Hot melt adhesive cooling and drying method and hot melt adhesive cooling and packaging assembly line

A packaging line, cooling and drying technology, used in cooling fluid circulation devices, packaging, packaging machines, etc., can solve the problems of poor cooling effect, difficult heat dissipation, poor drying effect, etc., to prevent incomplete cooling and discharge blockage, Improve operational efficiency and use good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for cooling and drying hot melt adhesives, comprising the steps of:

[0060] S1 processes the hot-melt plastic bag packed with plastic film through the scissor-type hot-melt glue packaging machine;

[0061] S2 Cooling of hot melt adhesive: the packaging bag containing hot melt adhesive falls into the cooling line set below for cooling and cooling treatment;

[0062] S3 Drying of hot-melt adhesive packaging bags: the cooled hot-melt adhesive packaging bags are sent to the blowing drying mechanism through the conveyor belt for drying.

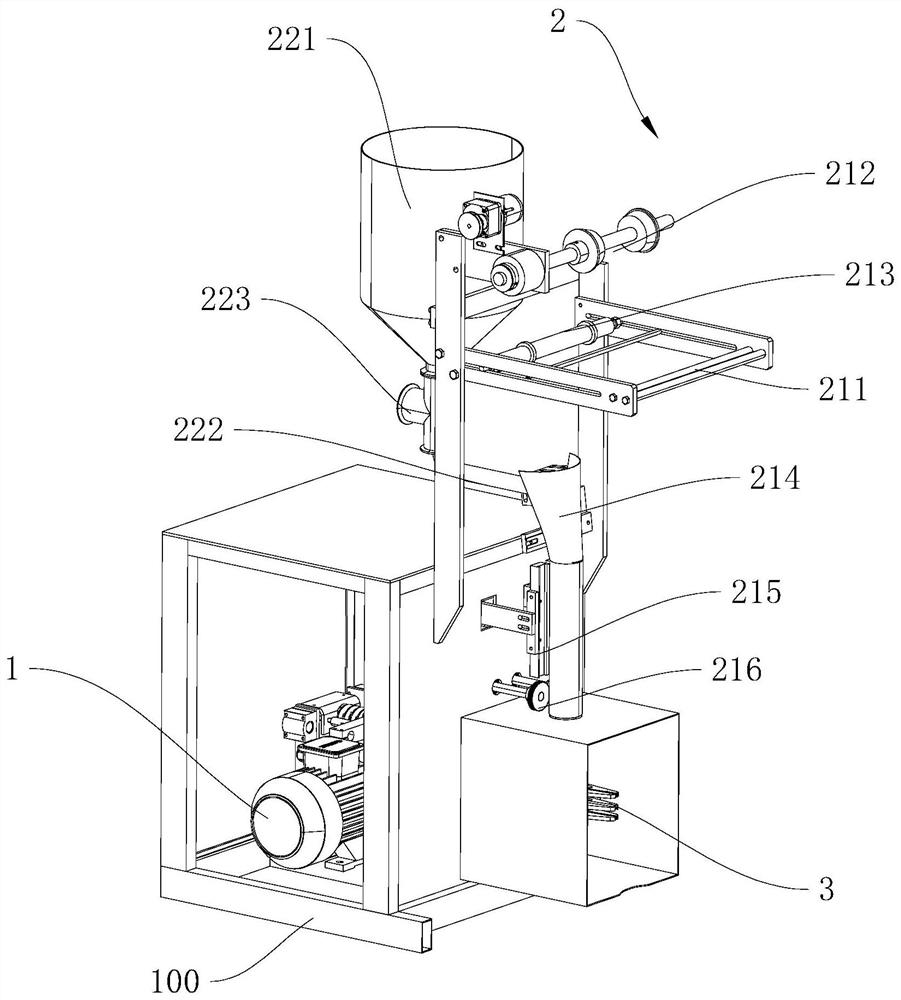

[0063] The hot melt adhesive cooling packaging line includes the following:

[0064] Rack 100;

[0065] A feeding mechanism 2, the feeding mechanism 2 is arranged on the frame 100, and the feeding mechanism 2 feeds the hot melt adhesive into the packaging film;

[0066] Sealing and cutting mechanism 3, described sealing and cutting mechanism 3 is located at the bottom of feeding mechanism 2, and described sealing and cutting me...

