Patents

Literature

191results about How to "Simple cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ventilation system

InactiveUS7073566B2Low costSimple cuttingMechanical apparatusSpace heating and ventilation detailsFresh airEngineering

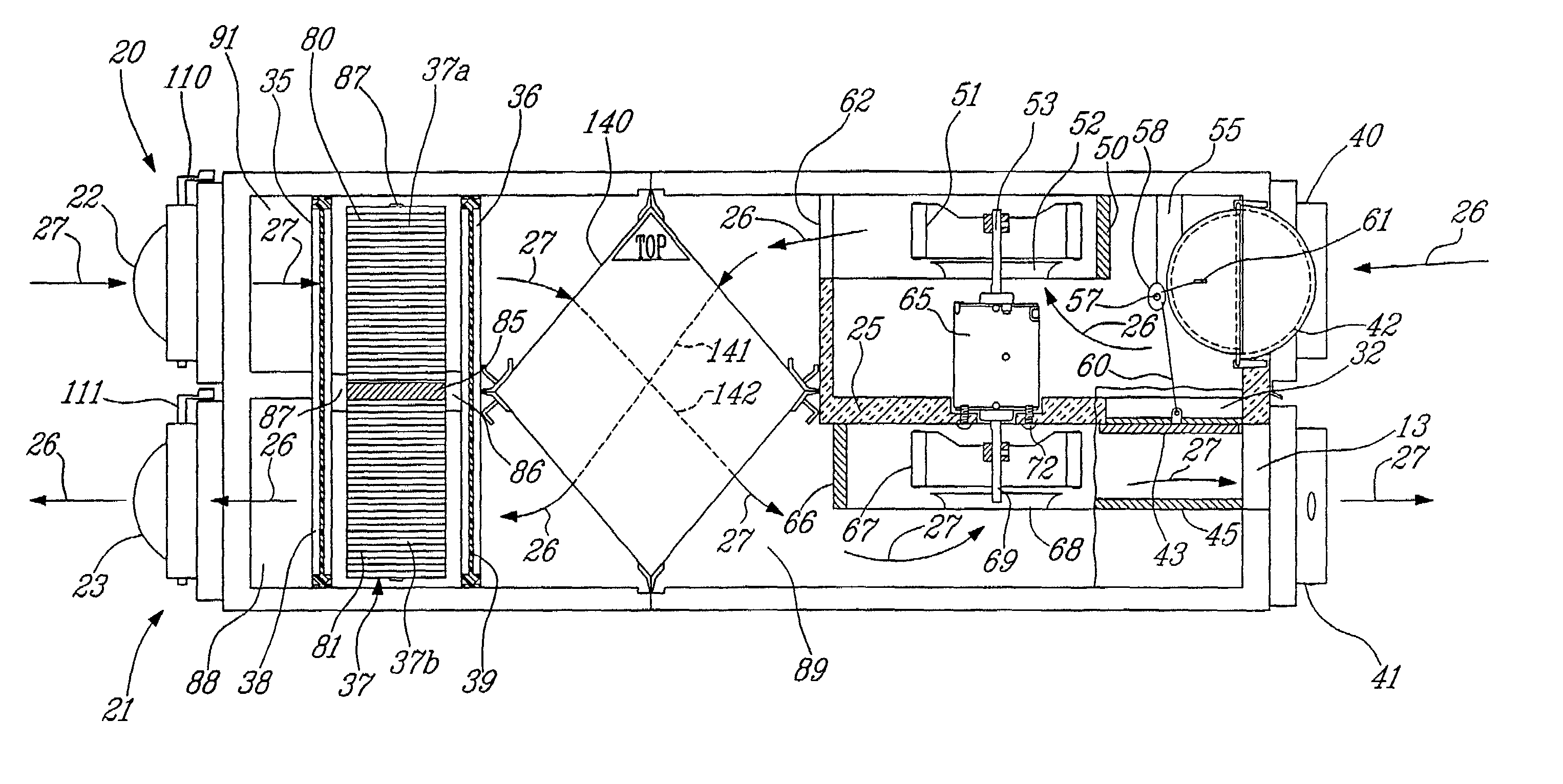

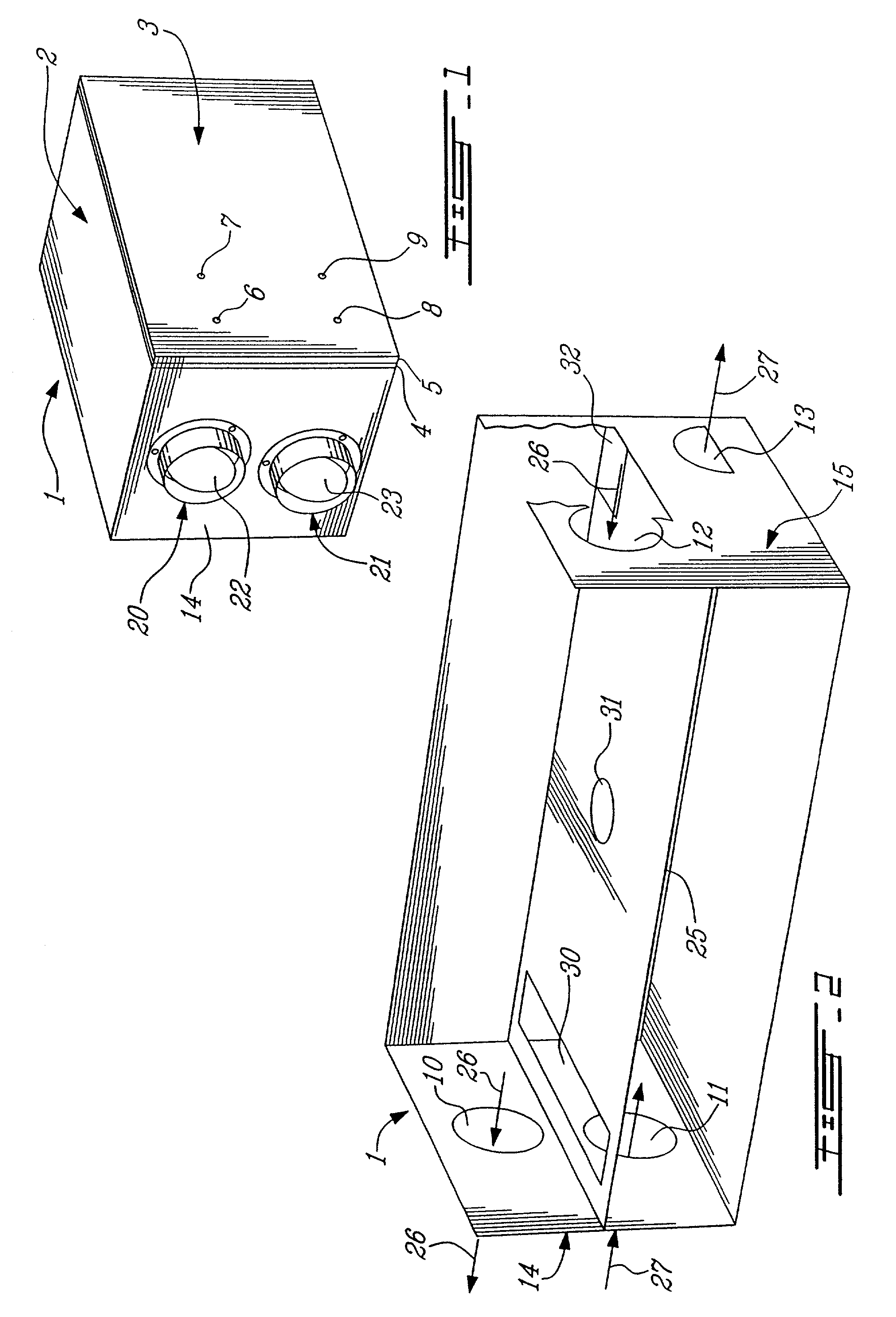

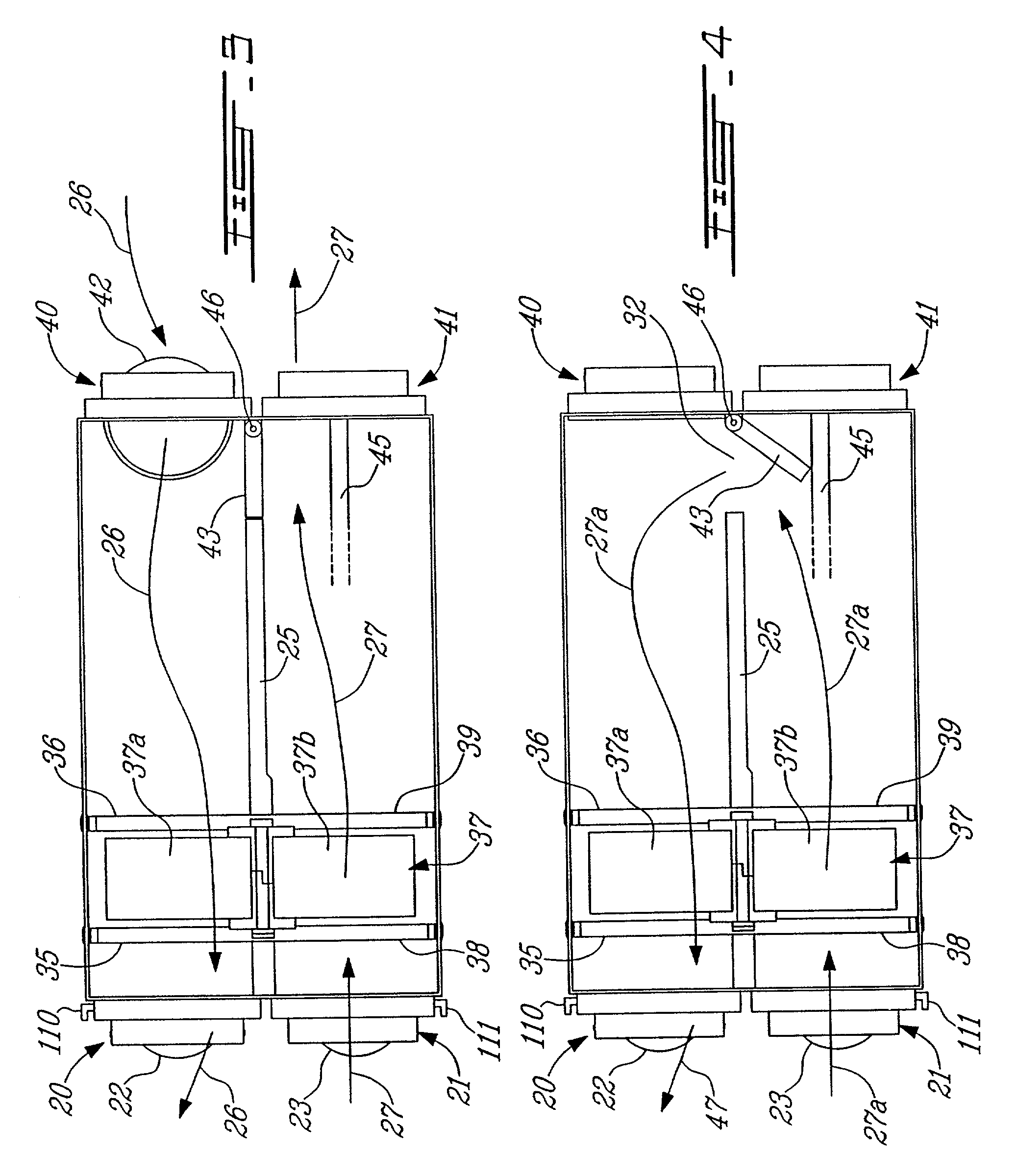

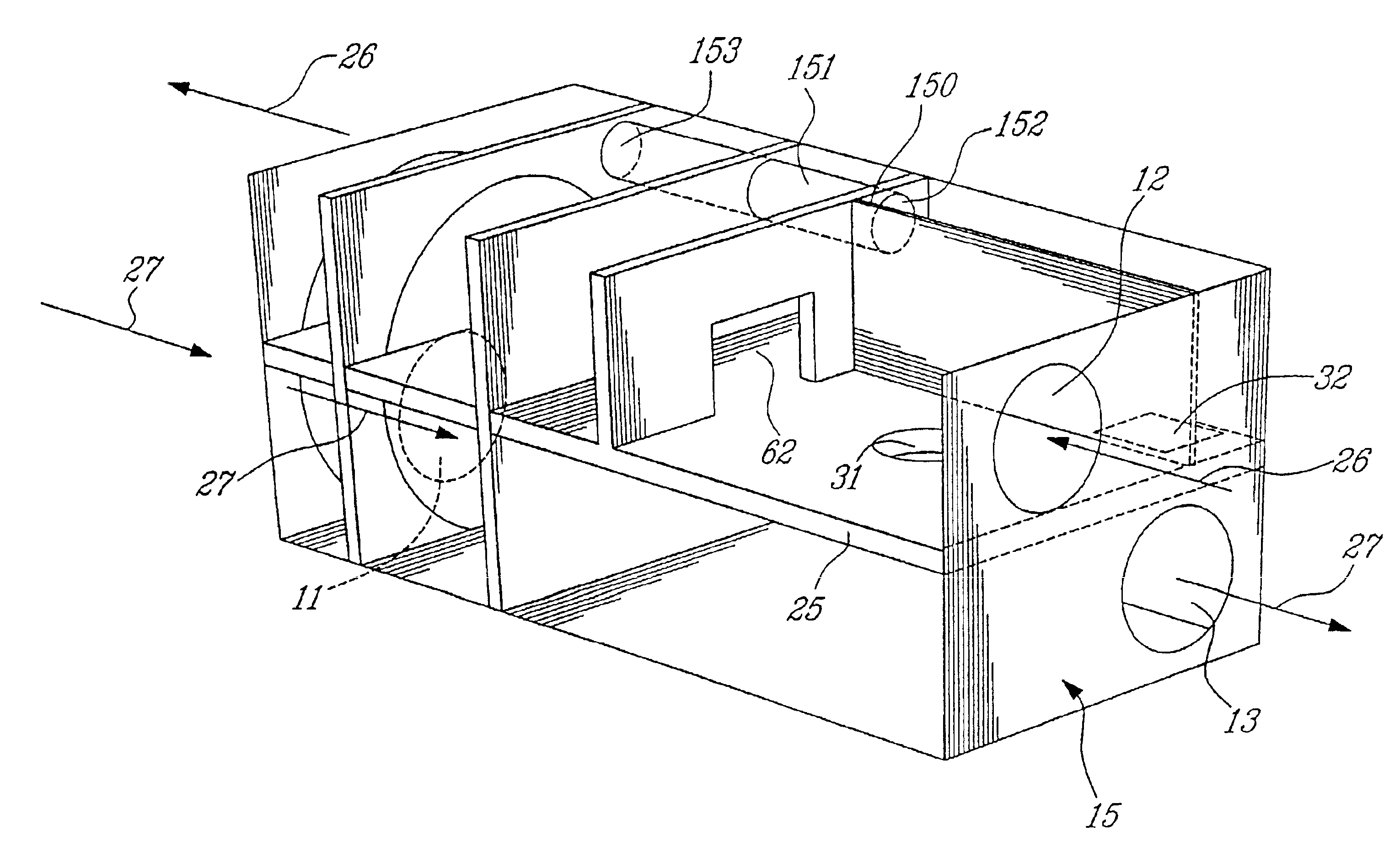

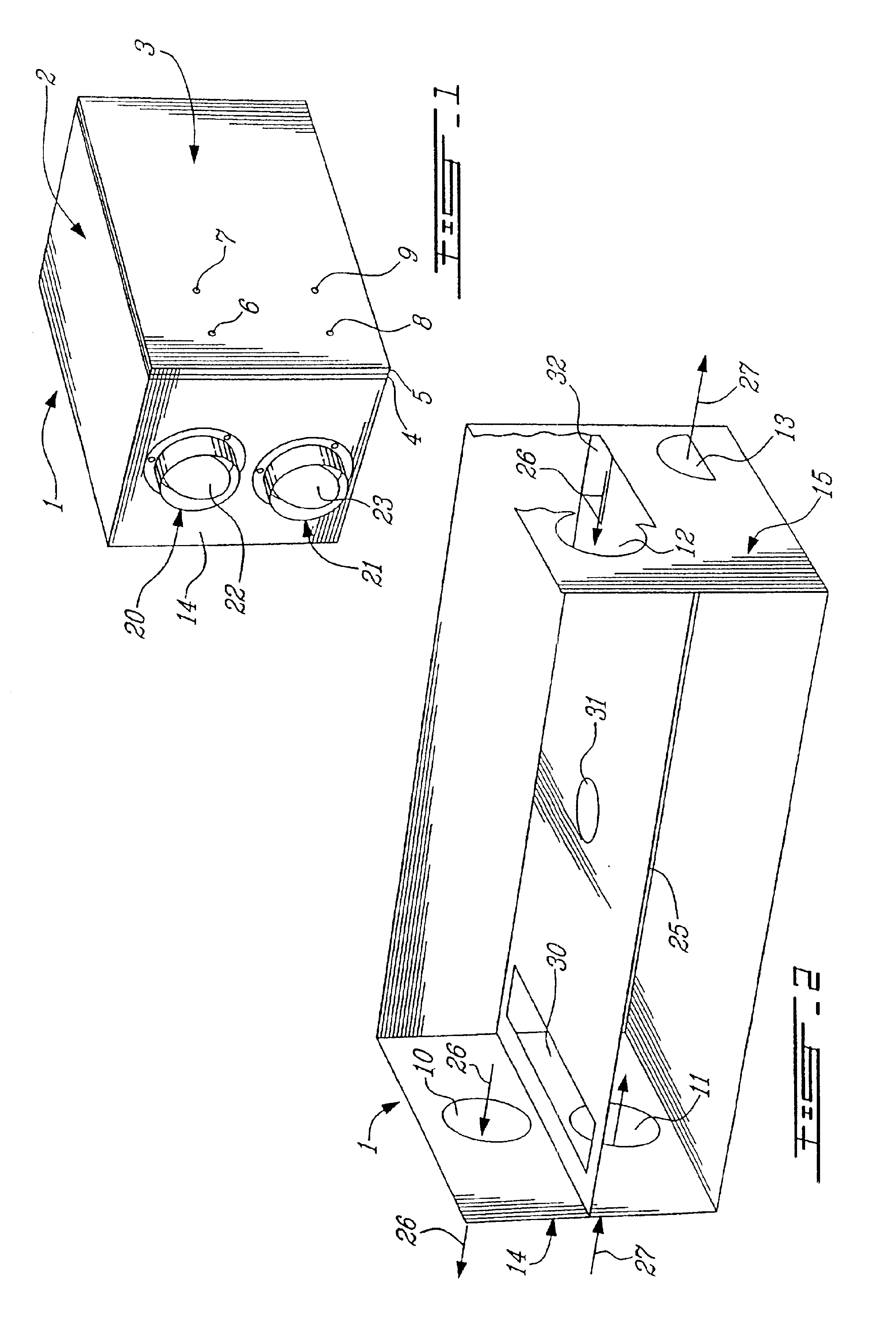

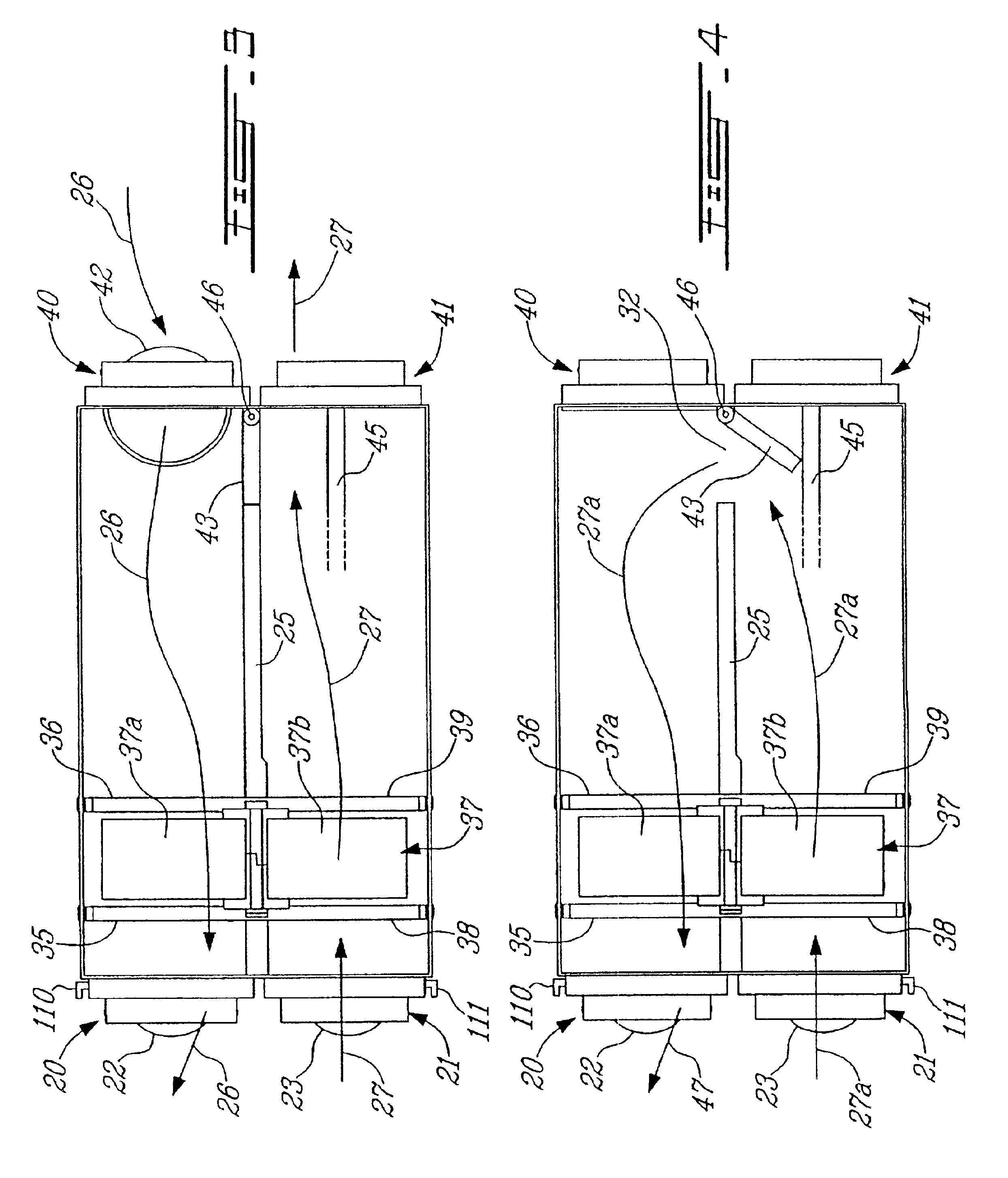

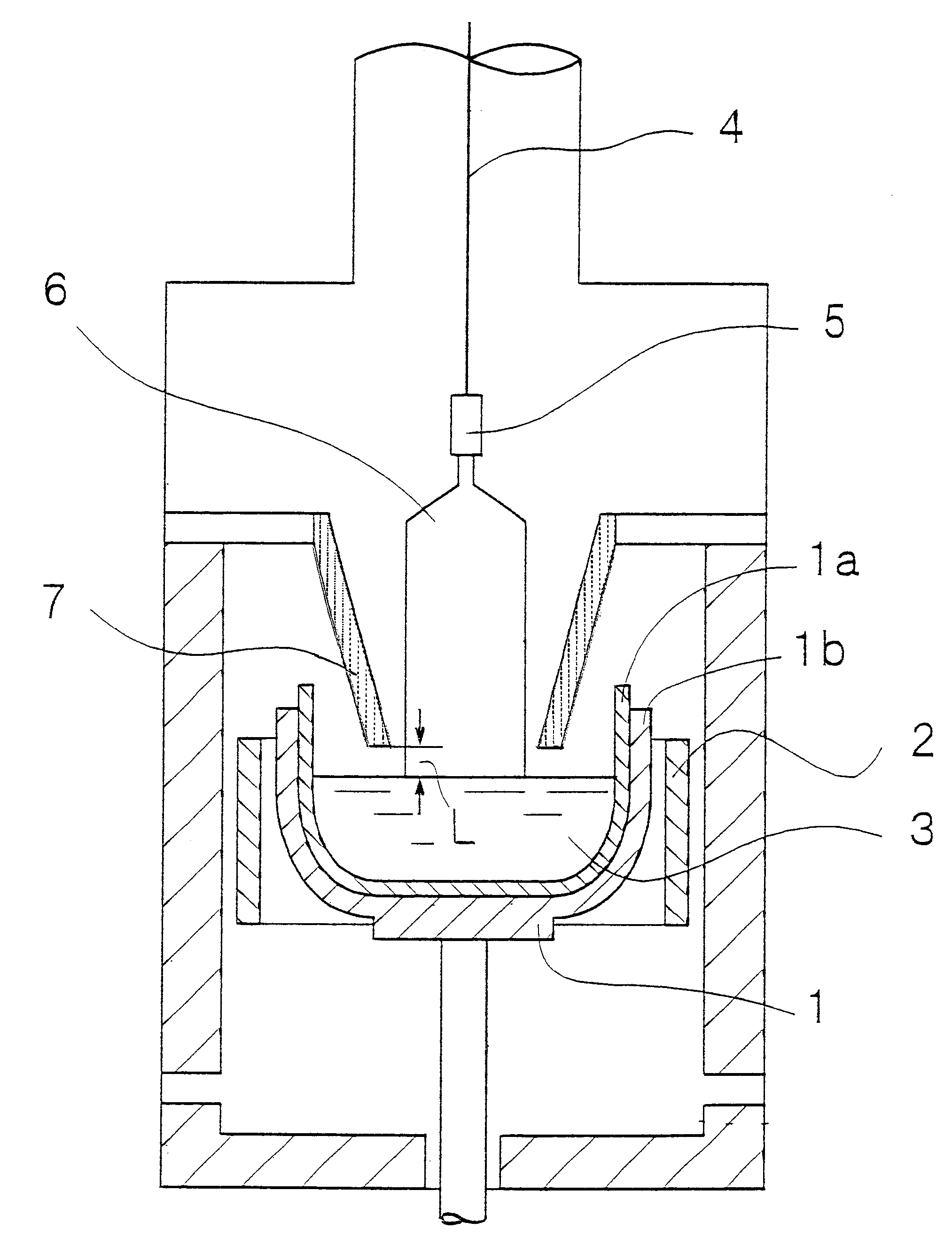

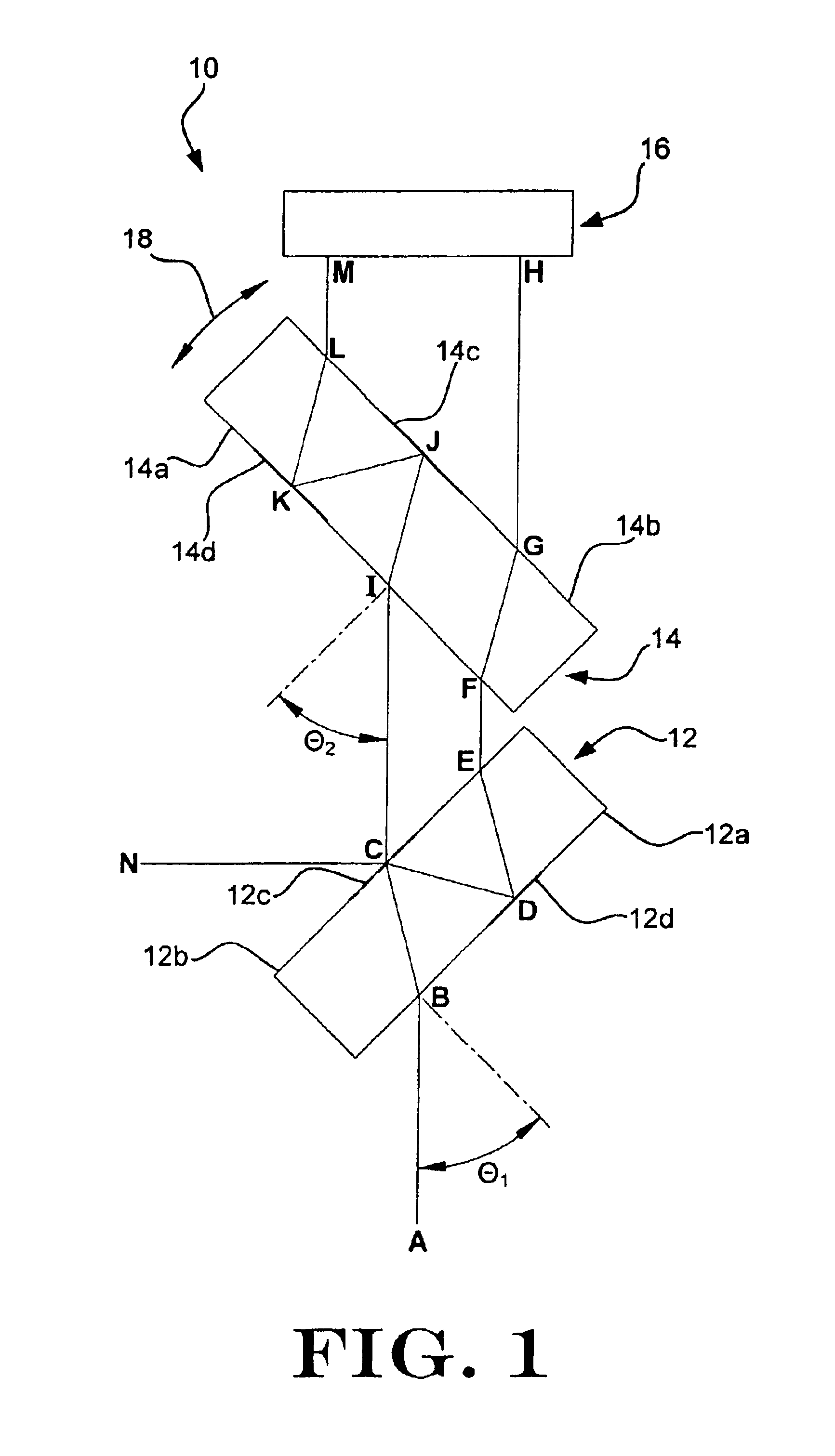

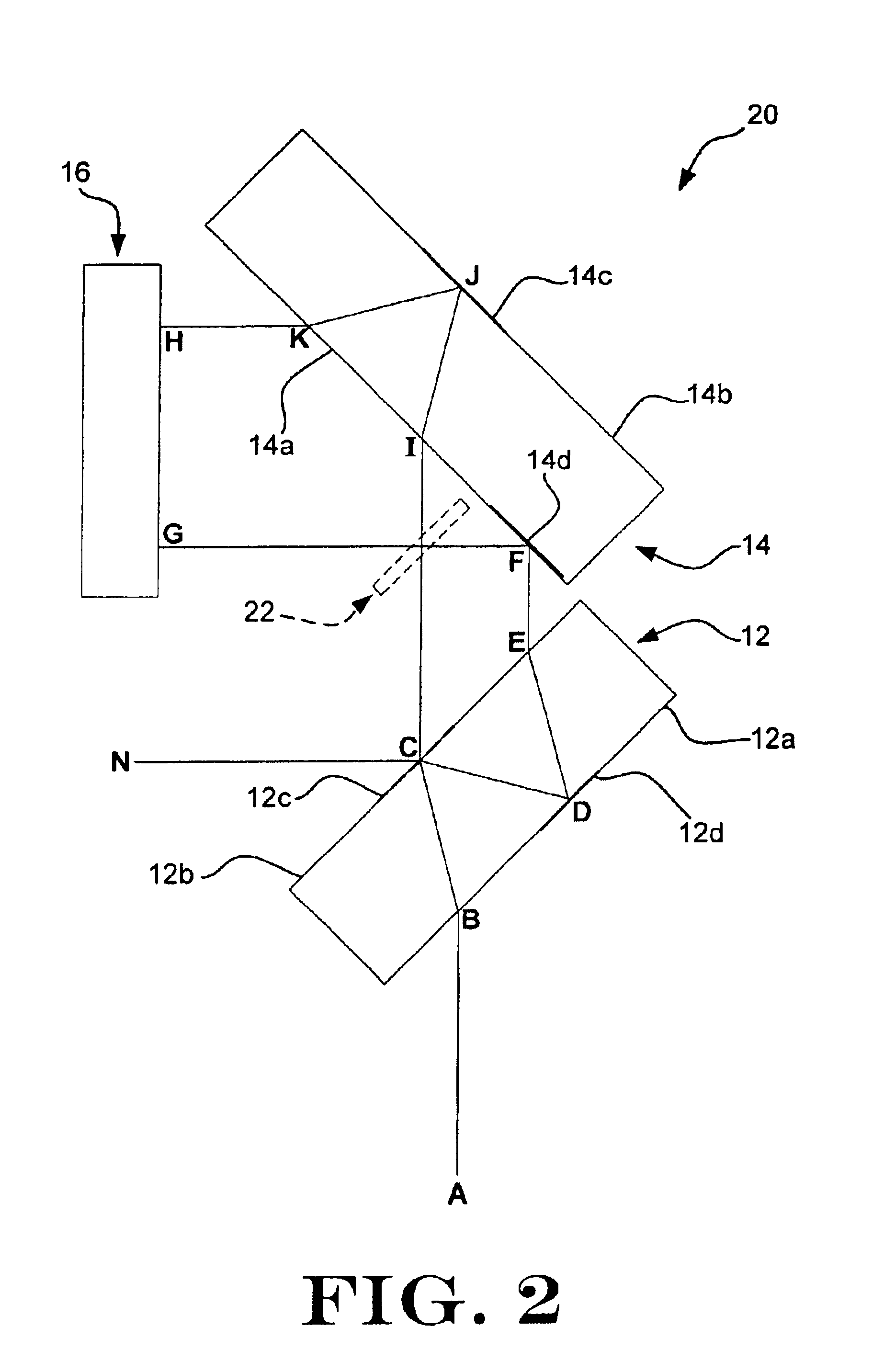

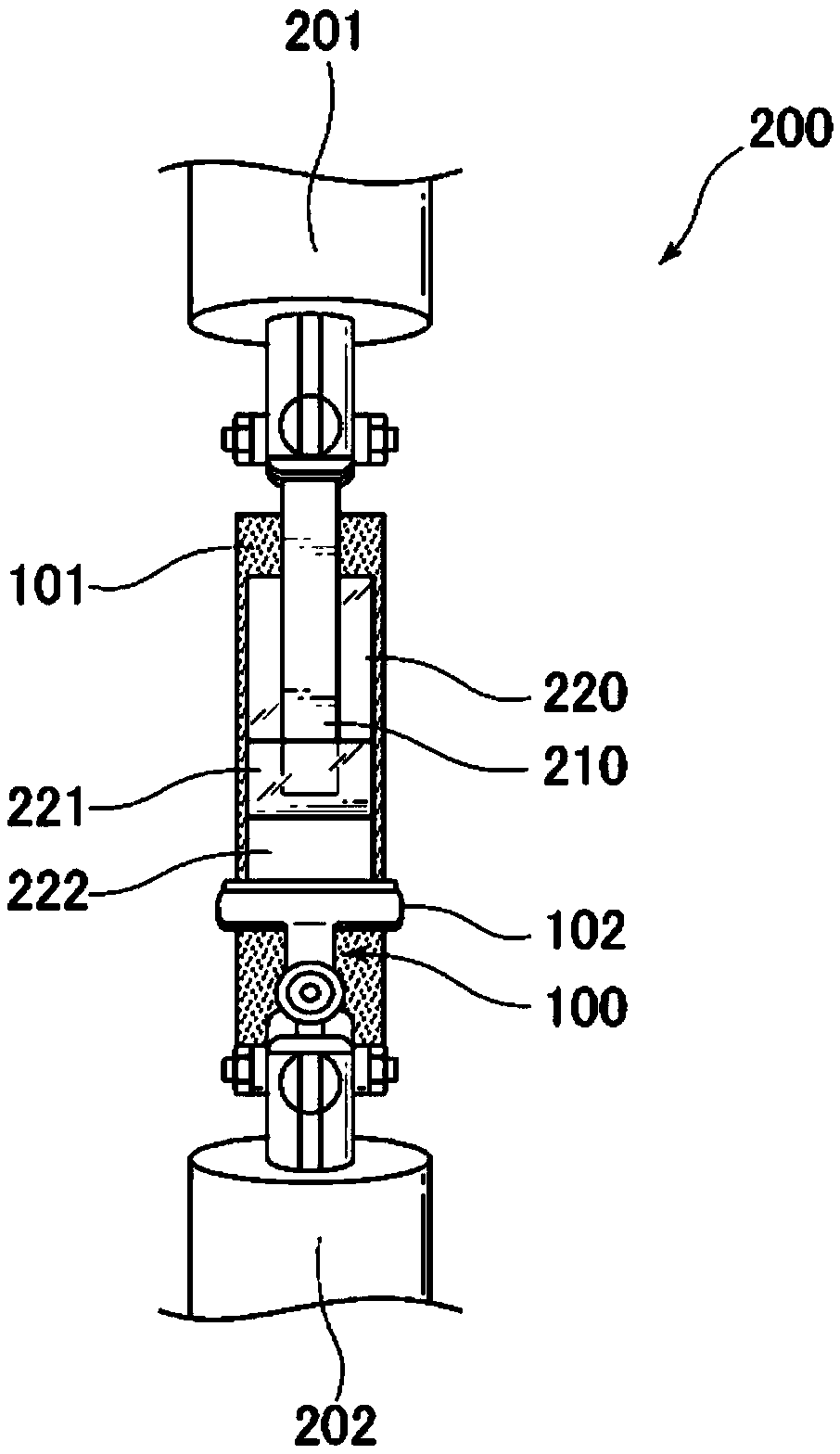

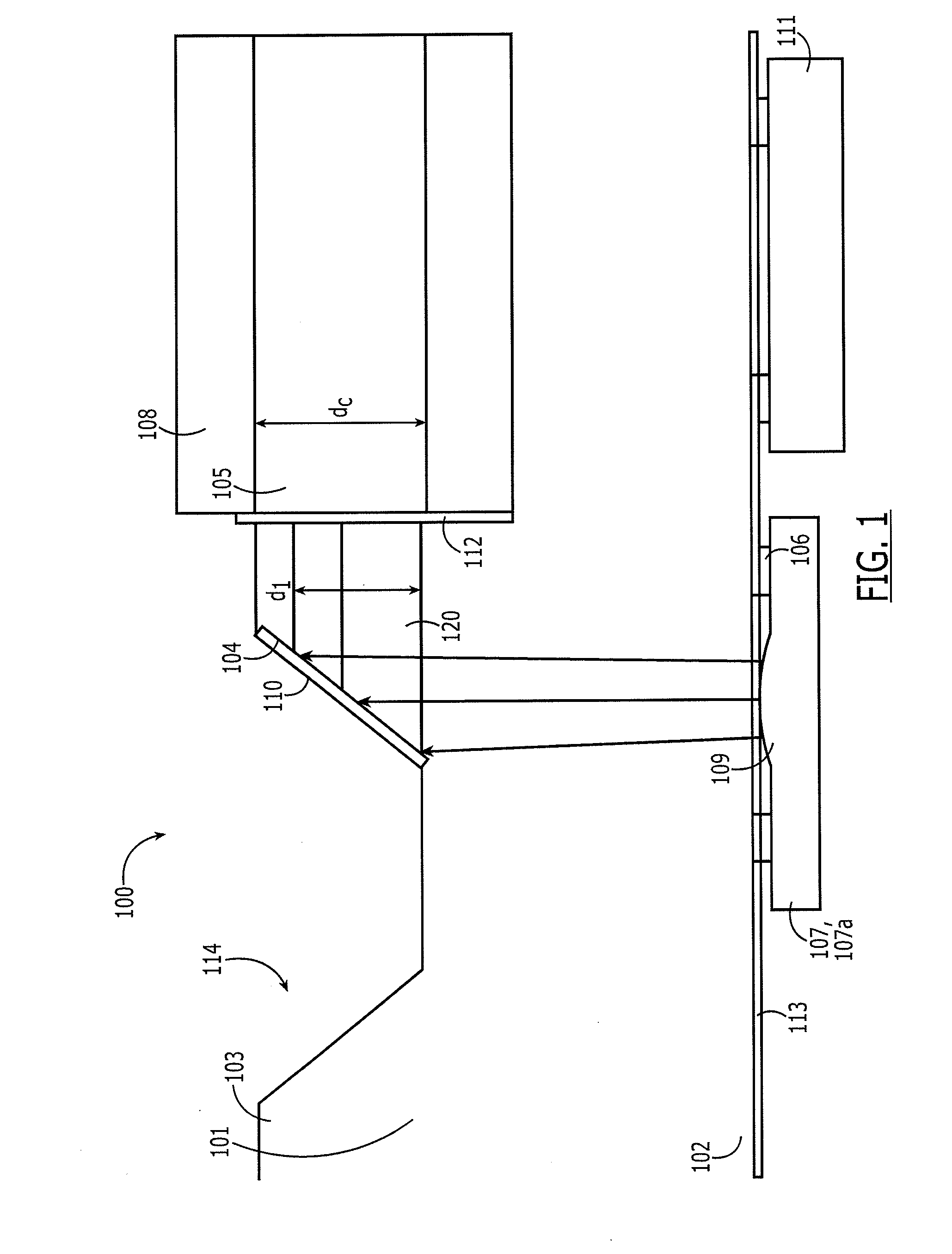

An apparatus for ventilation systems includes an element for the transfer of heat from warm exhaust air (taken from inside a building) to cooler exterior fresh air which is drawn into the building. The present invention in particular provides an apparatus whereby, during a defrost cycle, interior air may circulate through both of the fresh air and exhaust air paths for delivery back into the building, i.e. the warm interior air, used as defrost air, may be able to circulate from the interior of the building into the ventilation apparatus and back to the interior of the building. The apparatus can thus use interior air as defrost air while diminishing or avoiding the creation of a negative air pressure in the building.

Owner:VENMAR VENTILATION

Ventilation system

InactiveUS6889750B2Advantageously operateLow costMechanical apparatusDomestic cooling apparatusFresh airWaste management

An apparatus for ventilation systems which include an element for the transfer of heat from warm exhaust air (taken from inside a building) to cooler exterior fresh air which is drawn into the building. During a defrost cycle, interior air may circulate through both of the fresh air and exhaust air paths for delivery back into the building, i.e. the warm interior air, used as defrost air, may be able to circulate from the interior of the building into the ventilation apparatus and back to the interior of the building. The apparatus can thus use interior air as defrost air while diminishing or avoiding the creation of a negative air pressure in the building.

