A discharge system for agricultural seeding drones

A discharging system and unmanned aerial vehicle technology, which is applied in sowing seeders, agriculture, and sowing, can solve the problems of low drone sowing area, reduced drone flight mileage, and low sowing efficiency, so as to improve sowing The effect of area area, improved seeding efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

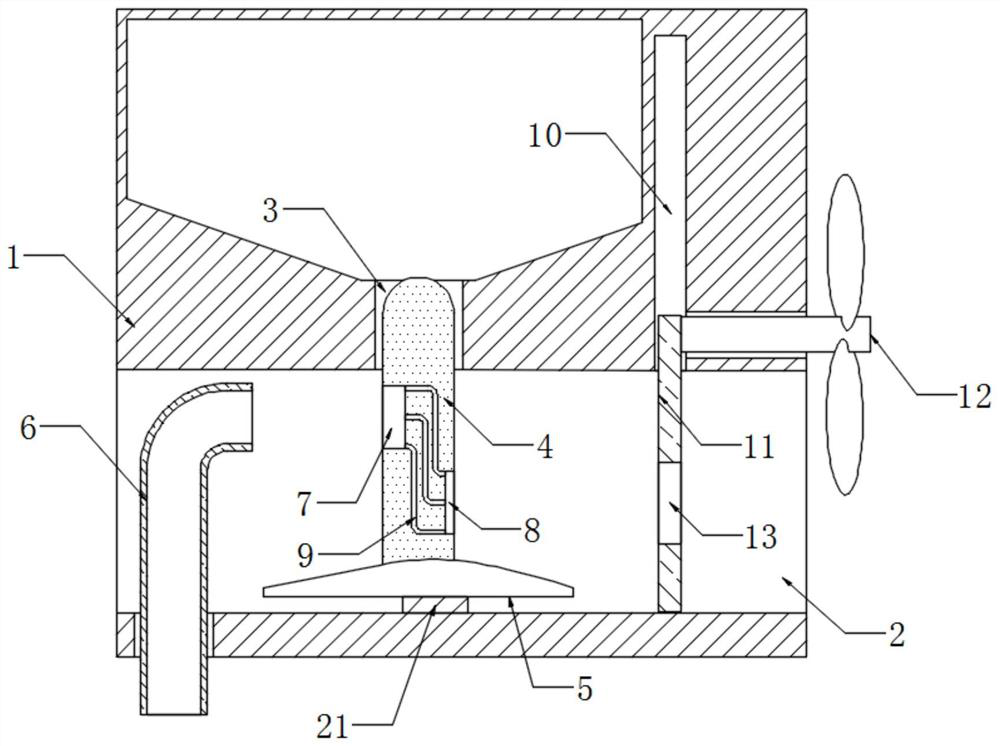

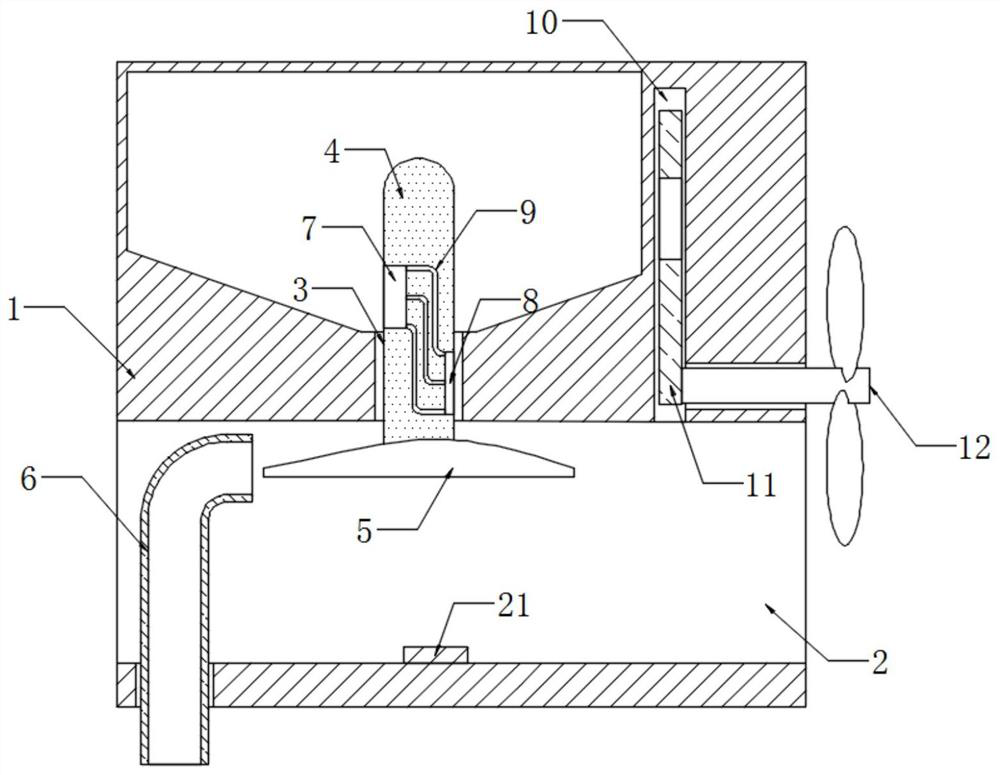

[0023] refer to Figure 1-2 , a discharge system for agricultural seeding unmanned aerial vehicles, including a storage bin 1, a vent 2 is provided on the side wall of the storage bin 1, and the vent 2 communicates with the inside of the storage bin 1 through a guide groove 3, and the guide A conveying plate 4 is slidably connected to the slot 3, and an airfoil 5 is fixedly connected to the lower end of the conveying plate 4. It should be noted that a spacer 21 is fixedly connected to the inner bottom of the vent 2 to support the airfoil 5. , to ensure that the airflow in the vent 2 can pass through the upper and lower sides of the airfoil plate 5, thereby generating a pressure difference between the upper and lower sides of the airfoil plate 5 and the ground airfoil plate 5 moving upward.

