Multi-jetflow bodied tricone bit

A three-cone, multi-jet technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems that can only be installed under the cone, the erosion of the cone shell, and the loss of cutting teeth, so as to reduce the Repeated crushing, reduced drilling costs, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

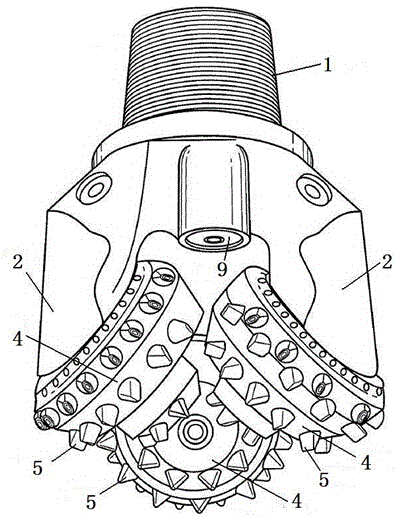

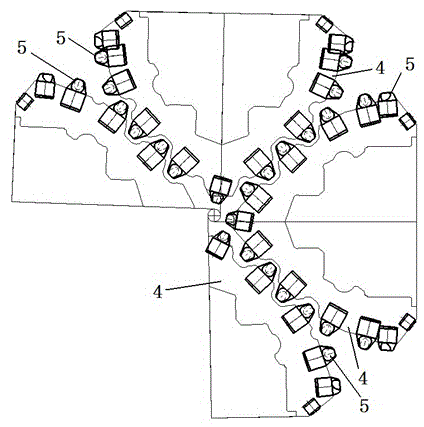

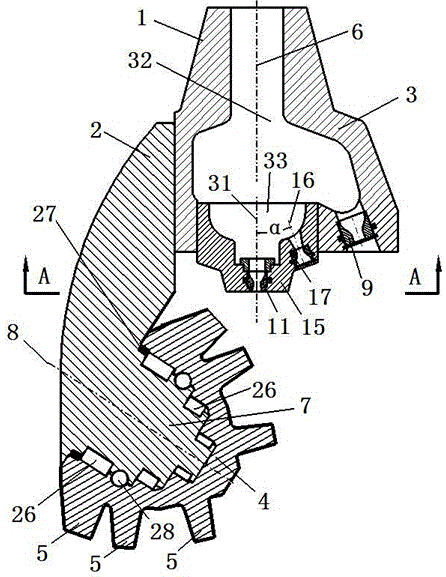

[0042] This embodiment is a body type steel tooth roller cone bit with a drill diameter of 508mm (20 "), comprising a drill body 3, a tooth palm 2 and a cone 4, the drill body 3 is provided with a drill shank 1, and is provided with a drill that can allow drilling. Liquid through the inner flow channel 32, the drill body is provided with three holes for installing three side nozzles 9 respectively. The three palms 2 are welded and fixed on the three grooves of the drill body 3. The lower end of each palm 2 is provided with A journal 7, on which a steel-toothed cone 4 is installed. The cone and the shaft diameter 7 on the tooth palm 2 form a bearing pair, and the bearing pair is provided with a sealing ring element 27. In the tooth palm journal 7 and the cone Roller bodies 26 are arranged between the holes to form a rolling bearing pair. Steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com