Fluid filter

A technology of fluid filter and filter body, which is applied in the direction of fixed filter element filter, filter separation, chemical instrument and method, etc. It can solve the problems of high cost, frequent maintenance and replacement of filter element, poor backwashing effect, etc. Less dust and dirt, reduced spare parts consumption costs, and labor cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

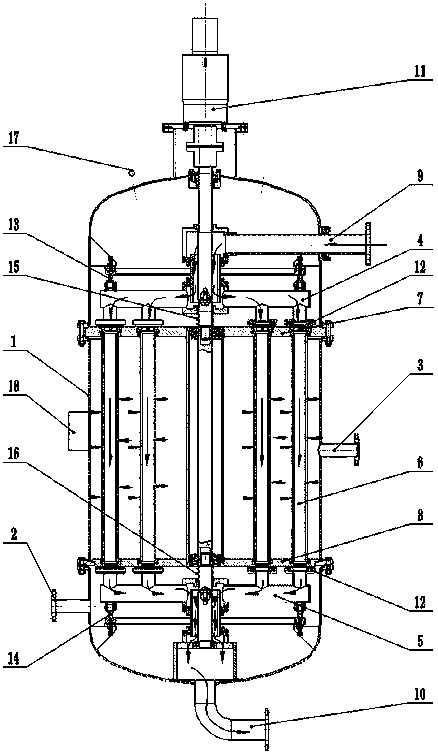

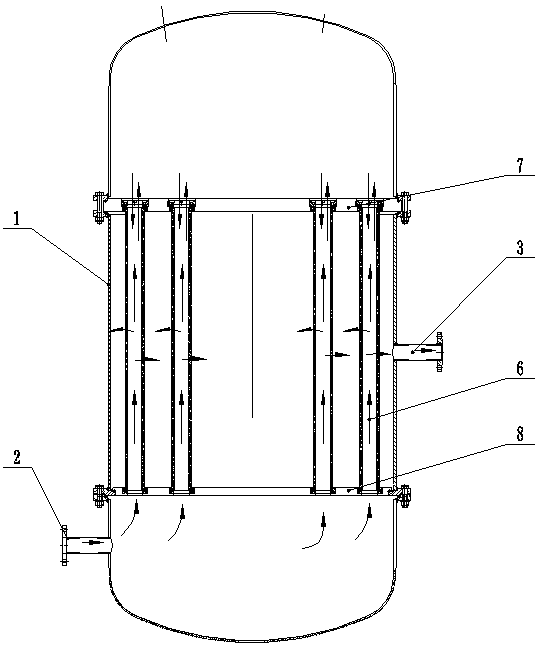

[0026] A fluid filter, comprising a container housing 1, a feed port 2, a discharge port 3, a filter body, a rotary displacement backwash mechanism 4 and a rotary displacement sewage discharge mechanism 5, the filter body includes a Filter elements 6 and multiple filter units consisting of upper trays 7 and lower trays 8 fixed to both ends of the filter elements, the upper trays 7 are connected to the container shell 1, the lower trays 8 are connected to the container shell 1, and the feed port 2 communicate with the inner cavity of the filter element 6 through the fixing holes on the upper tray 7 and the lower tray 8, and the discharge port 3 communicates with the cavity surrounded by the outer surface of the filter element 6 and the container shell 1, so The rotary displacement backwashing mechanism 4 is arranged above the upper tray 7, one end communicates with a group of filter unit inner chambers through the fixing hole of the upper tray 7, and the other end communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com