Multifunctional ceramic filterer ultrasonic washing system

A ceramic filter and cleaning system technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve problems such as affecting the filtration effect, achieve uniform cleaning, easy maintenance, and eliminate the effect of cleaning blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

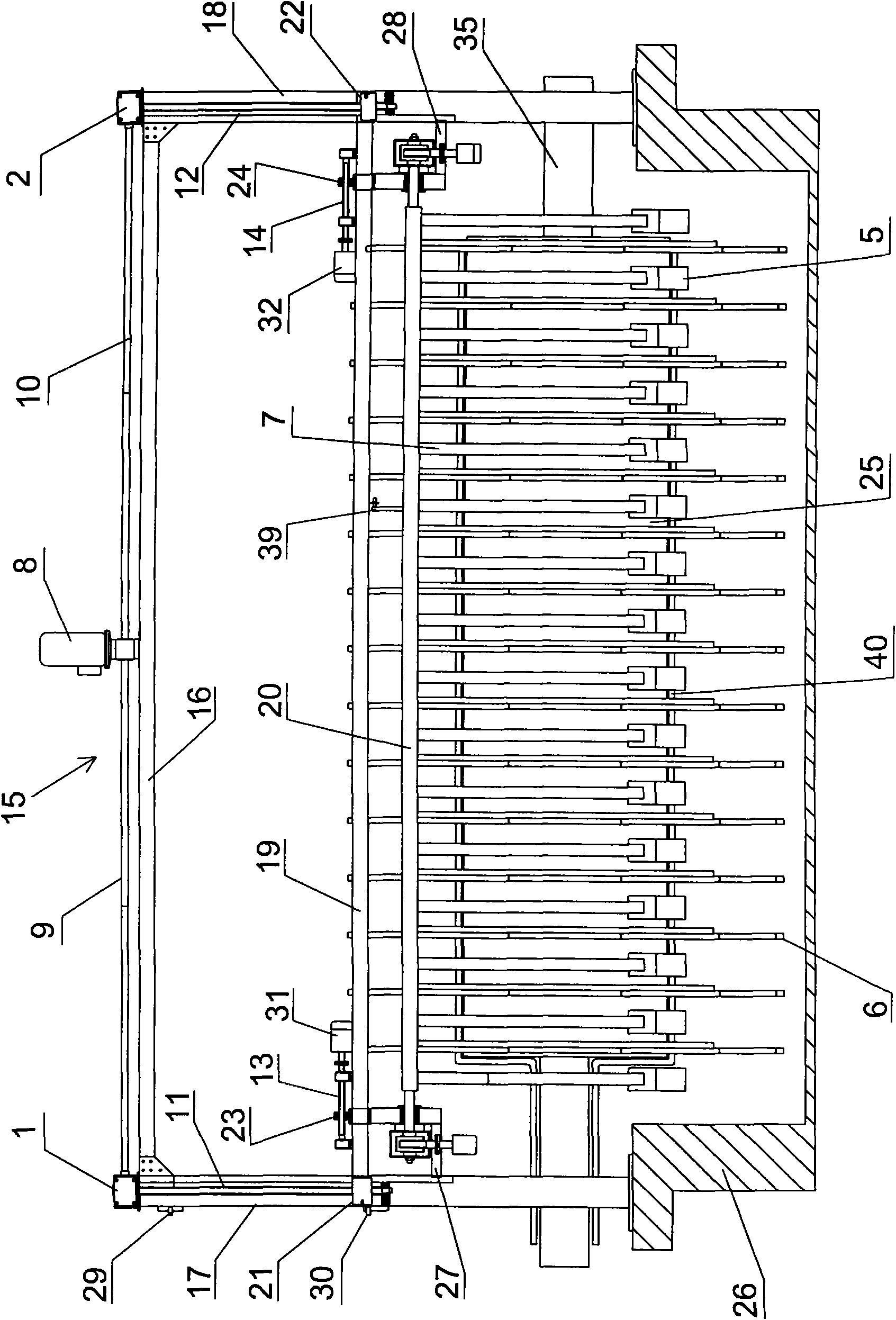

