the monofilament produced through the production line and monofilament which needs to be twisted, rewinding does not need to be conducted repeatedly, the process time and the workshop space are saved, requirements for plying and twisting production of two or more monofilament are met, and the production efficiency is greatly improved.

Owner:QINGDAO QINGHE ARTIFICIAL TURF

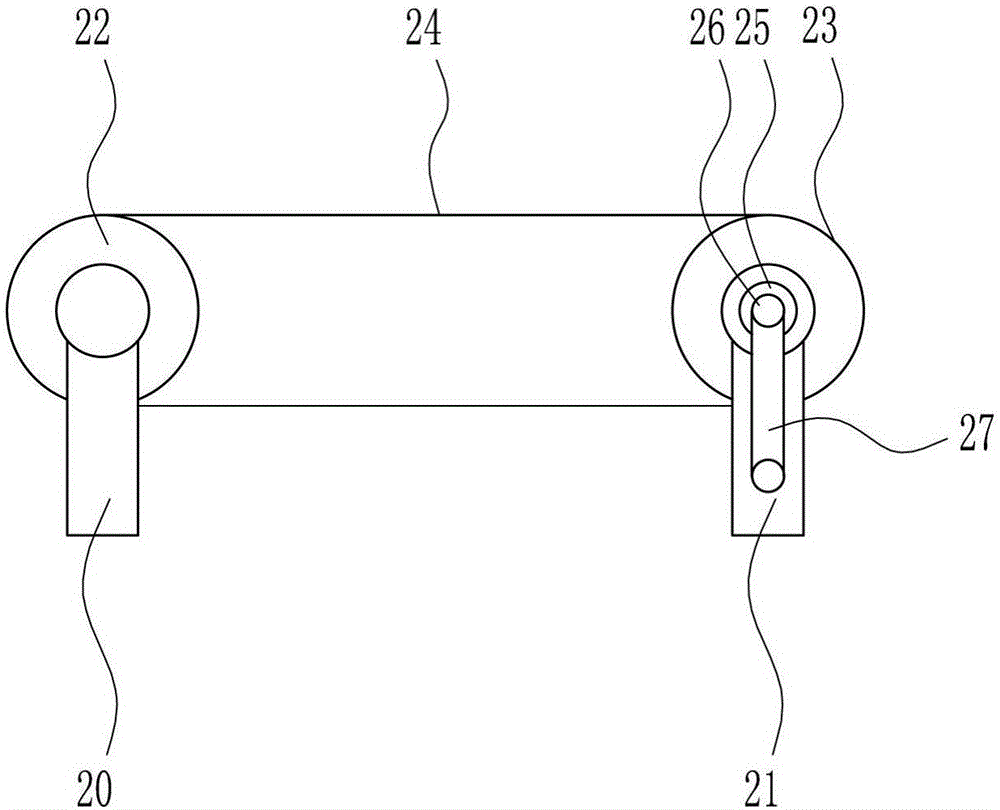

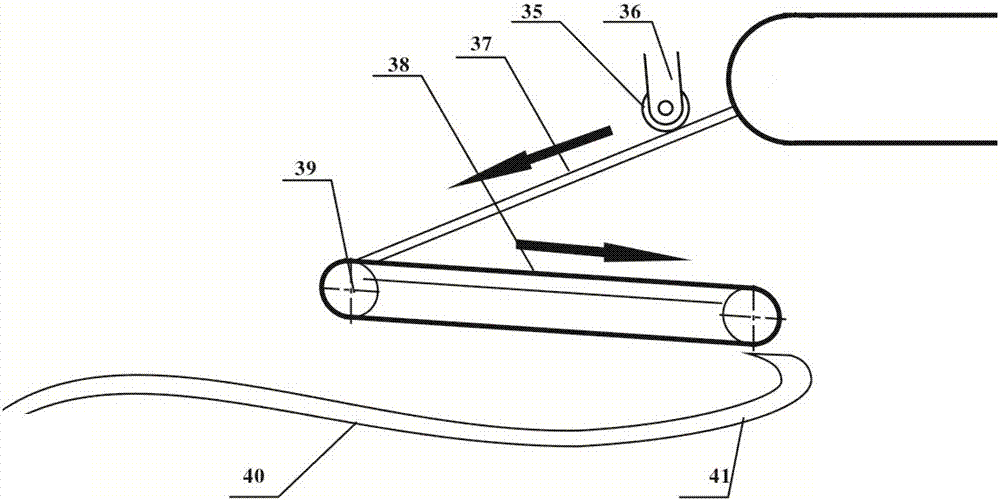

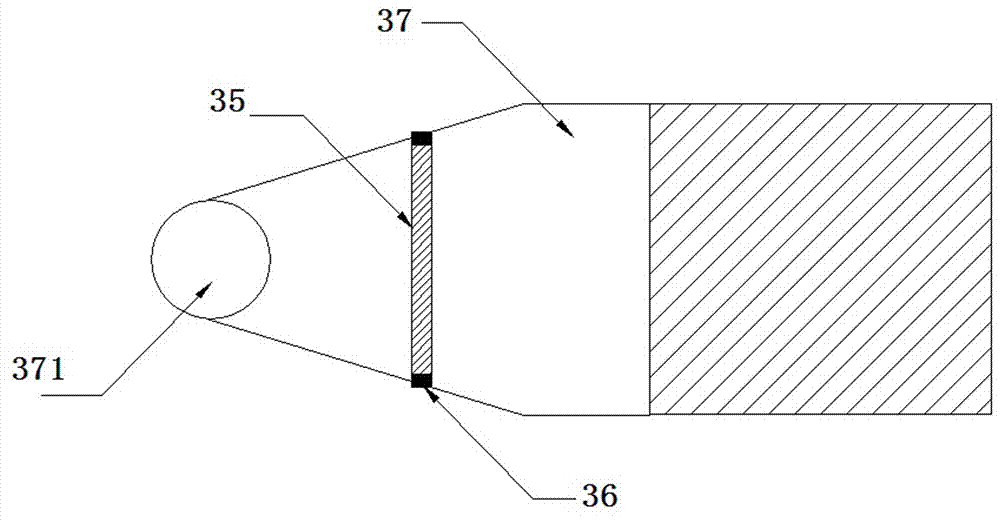

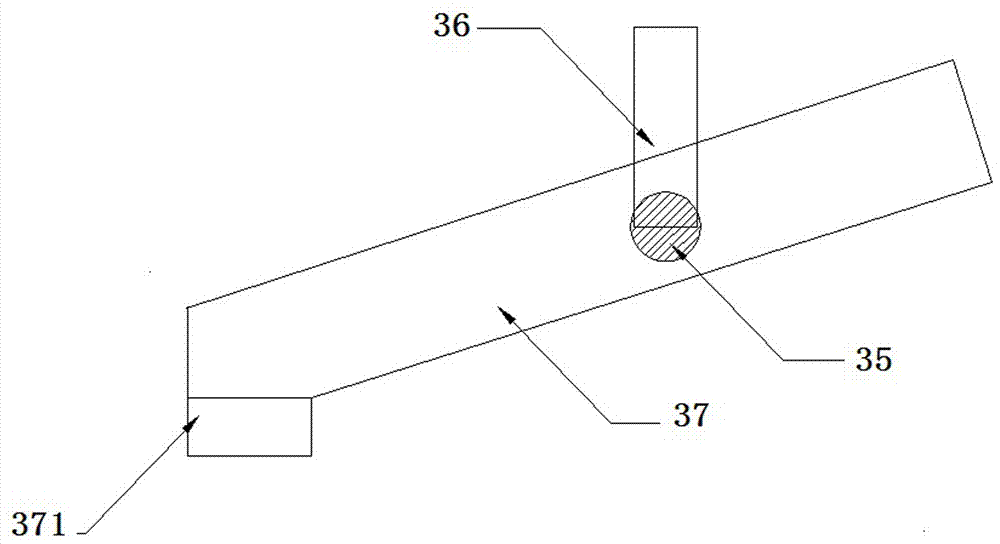

Automatic ramie strip reversing device and intelligent ramie baking equipment thereof