Owner:BROAN NUTONE +10

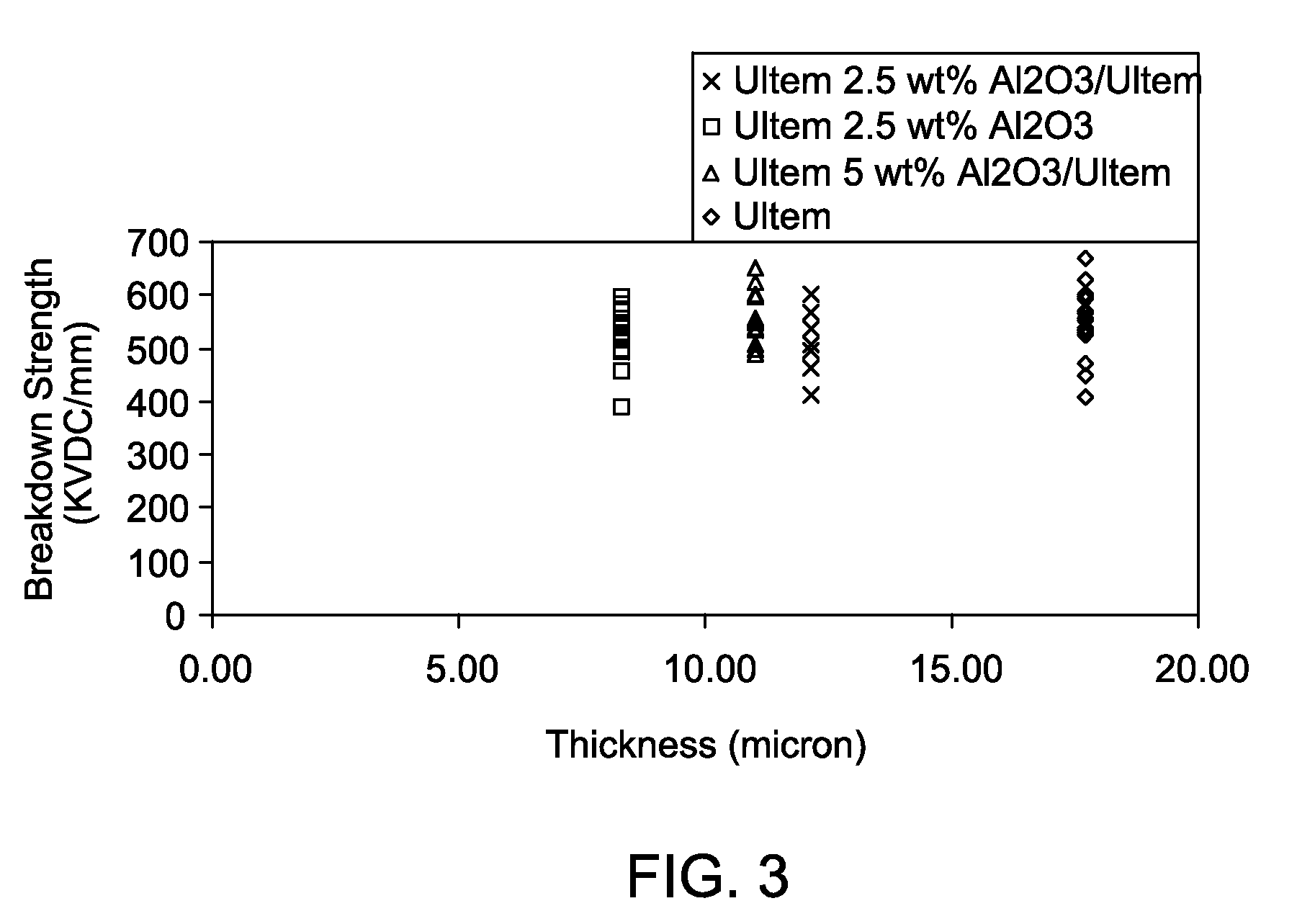

Composite structures for high energy-density capacitors and other devices

InactiveUS20100302707A1Long lastingImprove reliabilityLayered product treatmentFixed capacitor dielectricBreakdown strengthMicrometer

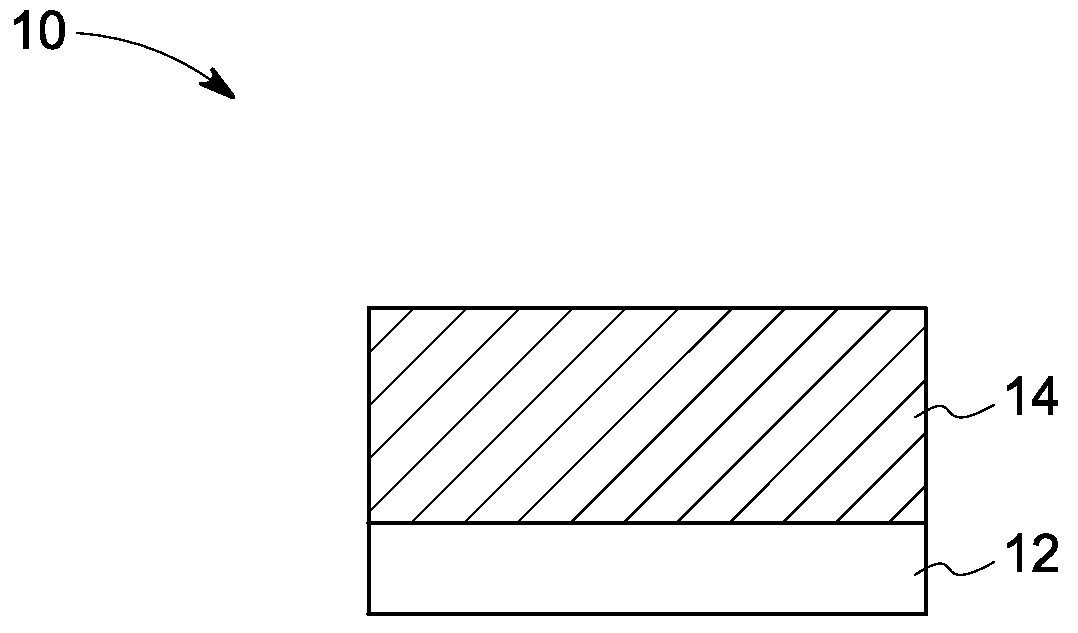

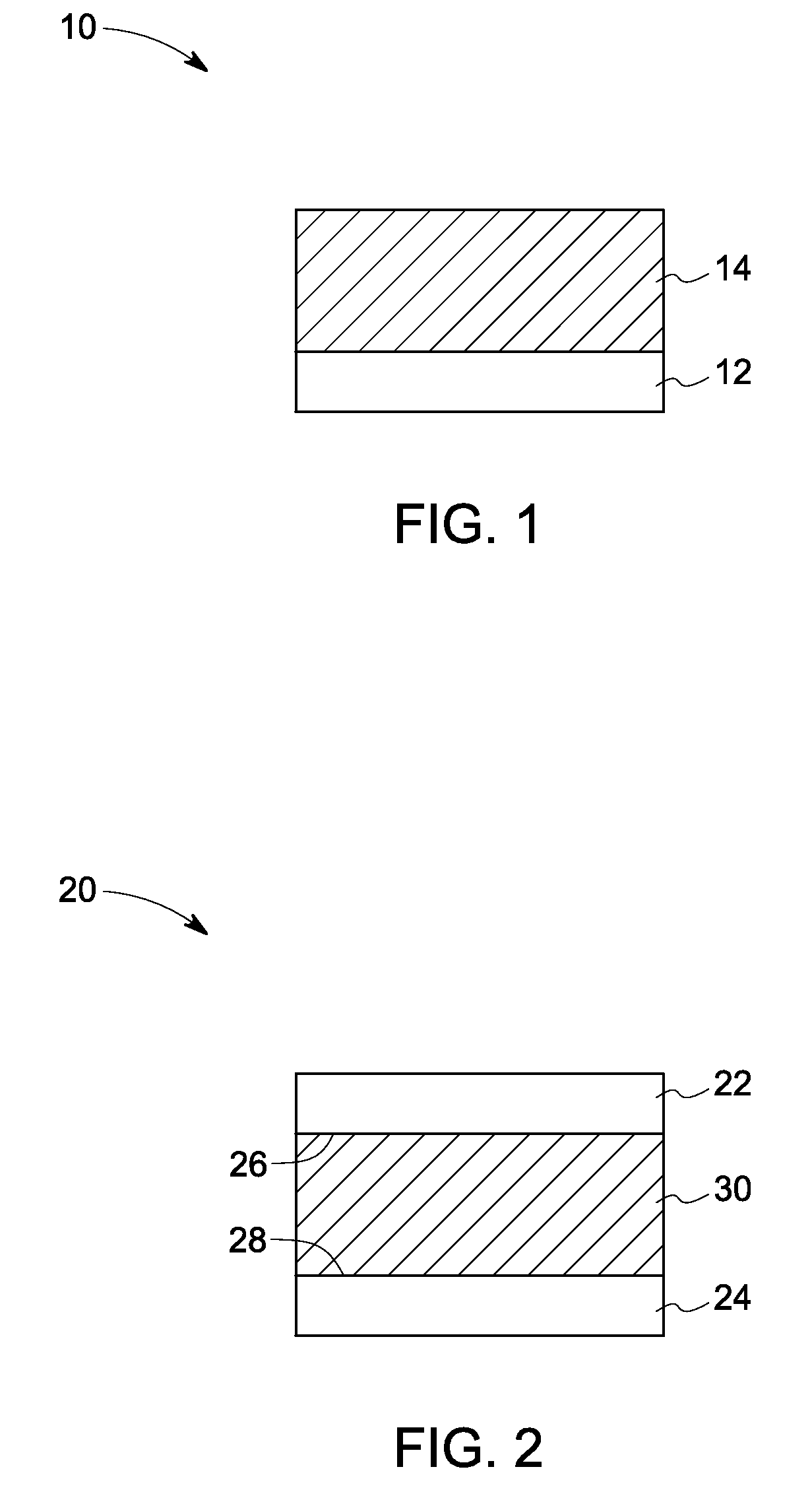

In one aspect of the present invention, an article is described, including a polymer layer; and a composite layer disposed on the polymer layer. The composite layer includes a thermoplastic polymer, which contains at least one inorganic component having selected dimensions; wherein the largest dimension of the inorganic component is less than about 1 micrometer. The composite layer has a dielectric constant, which is at least about 30 percent greater than the dielectric constant of the polymer layer. The article has a breakdown strength of at least about 150 kV / mm. Related devices are also described.

Owner:GENERAL ELECTRIC CO

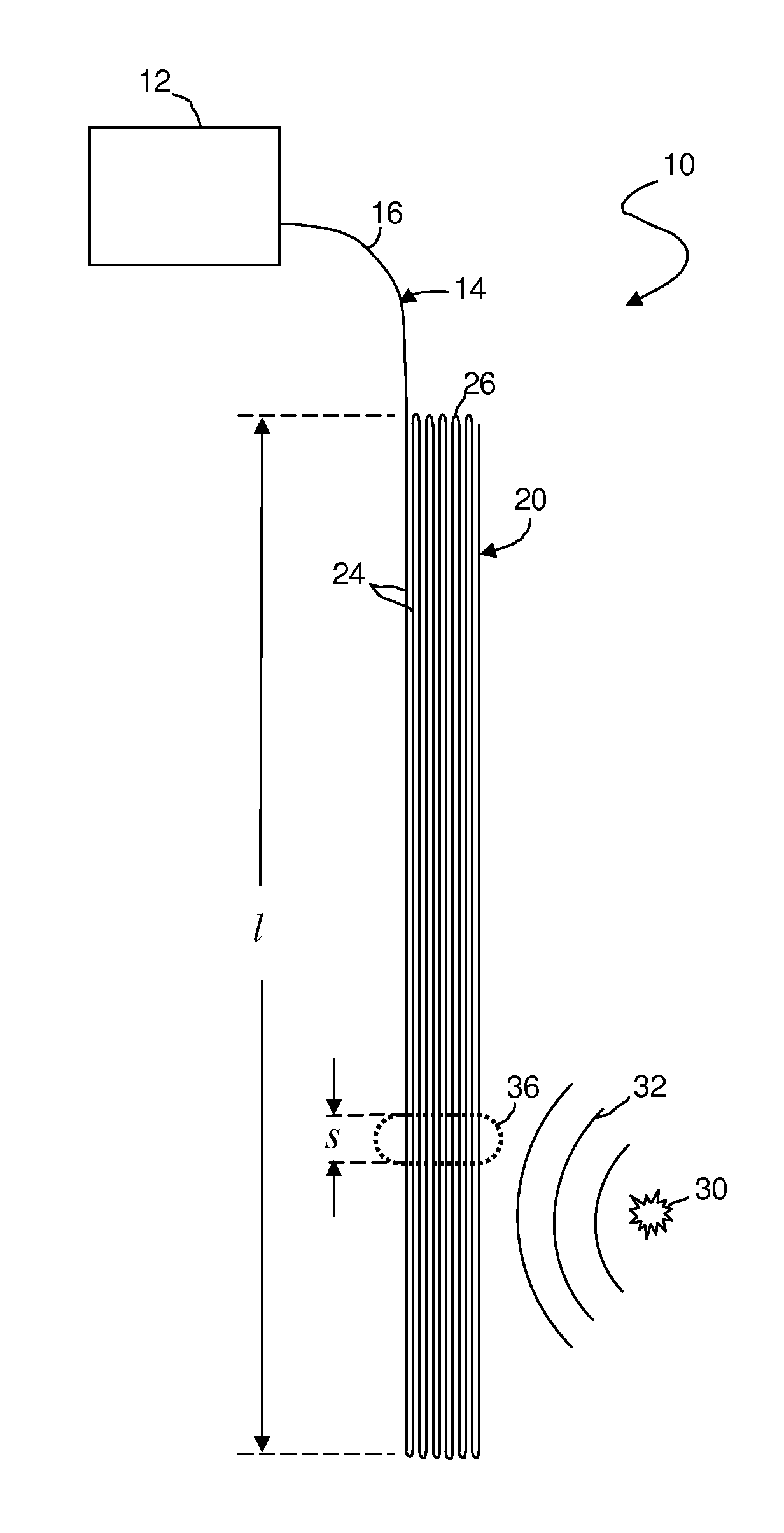

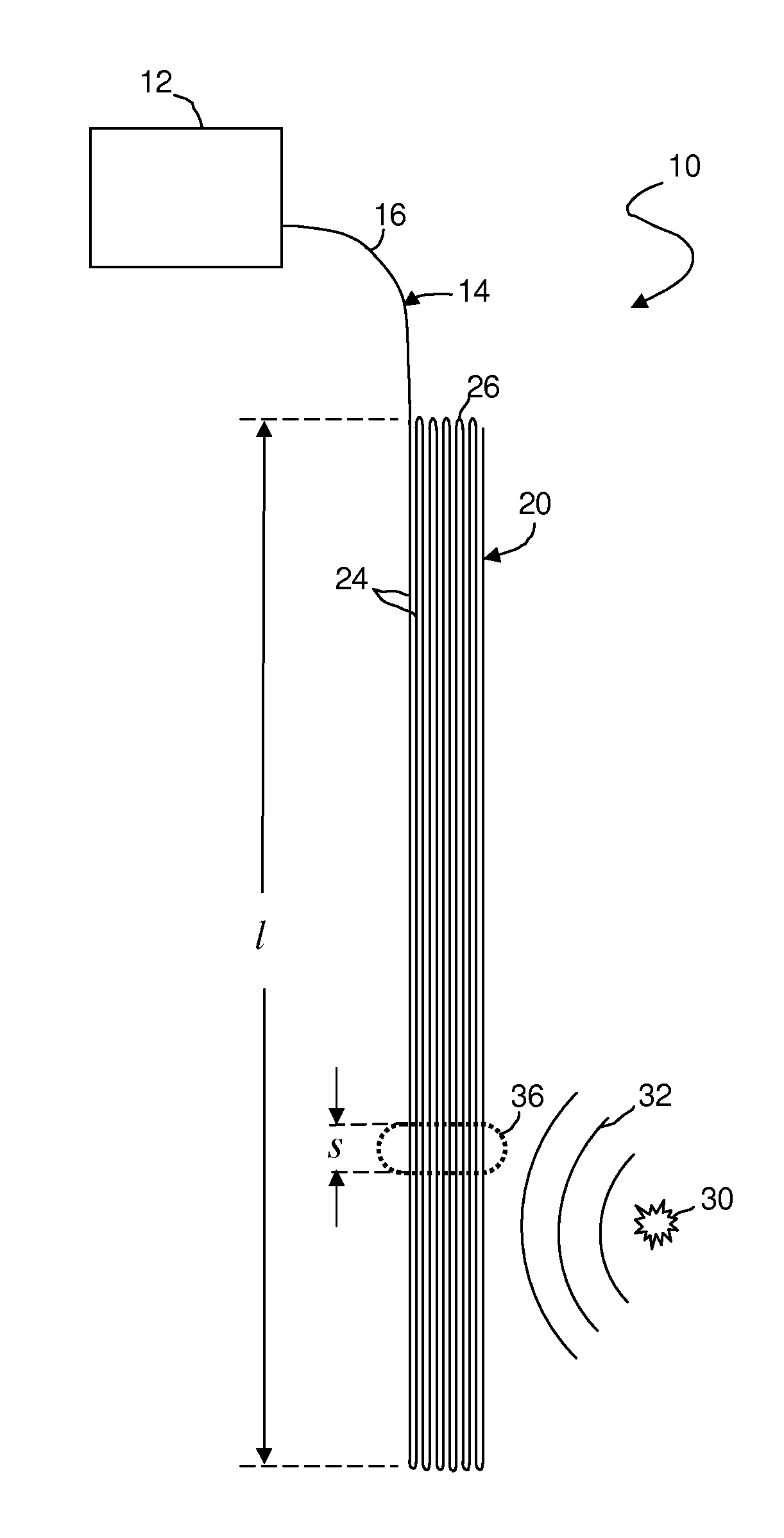

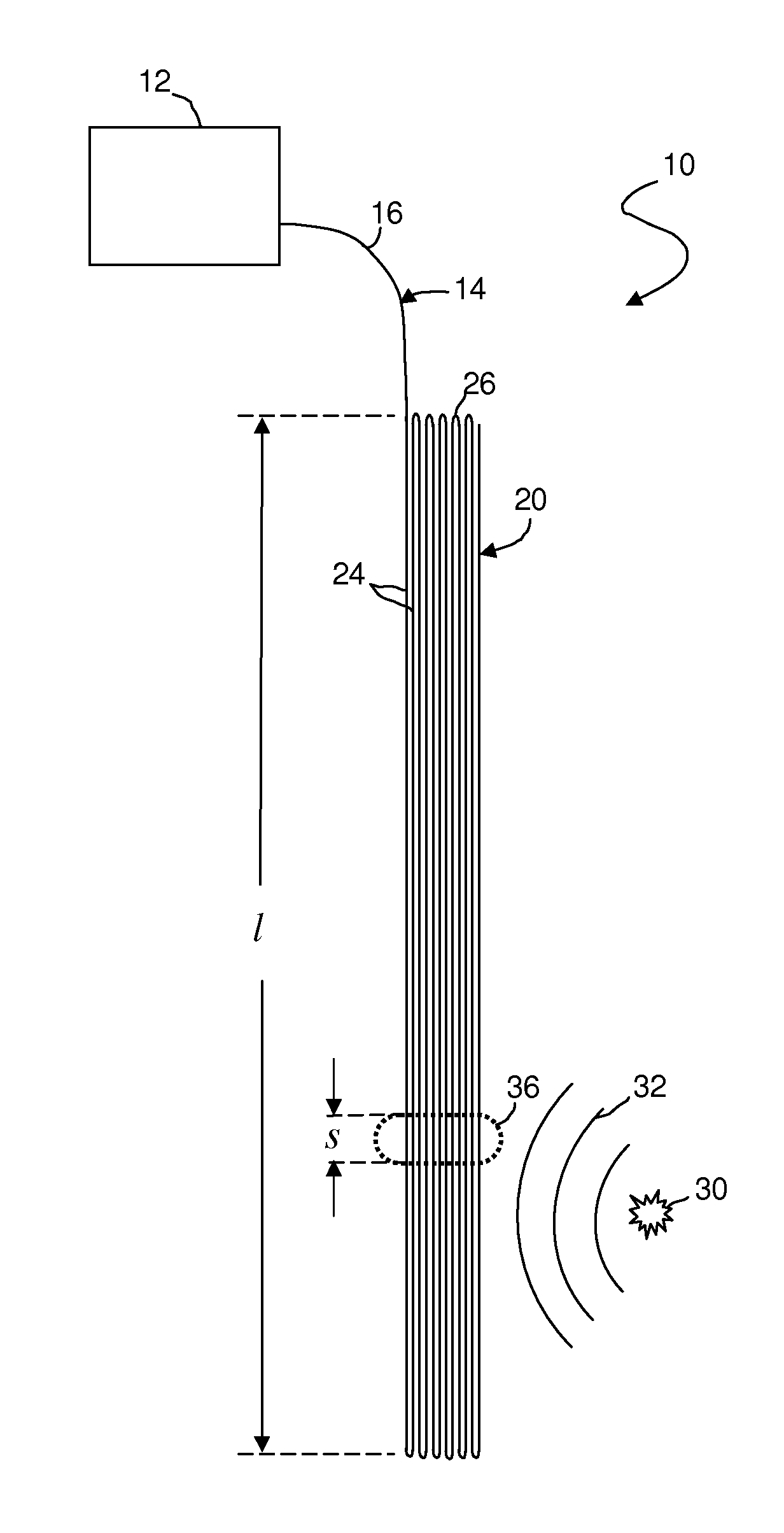

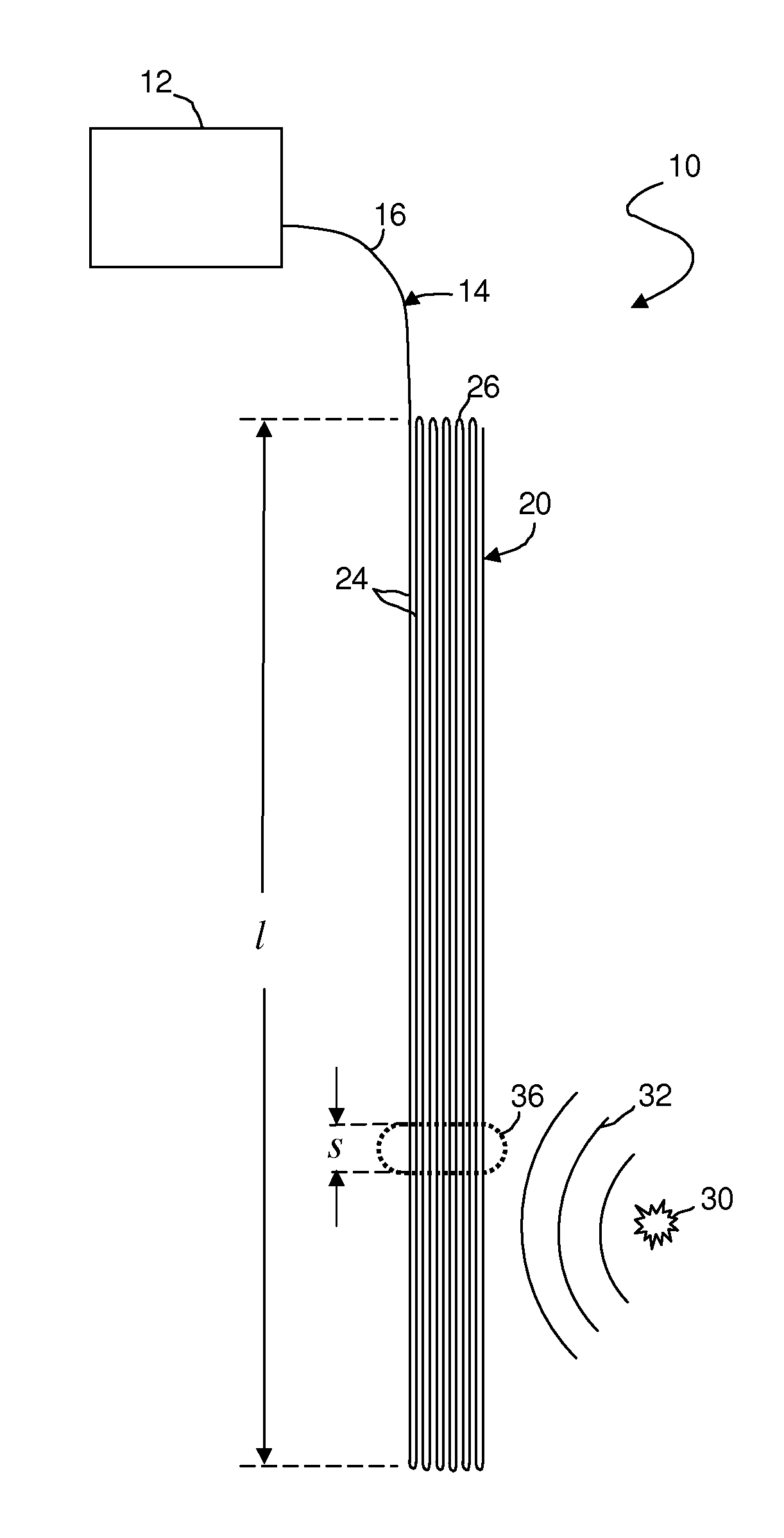

Signal stacking in fiber optic distributed acoustic sensing

ActiveUS9140815B2Improve signal-to-noise ratioLow costSeismic signal receiversSeismic signal processingFiberDistributed acoustic sensing

A method for obtaining information about a subsurface formation from acoustic signals that contain information about the subsurface formation, comprises a) transmitting an optical signal into a fiber optic cable (14) that includes a sensing apparatus (20) comprising a plurality of substantially parallel fiber lengths (24), b) collecting from the sensing apparatus a plurality of received optical signals, each received signal comprising a portion of the transmitted signal that has been reflected from a different segment of a cable length, wherein the different segments are each in different cable lengths and correspond to a single selected location along the sensing cable, and c) processing the collected signals so as to obtain information about an acoustic signal received at the different segments. The cable may be ribbon cable and the lateral distance between the different segments may be less than 10 meters.