[0015] Label in the figure

[0016] 1 first reducer 2 second reducer 3 third reducer 4 fourth reducer

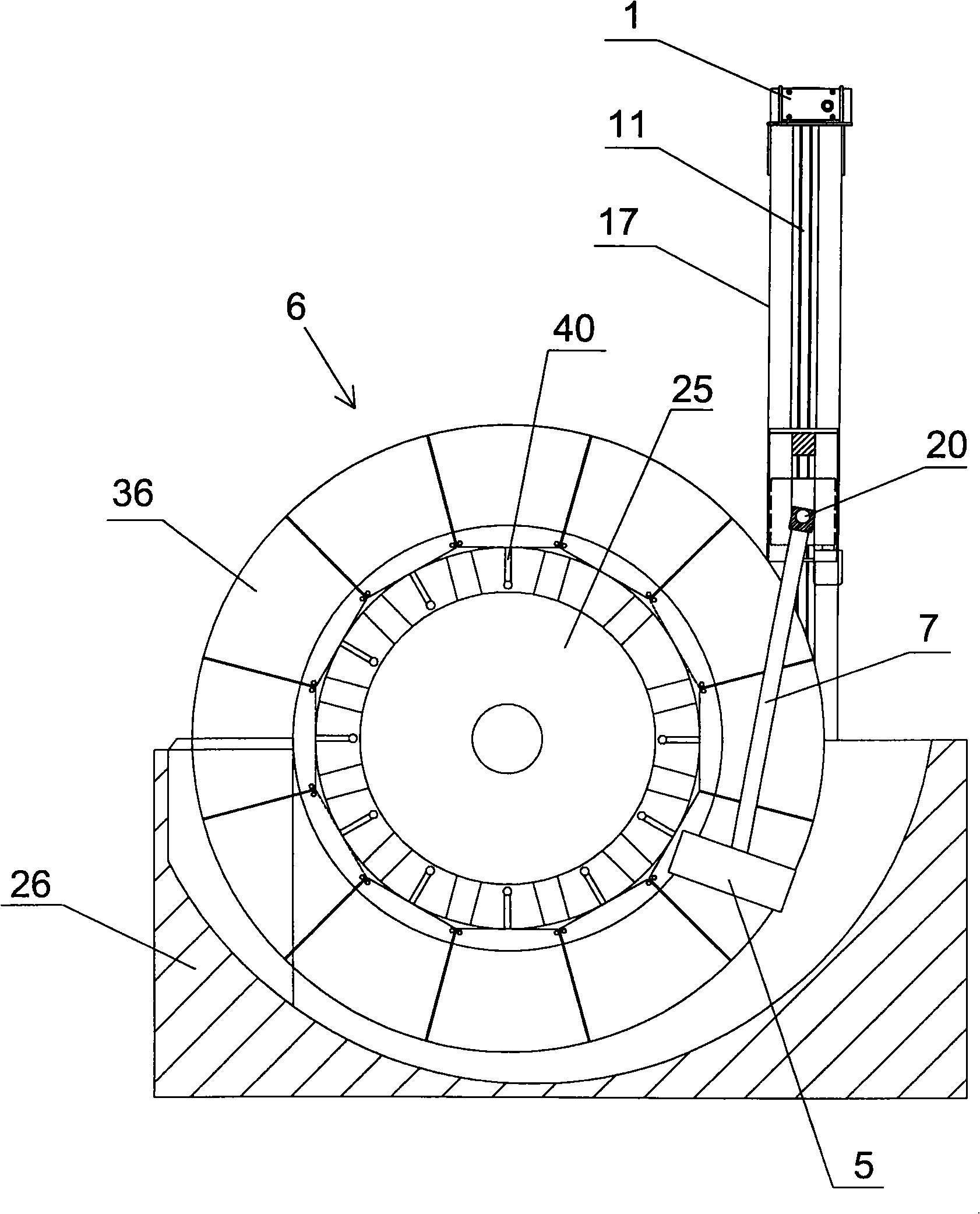

[0017] 5 vibrator box 6 filter plate 7 hanging arm

[0018] 8 Bidirectional output geared motor 9 Output shaft 10 Output shaft

[0019] 11 The first lead screw 12 The second lead screw 13 The third lead screw 14 The fourth lead screw

