Energy-saving oven equipment

An oven and equipment technology, which is applied in the field of energy-saving oven equipment with turbulent flow plates, can solve the problems of no designed air volume balance flow plate, energy-saving effect needs to be improved, and hot air intensity is not high, so as to improve energy utilization rate and turbulent flow. Strengthen and reduce the effect of wind area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

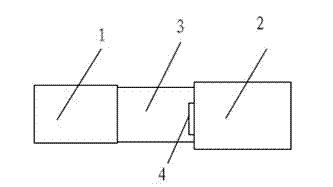

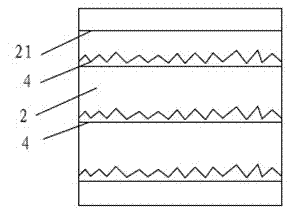

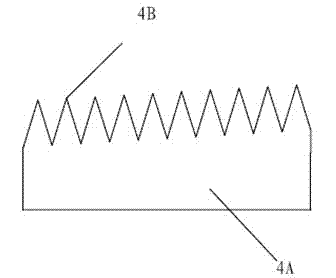

[0032] Such as figure 1 and figure 2 As shown, the energy-saving oven equipment includes a heat dissipation device 1, a hot air channel 3 and a CT oven 2. The oven 2 is provided with a hot air inlet 21, and the hot air inlet 21 is connected to the outlet of the hot air channel 3. The hot air inlet of the oven 2 is provided with a turbulent flow plate 4, see image 3 , the lower surface 4A of the turbulence plate 4 is rectangular, and the upper surface 4B is zigzag. The heat dissipation device 1 is a steam radiating pipe with upper and lower floors arranged side by side, a support plate (not shown in the figure) is provided at the hot air inlet 21 of the oven 2, and the turbulence plate is fixed or screwed on the support plate.

[0033] The CT oven 2 can be a straight-through 15-layer oven, provided with 15 hot air inlets 21, the height of the hot air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com