Embodiment 2

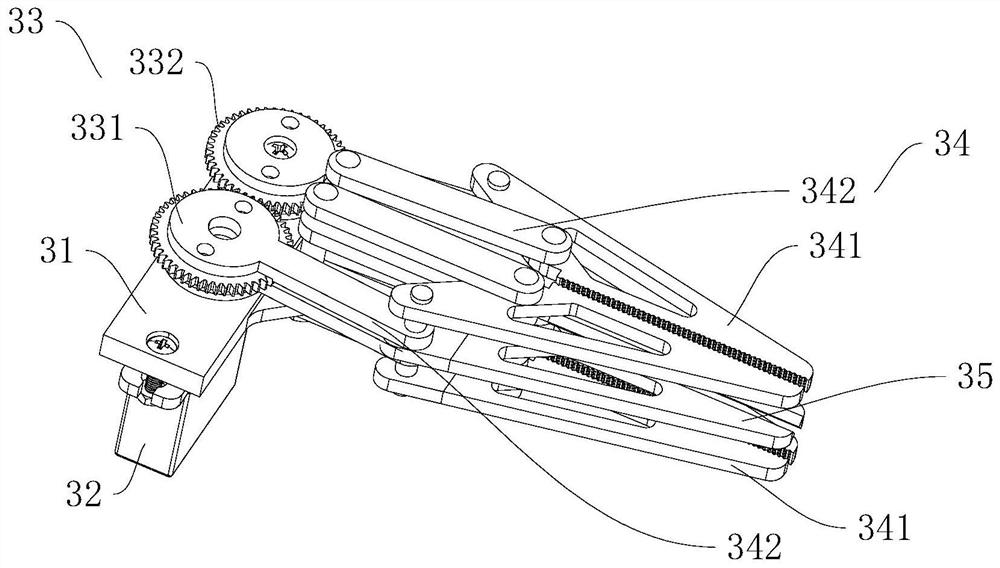

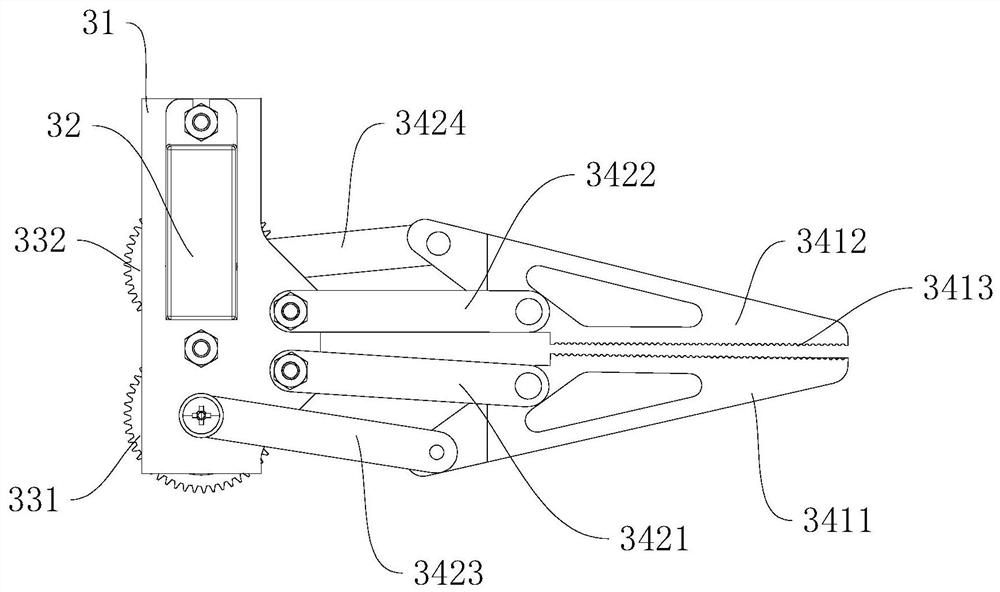

[0081] The heat-sealing clamp block set 341 includes heat-sealing clamp block one 3411 and heat-sealing clamp block two 3412, and the connecting rod set 342 includes connecting rod one 3421, connecting rod two 3422, connecting rod three 3423 and connecting rod four 3424, The first connecting rod 3421 and the second connecting rod 3422 are rotatably connected to the fixed plate 31, the third connecting rod 3423 is connected with the first gear 331, the fourth connecting rod 3424 is connected with the second gear 332, and the first connecting rod 3421 rotates connected to the tail end of the heat-sealing clamp block 1 3411, the connecting rod 2 3422 is rotatably connected to the tail end of the heat-sealing clamp block 2 3412, and the connecting rod 3 3423 is rotatably connected to the tail end of the heat-sealing clamp block 1 3411, The fourth connecting rod 3424 is rotatably connected to the tail end of the second heat-sealing clamping block 3412.

[0082] The heat-sealing cla...

Embodiment 3

[0084] The second motor 32 is a stepper motor, which can realize open-loop control through the stepper motor, that is, realize the angle and speed control of the stepper motor through the pulse quantity and frequency input by the driver signal input end, and further control the heat sealing and sealing of the sealing and cutting mechanism. Cutting speed meets production needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com