Owner:SHELL USA INC

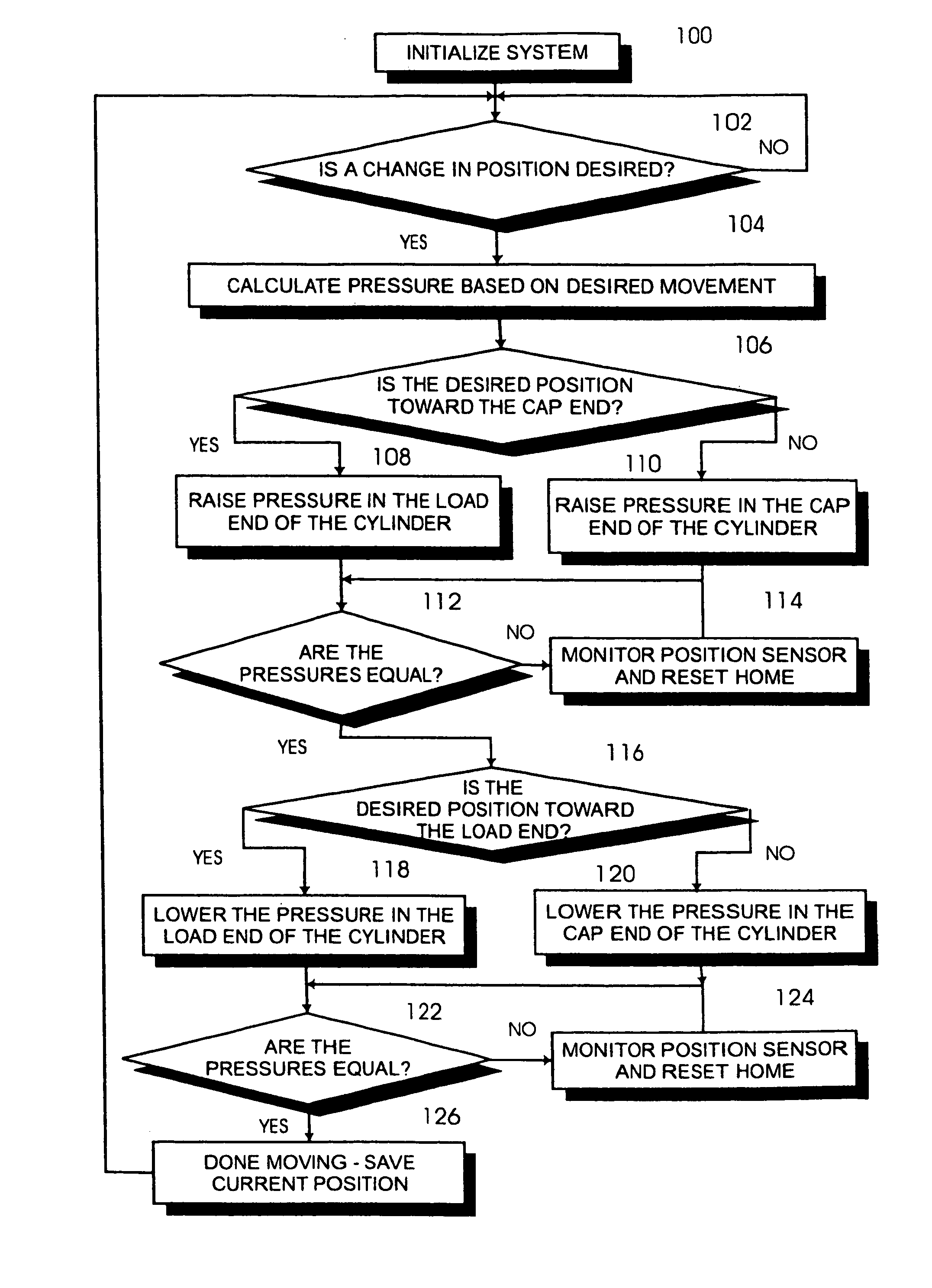

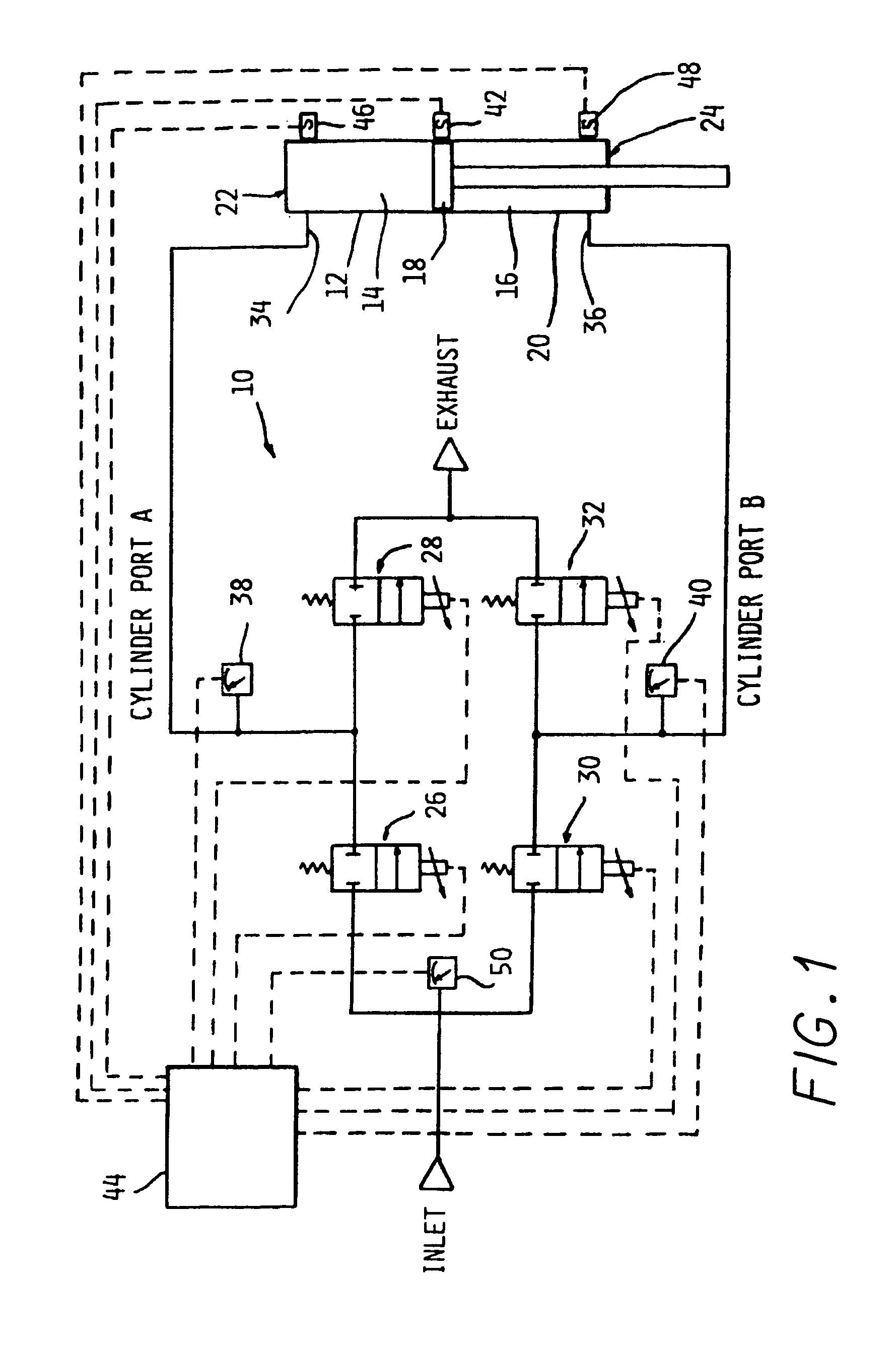

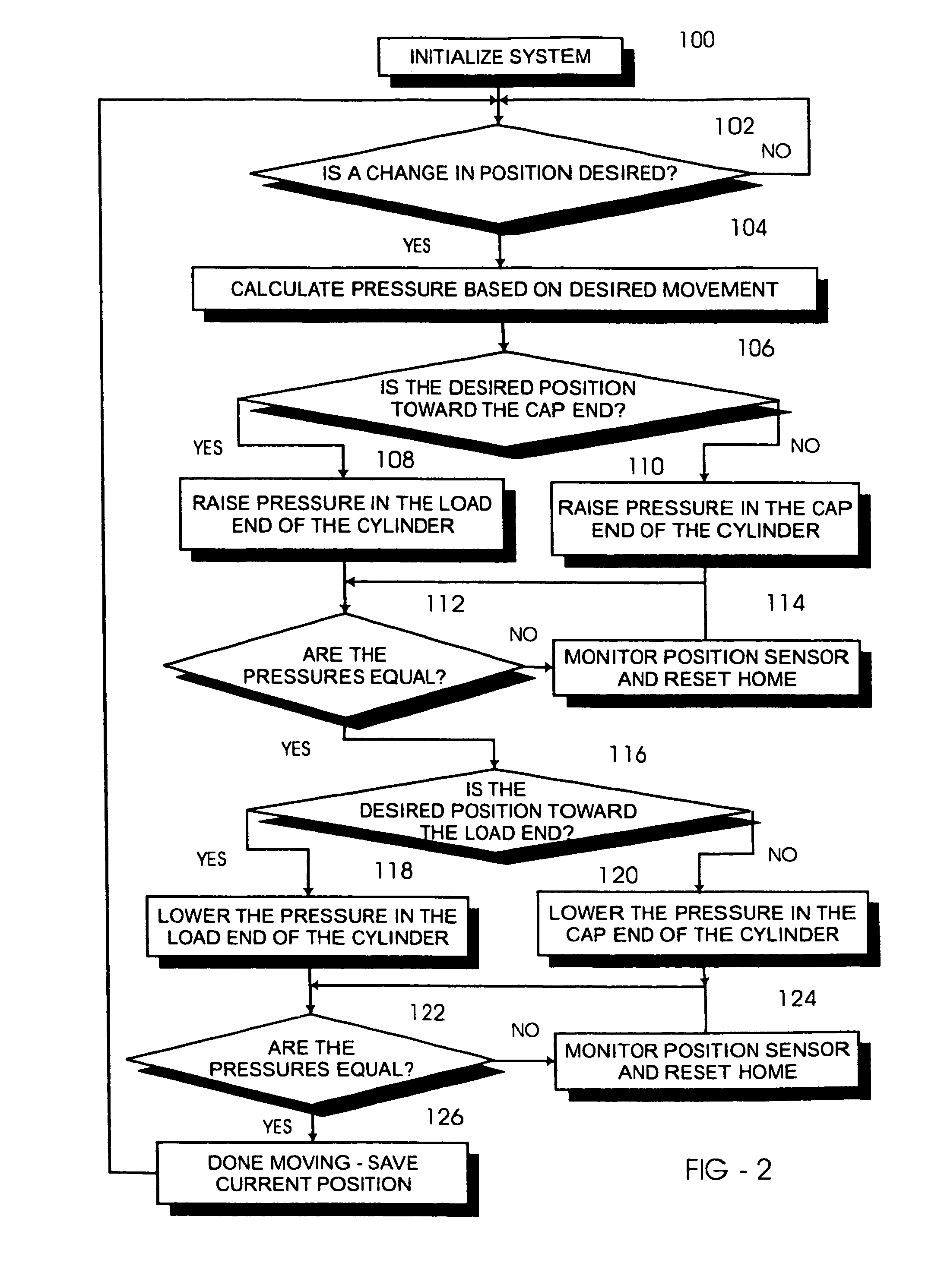

Multi-valve fluid operated cylinder positioning system

InactiveUS7353743B2Inexpensive and accurate fluid operated cylinder positioningLow costPneumatic programme controlServomotor componentsMulti-valveEngineering

A position control system is used for controlling a fluid operated cylinder having at least one fluid chamber defined by a piston located within a housing for movement between first and second end limits of travel. The system includes at least two electrically actuated proportional flow control valves connected to each port of the cylinder for selectively and proportionally controlling fluid flow into and out of the at least one chamber. At least one pressure sensor is provided for measuring fluid pressure with respect to each chamber. At least one discreet position sensor is located adjacent a midpoint of the cylinder for sensing a discreet centered position of the piston. A controller includes a program and is operably connected for controlling actuation of the at least two valves in response to pressure measured by the at least one pressure sensor and location measured by the at least one position sensor.

Owner:PARKER INTANGIBLES LLC

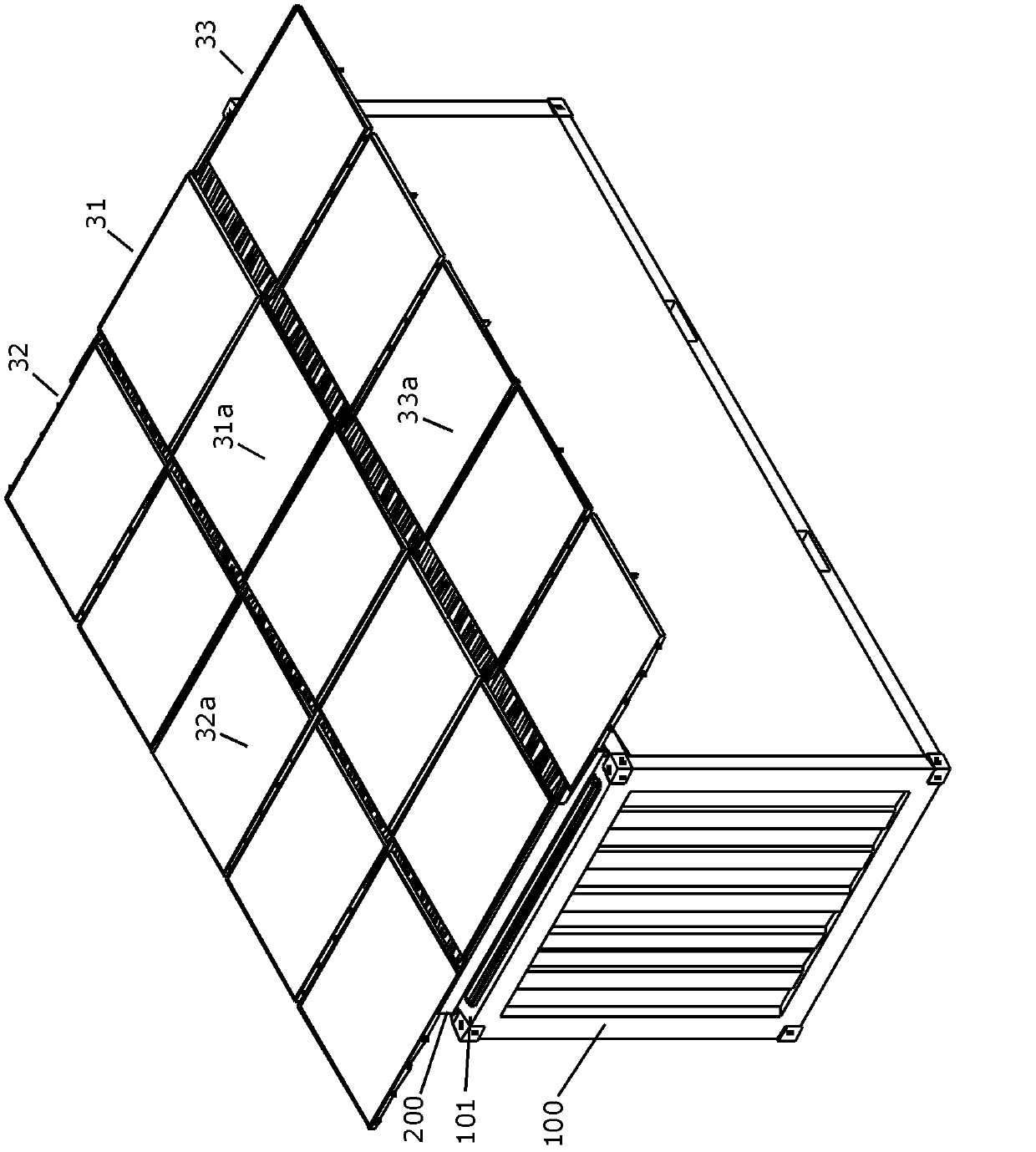

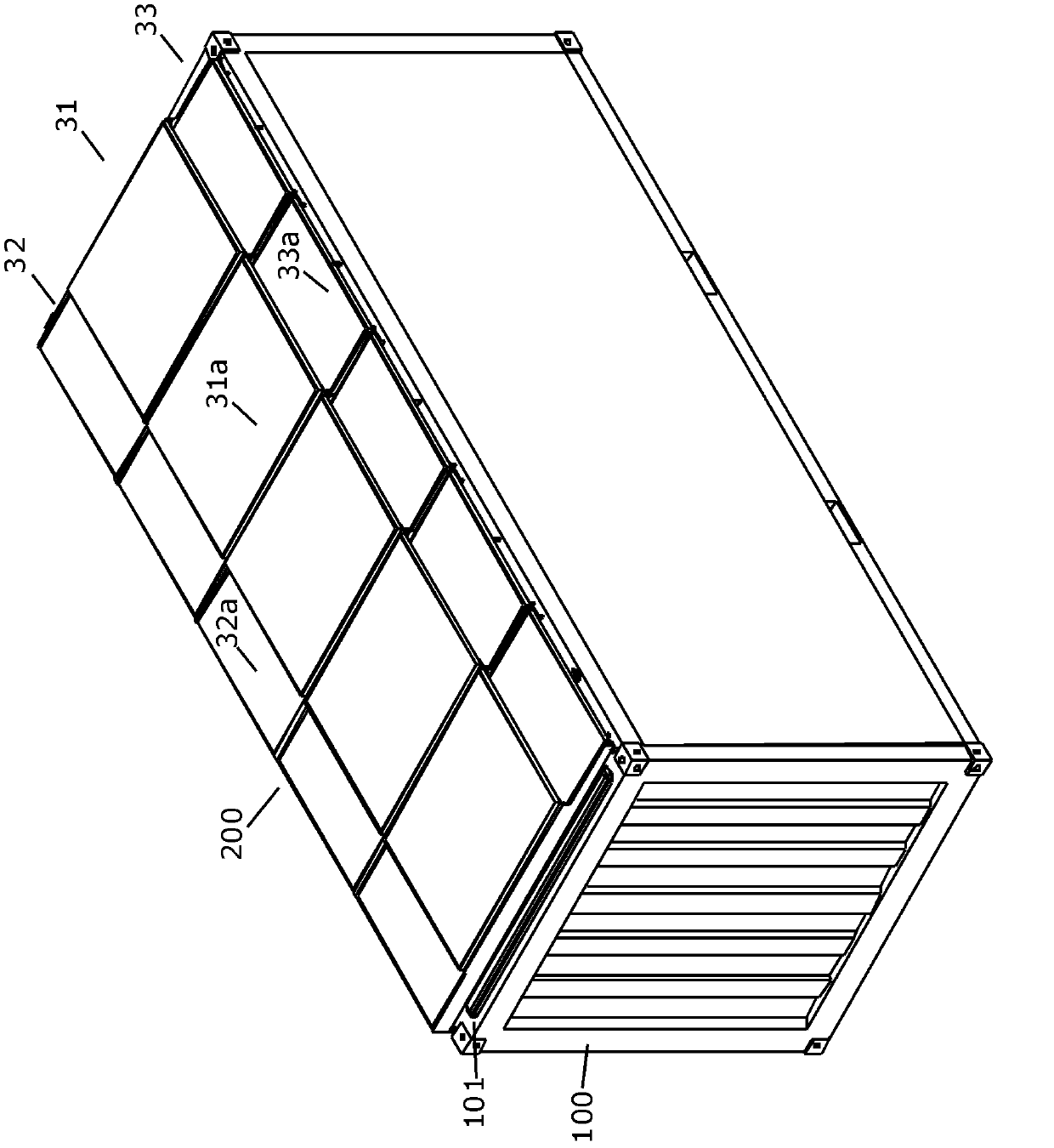

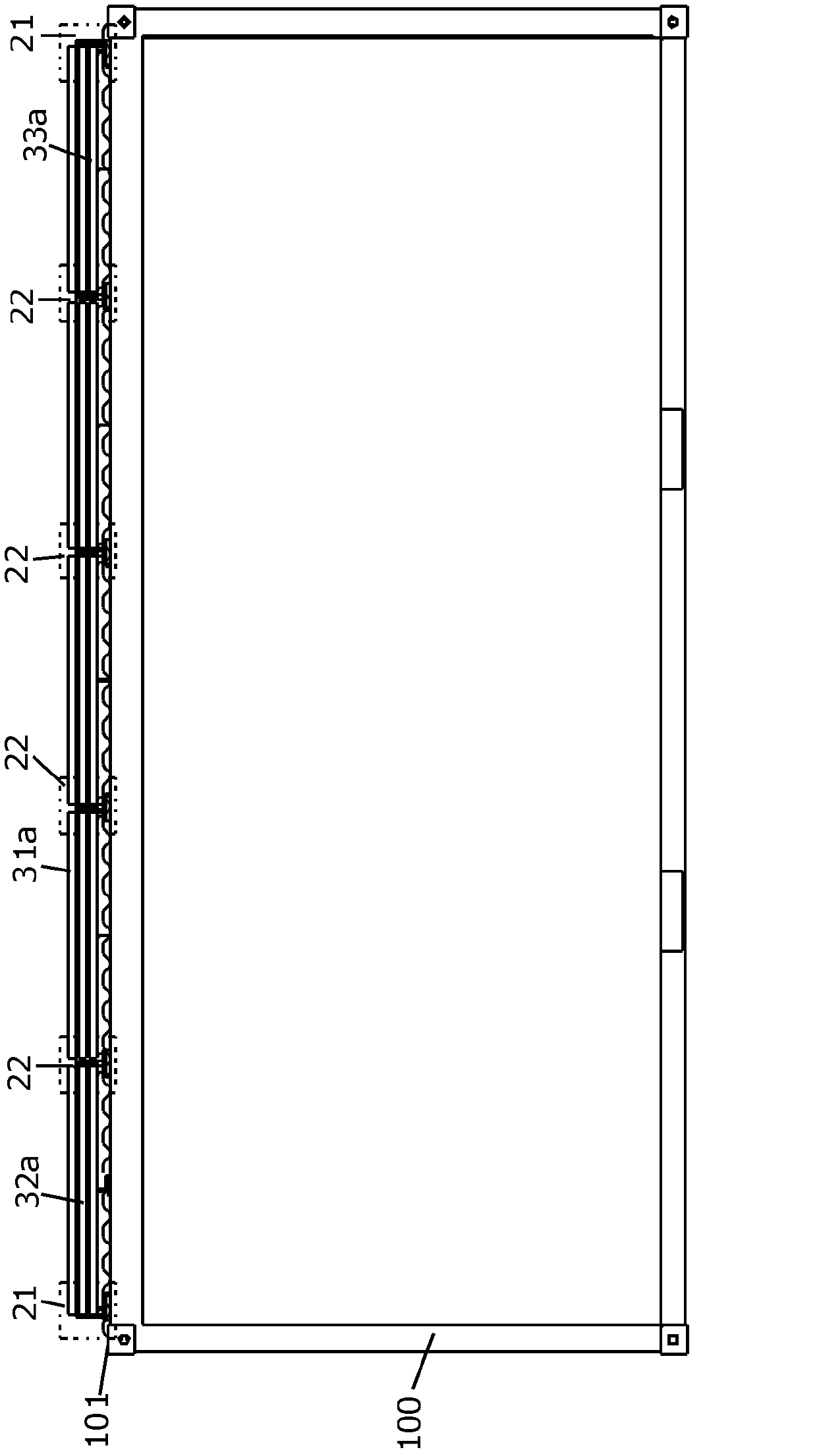

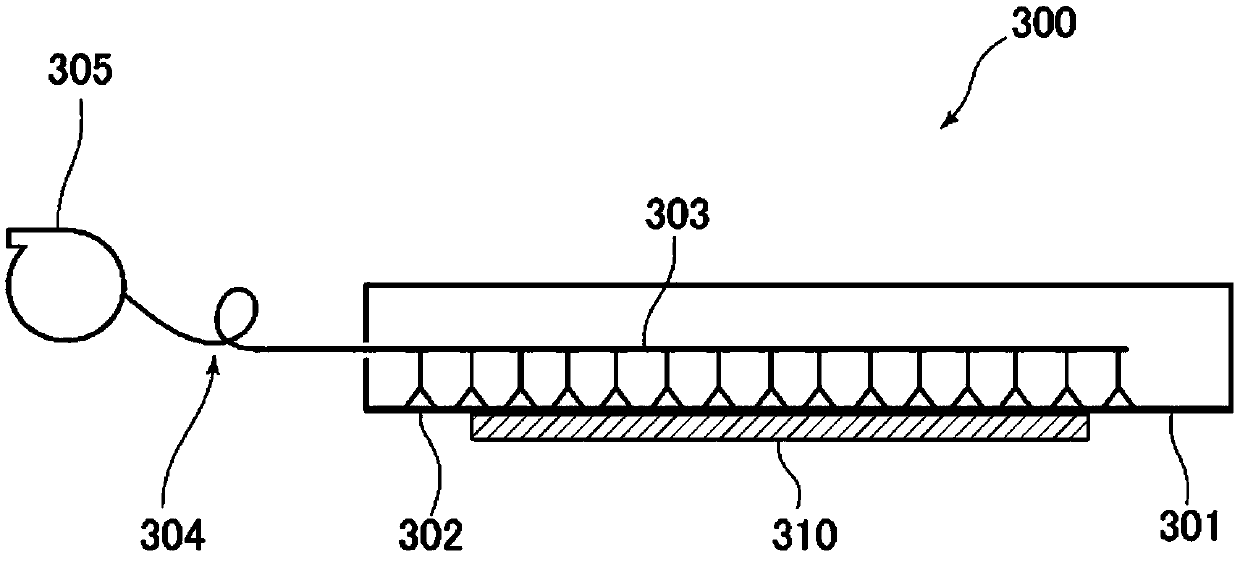

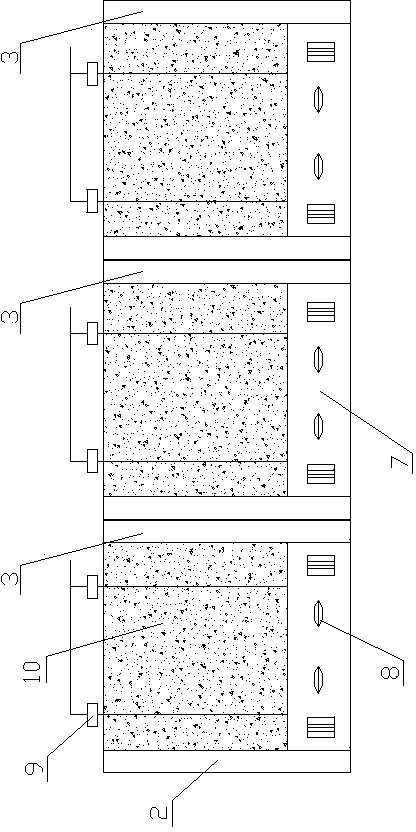

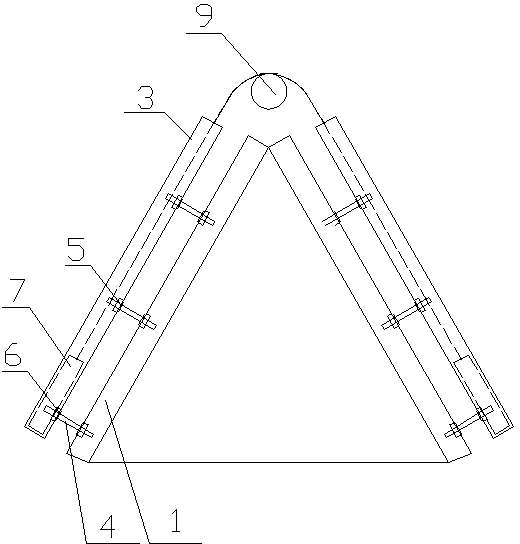

Stretchy type solar photovoltaic assembly and photovoltaic system

InactiveCN103378191AIncrease power generationOptimized use of support surfacesPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention discloses a stretchy type solar photovoltaic assembly and a photovoltaic system. The stretchy type solar photovoltaic assembly comprises a fixed support and a plurality of layers of solar cell panels, wherein the fixed support is fixed on a supporting face. The fixed support comprises track support bodies. Each track support body comprises a plurality of layers of tracks. The solar cell panels are installed on the tracks. At least one solar cell panel can be stretched out and drawn back in the stretching direction of the track where the solar cell panel is located. The photovoltaic system comprises a carrier and the stretchy type solar photovoltaic assembly which is installed on the top face of the carrier. According to the stretchy type solar photovoltaic assembly, when the solar cell panels are drawn back, the size of the stretchy type solar photovoltaic assembly is effectively controlled, and convenience is brought to carry; when the solar cell panels are stretched out, large-area solar cell panel installation is achieved in a limited supporting face area, the insolation area of the stretchy type solar photovoltaic assembly is effectively improved, and therefore the generated energy of the stretchy type solar photovoltaic assembly is improved.

