A label laminate and a method and a system for manufacturing a label laminate

A technology for laminated products and labels, which is applied in the direction of labels, laminated, layered products, etc., and can solve the problems of easy shrinkage of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

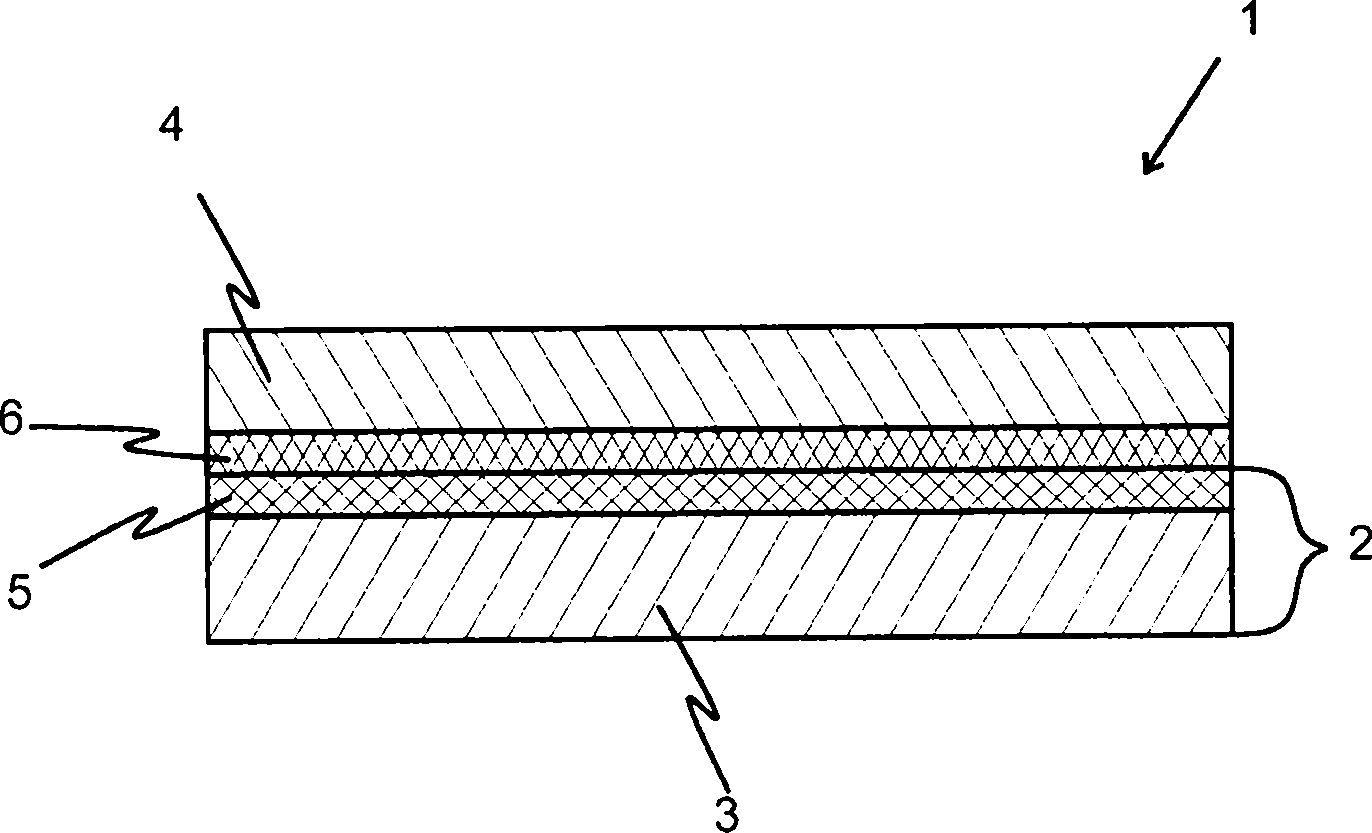

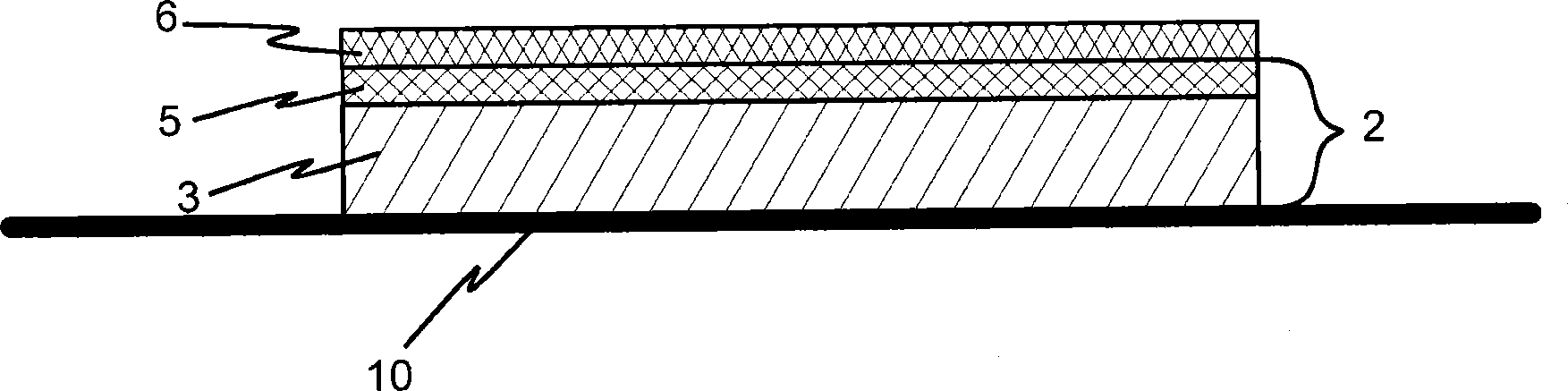

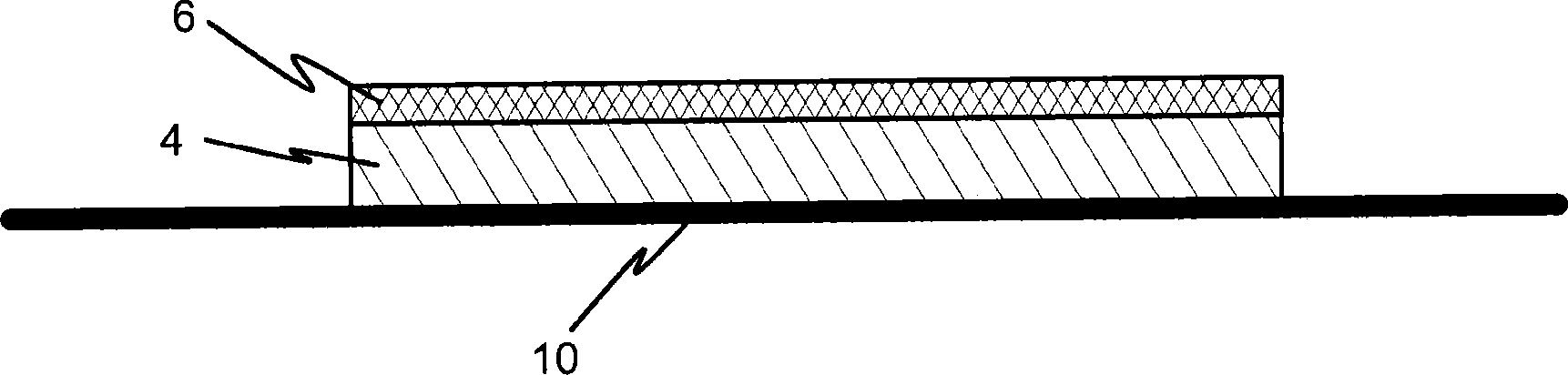

[0047] This application uses the following reference signs:

[0048] 1 label laminate,

[0049] 2 release liner,

[0050] 3 substrate layers,

[0051] 4 surface layers,

[0052] 5 release coating,

[0053] 6 layers of water-based adhesive,

[0054] 10 metal straps,

[0055] 10a the first side of the metal strip,

[0056] 10b the second side of the metal strip,

[0057] 11 first deployment device,

[0058] 12 second deployment device,

[0059] 13 lamination clips,

[0060] 14 Rewinding devices for label laminates,

[0061] 15 coating units,

[0062] 20 induction heating means and / or infrared heating means, and

[0063] 21 air dryer

[0064] In this application, the term "label laminate 1" refers to so-called pressure-sensitive label laminates and self-adhesive label laminates. Preferably, the label laminate 1 comprises two layers laminated together, namely a release liner 2 and a surface layer 4 , wherein an adhesive layer 6 is located between the release liner 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com