Automatic vacuum spraying process method

A technology of vacuum spraying and process method, which is applied in the fields of food, aquatic feed processing, and pet food. It can solve problems such as tight closure, air leakage risk, and uneven spraying, and achieve good sealing performance, easy cleaning, and fast discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

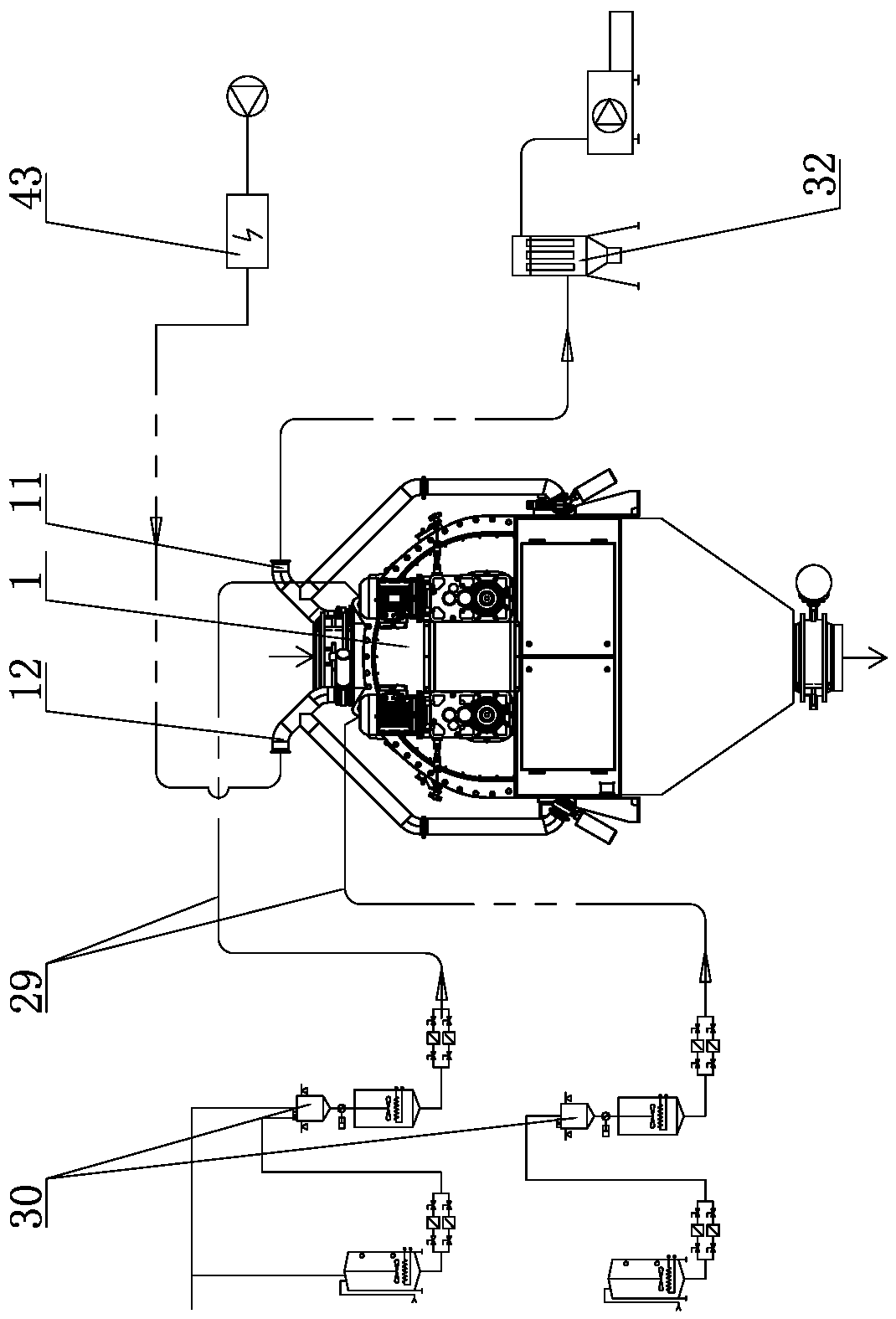

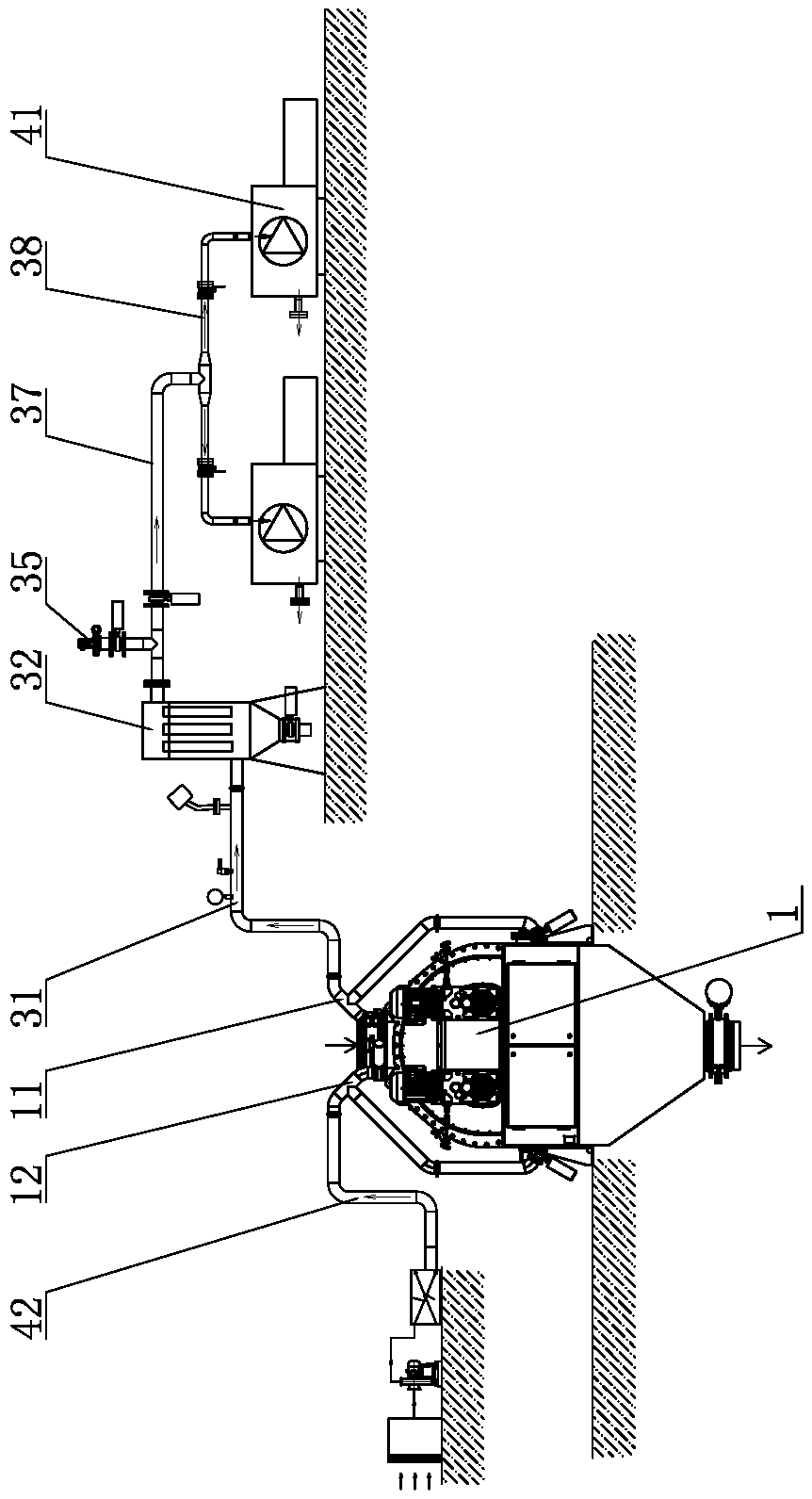

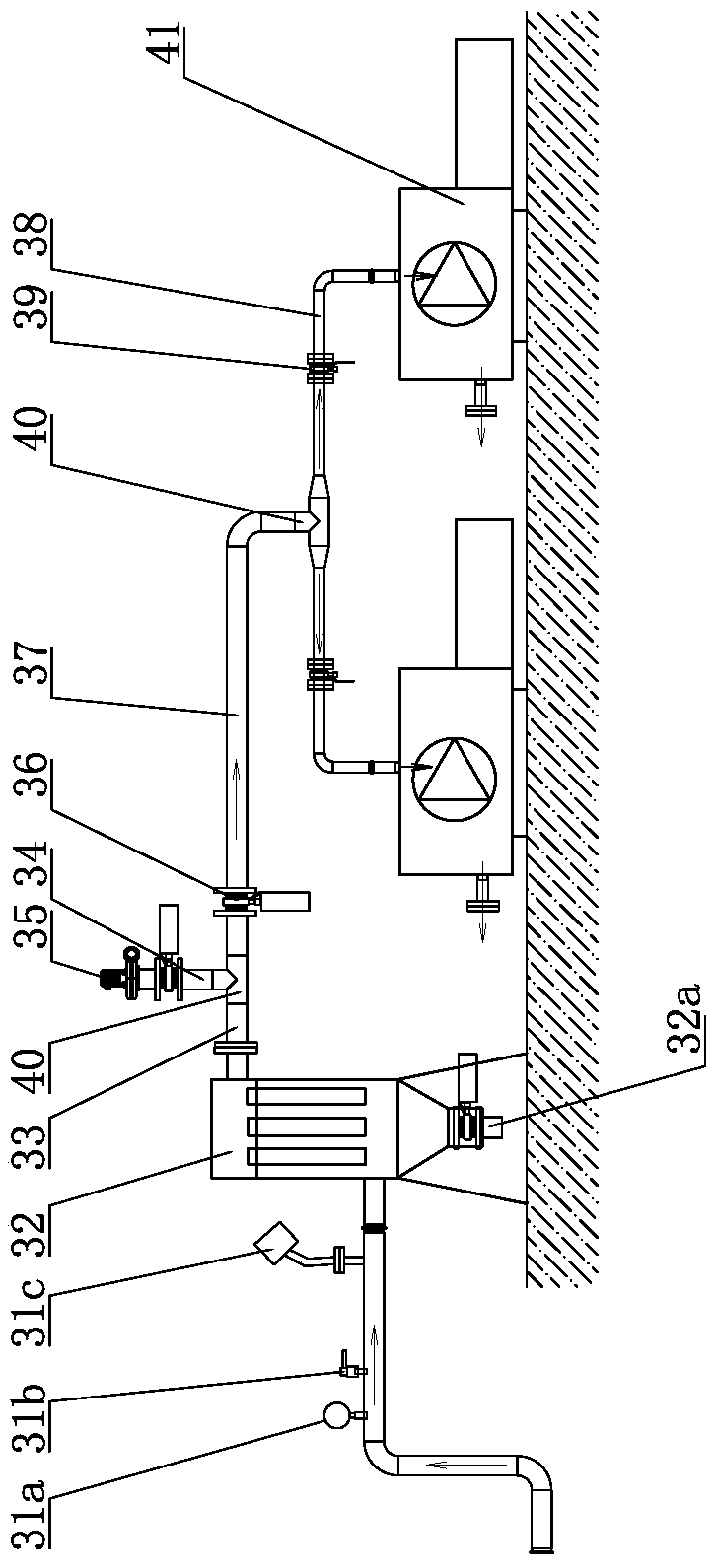

[0043] The automatic vacuum spraying process method of the present embodiment, as Figure 1-12 As shown, it includes the spraying host 1, the top of the spraying host 1 is provided with a material inlet 2, the inside of the spraying host 1 is provided with a mixing chamber 101, and the bottom of the spraying host 1 is provided with a discharge port 9, and there are 2 feed ports and 9 discharge ports Both are provided with disc valves 36, and the mixing chamber 101 includes two left and right symmetrical sub-chambers 101a, and a stirring shaft 3 is rotatably arranged in the two sub-chambers 101a respectively, and the stirring shaft 3 is connected with the spraying host 1 