Automatic solid catalytic promoter adding system

A catalytic aid and catalyst technology, applied in catalytic cracking, chemical/physical/physicochemical processes, cracking, etc., can solve problems such as blockage, no use of fluidized tanks, and small diameter of conveying pipelines to achieve uniform discharge , save space, reduce the effect of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The automatic solid catalyst addition system of the present invention is described in a non-limiting manner below in conjunction with the accompanying drawings and specific embodiments, so that the public can better understand the technical solution.

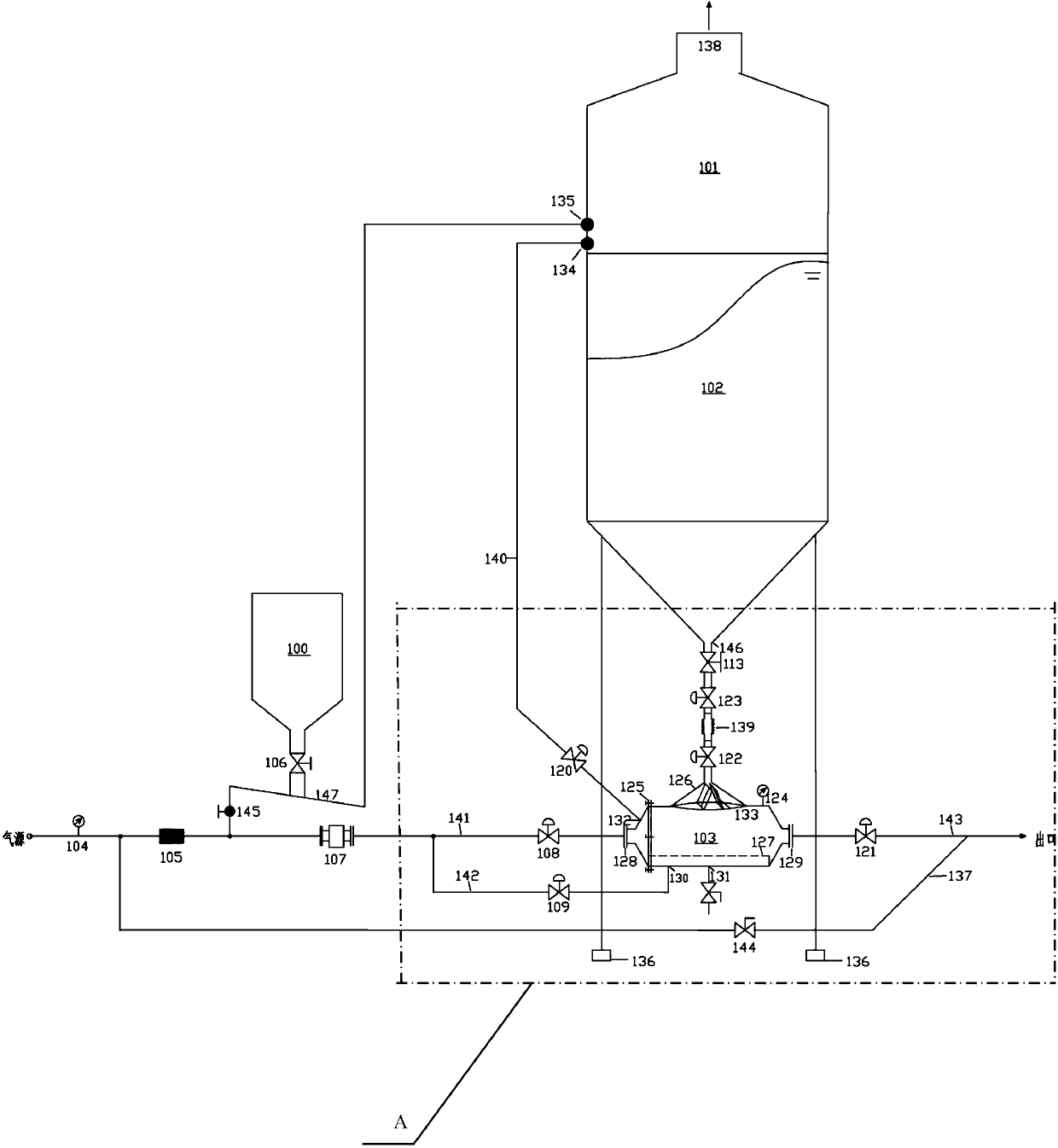

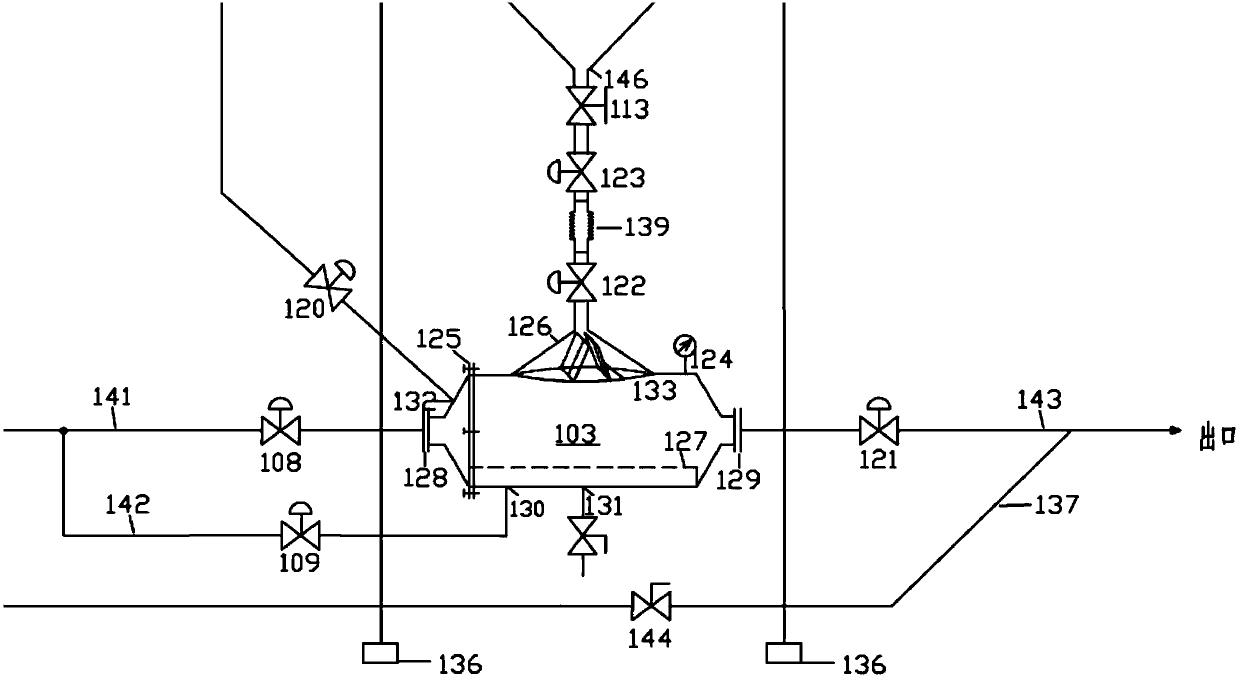

[0032] Such as figure 1 , 2 As shown, the automatic solid catalytic additive adding system of the present invention includes a catalyst storage tank 102, a hopper 100 and a fluidized tank 103, and the catalyst storage tank (which can be called a high-level silo) 102 is an upper part and a lower part of a cylinder It is a conical silo, and the top is provided with a gas-solid separation device 101 so that the gas-solid separation can be carried out when fresh catalyst is transported to the high-level silo. The gas-solid separation device 101 can be a pulse bag filter or a secondary cyclone separator. Fixed on the side wall or top, the outlet of the gas-solid separation device 101 passes through the top of the catalyst sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com