[0020] 15 Gantry frame 16 Beam 17 Left column 18 Right column

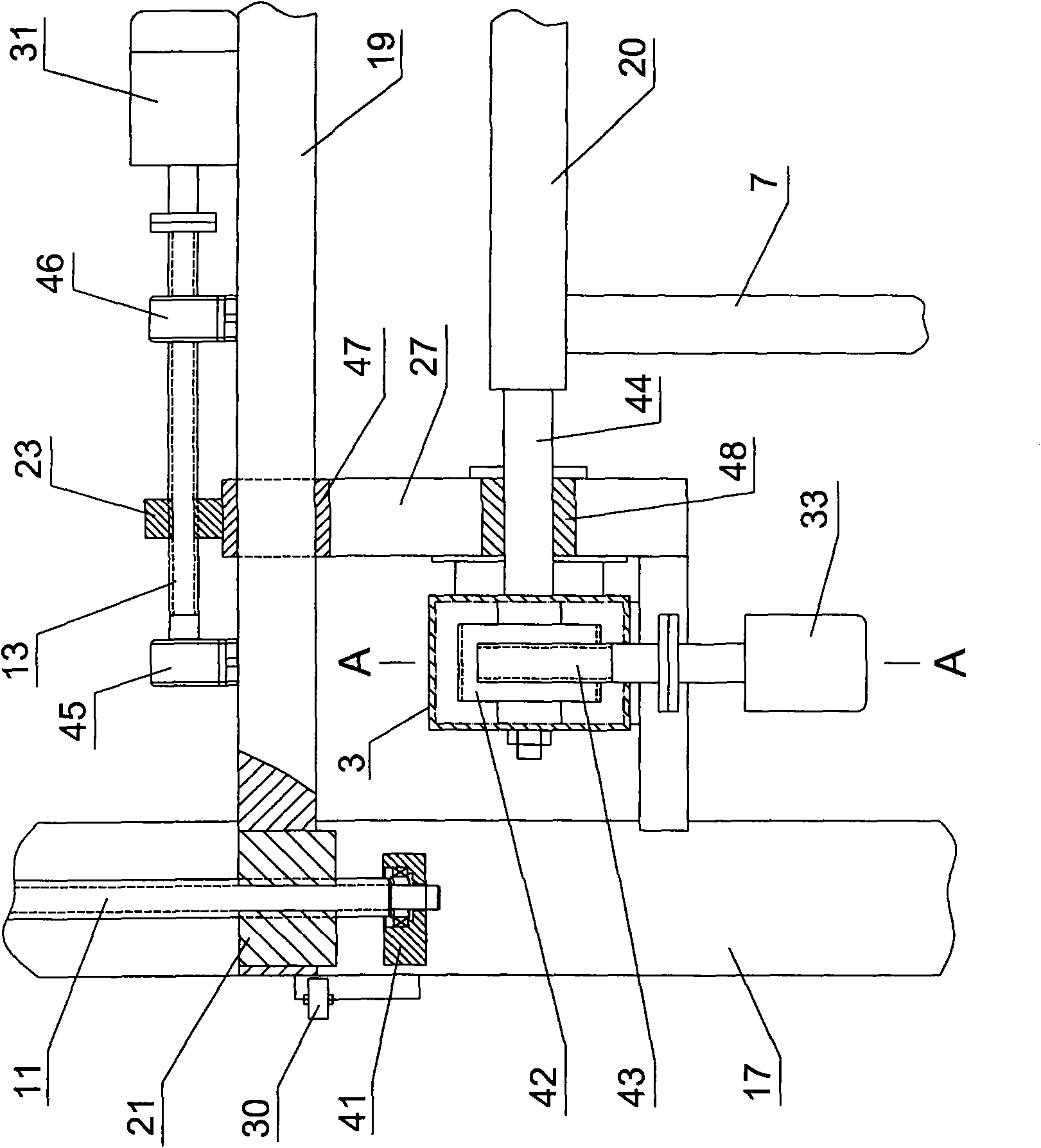

[0021] 19 Lifting lever 20 Rotation axis

[0022] 21 first nut 22 second nut 23 third nut 24 fourth nut

[0023] 25 roller 26 material chute 27 left hanger 28 right hanger

[0024] 29 upper limit sensor 30 lower limit sensor

[0025] 31 The first servo motor 32 The second servo motor

[0026] 33 The third servo motor 34 The fourth servo motor

[0027] 35 central axis 36 ceramic filter plate

[0028] 37 front limit sensor 38 rear limit sensor

[0029] 39 guide rod 40 gas-liquid pipeline

[0030] 41 bearing seat 42 worm gear 43 worm 44 shaft head

[0031] 45 bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com