Back-flush-type preposed water filter

A water filter and backwashing technology, applied in the field of daily utensils, can solve the problems of limited air pressure, bacteria breeding on the filter net, impurities on the filter net cannot be effectively washed down, etc., to achieve the effect of self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein like reference numerals designate like or similar elements throughout. The specific embodiments described below with reference to the accompanying drawings are exemplary and intended to explain the present invention, but not construed as a limitation of the present invention.

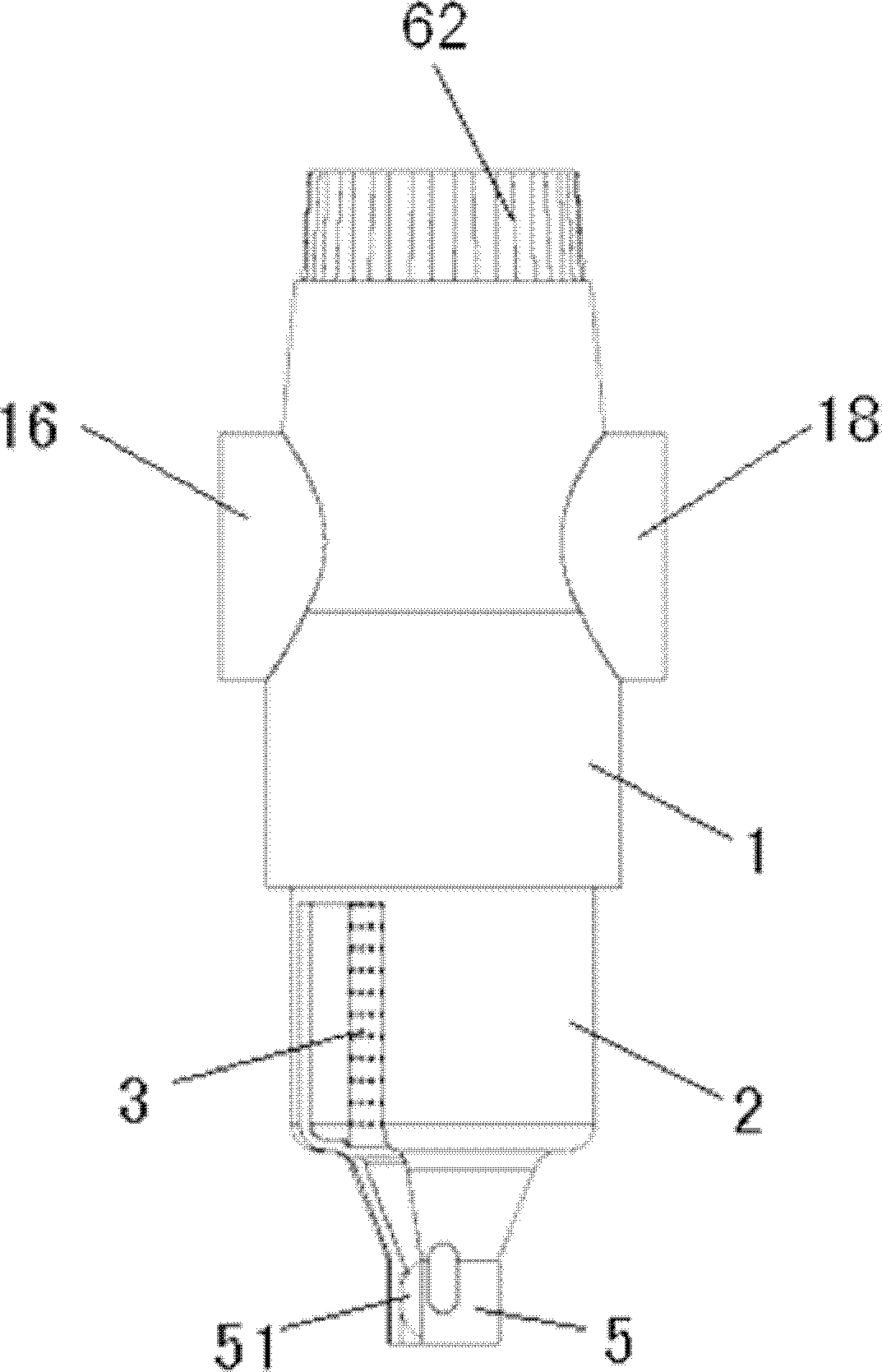

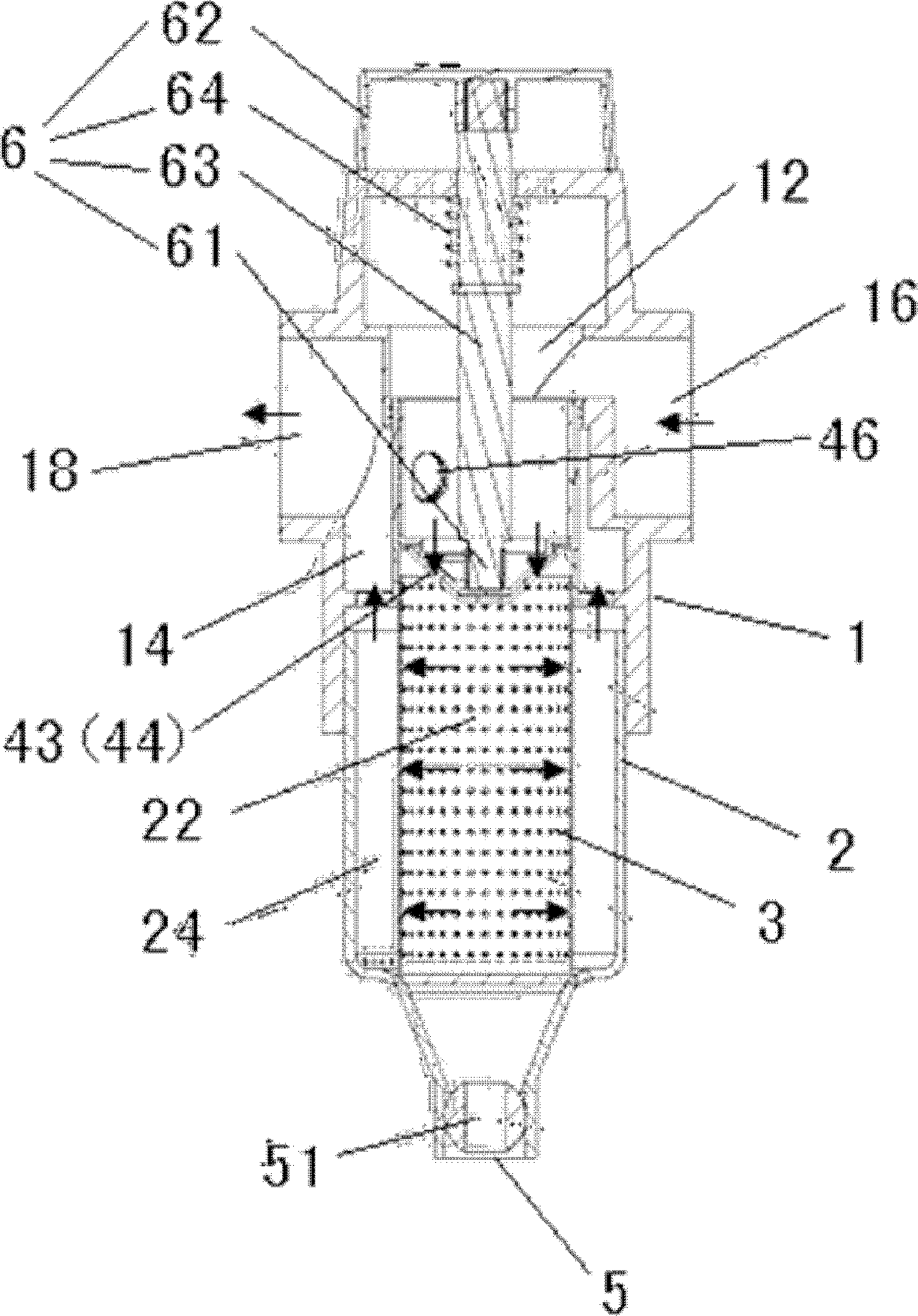

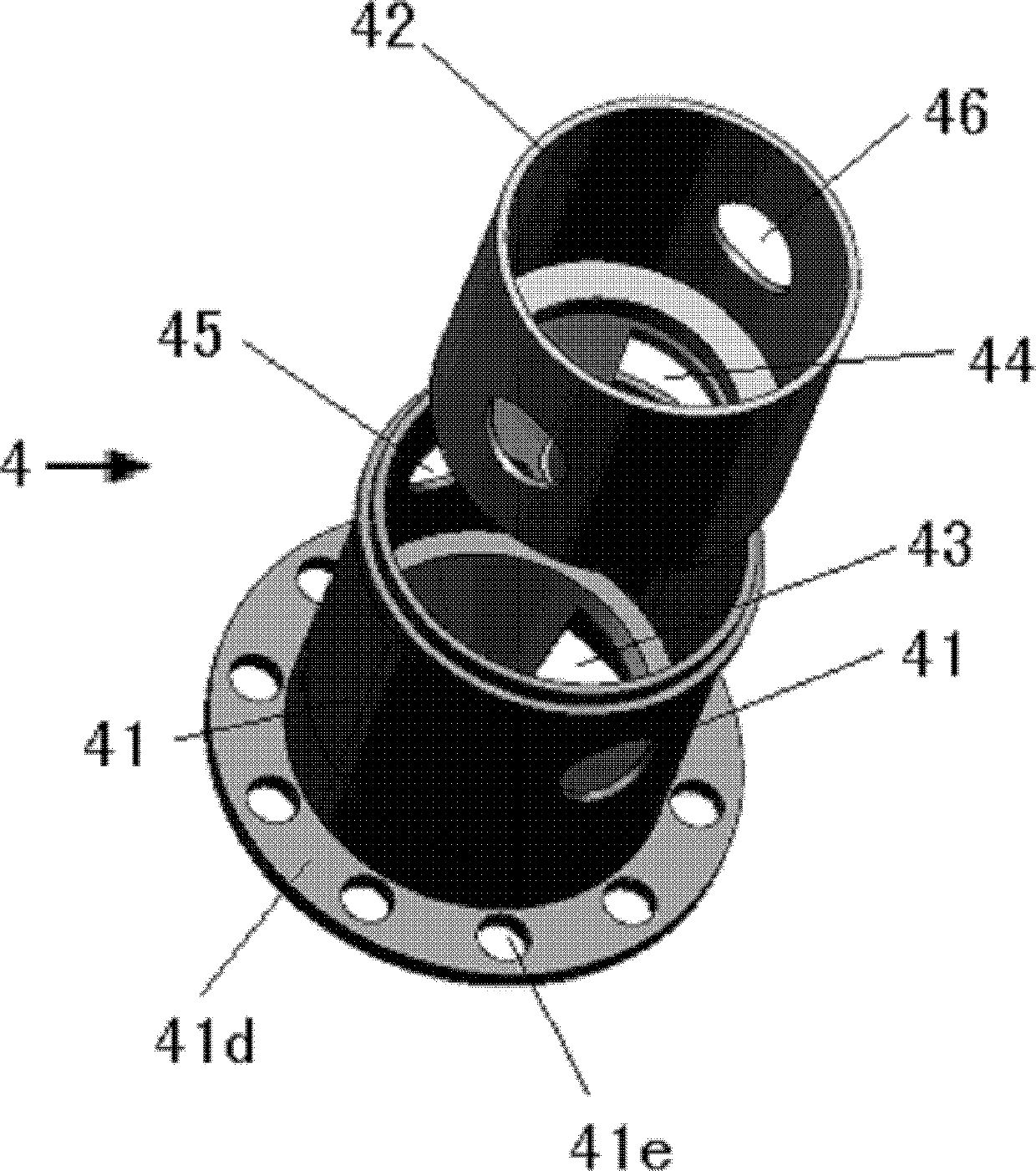

[0041] by figure 1 and 2 Taking the specific embodiment shown in the example as an example, the present invention provides a backwash type pre-water filter, including a water inlet 16 and a water outlet 18 , a housing 2 , a filter screen 3 , and a water flow direction changing device 4 . The casing 2 defines a filter chamber 20 , wherein the water flowing in from the water inlet 16 flows through the filter chamber 20 and then flows out from the water outlet 18 . It should be noted that, in the description above and below, the water flow described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com