Liquid discharging mechanism based on food processing equipment

A food processing and equipment technology, applied in the field of liquid drains, can solve the problems of insufficient cleaning, single cleaning structure and function, and inconvenient garbage removal, etc., and achieve the effect of quick cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

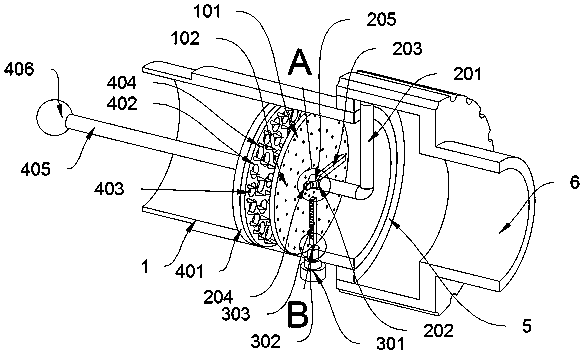

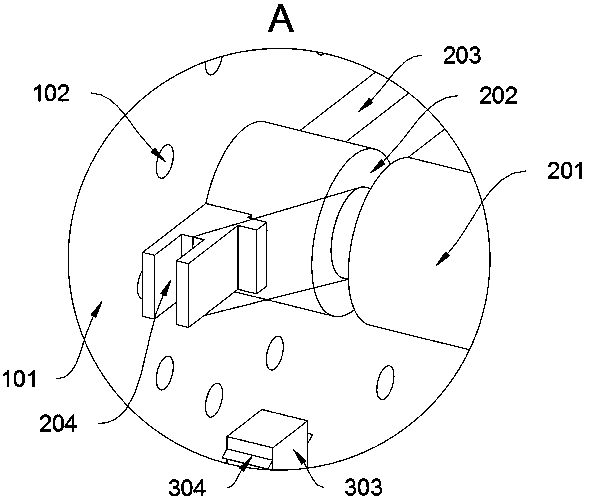

[0031] as attached figure 1 to attach Figure 8 Shown:

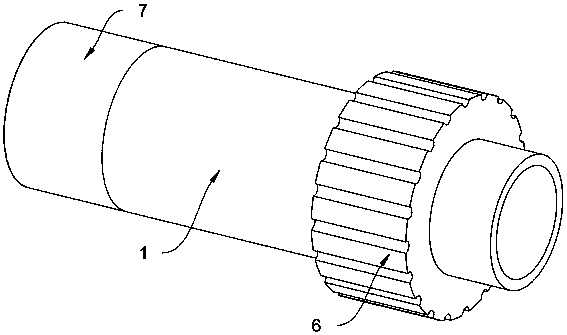

[0032] The present invention provides a liquid discharge mechanism based on food processing equipment, which includes a main pipe 1; a cleaning structure 2 is arranged inside the main pipe 1, and a collection structure 3 is clamped on the bottom of the main pipe 1; refer to figure 2 and 8 The cleaning structure 2 includes a connecting rod 201, an annular slot 202, a cleaning rod 203, a rectangular slot 204 and a rubber band 205. The connecting rod 201 on the cleaning structure 2 is an L-shaped structure, and the connecting rod 201 is rotatably connected to the filter plate 101 On; the connecting rod 201 is provided with an annular slot 202, and the connecting rod 201 is welded to the inner wall of the connector 6; the cleaning rod 203 is slidably connected to the connecting rod 201, and the cleaning rod 203 is in contact with the filter plate 101; the cleaning rod The top of 203 is provided with a rectangular slot 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com