ActiveCN107955976AControl transmission speedRegular transmissionMechanical fibre separationTextile disintegration and recoveryControl theoryConveyor belt

The invention discloses an automatic ramie strip reversing device. The automatic ramie strip reversing device comprises a collecting device basin, a collecting device discharging pipe, a collecting device downward-sliding discharging compression roller, a discharging compression roller support, a steering device and a steering device belt pulley, after passing through the collecting device basin,ramie strips are conveyed to the collecting device discharging pipe to be perpendicular, and the steering device moves reversely to make the other sides of the ramie strips attached to the steering device to be reversed; meanwhile, the automatic ramie strip reversing device further comprises a 180-degree-steering conveyor belt mechanism and a 180-degree-steering conveyor belt mechanism belt pulley, and the ramie strips can be steered for 180 degrees. The automatic ramie strip reversing device has the advantages that the ramie strips can be conveyed regularly and more easily reversed and steered, the reversed ramie strips are conveyed to the same or the next working station of the beating position so that the ramie strips can be repeatedly beaten till a completely-degumming state is reached. By means of the automatic ramie strip reversing device, the work process is flexibly controlled, the reversing and steering effect is obvious, and the automatic ramie strip reversing device also hashigh transportability, expandability and practicability.

Owner:湖南湘麻纺织有限公司

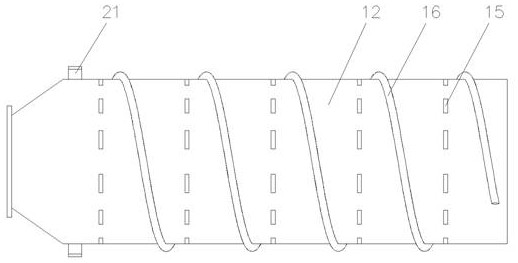

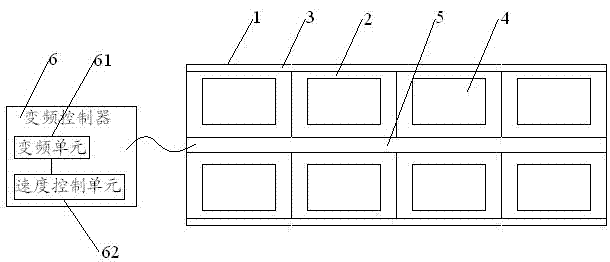

Combined type yarn steam box

InactiveCN103046277AReduce wrinklesControl transmission speedTextile treatment containersYarnFrequency conversion

The invention discloses a combined type yarn steam box which comprises a steam box unit. The steam box unit comprises a plurality of box bodies which are connected together and arranged in an upper-lower layer manner, a transport roller is arranged in the middle of the box bodies, a frequency conversion controller is connected on the transport roller, comprises a frequency conversion unit and a speed control unit and is inductively connected on one side of the transport roller and used for controlling the transmission speed of the transport roll, and the frequency conversion unit and the speed control unit are mutually connected. By the means, the combined type yarn steam box can be guaranteed to adapt to various different production varieties and various different production processes, thereby use range is widened, economic benefits are increased, the transmission speed of the transport roller can be controlled, and wrinkling of yarns is reduced.