sub-chamber 101a The length direction of the mixing shaft 3 is set parallel to each other. A number of paddles 5 are staggered on the stirring shaft 3. The paddles 5 on the two stirring shafts 3 are staggered along the circumferential direction. The two stirring shafts 3 are connected to the rotating drive mecha...

Embodiment 2

[0063] The difference from Example 1 is that, as Figure 13 and 14 , the first nozzle assembly 13 is connected to the pumping pipeline 1301 located above, the first nozzle assembly 13 includes a left branch pipe 1301a, a right branch pipe 1301b and a right branch pipe 2 1301c, and the left branch pipe 1301a is provided with Six nozzles 26, four nozzles 26 are arranged on the right branch pipe one 1301b and the right branch pipe two 1301c; the second nozzle assembly 13 is connected with the pumping pipeline 1302 located below, and the second nozzle assembly 13 includes a left branch Pipe 2 1302a and right branch pipe 3 1302b, left branch pipe 2 1302a is provided with four nozzles 26, right branch pipe 3 1302b is provided with two nozzles 26, left branch pipe 2 1302a is set corresponding to left branch pipe 1 1301a , the right branch pipe three 1302b is set corresponding to the right branch pipe one 1301b and the right branch pipe two 1301c; the outlet of the nozzle 26 is provi...

Embodiment 3

[0075] The difference from Example 1 is that the processing method of this embodiment includes the following steps:

[0076] (1) Self-inspection: The weighing sensor of the material adding equipment performs a self-inspection reset, and the reset time is 6s;

[0077] (2) Feeding: The material adding equipment weighs 500kg of material granules, the material is extruded aquatic product material, the size of the material granules is 6~18mm, and the bulk density of the material granules is 0.3~0.7t / m 3 , feed the material particles into the mixing chamber 101 through the feed port 2, when the disc valve 36 of the feed port 2 is opened, the drive motor 7 of the stirring shaft 3 starts to run at a motor frequency of 32Hz, and the feeding process lasts for 19s;

[0078] (3) Vacuuming: Close the butterfly valve 36 of the feed port 2, open the butterfly valve connected to the vacuum tube 11, start the vacuum pump 41, and vacuum the inside of the mixing chamber 101 to 0.1 bar, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com