Owner:DU PONT APOLLO

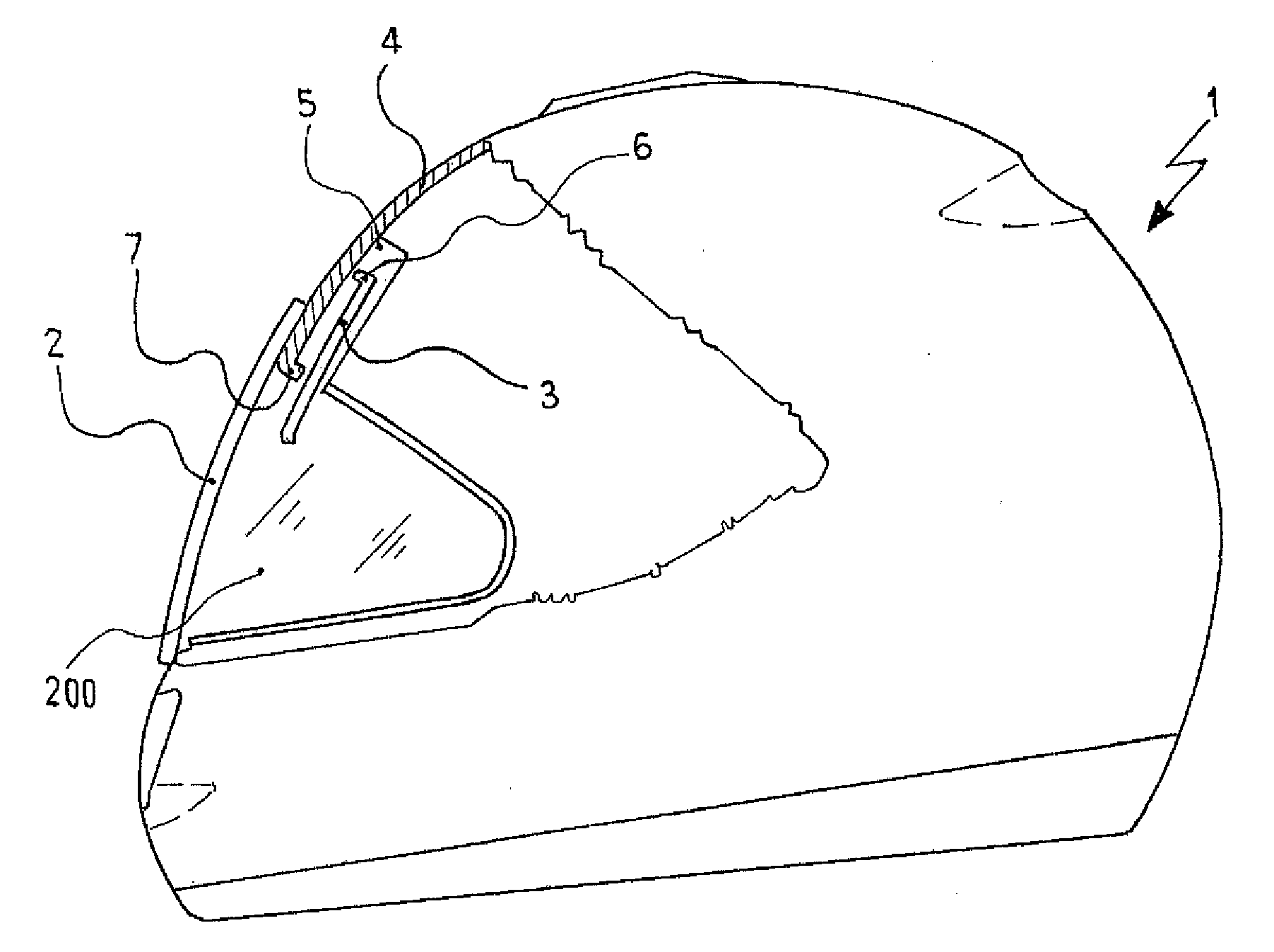

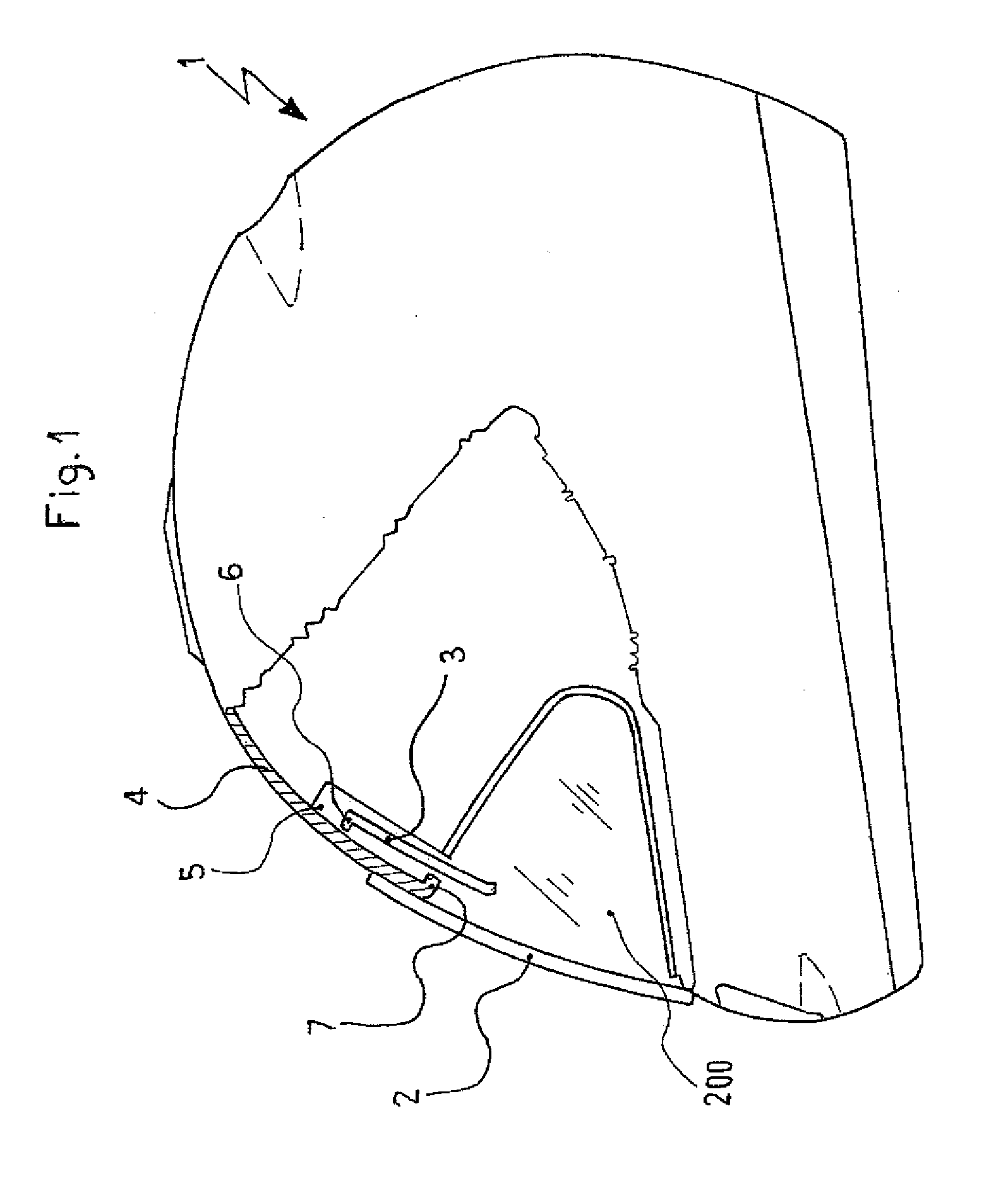

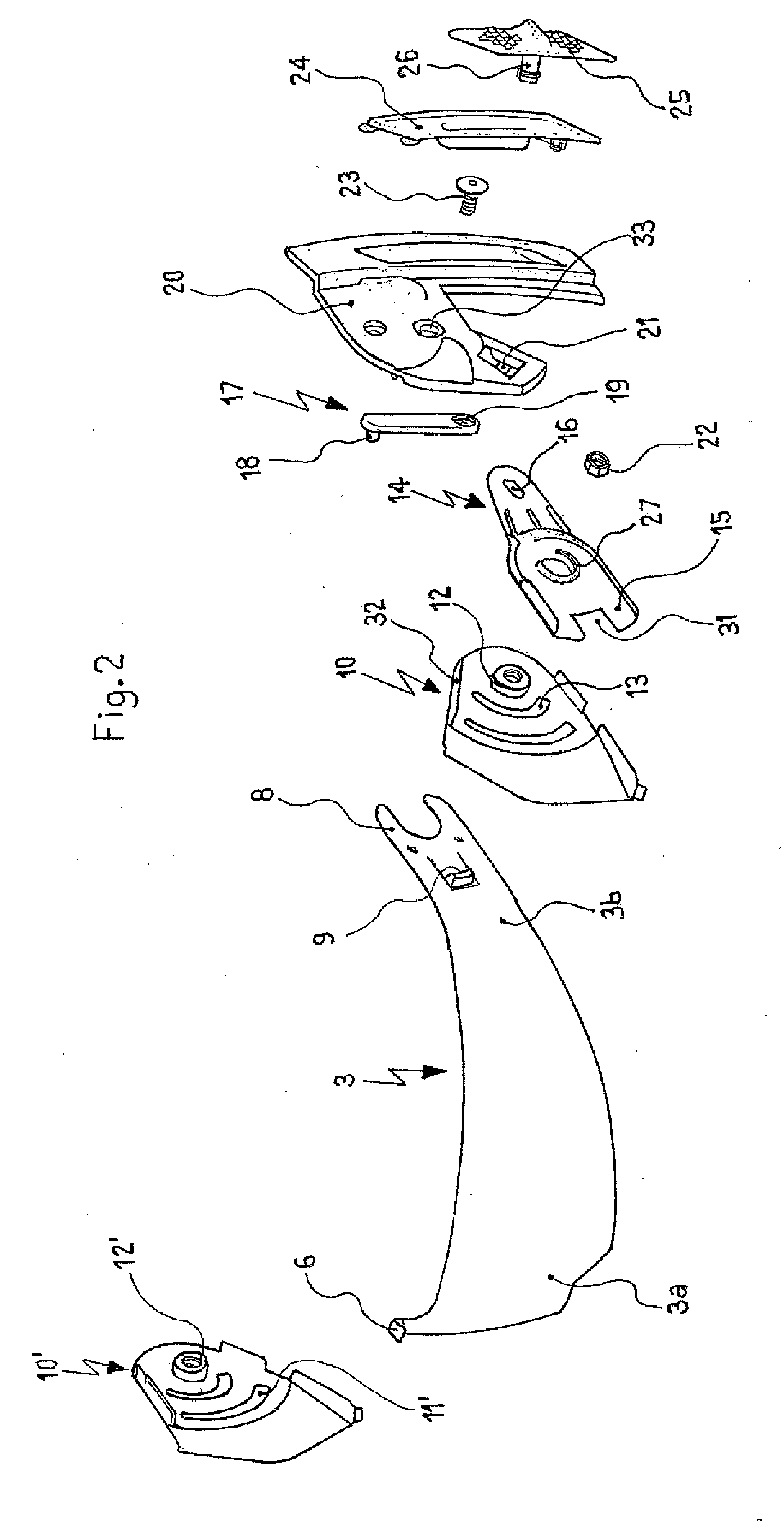

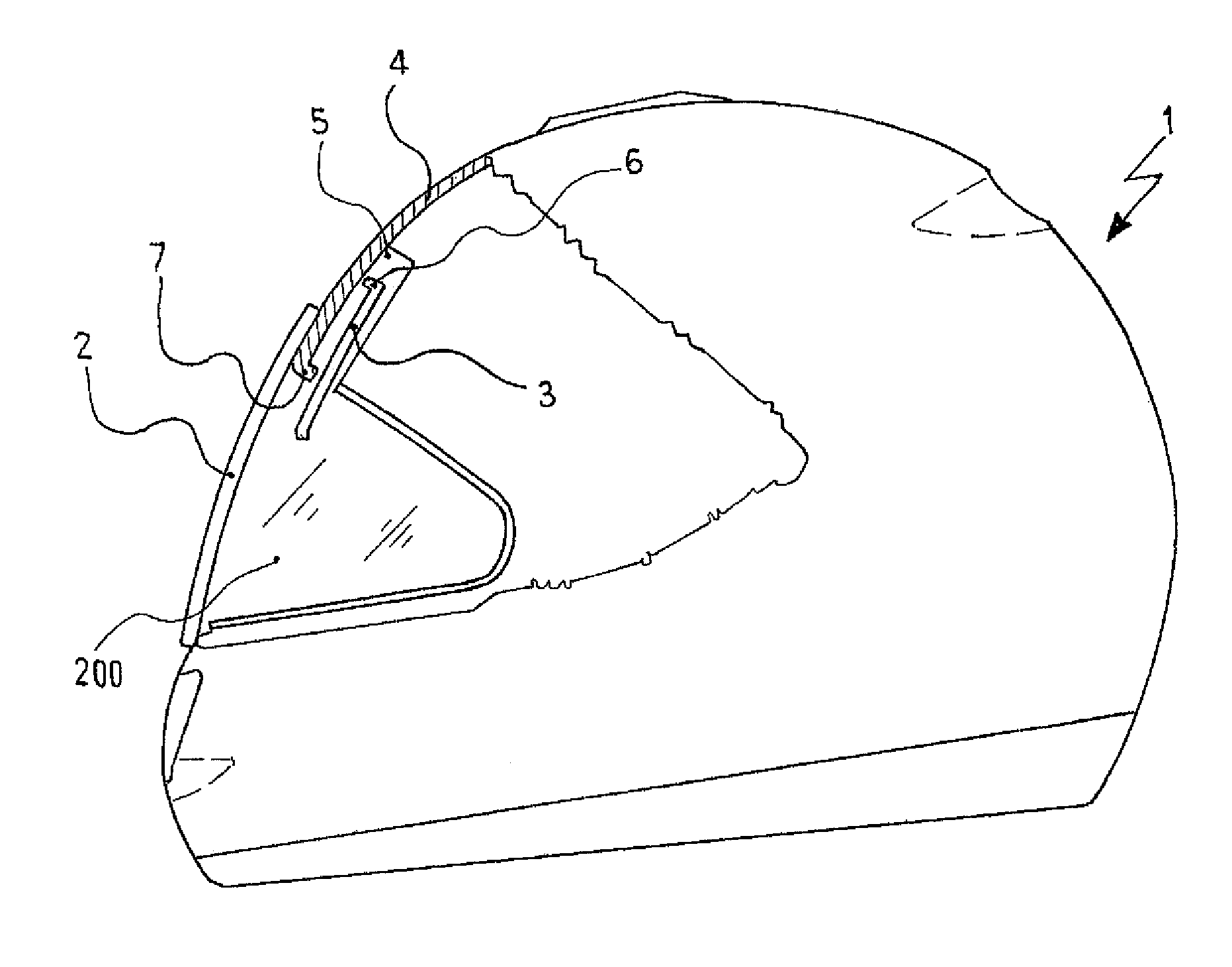

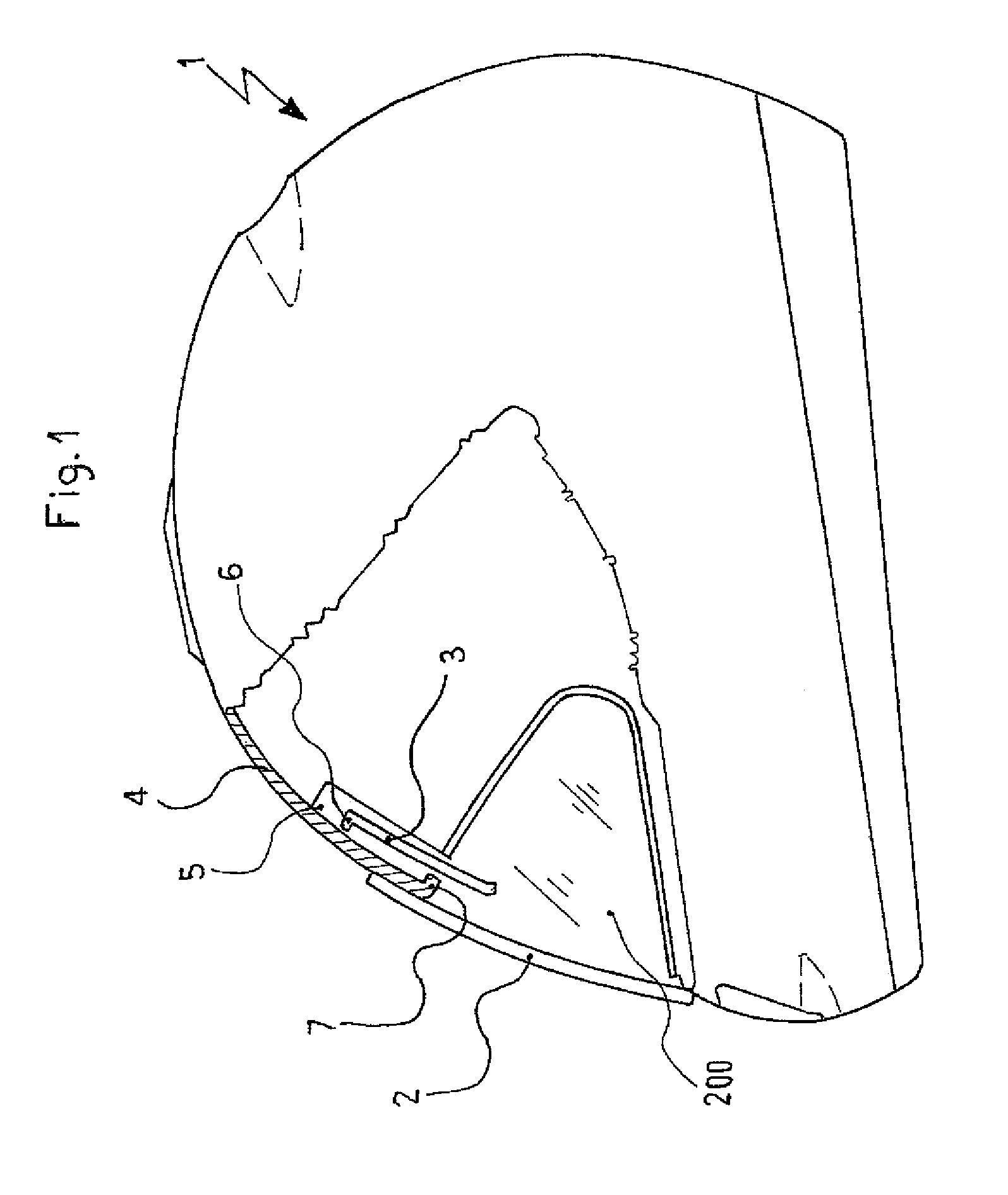

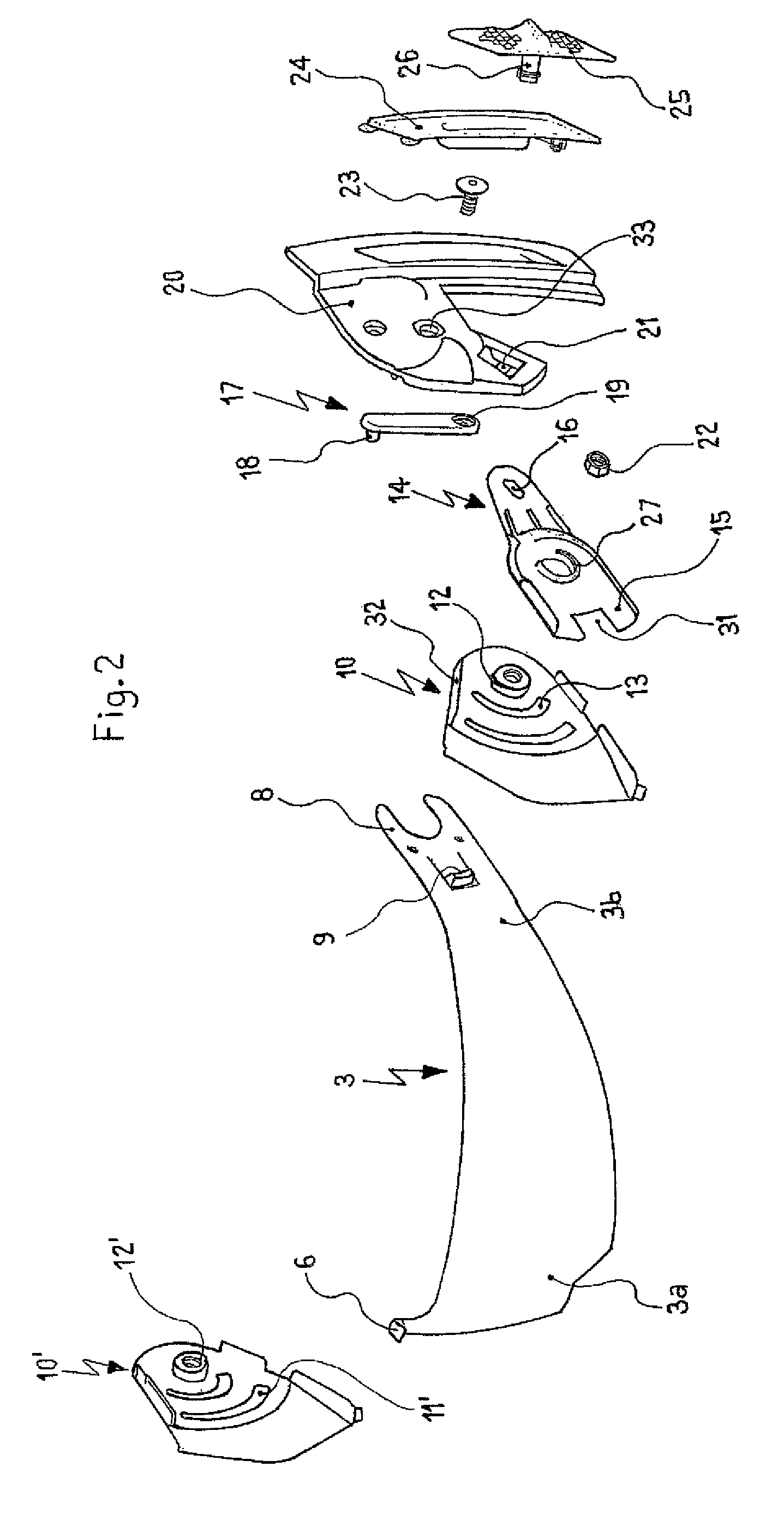

Safety helmet with supplemental inner visor

ActiveUS20090070908A1Facilitate correct insertionSimple and precise mannerEye treatmentHatsMechanical engineering

Protective helmet of the type comprising a first outer visor to intercept the viewing aperture of the helmet mounted rotatably on said helmet, a second visor mounted, inside said first outer visor, rotatably on the cap of the helmet, and a device for actuation and mounting of said second visor on said cap, said second visor including a shielding portion and two ends at the sides of said shielding portion and being at least partly elastically deformable. The inner visor comprises, at least at one side end thereof, a fork and, at or in proximity of one or other of the side ends thereof, at least one externally projecting tooth. Correspondingly, said device for actuation and mounting comprises at least one pin for engaging, directly or indirectly, with said fork and at least one circular guide inside which said projecting tooth of said second visor is removably coupled in a sliding manner, said at least one pin and said at least one circular guide being integral and / or integrated with said cap.

Owner:NOLANGRP

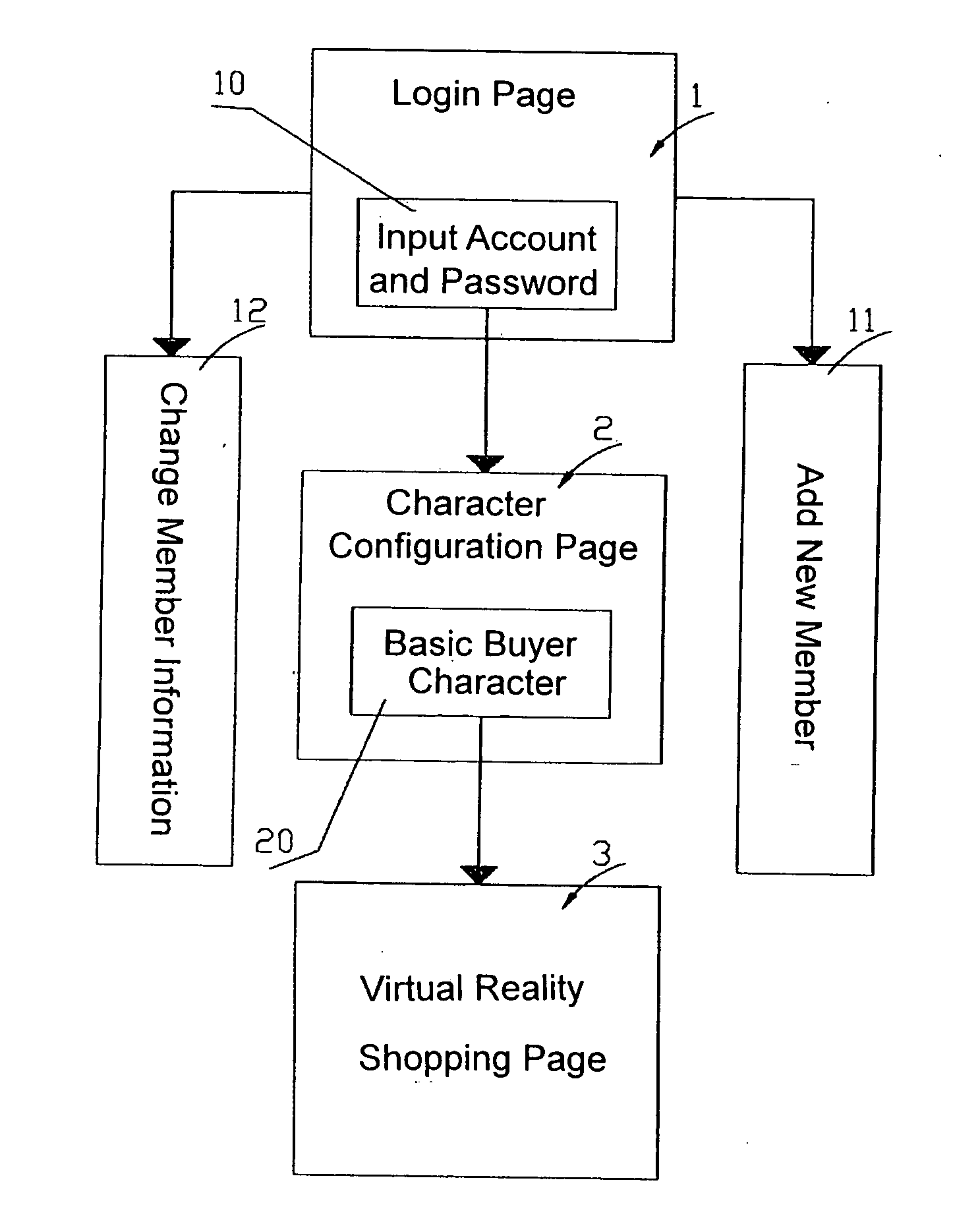

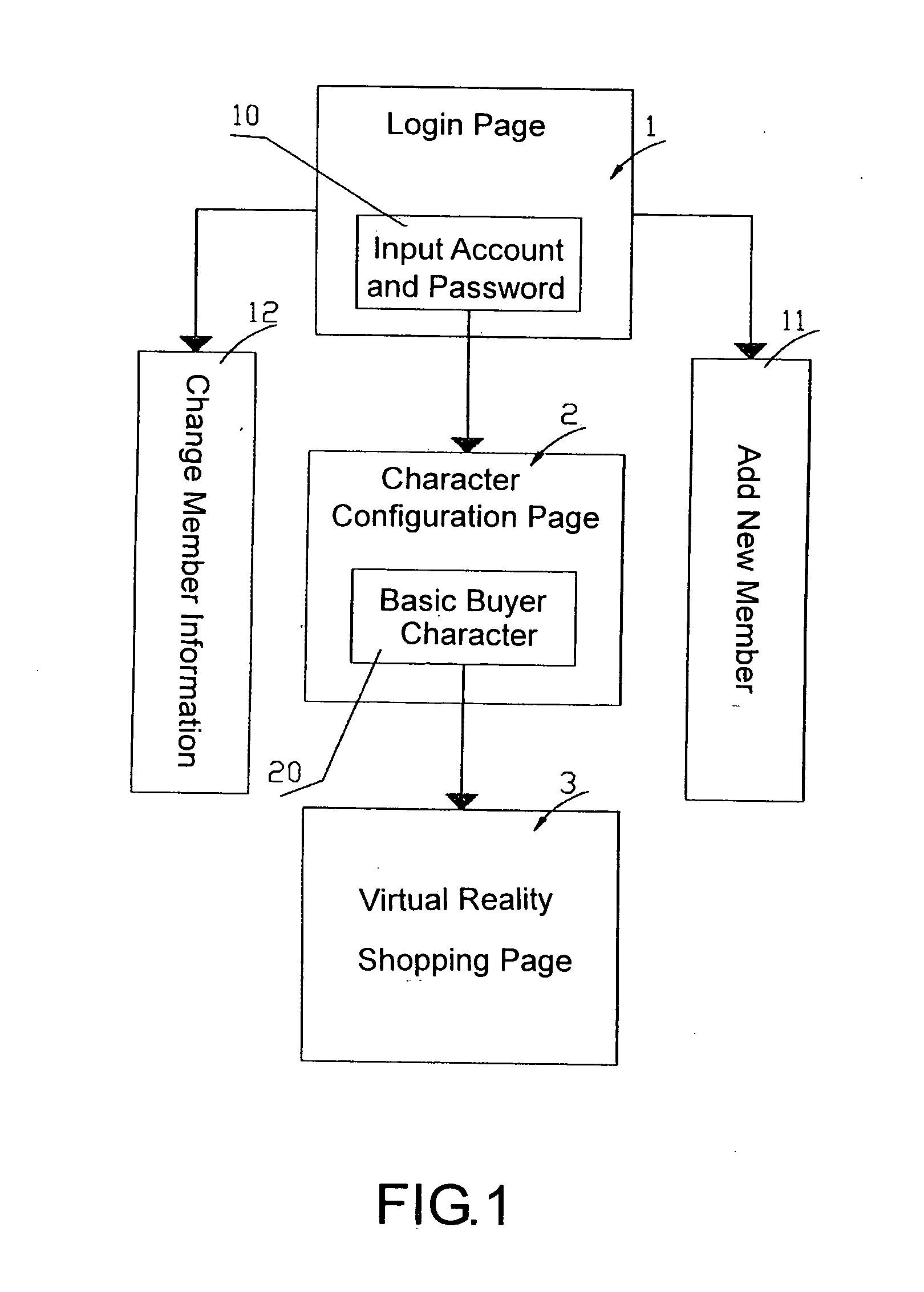

Virtual reality shopping system

A virtual reality shopping system is composed of a login page, a character configuration and selection page, and a virtual reality shopping page. The login page is configured as a system for acknowledging or adding members. After a basic buyer character is chosen, the character configuration and selection page can provide a buyer for performing a modeling to the virtual character. The virtual reality shopping page is designed as a virtual reality three-dimensional shopping website enabling individual buyers to mutually interact by assembling virtual map files, according to the design of virtual reality map files and the interaction with a plurality of virtual characters in the map files. In addition, the virtual characters can fit on virtual clothes or accessories in advance, when performing an Internet transaction on the virtual reality shopping website.