[0024] The vent 2 is embedded with an elbow 6, so that when the airflow is discharged along the elbow 6, it can finally be discharged vertically downwards, so that the seeds are given a ve...

Embodiment 2

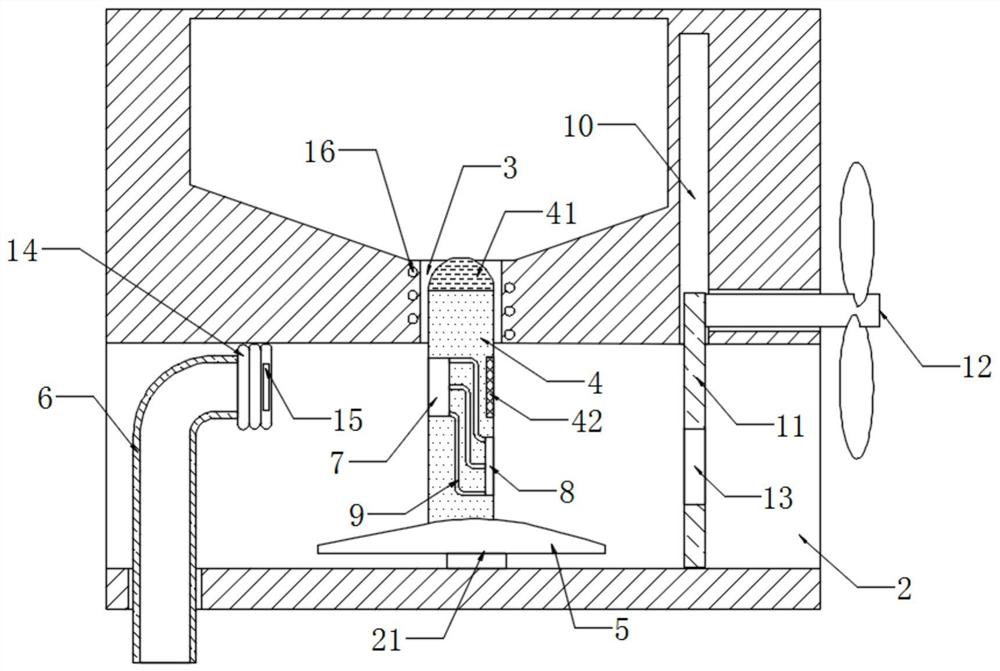

[0030] refer to image 3 , different from Embodiment 1, the inlet end of the elbow 6 is fixedly connected with a bellows 14 communicating with the inside, the bellows 14 is made of rubber material with good elasticity, and the side wall of the bellows 14 is fixedly connected with an electromagnet 15 , The side wall of the conveying plate 4 is fixedly connected with an iron sheet 42, the center of the iron sheet 42 is located on the same horizontal line as the center of the material storage port 7, and the bellows 14 is made of elastic rubber material. The power supply device to the electromagnet 15 is installed on the conveying plate 4, and the power supply device comprises a permanent magnet 41 fixedly connected on the conveying plate 4, and a closed helical coil 16 is embedded on the guide groove 3 inwall, and the helical coil 16 is connected with the electromagnet. Iron 15 is electrically connected.

[0031] It should be noted that, since the permanent magnet 41 is only ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com