Lawn rayon production line and production method

A technology of rayon, production line, applied in the field of plastic processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

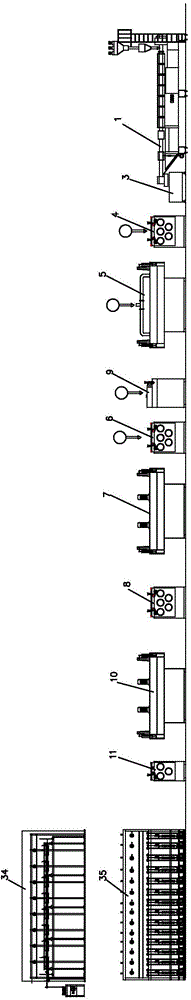

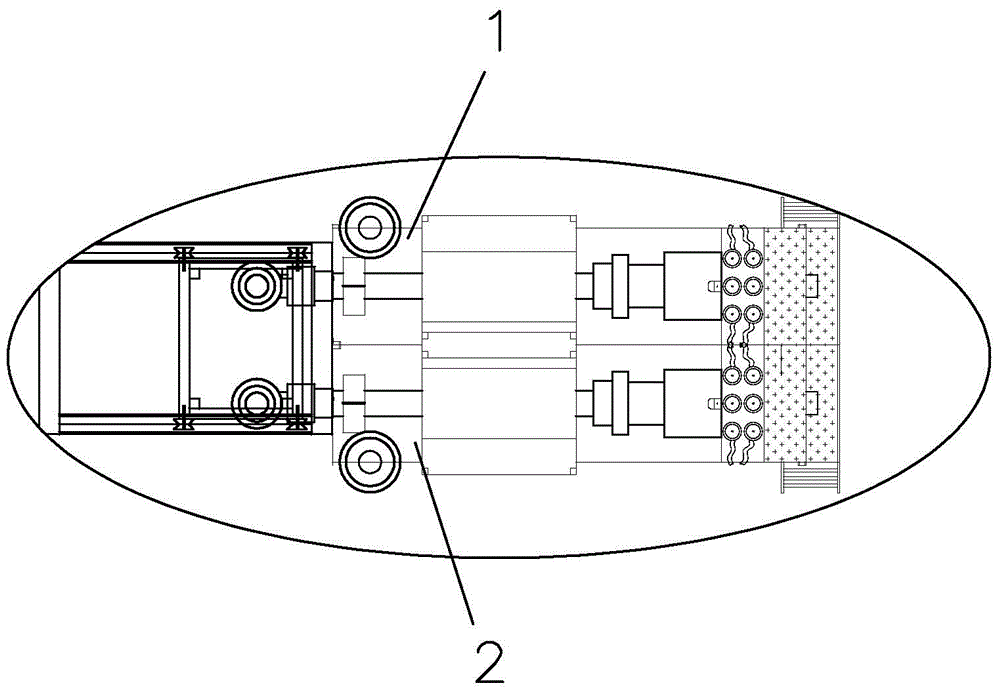

[0038] see Figure 1-Figure 7 , the lawn rayon production line of the present invention, comprises the monofilament production equipment of installing successively, after-finishing equipment and ply ply twisting unit; Heating device and spinning die head device; the finishing equipment includes cooling water tank 3, seven-roll drafting roll 4, hot water tank I5, dehumidification device 9, drafting roll I6, hot water tank II7, drafting roll II8, Hot oven 10 and cold setting roller 11;

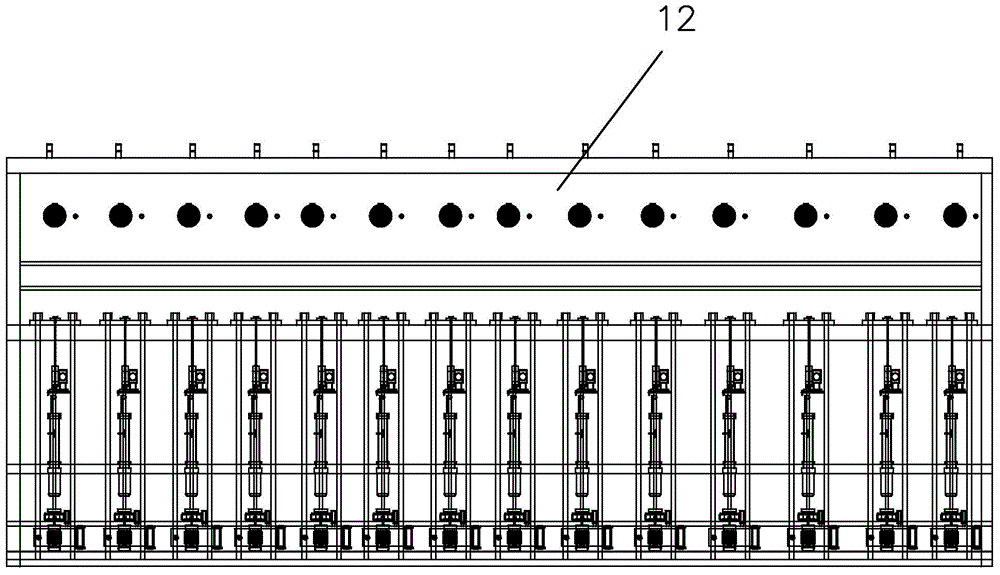

[0039]Plying and twisting unit includes yarn frame, tension transmission device 34 and plying and twisting equipment 35; yarn frame main body includes several yarn rods 12, tension transmission device 34 is installed on yarn rod 12, comprises two roller bars installed horizontally 13. The roller bar 13 is driven by a variable speed motor 14 installed on one side of the complete machine, and a transmission pressure roller 15 is installed on each yarn bar 12 between the two roller bars 13, and al...

Embodiment 2

[0045] The lawn rayon processing method carried out based on the equipment of the embodiment of the present invention, comprises the steps:

[0046] 1) Run the monofilament production and processing equipment, and melt and extrude the raw materials through the extrusion unit;

[0047] 2) After being cooled and shaped by cooling equipment, the wires are separated by the splitting rod;

[0048] 3) Traction and transmission by the traction equipment, stretching by the drafting equipment, removal of moisture on the surface of the yarn by the dehumidification device 9, presetting on the surface of the drafting equipment, heat setting by the hot oven 10, and cold setting by the cold setting roller 11 to control the shrinkage ratio; output Yarn to ply twisting equipment 35;

[0049] 4) The produced yarn that needs to be twisted is delivered to the ply twisting device 35 through the yarn frame and the tension conveying device;

[0050] 5) Yarn bobbins are installed on the plying and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com