Owner:ROYAL PLANET

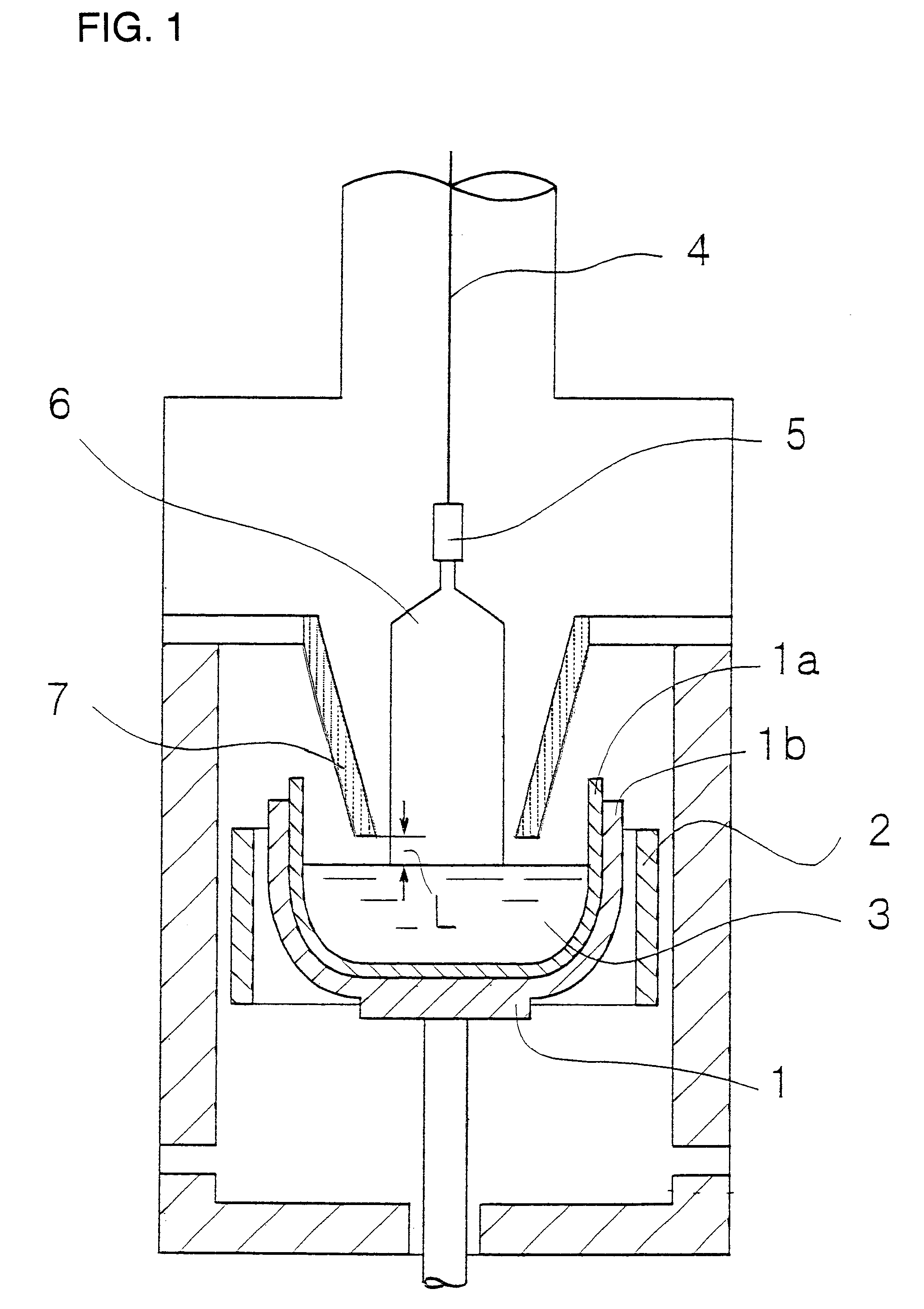

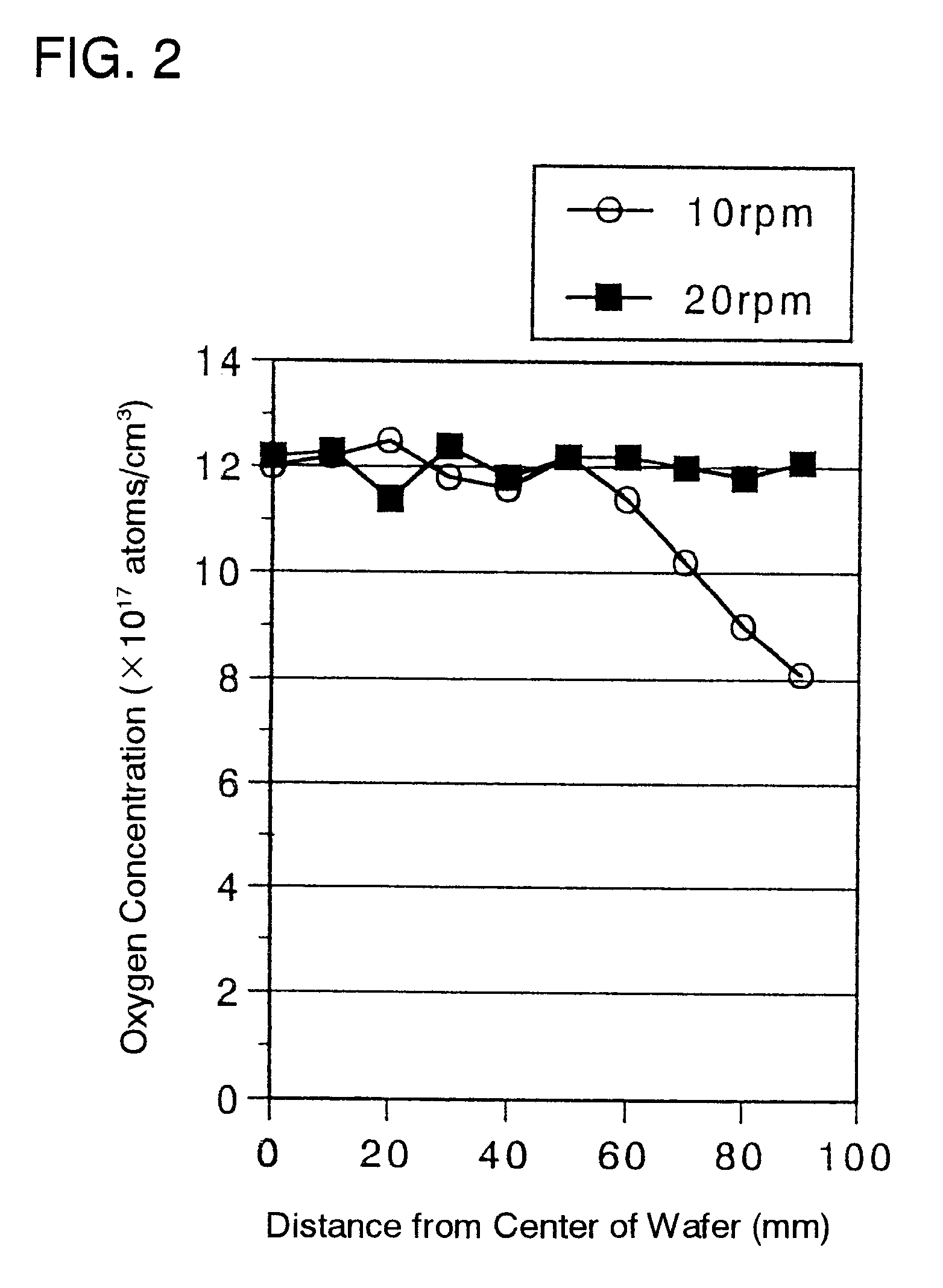

Method of manufacturing epitaxial wafer

InactiveUS6365461B1Simple cuttingIncrease widthPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenSingle crystal

Methods are designed to manufacture an epitaxial wafer wherein the formation of defects in an epitaxial layer is sufficiently suppressed even if the epitaxial wafer is prepared from a silicon single crystal which is grown while doped with nitrogen. Specifically, the methods are to grow an epitaxial layer on a wafer sliced from (1) a silicon single crystal wherein the oxygen concentration at an OSF ring region is 9x1017 atoms / cm3 or less, (2) a silicon single crystal wherein the inside diameter of an OSF ring region is located at a position which is 85% or more of the wafer diameter, and (3) a silicon single crystal doped with nitrogen at a concentration between 1x1012 atoms / cm3 or more and 1x1014 atoms / cm3 or less. Further, another method is to grow an epitaxial layer on (4) a wafer sliced from a silicon single crystal doped with nitrogen at a concentration between 1x1012 atoms / cm3 or more and less than 1x1014 atoms / cm3, the epitaxial layer being grown after the sliced wafer has been heat-treated at a temperature between 1200° C. and 1300° C. for 1 minute or more. According to the above methods, the density of defects in an epitaxial layer can be reduced to 0.1 piece / cm2 or less.

Owner:SUMITOMO MITSUBISHI SILICON CORP

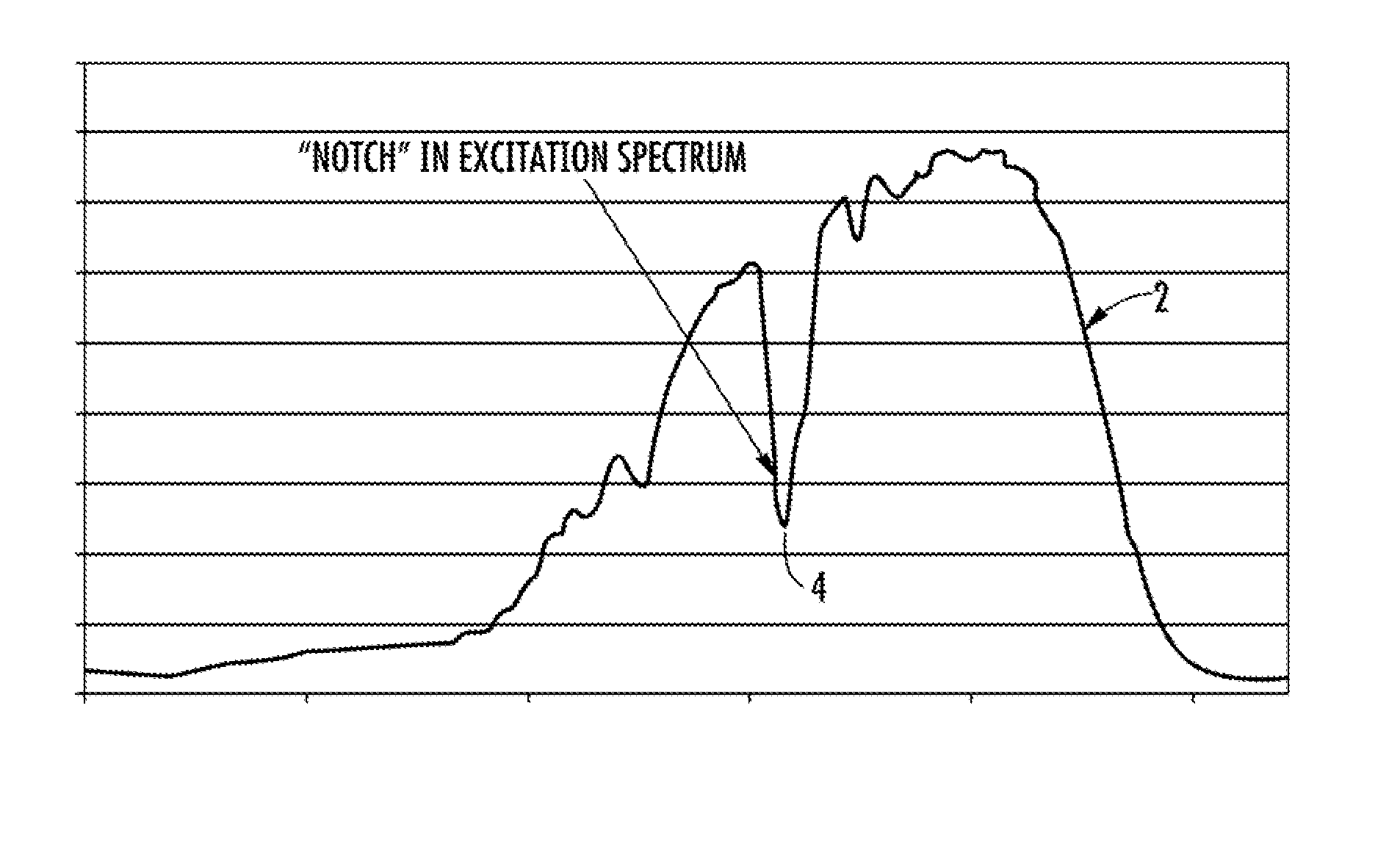

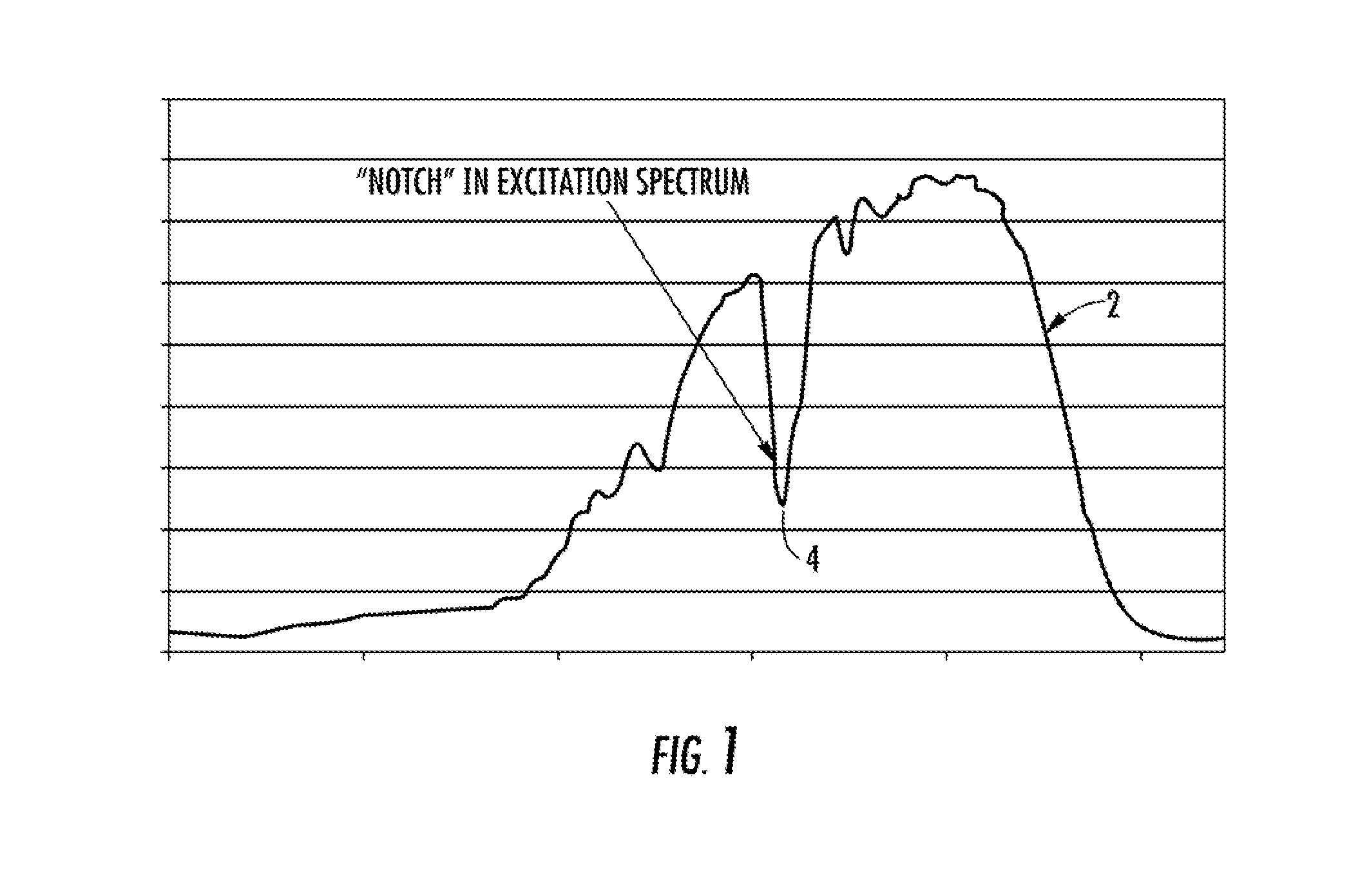

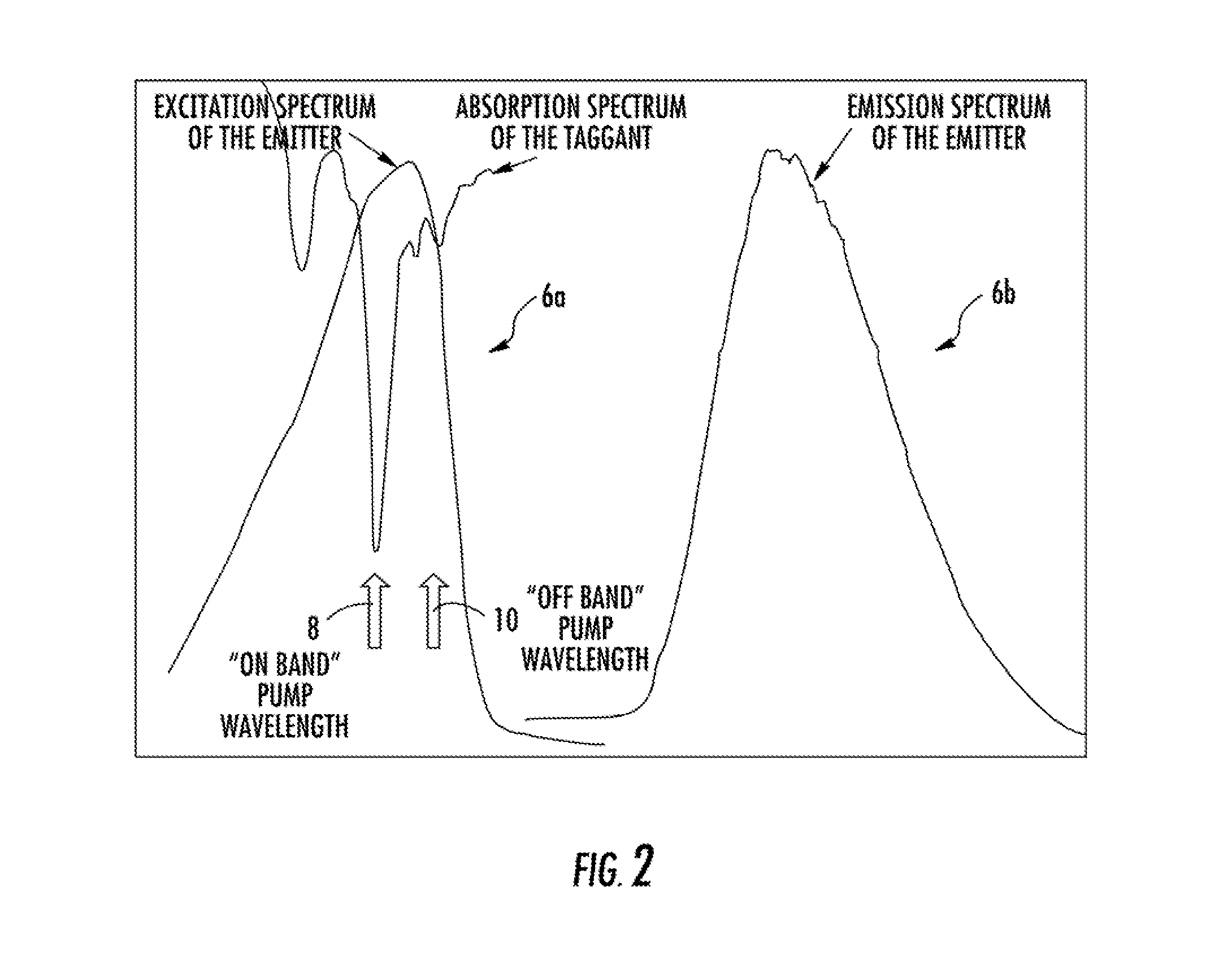

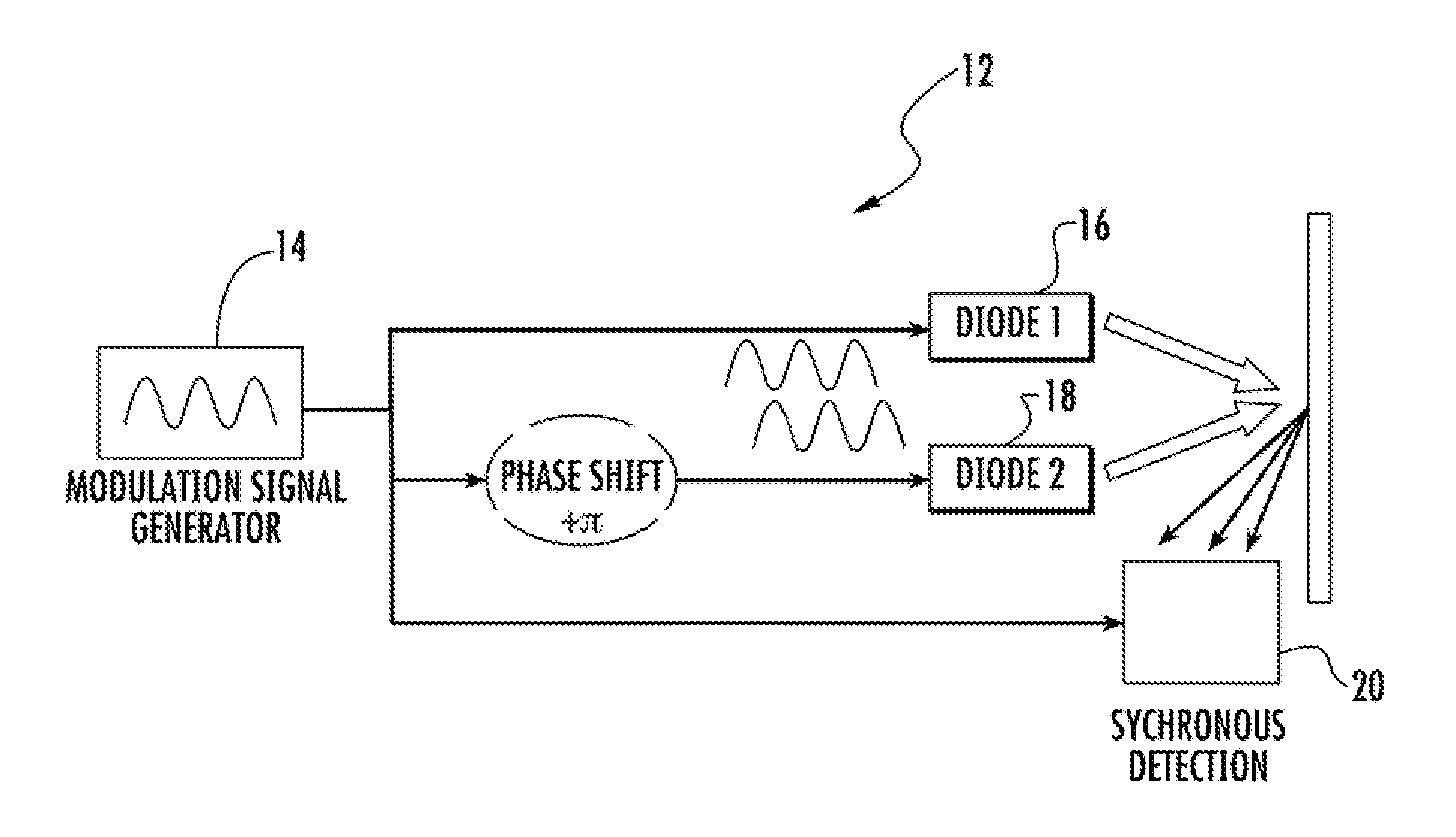

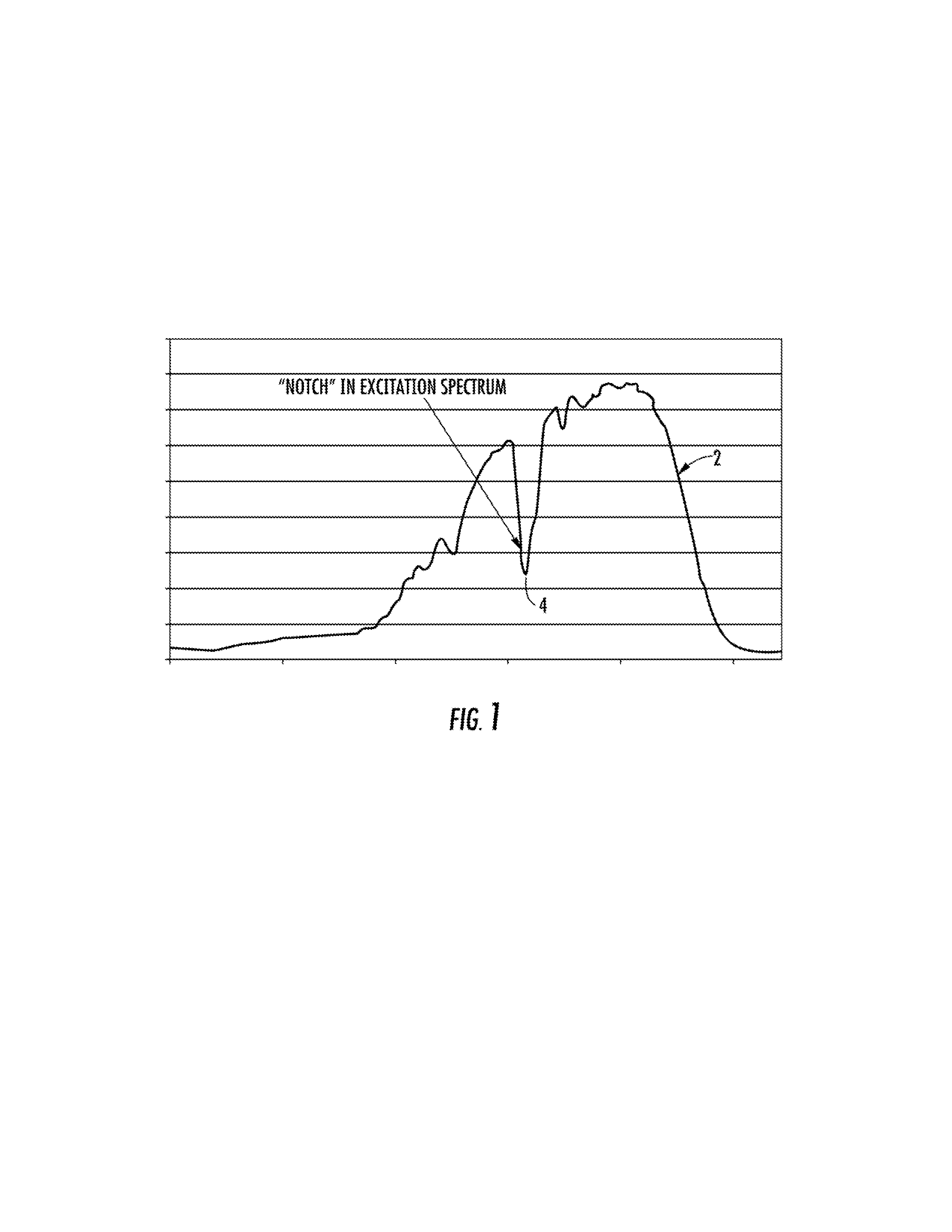

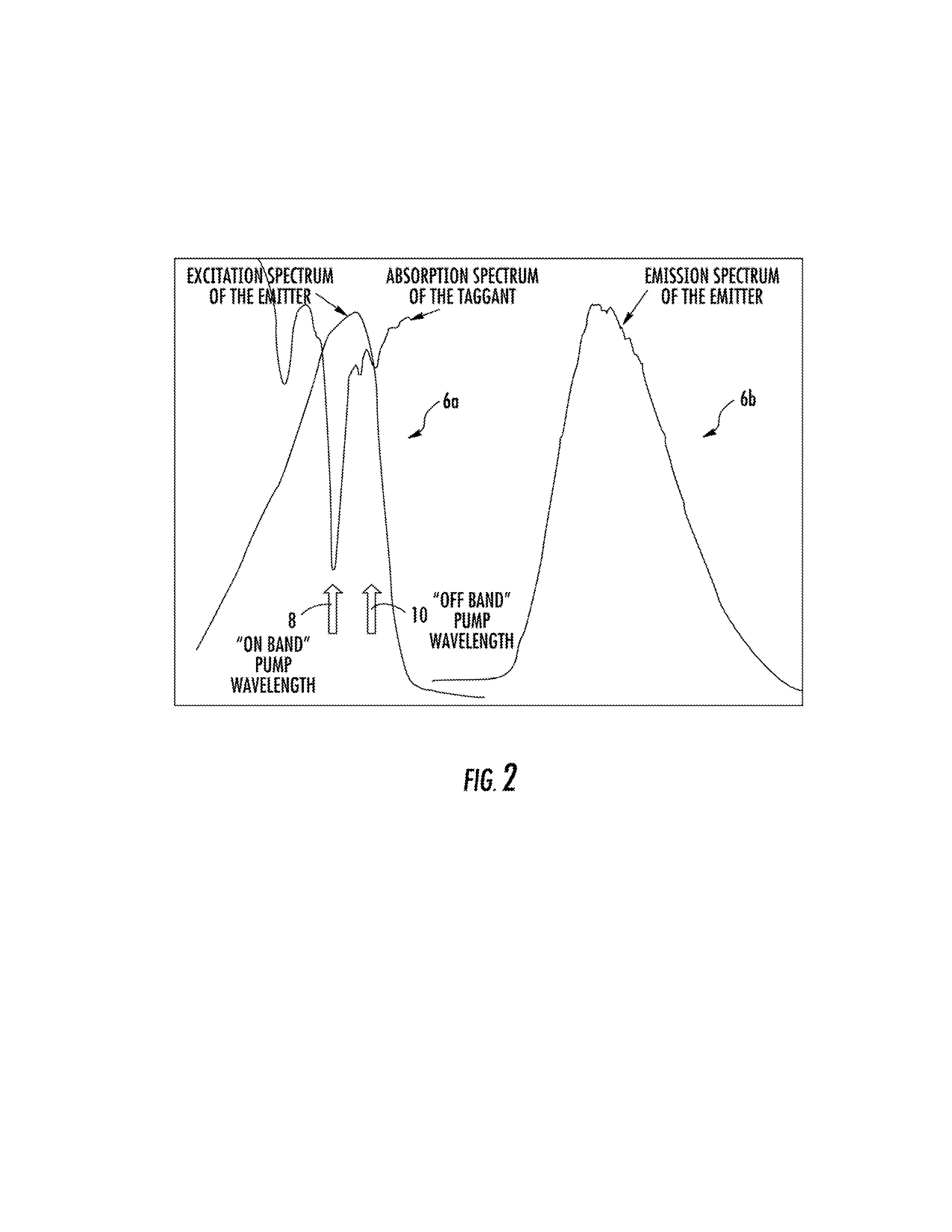

Multi wavelength excitation/emission authentication and detection scheme

ActiveUS8840029B2Low costSimple cuttingRadiation pyrometryRaman/scattering spectroscopyLength waveComputer science

A system and method for authentication of secure products is disclosed. The security feature contains a first component in the form of an emitter capable of emitting light in response to external pump light. The security feature also contains a second component in the form of a taggant that absorbs light in a spectrally narrow range compared to the broader excitation spectrum of the first material. In this manner the emitter and taggant work in combination with one another to create an emission response significantly dependent on the illumination wavelengths and unique to the specific combination of the components. The emitter and taggant can be in the form of a mixture. Further the emitter and taggant may be applied in close proximity to one another, such as within two separate coating layers on a suitable substrate.

Owner:SPECTRA SYST CORP

Signal stacking in fiber optic distributed acoustic sensing

ActiveUS20130100768A1Improve signal-to-noise ratioLow costSeismic signal receiversSeismic signal processingDistributed acoustic sensingFiber

A method for obtaining information about a subsurface formation from acoustic signals that contain information about the subsurface formation, comprises a) transmitting an optical signal into a fiber optic cable (14) that includes a sensing apparatus (20) comprising a plurality of substantially parallel fiber lengths (24), b) collecting from the sensing apparatus a plurality of received optical signals, each received signal comprising a portion of the transmitted signal that has been reflected from a different segment of a cable length, wherein the different segments are each in different cable lengths and correspond to a single selected location along the sensing cable, and c) processing the collected signals so as to obtain information about an acoustic signal received at the different segments. The cable may be ribbon cable and the lateral distance between the different segments may be less than 10 meters.

