Multifunctional chemical raw material conveying and packaging device

A chemical raw material and multi-functional technology, applied in the direction of packaging, etc., can solve the problems of high labor consumption, low degree of automation, and increased production costs, and achieve the effects of improving production efficiency, improving efficiency, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

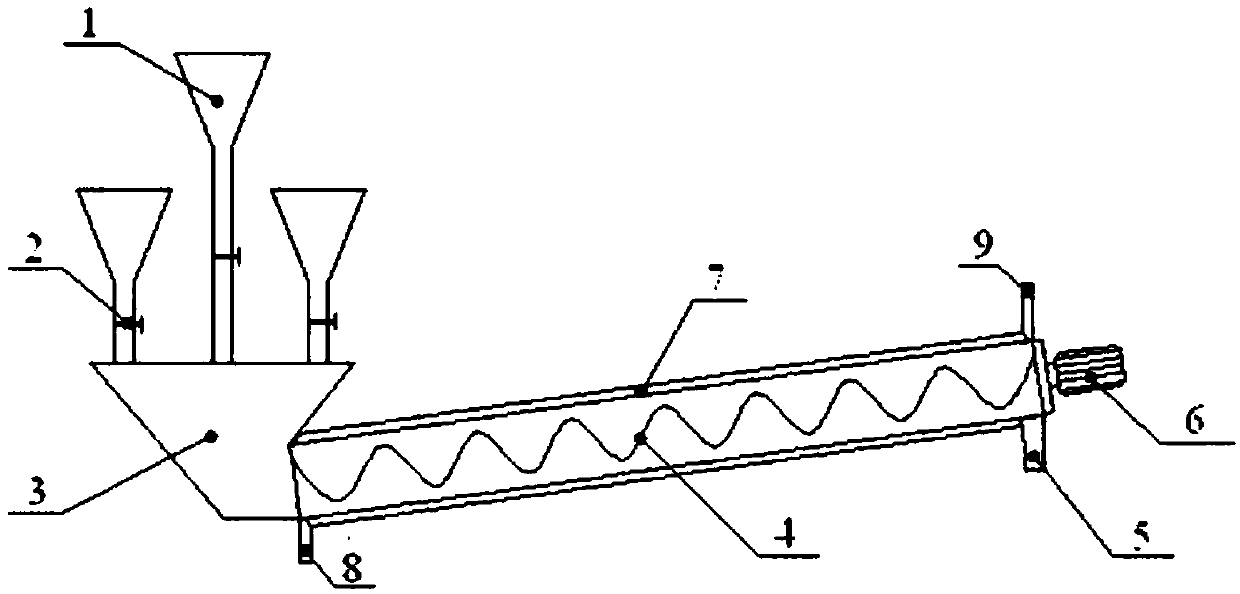

[0012] Such as figure 1 As shown, the multifunctional chemical raw material conveying and packaging device includes a feed bin group 1, a total feed bin 3 and a conveyor 4, and a conveyor material outlet 5 provided below the tail end of the conveyor 4, and installed on the conveyor 4 The motor 6 at the tail end has at least two feed bin groups 1 arranged side by side on the upper end of the total feed bin 3, the total feed bin 3 is connected to the front end of the conveyor 4, and the conveyor jacket 7 is set on the conveyor 4, and the conveyor clamp The front end of the sleeve 7 is provided with a cooling water inlet 8, and the rear end is provided with a cooling water outlet 9.

[0013] Each feed bin group 1 is communicated with the total feed bin 3 through the regulating valve 2, and the speed at which materials are lowered into the total feed bin 3 can be controlled by regulating the valve 2.

[0014] The conveyor 4 is a screw conveyor, which can fully mix different mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com