Efficient food processing and sorting machine

A food processing and sorting machine technology, applied in the field of agricultural machinery, can solve the problems of low sorting efficiency, poor sorting accuracy, and inability to recycle sorted items, and achieves the effect of high degree of automation and improved sorting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

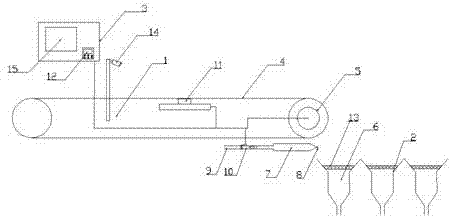

[0018] Such as figure 1 As shown, a high-efficiency food processing sorting machine includes a transmission device 1, a sorting device 2 and a control device 3, and is characterized in that: the sorting device 2 is located at the front end of the transmission device 1, the transmission device 1, the sorting device The sorting devices 2 are all connected with the control device 3, the transfer device 1 includes a conveyor belt 4, the front end of the transfer belt is provided with a transmission motor 5, and the sorting device 2 includes at least two collection boxes 6, and the collection box 6 A blowing device 7 is arranged on it, and the blowing device 7 includes an air blowing port 8 and an air inlet pipe 9 connected with the air blowing port 8, a flow control device 10 is arranged on the air inlet pipe, and a There is a quality sensor 11, and the transmission motor 5, the flow control device 10 and the quality sensor 11 are all connected to the control device 3, and the mot...

Embodiment 2

[0020] On the basis of Embodiment 1, the collection boxes 6 in this embodiment are arranged in sequence along the direction of the conveyor belt 4 . According to the quality of the food to be sorted, food with different quality and volume can be sorted.

Embodiment 3

[0022] On the basis of Embodiment 1, the collection box 6 in this embodiment is provided with a screen 13 . When some accidental factors cause food of different quality to be transferred into the same collection box, the screen can be used to block and improve the sorting accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com