Owner:SHELL USA INC

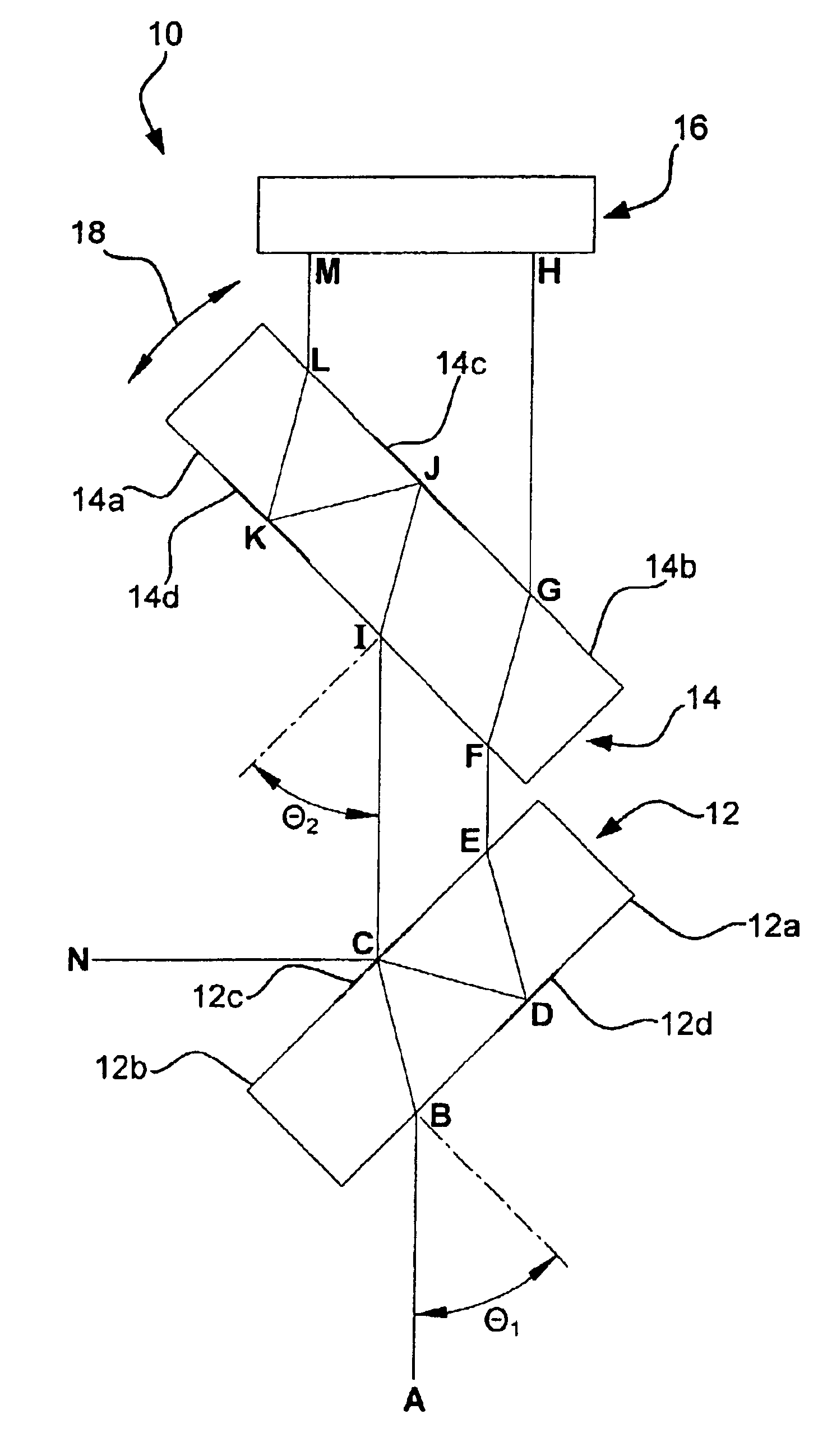

Interferometer spectrometer with reduced alignment sensitivity

InactiveUS7161679B2Increase throughputSuitable for useRadiation pyrometryInterferometric spectrometryOptical pathCollimator

An interferometer spectrometer that has reduced alignment sensitivity is described herein. Parallelism of an output ray pair formed by a single input ray is not affected by variations in relative alignment of the components. In comparison to other compensated interferometer designs, lateral separation errors in the output ray pair due to optical component misalignment are reduced. The reduced alignment sensitivity may be accomplished by utilizing simple planar components that are common to both light paths. The reduced alignment sensitivity and simplicity in design provides a more compact and more robust interferometer, with reduced manufacturing costs associated therewith. An elliptical field of view light source that utilizes an array of collimator lenses is also described. The light source provides a more compact design than a single circular collimator lens of the same area, and is suitable for single channel or multi-channel use.

Owner:INLIGHT SOLUTIONS

Antibacterial mildewproof polypropylene non-woven fabric and preparation method thereof

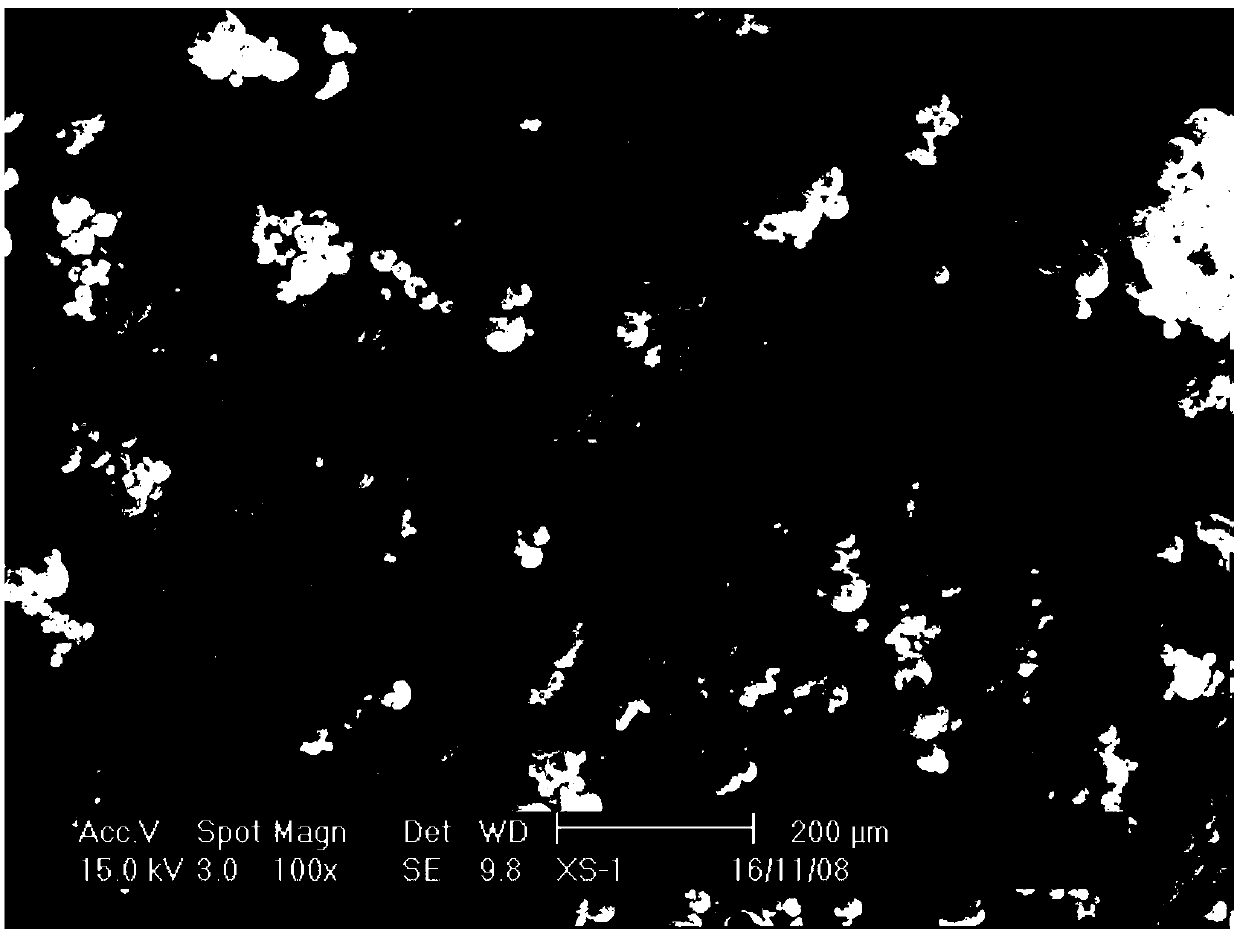

InactiveCN109706624AEvenly dispersedGood dispersionNon-woven fabricsMonocomponent polyolefin artificial filamentNonwoven fabricPolypropylene

The invention belongs to the field of preparation of polypropylene non-woven fabrics, and relates to an antibacterial mildewproof polypropylene non-woven fabric and a preparation method thereof. The antibacterial mildewproof polypropylene non-woven fabric comprises polypropylene, a guanidine salt composite antibacterial agent, a mildewproof agent and other auxiliaries; the guanidine salt compositeantibacterial agent is prepared from, by weight, 100 parts of a guanidine salt polymer, 0.01-40 parts of zinc salt and / or copper salt, 0.1-10 parts of an anti-migration agent, 0.5-100 parts of nano-sized powder rubber and 0.1-10 parts of a dispersing agent. The non-woven fabric has good antibacterial and mildewproof performance, a long-lasting effect and good water resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

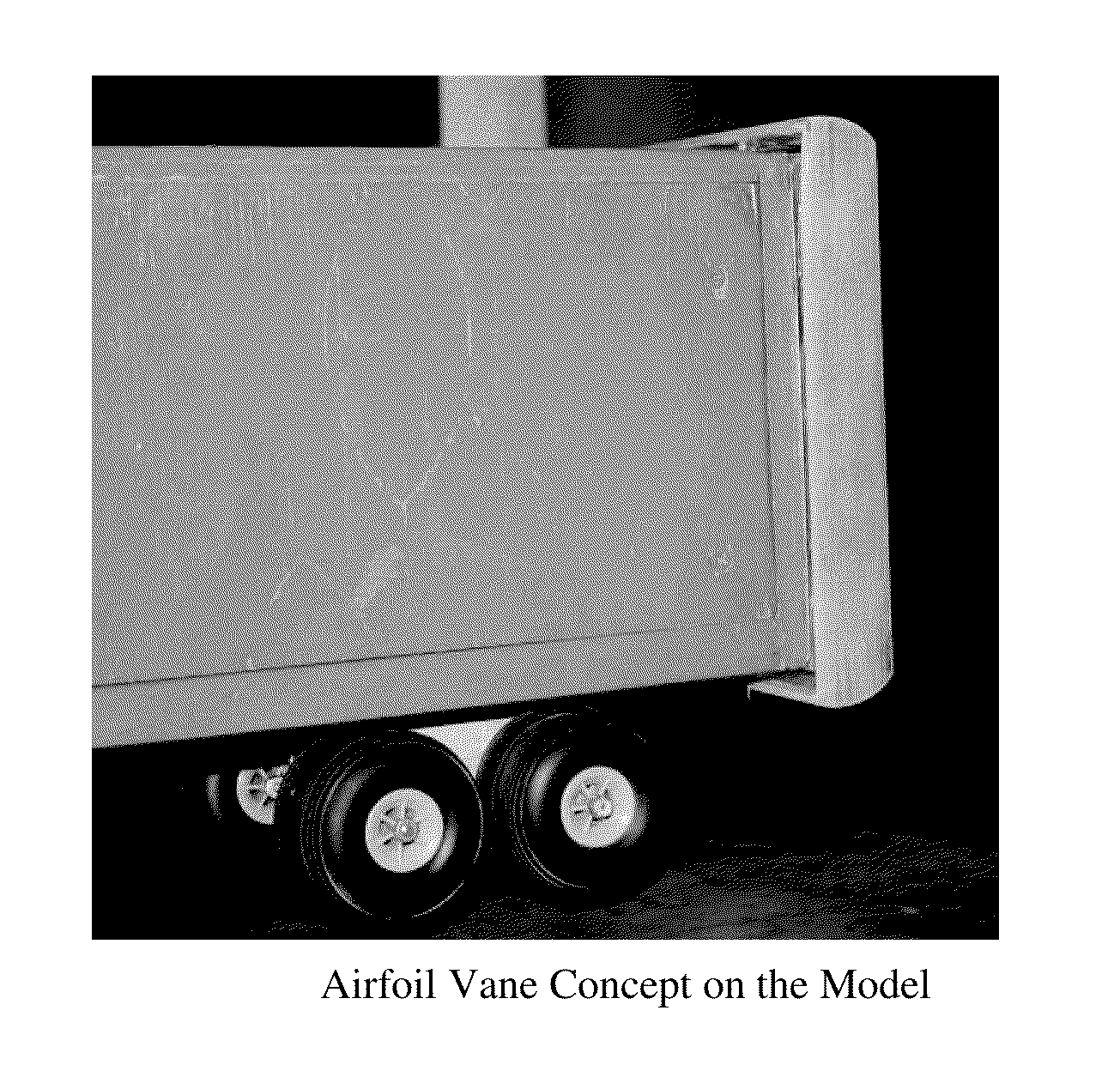

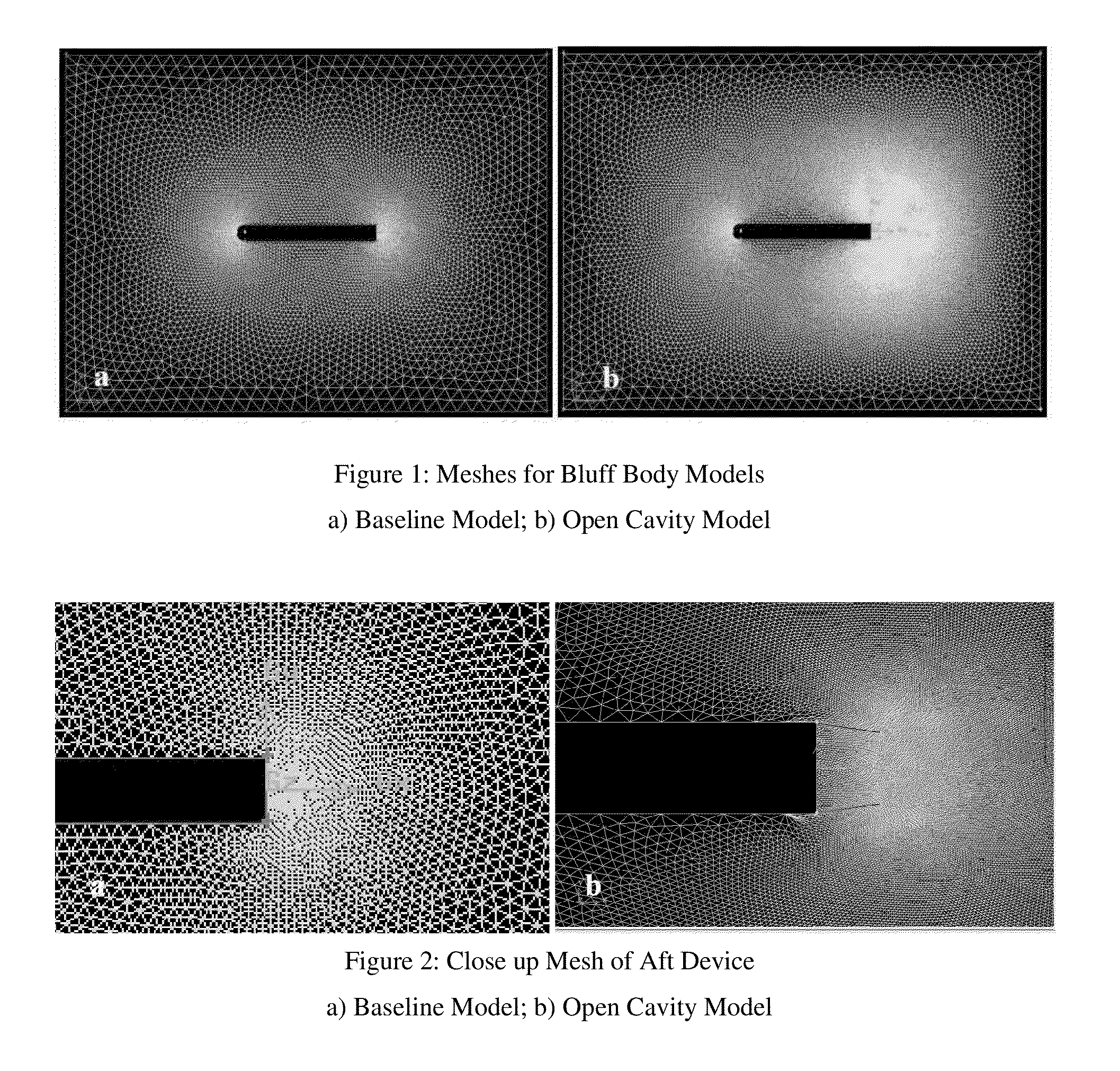

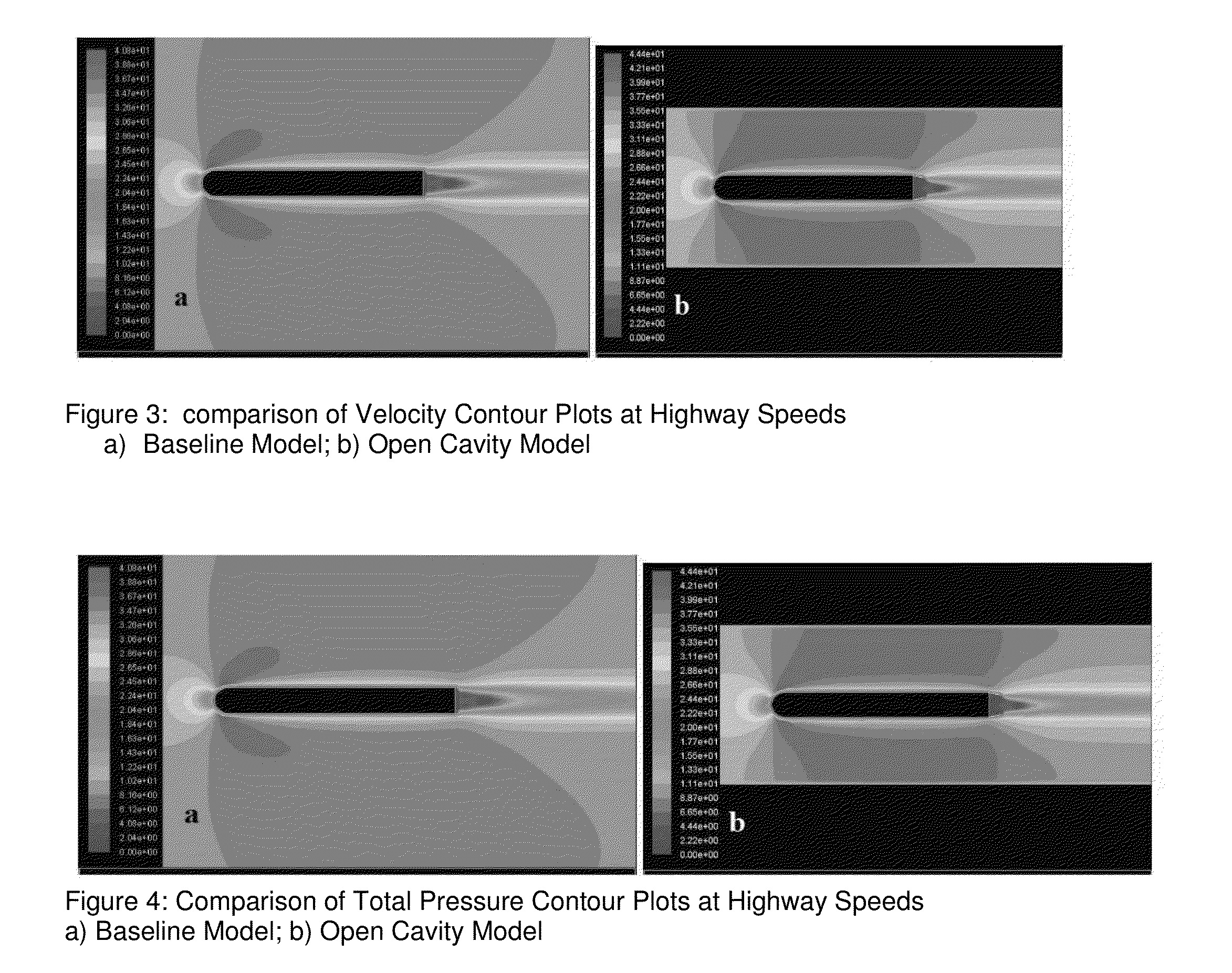

Drag reduction of a tractor trailer using guide vanes

The present invention relates to a vehicle having an apparatus mounted thereon for reducing aerodynamic drag and, more particularly, to a guide vane apparatus with an airfoil cross-section mounted to the aft portion of a tractor trailer.

Owner:CLARKSON UNIVERSITY

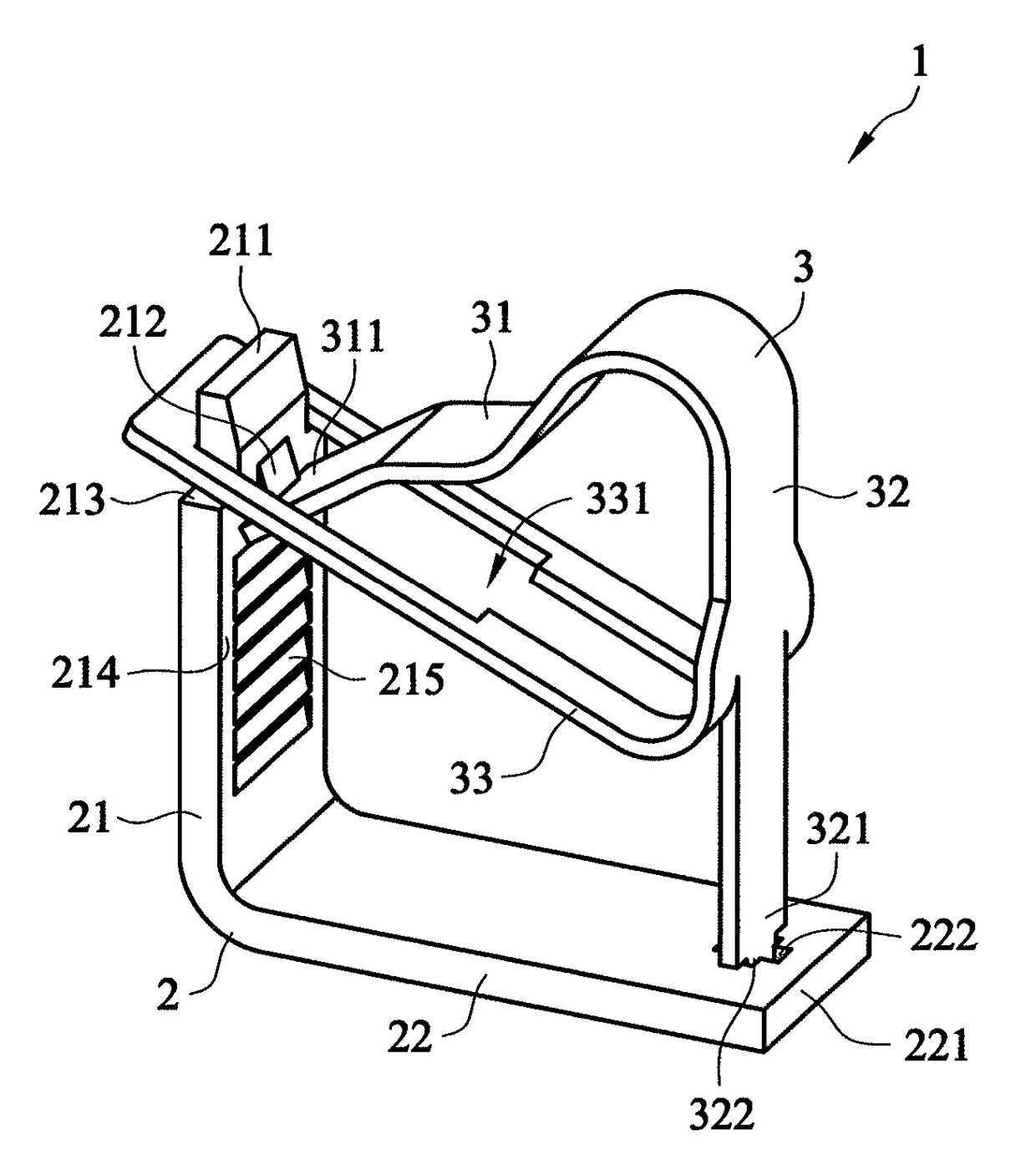

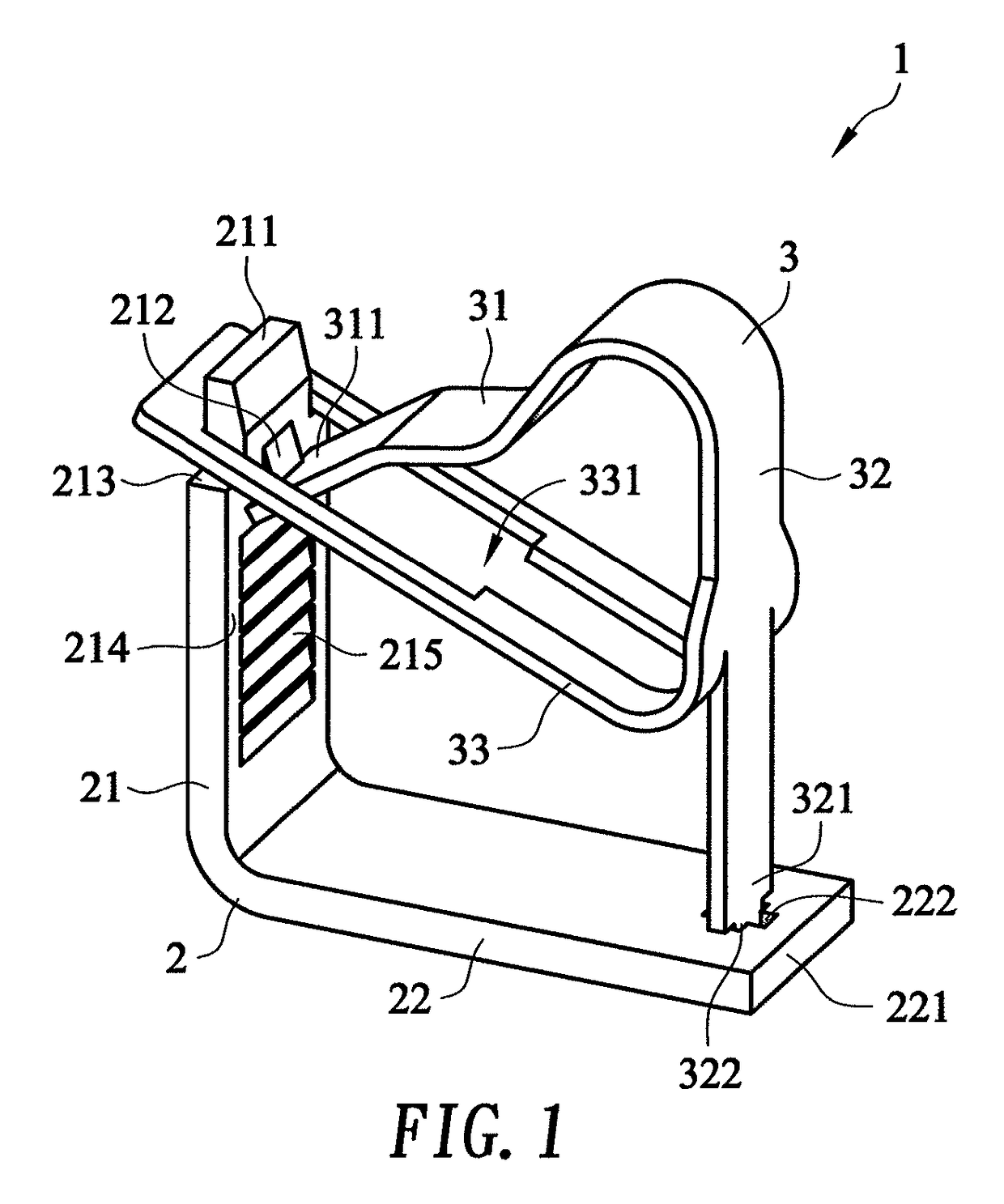

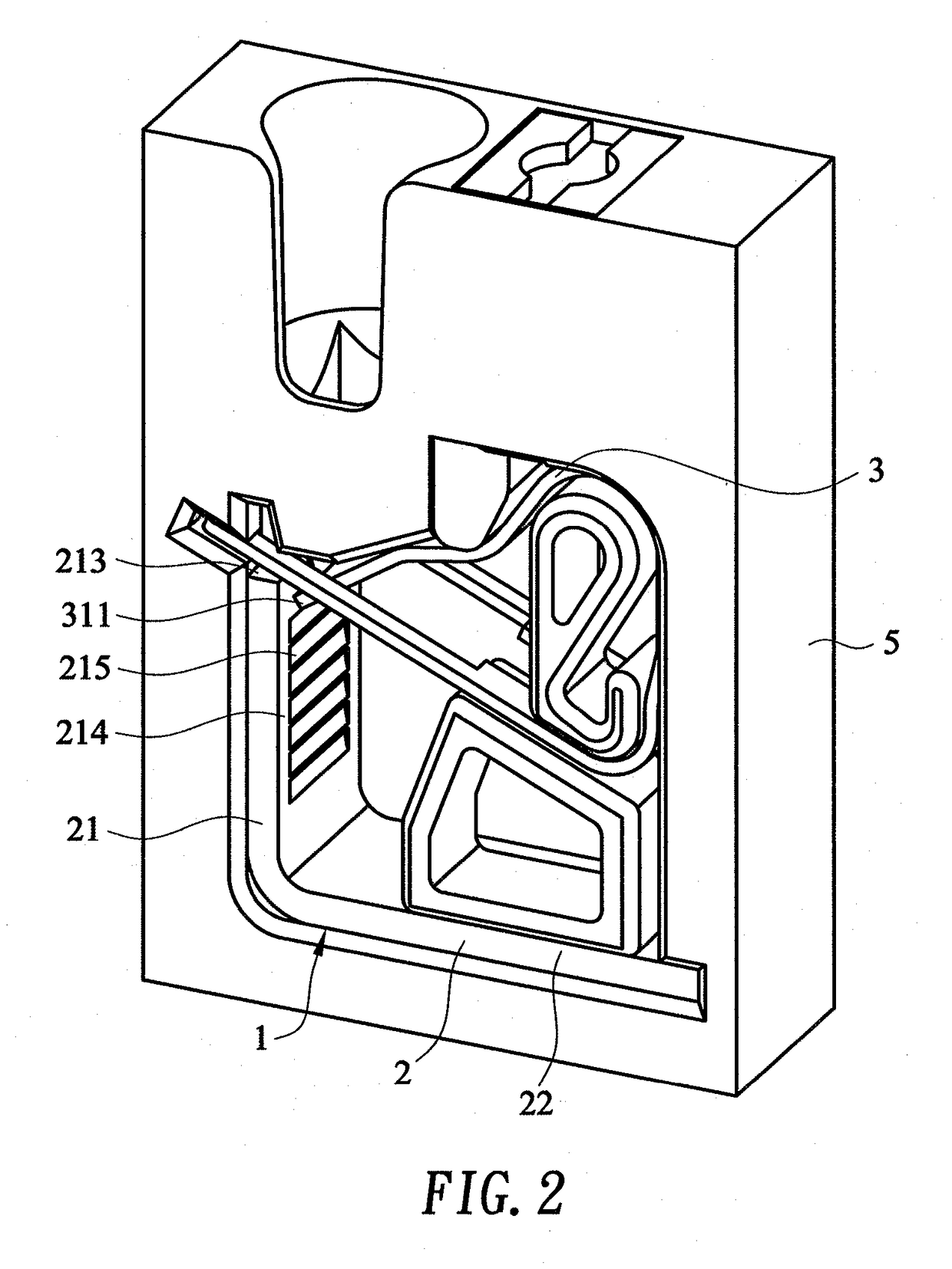

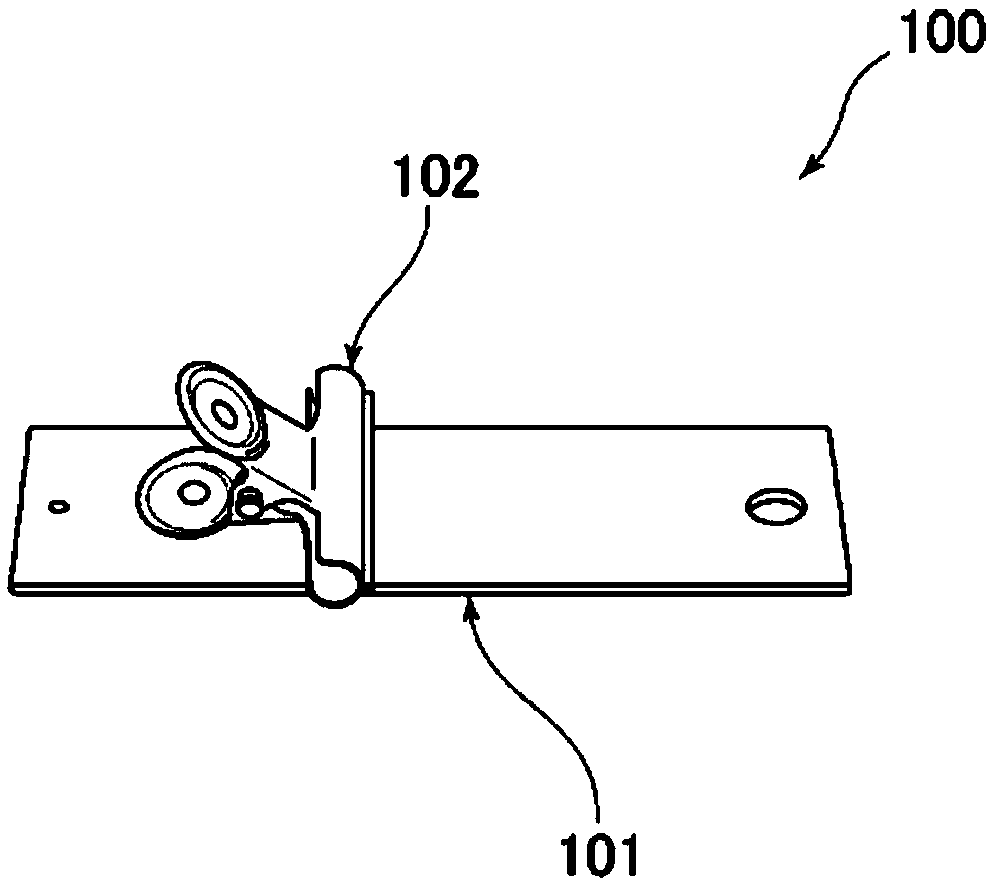

Connection terminal structure

ActiveUS9624951B2Easy to shapeLow costFriction grip releasable fasteningsClamped/spring connectionsEngineeringFlange

A connection terminal structure includes a basic element and a clamping element. The basic element is bent to be L-shaped and includes a longitudinal arm and a transverse arm connected to the longitudinal arm. An upper end of the longitudinal arm forms an engaging flange and an engaging shoulder portion. A right end of the transverse arm forms a joint portion. The clamping element comprises a resilient clamping arm, a supporting arm, and a connecting arm. The connecting arm forms an opening portion and extends from the supporting arm to the longitudinal arm. The opening portion fits around the engaging shoulder portion. A lower end of the supporting arm forms a joint end jointed to the joint portion. The resilient clamping arm connects with the supporting arm, extends to the longitudinal arm, has a front end engaging with the engaging flange, and penetrates the opening portion to move resiliently.