Owner:苏州焕乾纺织有限公司

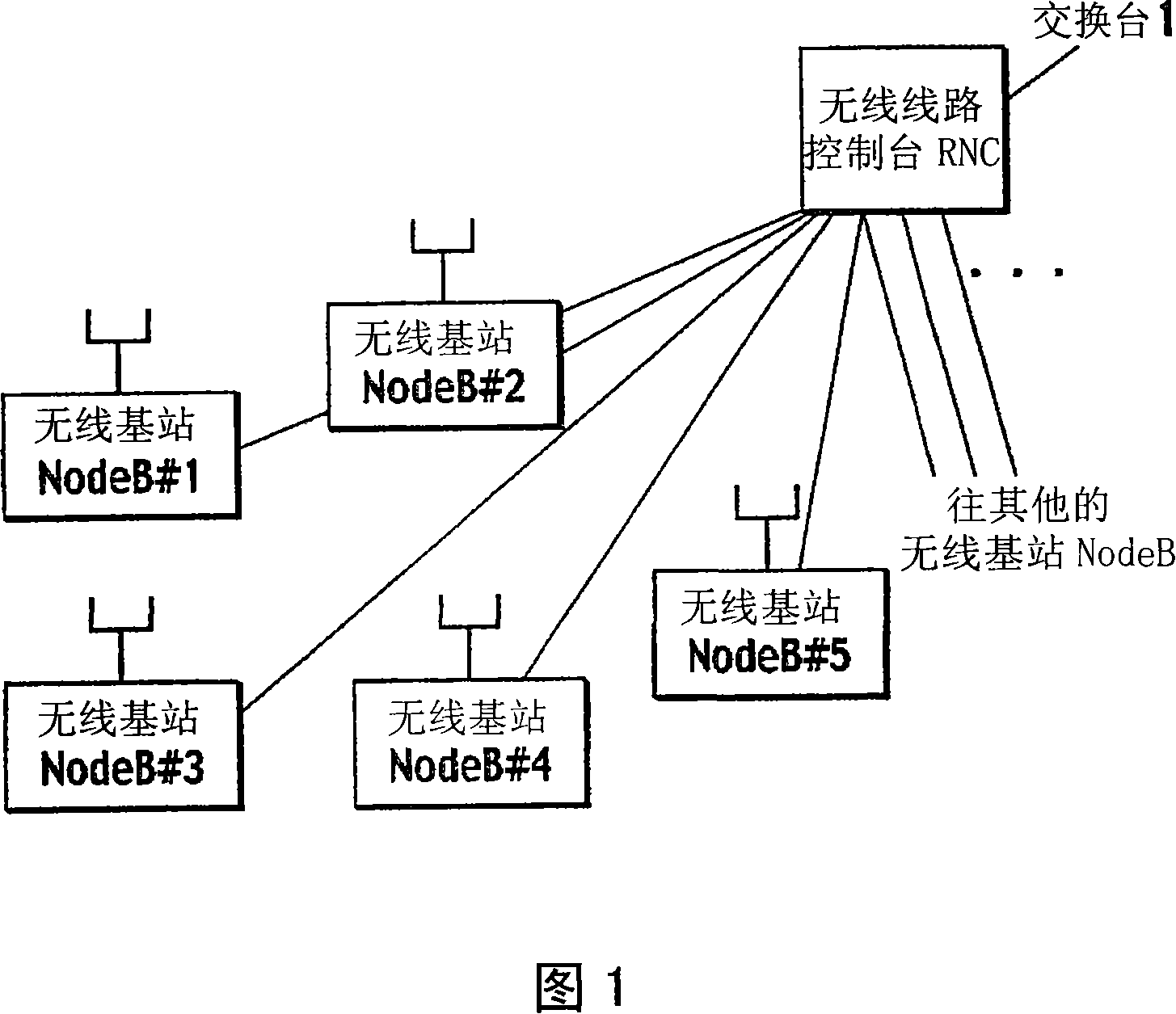

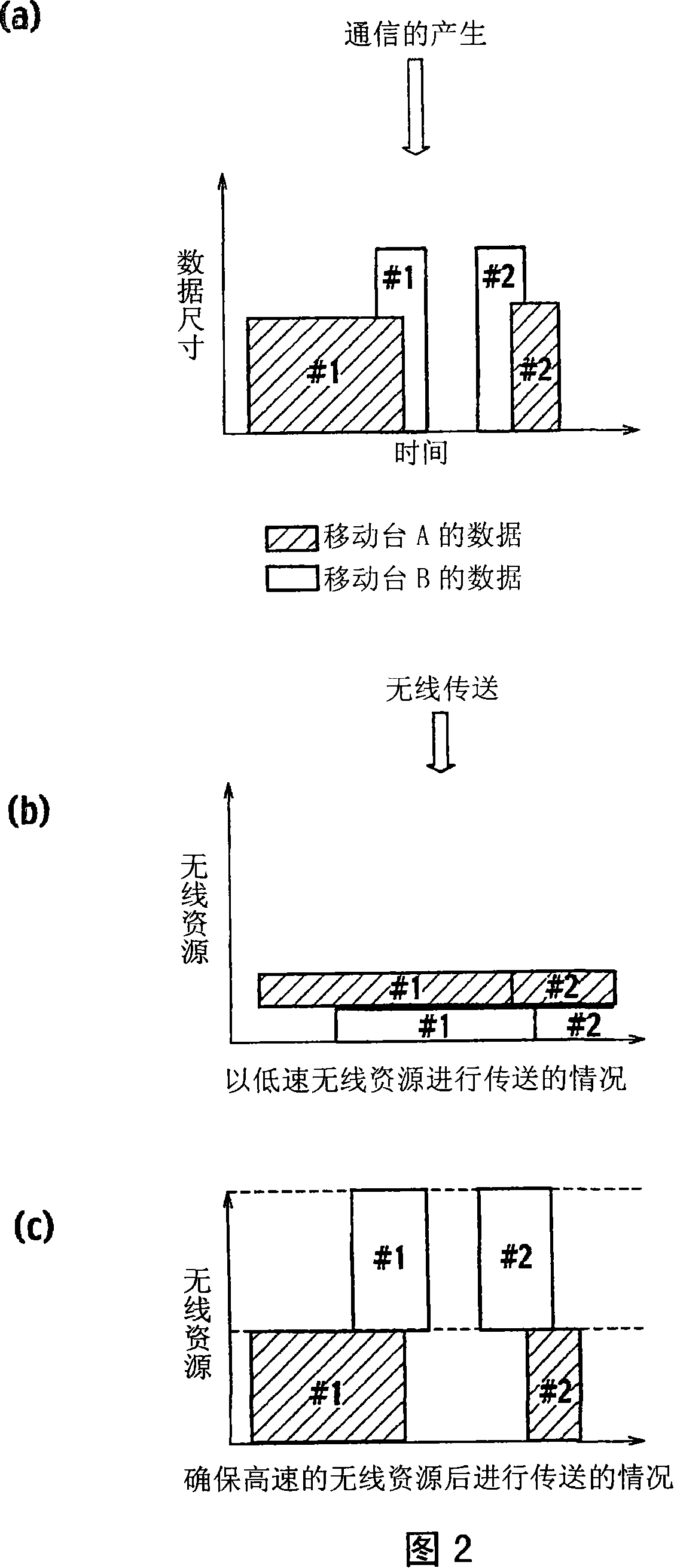

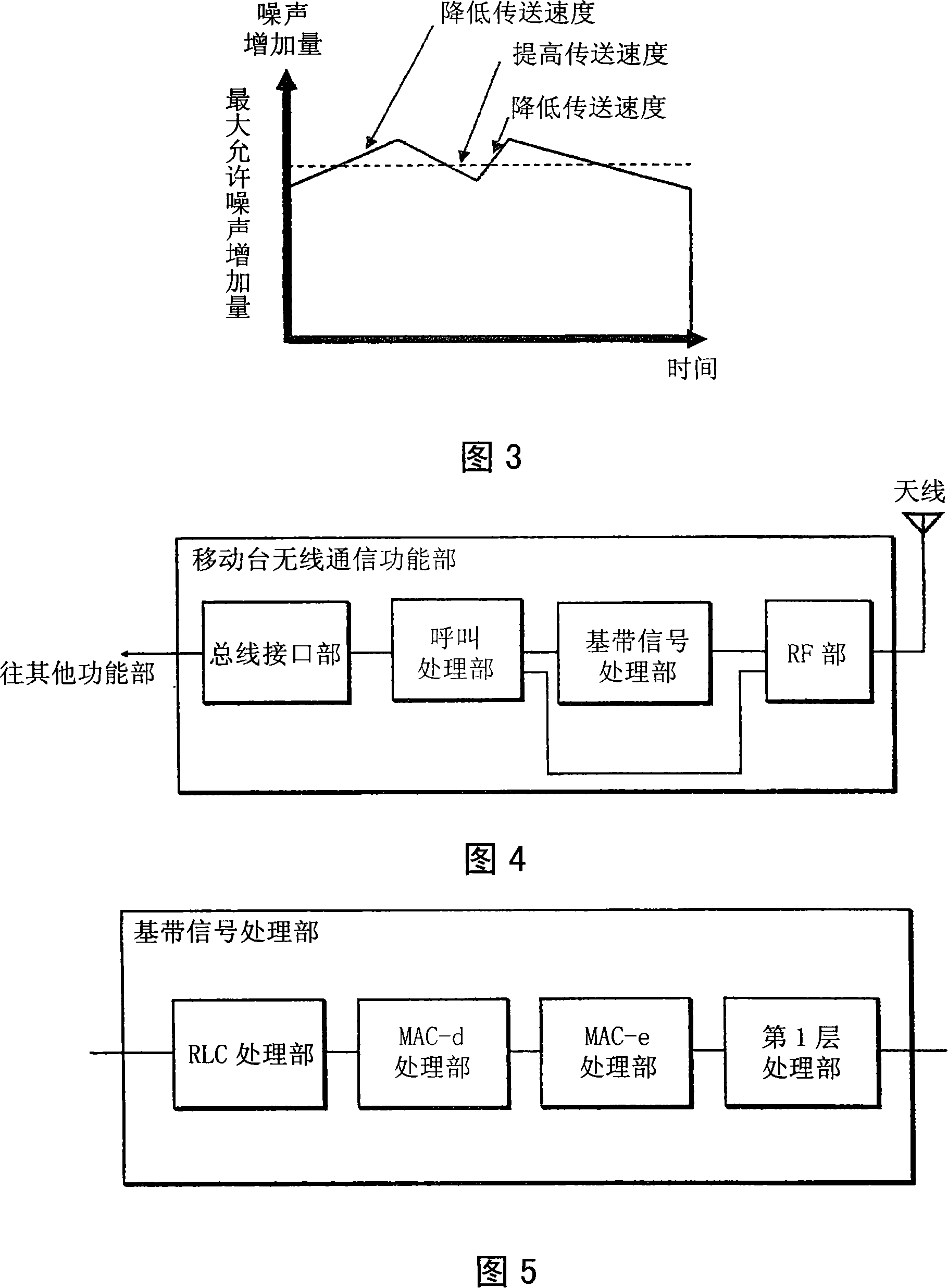

Transmission speed control method, wireless base station and wireless circuit control station

InactiveCN101142842AImprove qualityImprove throughputNetwork traffic/resource managementData switching by path configurationMobile stationSoft handover

A transmission speed control method for controlling a transmission speed of a user data to be transmitted to a wireless base station from a mobile station. The transmission speed control method is provided with a step wherein a wireless circuit control station instructs a transmission speed difference or a transmission speed ratio between a transmission speed of a mobile station performing soft handover with a subordinate wireless base station and a transmission speed of a mobile station not performing soft handover with a subordinate wireless base station. The transmission speed control method is also provided with a step of controlling the transmission speed of each mobile station based on the transmission speed difference or transmission speed ratio.

Owner:NTT DOCOMO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com