Concrete pouring process for large-angel sloping roof

A technology for concrete and sloping roofs, applied in roofs, buildings, building components, etc., can solve the problems of poor control of surface flatness, easy sliding and accumulation of concrete, long pouring time, etc., to improve the turnover rate, construction quality and molding. Improved effect, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

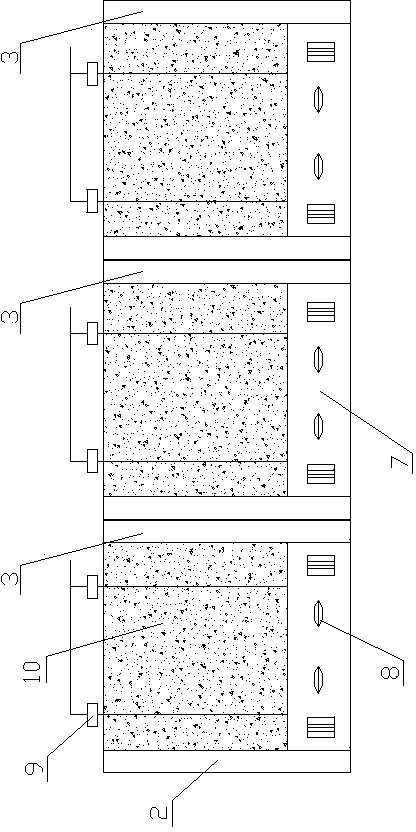

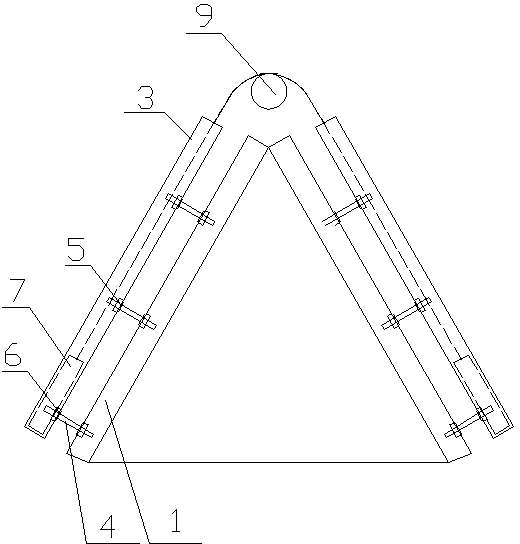

[0020] Combine below figure 1 , 2 , the process steps of the present invention are described in detail:

[0021] 1) Lay the bottom wooden formwork 1 of the sloping roof and tie up the steel bars.

[0022] 2) From the left end to the right end of the bottom wooden formwork 1, three sets of guide rails 3 composed of two channel steels 2 with opposite openings arranged along the direction from the bottom of the slope to the top of the slope are fixed in sequence, and the distance between the two channel steels 2 does not exceed 2.5m , there is no spacing between two adjacent groups of guide rails 3, the channel steel 2 and the bottom wooden formwork 1 are connected by a water-stop screw 4, and the two ends of the water-stop screw 4 are respectively provided with holes for limiting the channel steel 2 and the bottom wood formwork 1 The distance between the stopper 5, the two ends of the water stop screw 4 pass through the channel steel 2 and the bottom wooden formwork 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com