Owner:DINKLE ENTERPRISE CO LTD

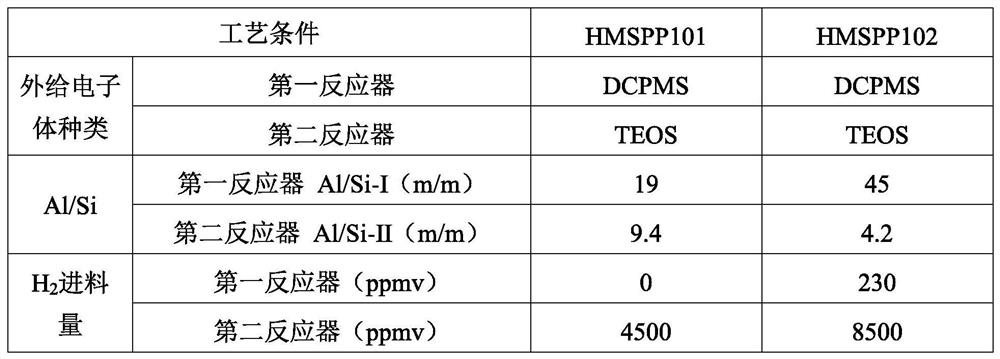

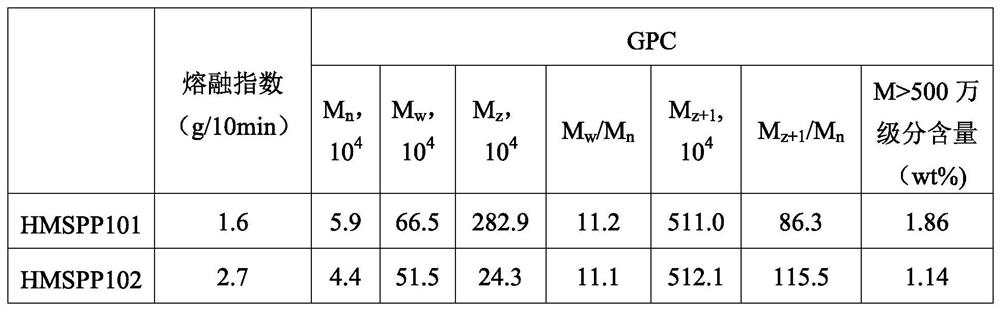

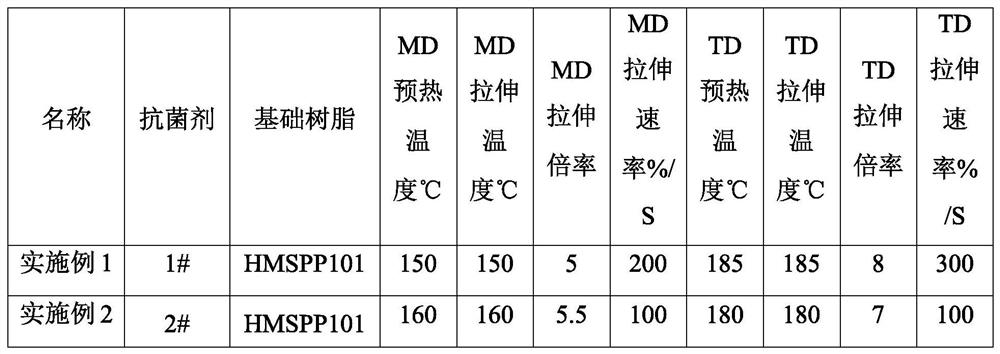

Antibacterial mildew-proof polypropylene composition, polypropylene film and preparation method thereof

The invention belongs to the field of antibacterial materials and products thereof, and relates to an antibacterial mildew-proof polypropylene composition, a polypropylene film and a preparation method of the polypropylene film. The antibacterial mildew-proof polypropylene composition contains high-melt-strength polypropylene base resin, a guanidine salt composite antibacterial agent, a mildewproof agent and an auxiliary agent, wherein the auxiliary agent contains an antioxidant, and based on 100 parts by weight of the high melt strength polypropylene base resin, the content of the guanidine salt composite antibacterial agent is 0.05-2.0 parts by weight, the content of the mildew inhibitor is 0.01-5.0 parts by weight, and the content of the antioxidant is 0.01-10 parts by weight. The antibacterial and mildewproof polypropylene composition has good antibacterial and mildewproof effects, the water resistance is also improved, and a polypropylene film prepared from the antibacterial and mildewproof polypropylene composition has the advantages of low transverse and longitudinal thermal shrinkage rate, excellent antibacterial and mildewproof performance, difficulty in discoloring afterlong-time use and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pressure-sensitive adhesive layer-attached polarizing film and image display device

InactiveUS20140272200A1Efficiently formedEasy to transformLiquid crystal compositionsFilm/foil adhesivesTectorial membraneMeth-

A pressure-sensitive adhesive layer-attached polarizing film contains a polarizing film containing a polarizer and a transparent protective film provided on at least one side of the polarizer, the polarizing film having a total thickness of 100 μm or less. A pressure-sensitive adhesive layer is provided on the polarizing film and made from a pressure-sensitive adhesive composition containing a (meth)acryl-based polymer and an antioxidant.

Owner:NITTO DENKO CORP

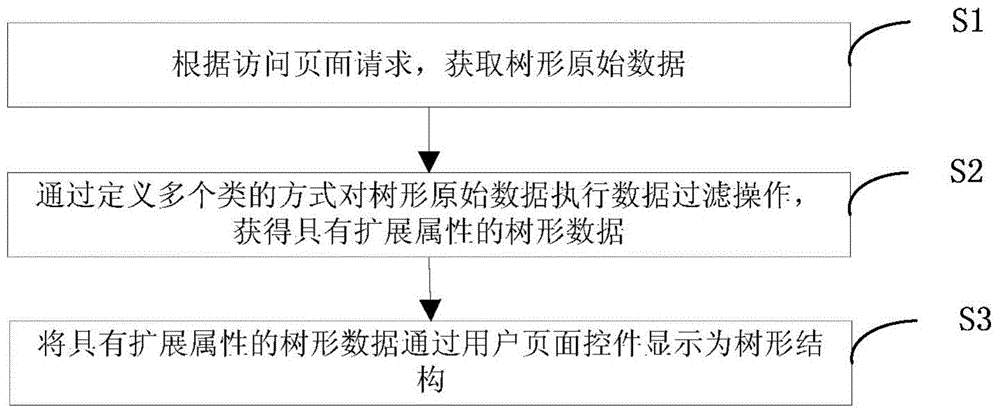

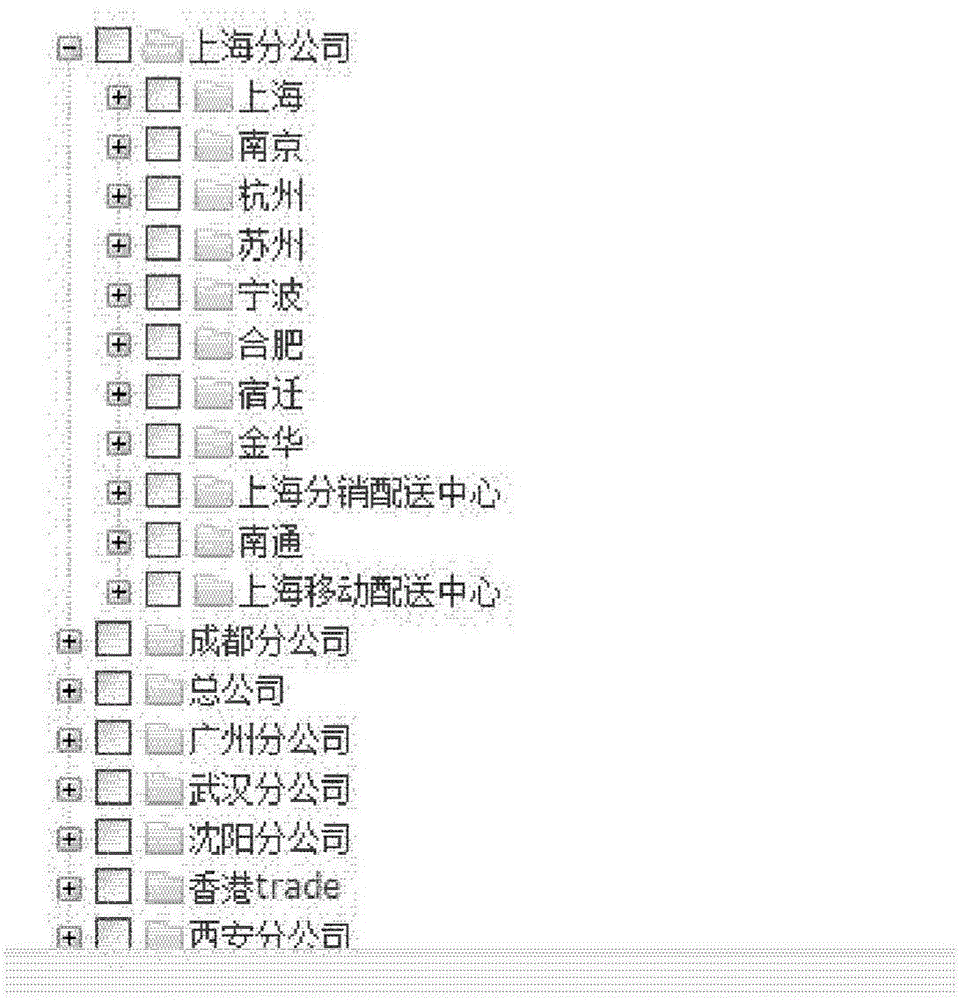

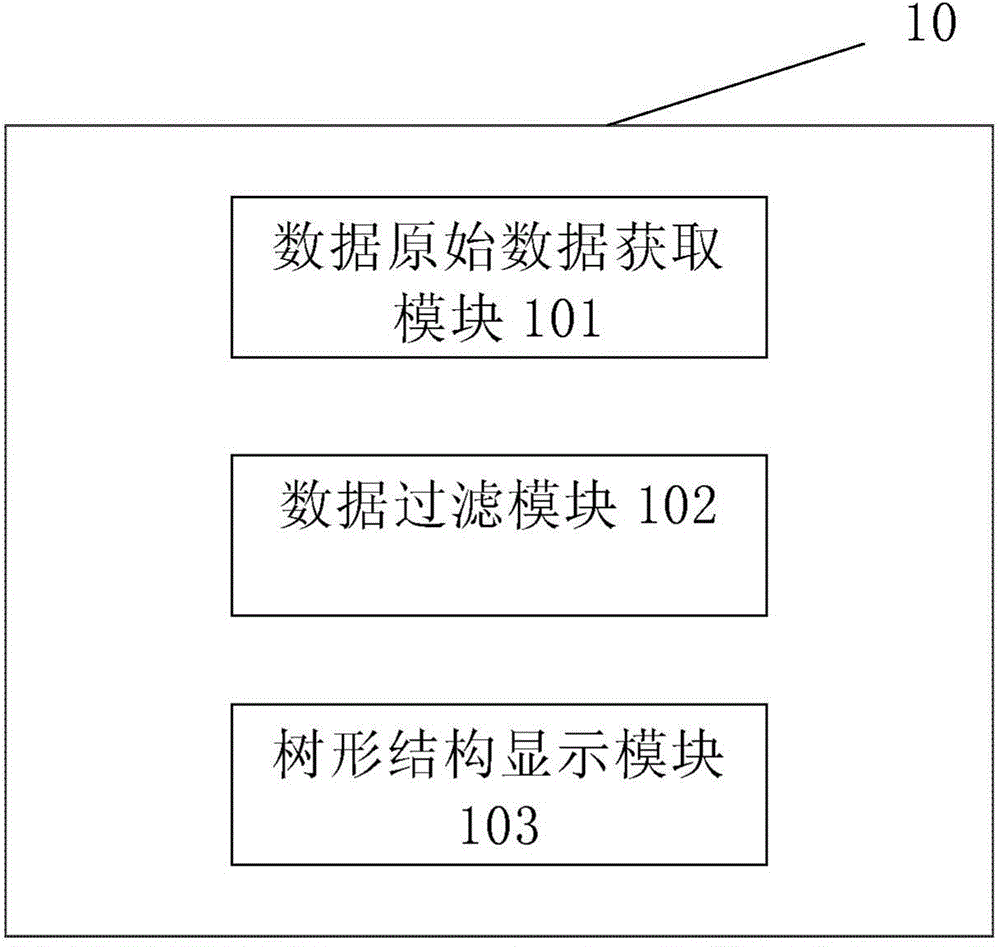

Filtering method and apparatus based on tree structure

ActiveCN104991778AReduce callsImprove data processing capabilitiesSpecific program execution arrangementsOriginal dataData mining

The present invention discloses a filtering method based on a tree structure, which comprises: according to a page access request, acquiring tree original data; executing an data filtering operation on the tree original data in a manner of defining a plurality of categories to obtain tree data with an extended attribute; and displaying the tree data with the extended attribute into the tree structure by a user page control. The present invention also discloses a filtering apparatus based on the tree structure.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Toughened flame-retarded poly propylene composition and its preparing method

The invention relates to a kind of platicizing and antiflaming polypropylene combination and its manufacturing method. The polypropylene combination contains polypropylene resin with 100 part by weight, grafts with 1-20 part by weight, and ammonium polyphosphate with 15-75 part by weight. Among them, the grafts are grafts of thermoplastic elastomer and polar monomer, and its percent grafting is 0.5-8.0%. Using the grafts to modify polypropylene resin of ammonium polyphosphate antiflaming can improve fire retardancu of polypropylene resin while improving tenacity of it greatly, so it adapts to extremely extensive fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adhesive layer with separator, method for producing same, polarizing film with adhesive layer with separator, method for producing polarizing film with adhesive layer with separator, and image display device

ActiveCN105518092AImprove gel fractionEasy to processNon-macromolecular adhesive additivesSynthetic resin layered productsMeth-Phenolic antioxidant

Provided are: an adhesive layer with a separator, which has excellent workability and durability, and wherein a separator exhibits adequate easy separability from an adhesive layer; and a method for producing this adhesive layer with a separator. A method for producing an adhesive layer with a separator, which comprises: a first step for forming a layer of an adhesive composition, which contains a (meth)acrylic polymer, a peroxide and a phenolic antioxidant, on the releasing surface of a separator, said surface having been subjected to a release treatment; and a second step for forming an adhesive layer by heating the adhesive composition after the first step so that the adhesive composition is crosslinked.

Owner:NITTO DENKO CORP

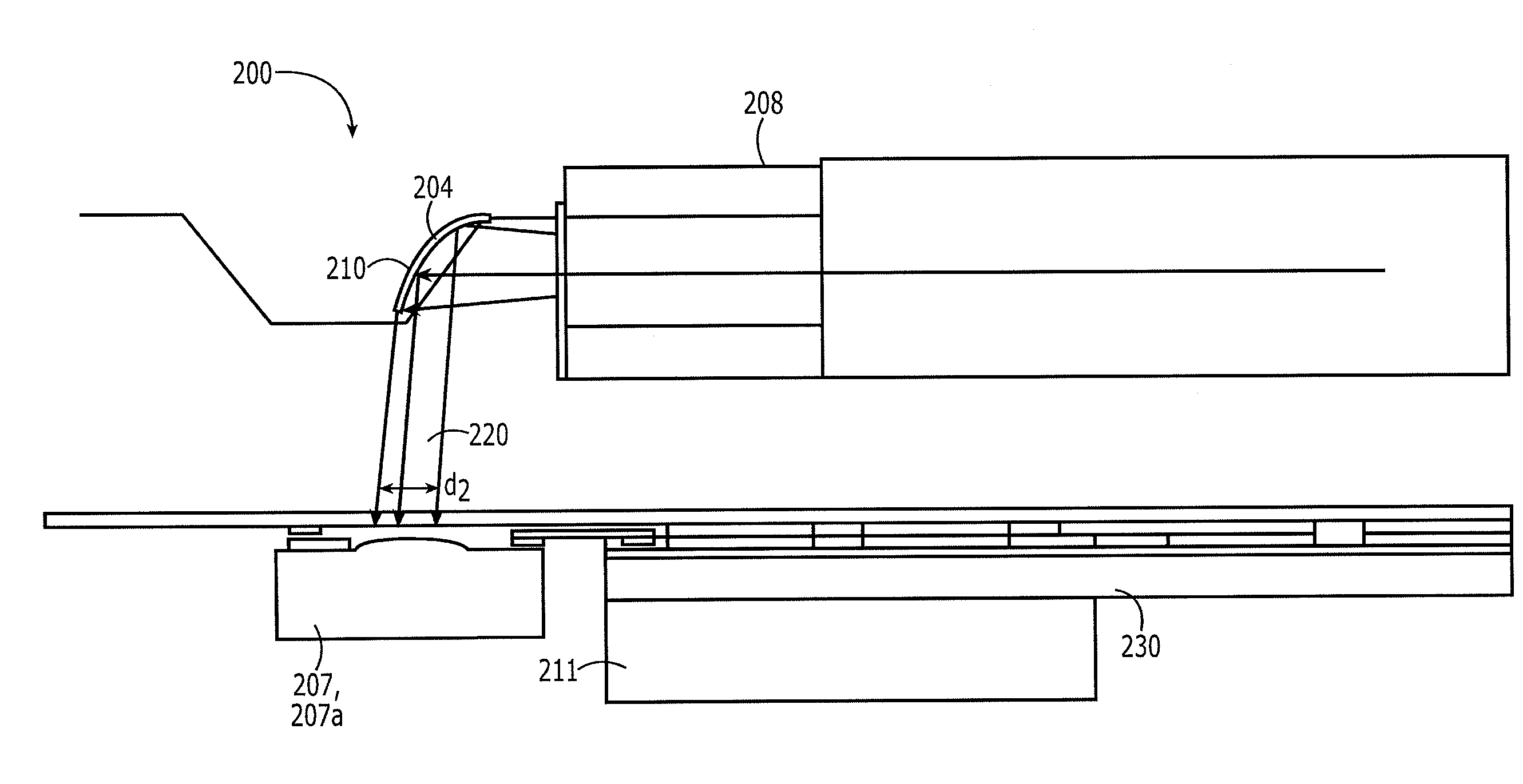

Transparent optical interposer

InactiveUS20130034325A1Low costSimple cuttingLine/current collector detailsCoupling light guidesInterposerEngineering

An optical interposer comprising a transparent substrate having first and second sides, at least one OED mounted to the first side, at least one reflective surface and at least one groove defined on the second side, and an optical conduit disposed in the groove optically coupled to the OED by the reflective surface

Owner:TE CONNECTIVITY CORP

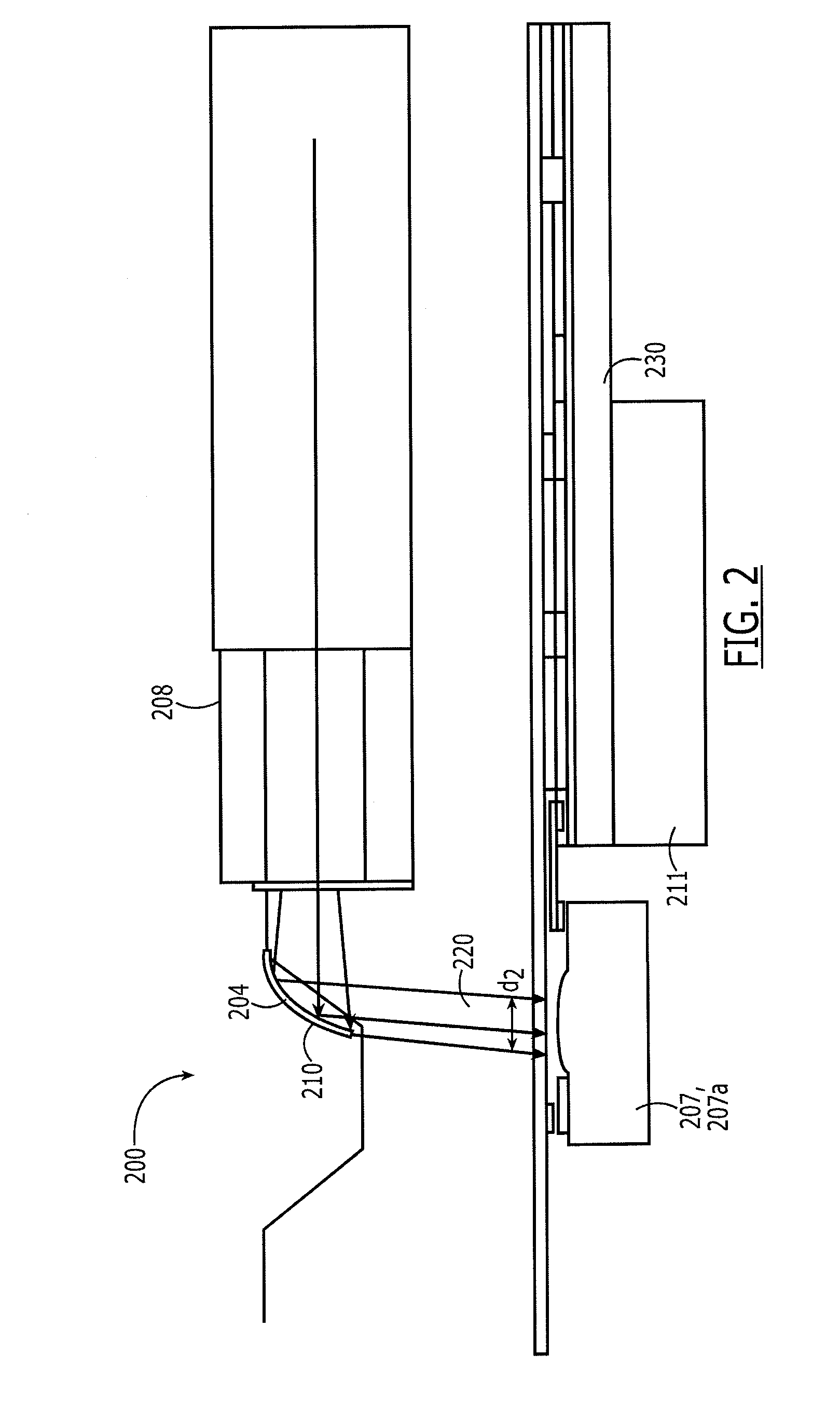

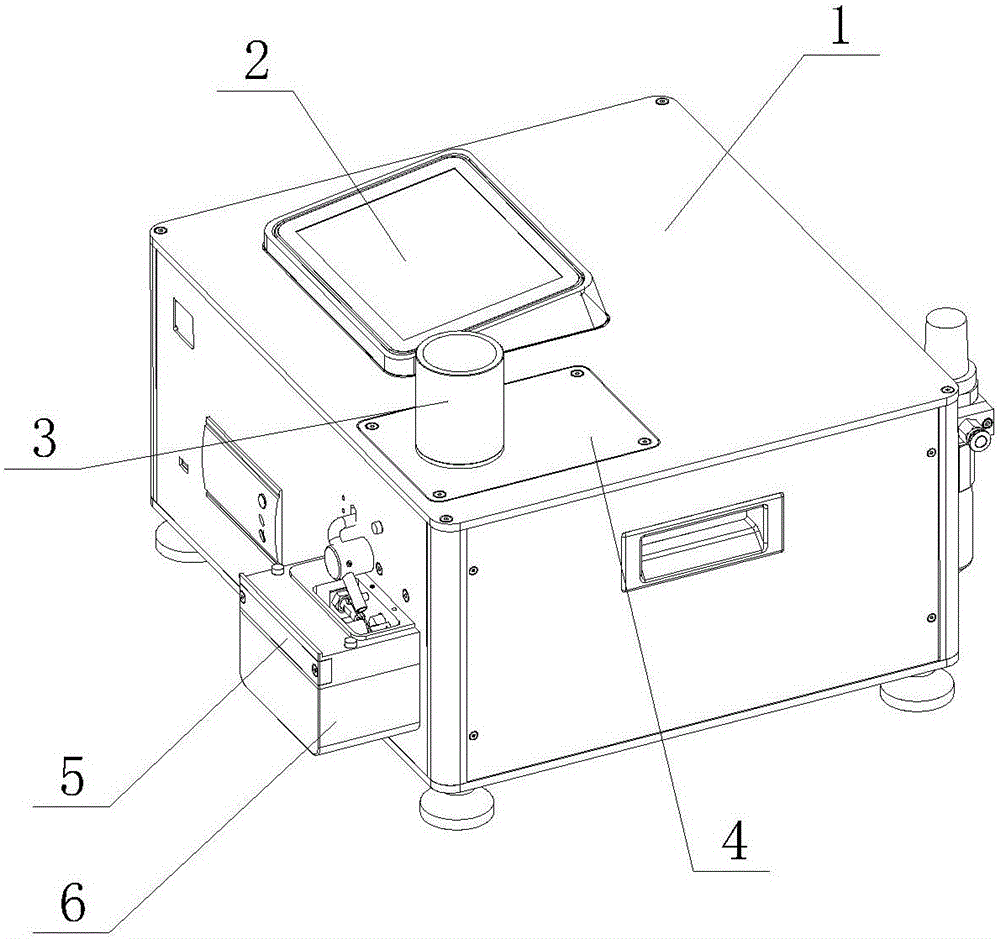

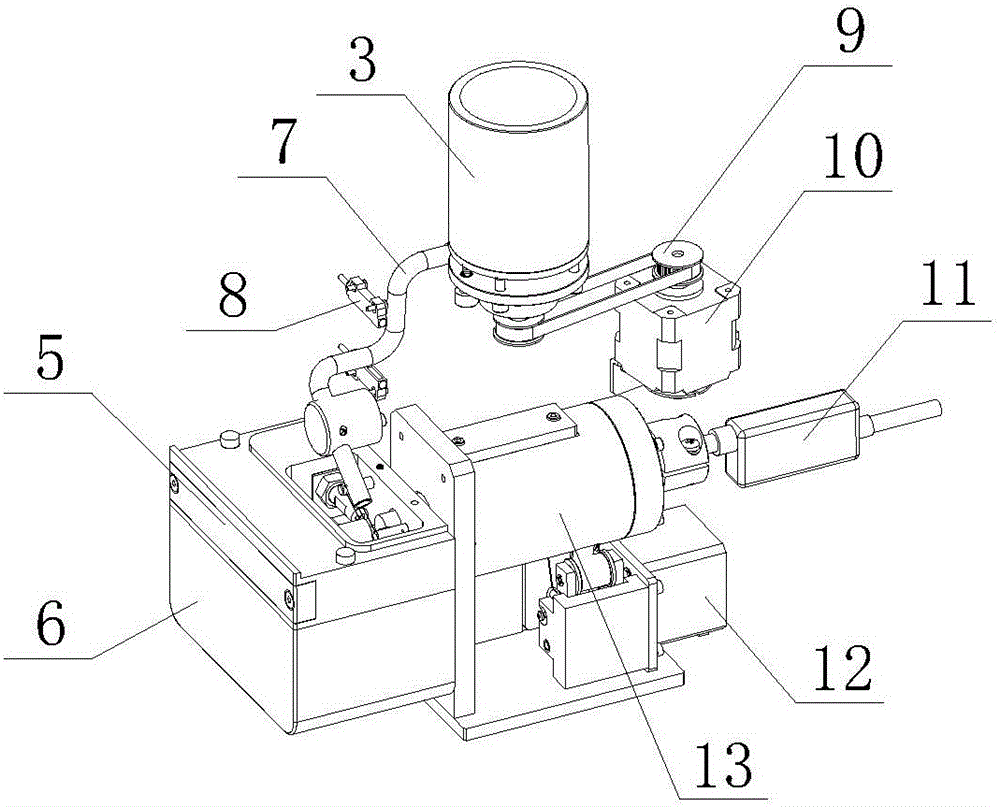

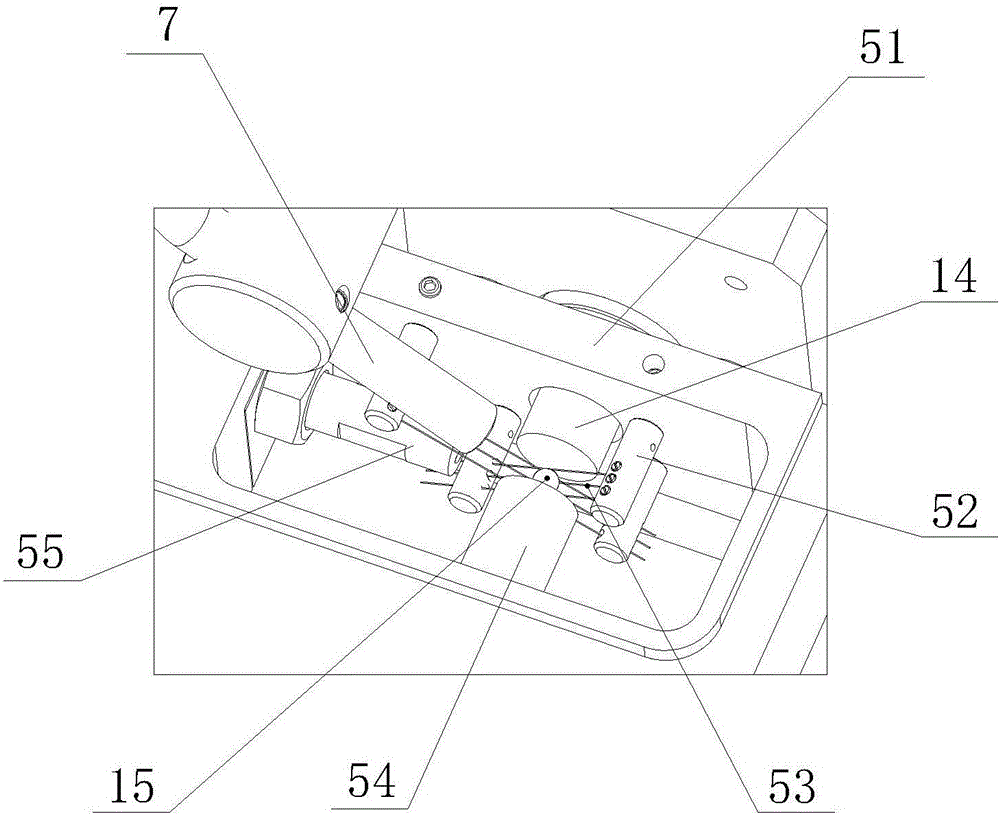

Popping bead strength testing instrument

ActiveCN105758729ASave labor efficiencySimple cuttingMaterial strength using tensile/compressive forcesEngineeringPressure sensor

The invention discloses a popping bead strength testing instrument which comprises a case.The case is provided with a controller and a feeding pressurizing mechanism.The feeding pressurizing mechanism comprises a material barrel, a carrying table, a pressure head, a compressing mechanism and a compressing motor, wherein the pressure head is fixed to the compressing end of the compressing mechanism, and the compressing motor is in driving connection with the compressing mechanism.The carrying table comprises a carrying table support, and the carrying table support is provided with an air blowing pipe, a pressure-bearing head, a pressure sensor and a steel wire groove, wherein the pressure-bearing head is in rigid connection with the pressure sensor, one end of the pressure head right faces the pressure-bearing head, a grating ruler is connected to the other end of the pressure head, the steel wire groove is located between the pressure-bearing head and the pressure head, a discharging port of the material barrel is provided with a flexible material guide pipe, an air blowing opening of the air blowing pipe faces the steel wire groove, a popping bead detector is arranged in a pipeline of the material guide pipe, and the pressure sensor, the grating ruler and the popping bead detector are electrically connected with the controller.The popping bead strength testing instrument is capable of saving manpower and high in efficiency, the discharging process is simple, the material barrel can be quickly replaced to be compatible to samples with different diameters, and material jamming and residual materials can be avoided.

