System and method for online measurement of filament winding pitch in composite pipe

A technology of fiber winding machine and composite pipe, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problem that there is no way to monitor the fiber winding pitch in real time, and achieve low modification costs, ensure consistency, and accurately measure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

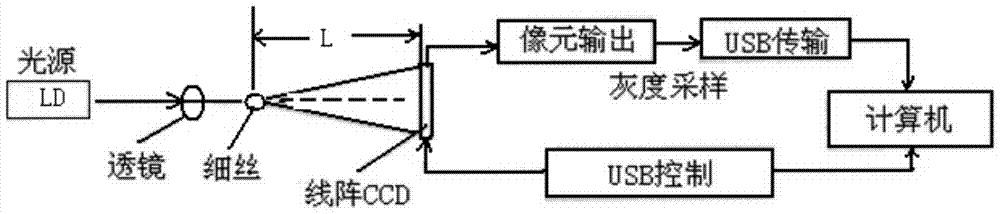

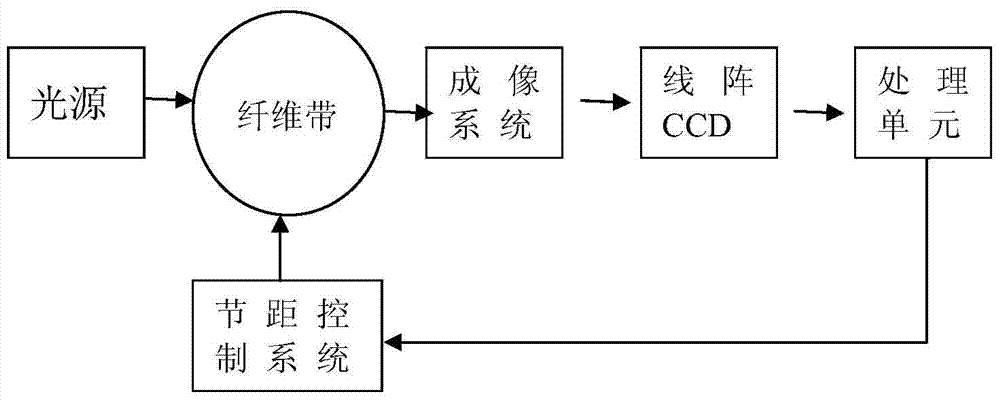

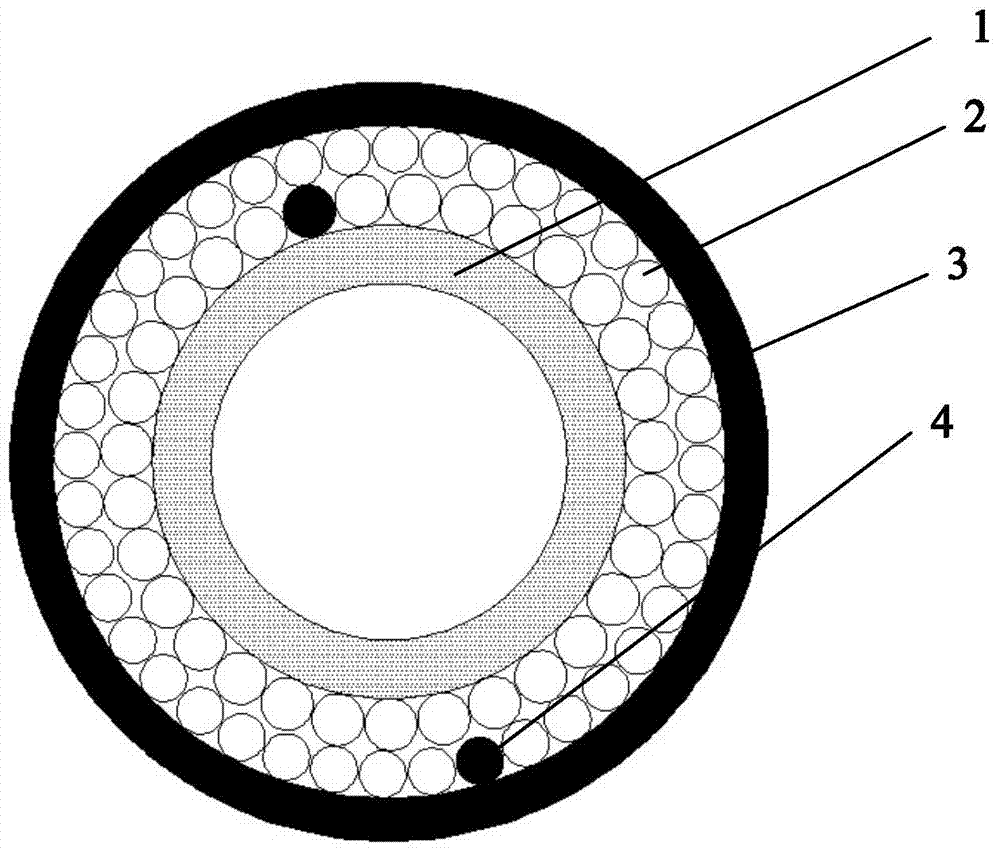

[0033] A system for online measurement of fiber winding pitch in composite pipe, including fiber winding machine, CCD camera and processing unit in composite pipe production equipment; fiber winding machine includes 80 silk spindles, 80 silk spindles include 1 or 2 The fiber color of the marked silk ingot is different from the fiber color of the other silk ingots. When there are two marked silk ingots, the colors are also different from each other; generally speaking, the fiber color of the marked silk ingot is colored , the fiber color of the rest of the spindles is white. The marked silk ingots should not exceed one-fifth of the number of all silk ingots at most; when the marked silk ingots are of one color, they should be placed in a centralized manner; when the marked silk ingots are of two colors, they should be placed symmetrically. One or two CCD cameras are aimed at the exit end of the fiber winding machine for real-time shooting of the wound fiber tape; the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com