Owner:CHENGDU RETOOL SCI & TECH CO LTD

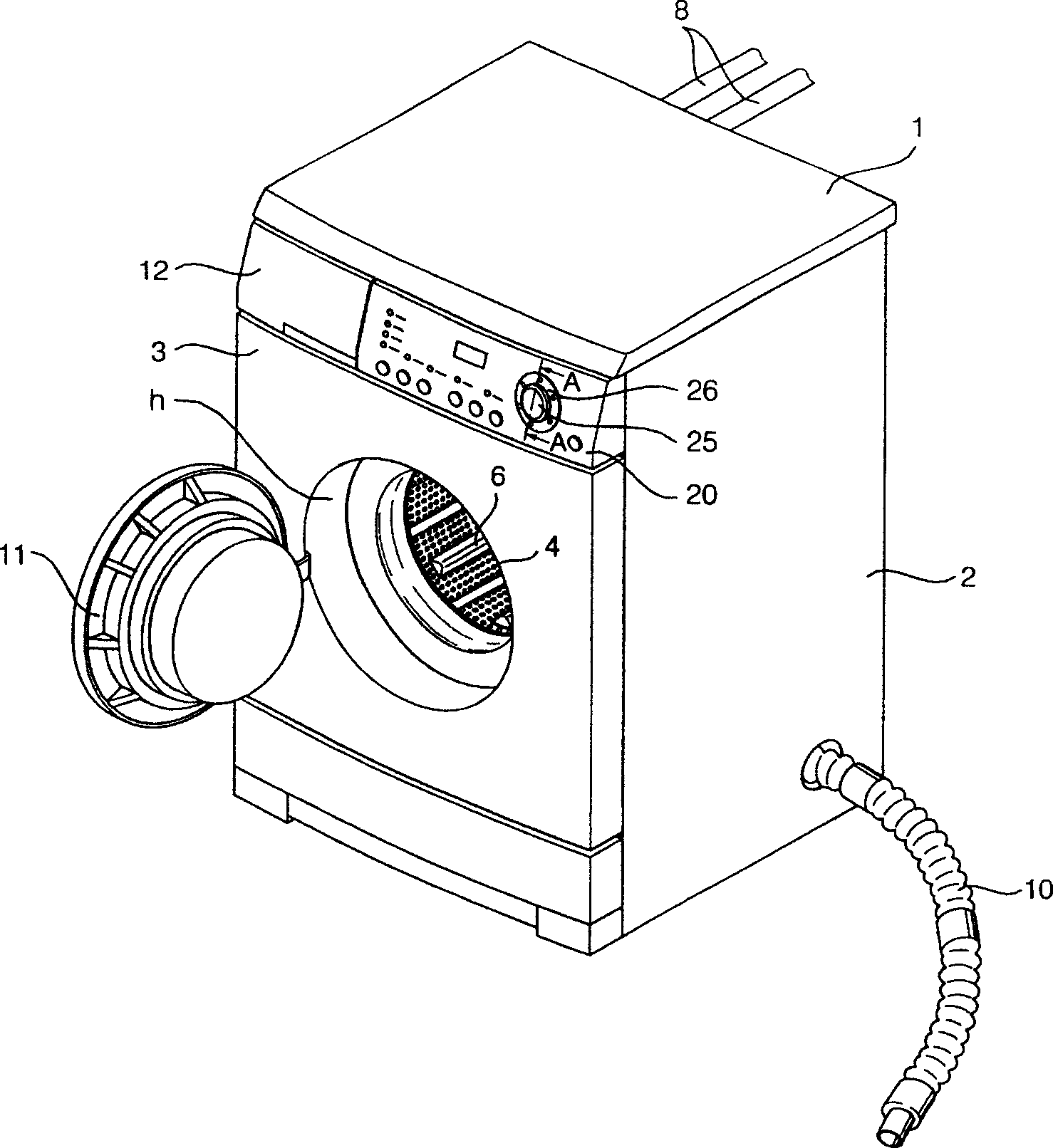

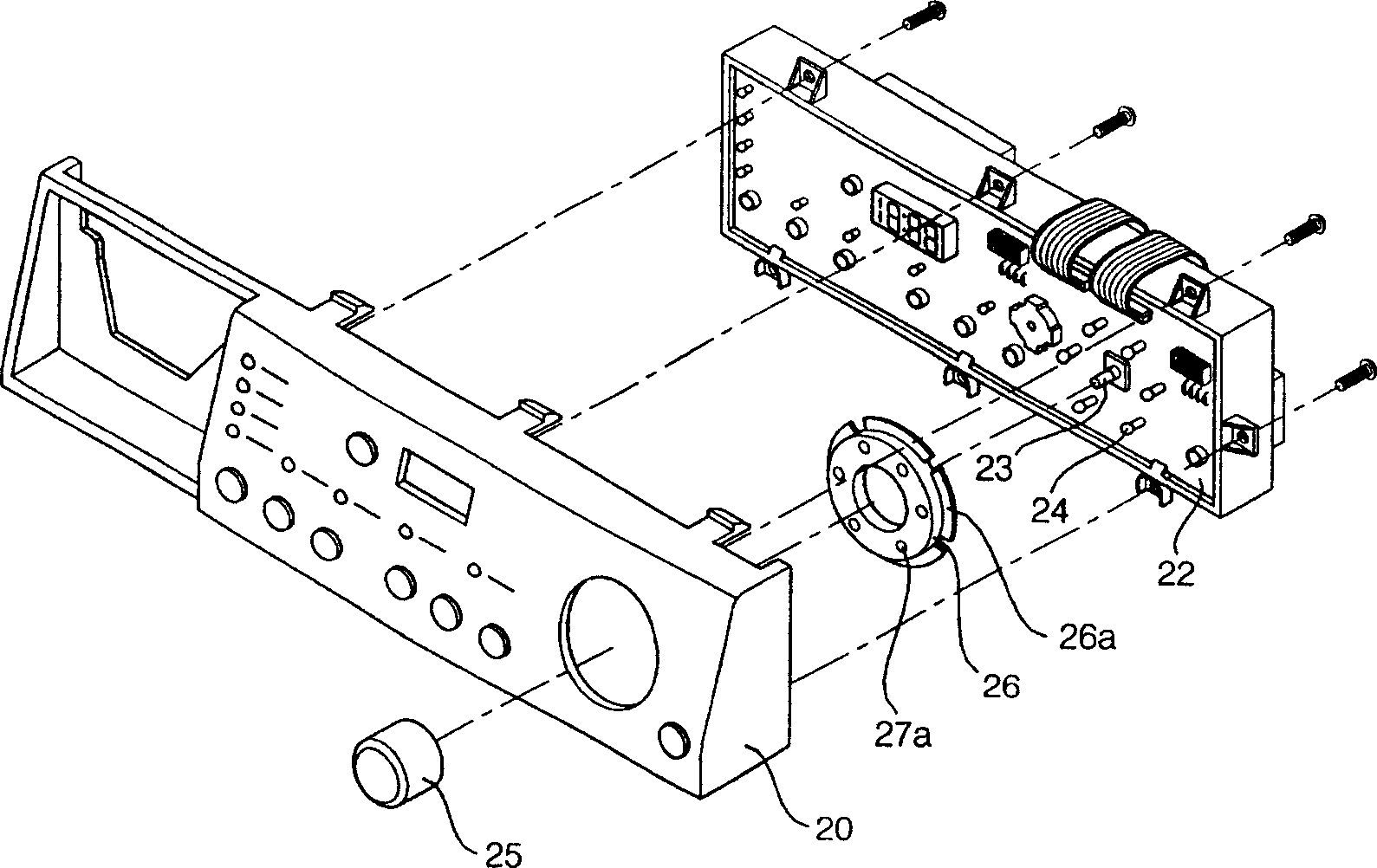

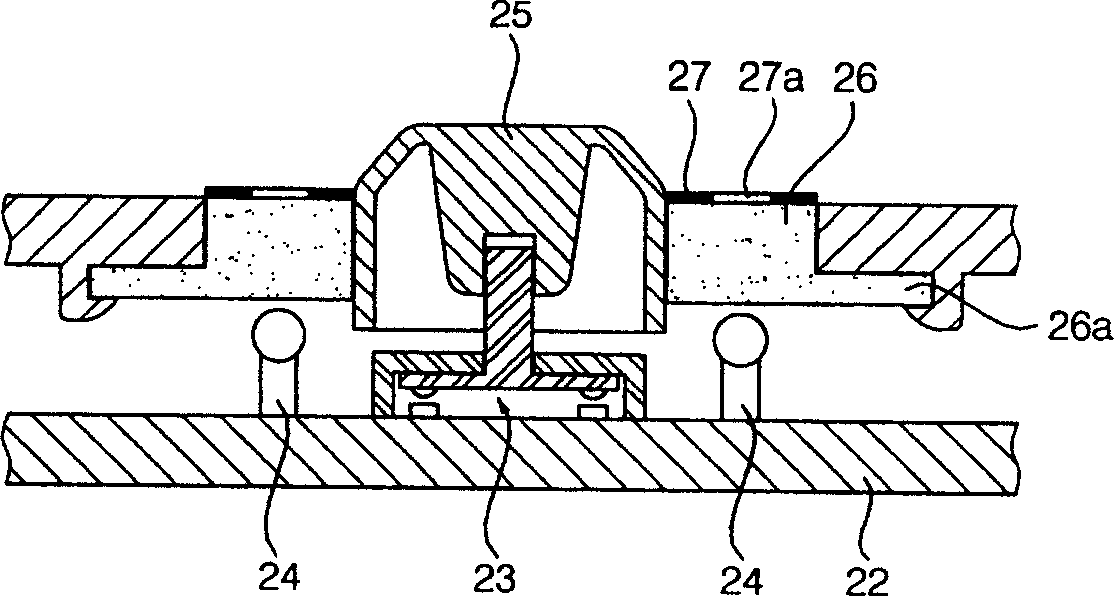

Controller device of washing machine

InactiveCN1683664APrevent shrinkageReduce machining errorsOther washing machinesTextiles and paperLiquid-crystal displayLiquid crystal

The controller device of washing machine includes base board, control panel, control buttons and display cover. There are rotating switch, touch switch, liquid crystal panel and LED's on the base board; control knobs for operating the rotating switch and the touch switch on the control panel covering the base board; and display cover for light from LED's to transmit outwards around the control buttons. The display cover consists of adhered sheets without shrinkage produced during formation, and has minimized machining error.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Antibacterial thermoplastic resin composition as well as preparation method and application thereof

The invention relates to an antibacterial thermoplastic resin composition as well as a preparation method and application thereof, belonging to the field of antibacterial thermoplastic plastics. The antibacterial thermoplastic resin composition comprises the following components in parts by weight: 100 parts of thermoplastic resin and 0.03-4.8 parts of a guanidine salt antibacterial microsphere, wherein the guanidine salt antibacterial microsphere has the characteristics of good fluidity and low moisture absorption, and in the preparation process of the antibacterial thermoplastic resin composition, a guanidine salt polymer does not adhere to the wall and is easy to discharge, production and operation are simple, and excessive production condition control is not needed. The prepared antibacterial thermoplastic resin composition has good antibacterial and mildew-proof effects, and is also improved in water resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

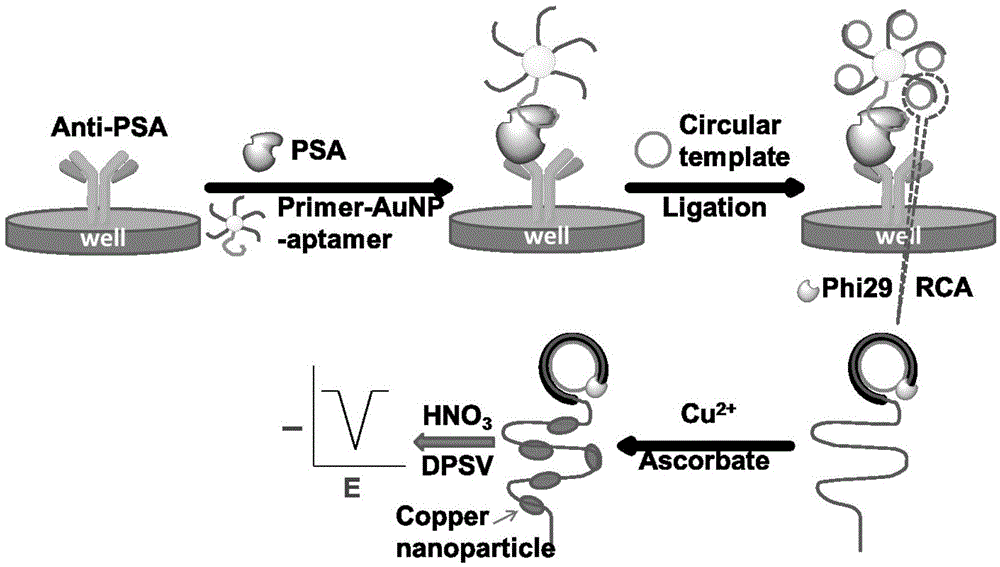

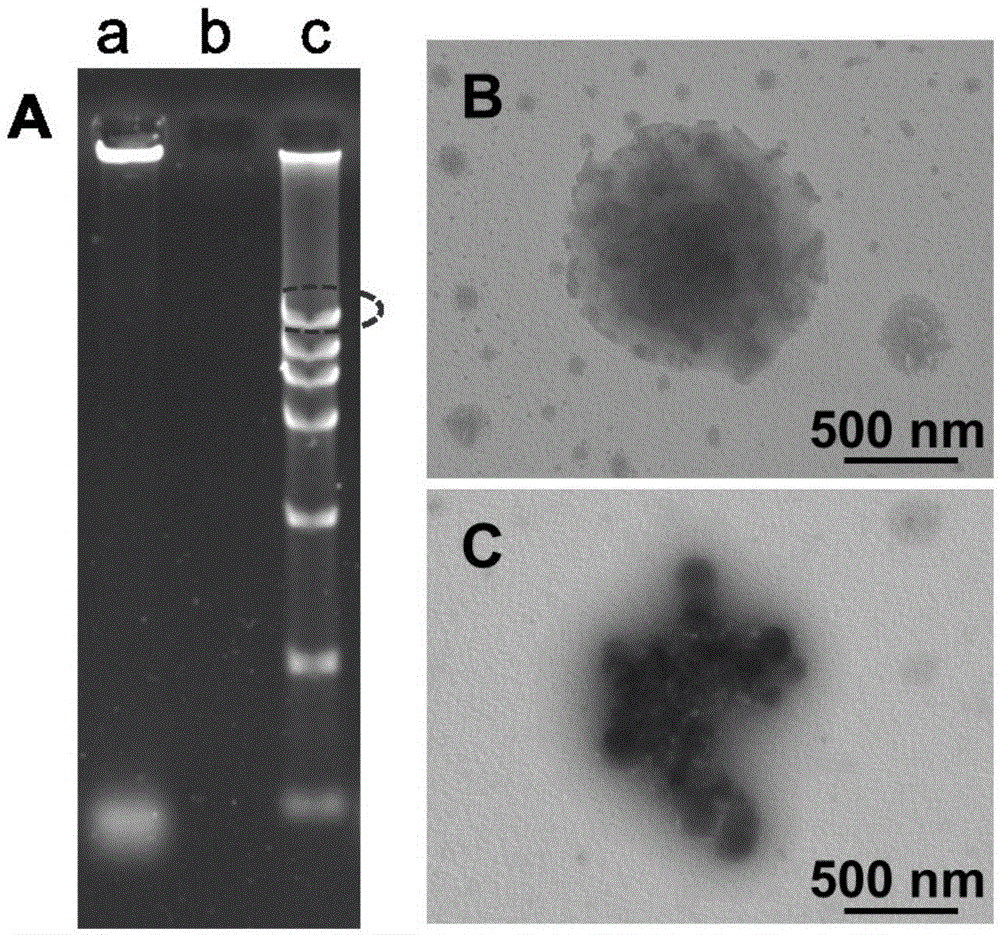

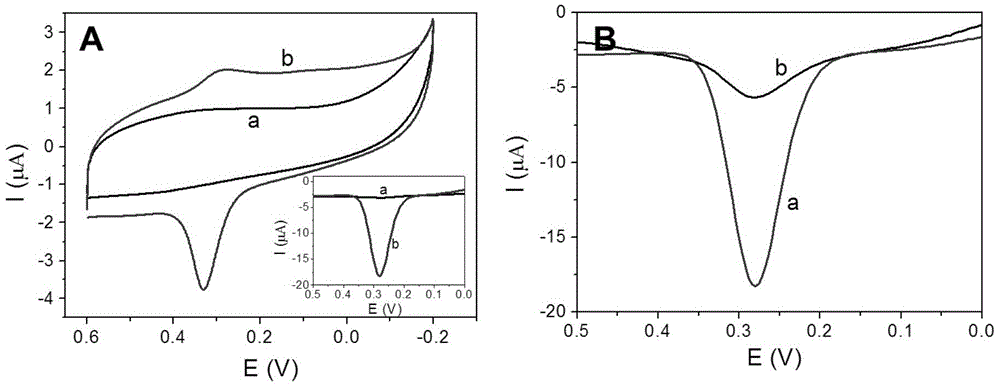

Copper nanoparticle synthetic method using rolling circle amplification product as template and application thereof in electrochemical detection

ActiveCN105567808ASensitive detectionHigh selectivityMicrobiological testing/measurementRepetitive SequencesAptamer

The invention provides a copper nanoparticle synthetic method using a rolling circle amplification product as a template and application thereof in electrochemical detection. A prostate specific antigen (PSA) is used as a model target molecule. The establishment of a primer-nanogold-aptamer / PSA / PSA antibody sandwich structure initiates a rolling circle amplification reaction, thus generating tens of thousands of poly-thymine repetitive sequences that serve as a template for synthesis of copper nanoparticles; the formed copper nanoparticles are dissolved further using nitric acid, copper ions obtained by dissolution are detected by using an electrochemical method, and finally target PSA content is determined. Benefited from a designed signal-level cascade amplifying strategy, a linear range of the PSA detected by the invention is between 0.05 fg / mL and 500 fg / mL, and a detection limit is 0.020+ / -0.001 fg / mL PSA. Finally, the practicality of the method is verified by detecting the PSA content in a clinical serum sample. With the supersensitivity, specificity and ability to detect an actual sample, the method has great potential in disease diagnosis application.

Owner:SHANDONG UNIV

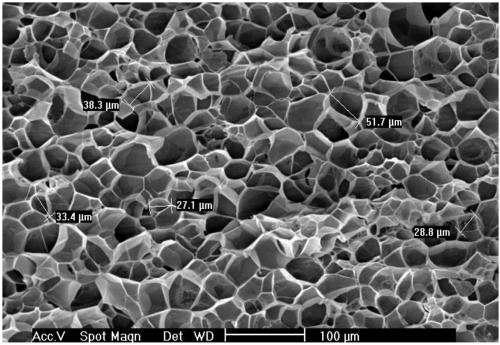

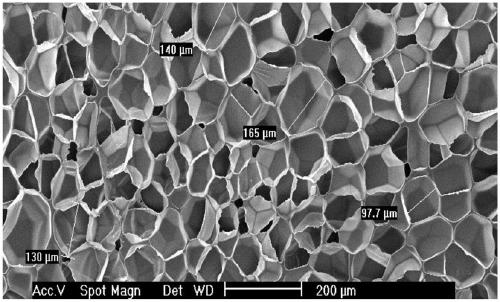

Antibacterial polypropylene composition, microporous antibacterial polypropylene foamed sheet, preparation method thereof and foamed sheet

The invention belongs to the field of antibacterial materials and products thereof, and discloses an antibacterial polypropylene composition, a microporous antibacterial polypropylene foamed sheet, apreparation method thereof and a foamed sheet. The antibacterial polypropylene composition contains polypropylene base resin, a guanidine salt composite antibacterial agent and an auxiliary agent, wherein the auxiliary agent contains a cell nucleating agent and an antioxidant, and based on 100 parts by weight of the polypropylene base resin, the content of the guanidine salt composite antibacterial agent is 0.05-2.0 parts by weight, the content of the cell nucleating agent is 0.01-10 parts by weight, and the content of the antioxidant is 0.01-10 parts by weight. The prepared foamed board / sheethas the characteristics of being easy to slice, excellent in mechanical property, antibacterial, simple and convenient in preparation process, large in multiplying power adjustable range, good in thermal insulation property and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Safety helmet with supplemental inner visor

ActiveUS8250669B2Prevents premature deteriorationEasy to assembleEye treatmentHatsEngineeringMechanical engineering

Protective helmet of the type comprising a first outer visor to intercept the viewing aperture of the helmet mounted rotatably on said helmet, a second visor mounted, inside said first outer visor, rotatably on the cap of the helmet, and a device for actuation and mounting of said second visor on said cap, said second visor including a shielding portion and two ends at the sides of said shielding portion and being at least partly elastically deformable. The inner visor comprises, at least at one side end thereof, a fork and, at or in proximity of one or other of the side ends thereof, at least one externally projecting tooth. Correspondingly, said device for actuation and mounting comprises at least one pin for engaging, directly or indirectly, with said fork and at least one circular guide inside which said projecting tooth of said second visor is removably coupled in a sliding manner, said at least one pin and said at least one circular guide being integral and / or integrated with said cap.

Owner:NOLANGRP

Multi wavelength excitation/emission authentication and detection scheme

ActiveUS20130182241A1Prevent fraudulent useLow costRadiation pyrometryRaman/scattering spectroscopyLength waveComputer science

A system and method for authentication of secure products is disclosed. The security feature contains a first component in the form of an emitter capable of emitting light in response to external pump light. The security feature also contains a second component in the form of a taggant that absorbs light in a spectrally narrow range compared to the broader excitation spectrum of the first material. In this manner the emitter and taggant work in combination with one another to create an emission response significantly dependent on the illumination wavelengths and unique to the specific combination of the components. The emitter and taggant can be in the form of a mixture. Further the emitter and taggant may be applied in close proximity to one another, such as within two separate coating layers on a suitable substrate.

Owner:SPECTRA SYST CORP

Concrete pouring process for large-angel sloping roof

InactiveCN104018674ASimple cuttingIt should be vibrated and compactedBuilding roofsBuilding material handlingBuilding construction

The invention discloses a concrete pouring process for a large-angel sloping roof, and belongs to the field of building construction. The concrete pouring process comprises the following steps: (1) laying bottom-layer wood formworks of the sloping roof; (2) fixing a plurality of guide rails to the bottom-layer wood formworks from the left ends to the right ends in sequence, wherein the guide rails are arranged from the slope bottom to the slope top and respectively composed of two pieces of U-steel, and the openings of the two pieces of U-steel of each guide rail are opposite; (3) installing steel formworks in the guide rails composed of the U-steel, wherein vibrators are installed on the steel formworks respectively; (4) arranging lifting devices on the portions, above the guide rails, of the roof; (5) pouring concrete into the two pieces of U-steel of each guide rail and starting the vibrators at the same time; (6) after pouring the concrete, starting the lifting devices to drive the steel formworks to slide upwards; (7) after the steel formworks slide upwards, secondary grinding is carried out. By means of the concrete pouring process, the traditional double-layer wood formwork construction process is improved, the concrete is easy to feed, vibrating compaction and formwork thickness control are easy, the surface is flat and does not need to be leveled secondarily, and waste of wood is reduced.

Owner:江苏吴州建工集团有限公司

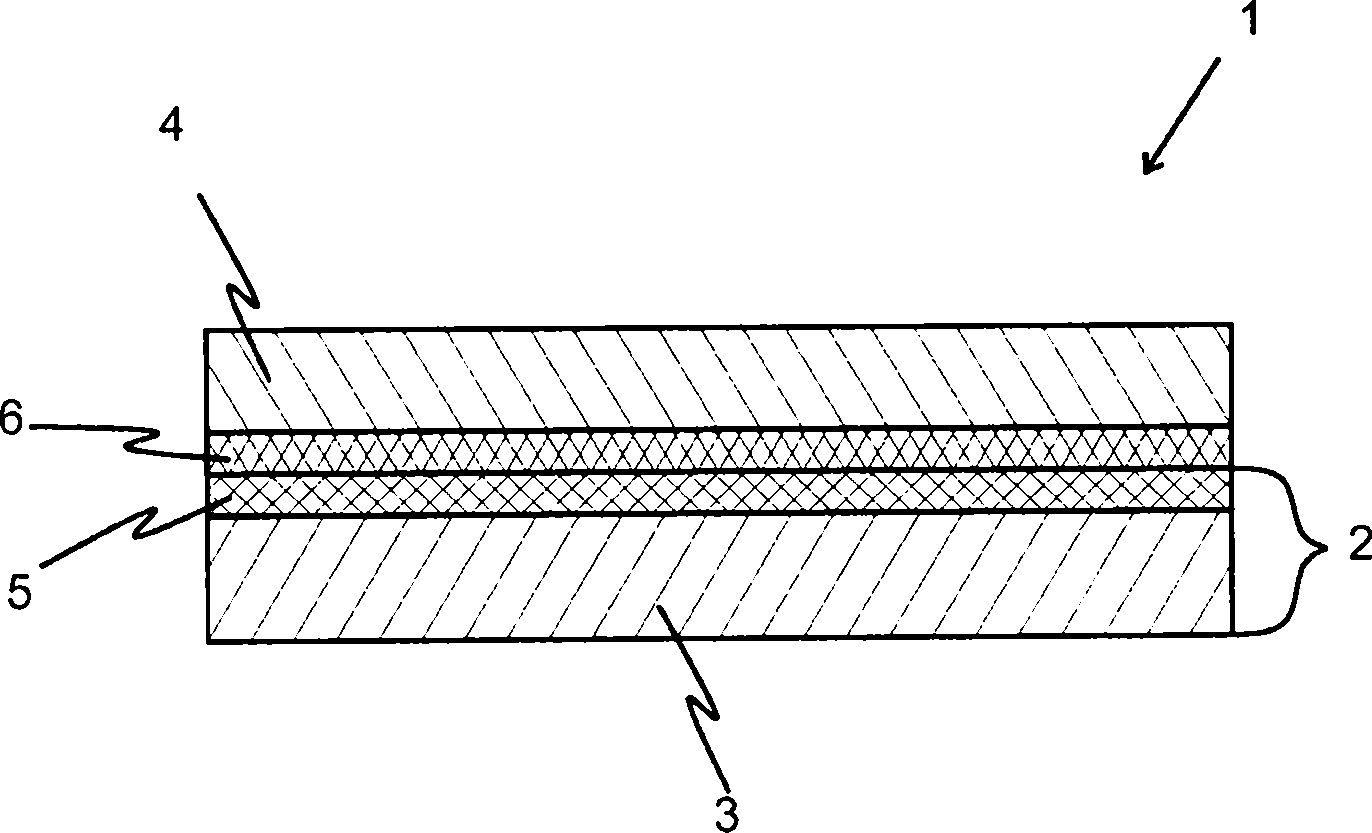

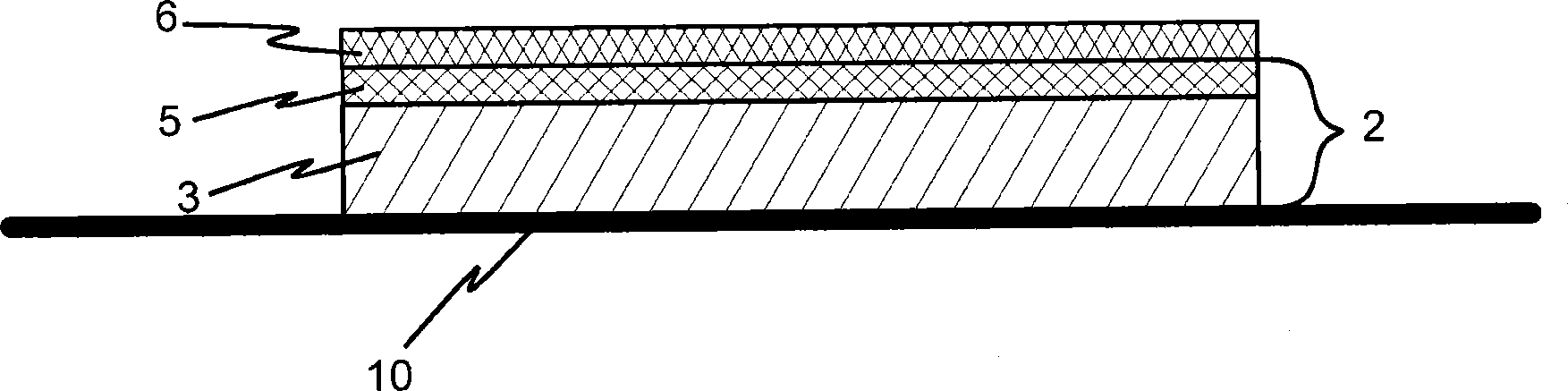

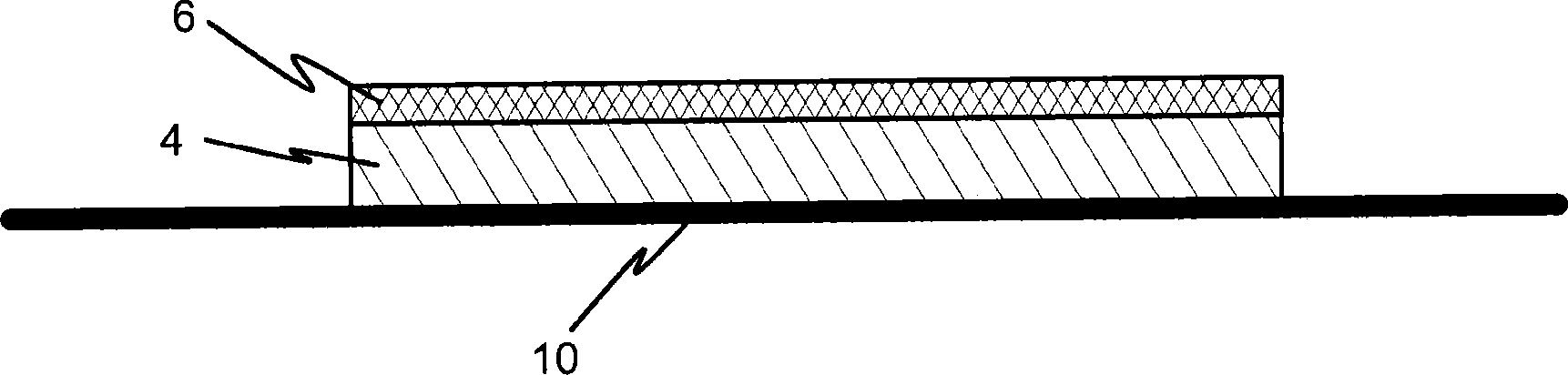

A label laminate and a method and a system for manufacturing a label laminate

InactiveCN103857527ASimple cuttingImprove uniformityStampsLiquid surface applicatorsWater basedMetal

The invention relates to a method for manufacturing a label laminate (1). The method comprises unwinding (11) a first material layer, unwinding (12) a second material layer, coating (15) the first material layer (2,4) with at least one water based adhesive layer (6), supporting the coated first material layer (2,4) by a metal belt while heating said at least one water based adhesive layer by said metal belt (10) in order to dry said at least one water based adhesive layer (6), and laminating the first material layer (2,4) having at least one water based adhesive layer together with the second material layer (2, 4) in order to form the label laminate (1). The invention further relates to a label laminate (1) and a system for manufacturing a label laminate.

Owner:UPM RAFLATEC OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com