Popping bead strength testing instrument

A tester and bead blasting technology, which is applied in the direction of strength characteristics, instruments, and measuring devices, can solve the problems of large manpower loss, long measurement time, and low efficiency, and achieve the effects of simple blanking, convenient layout, and labor-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

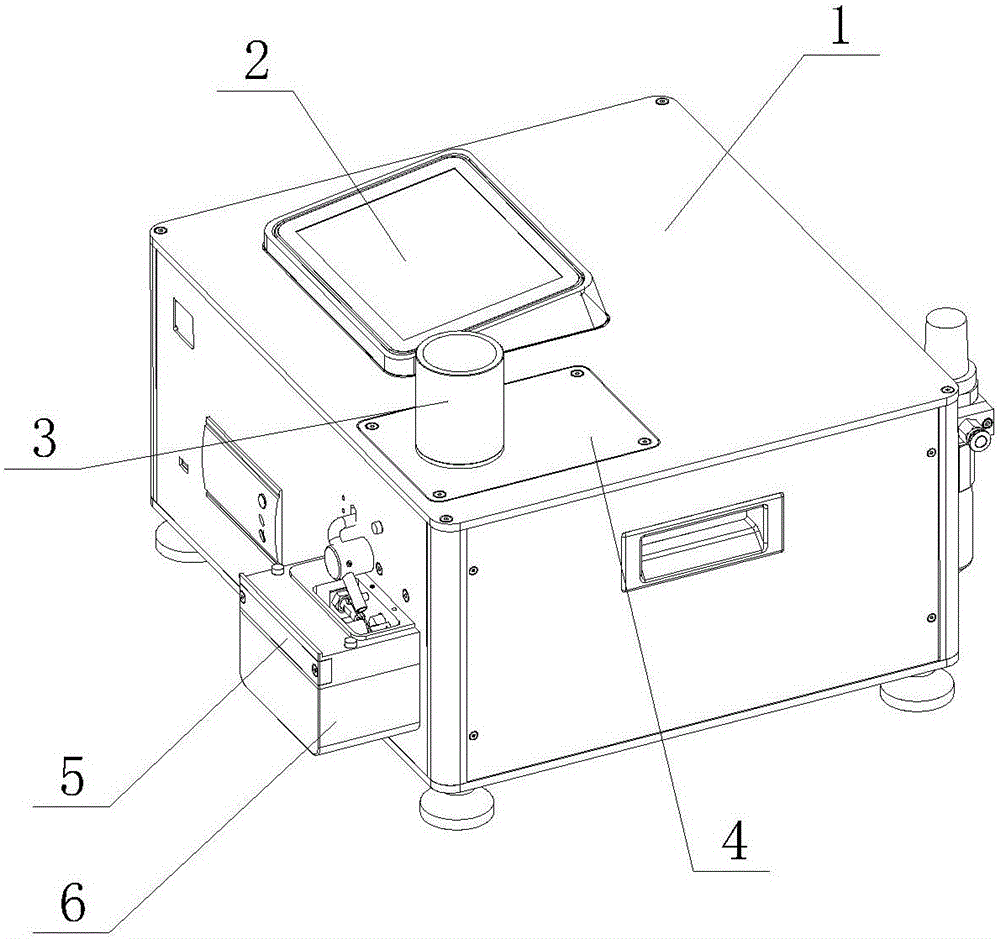

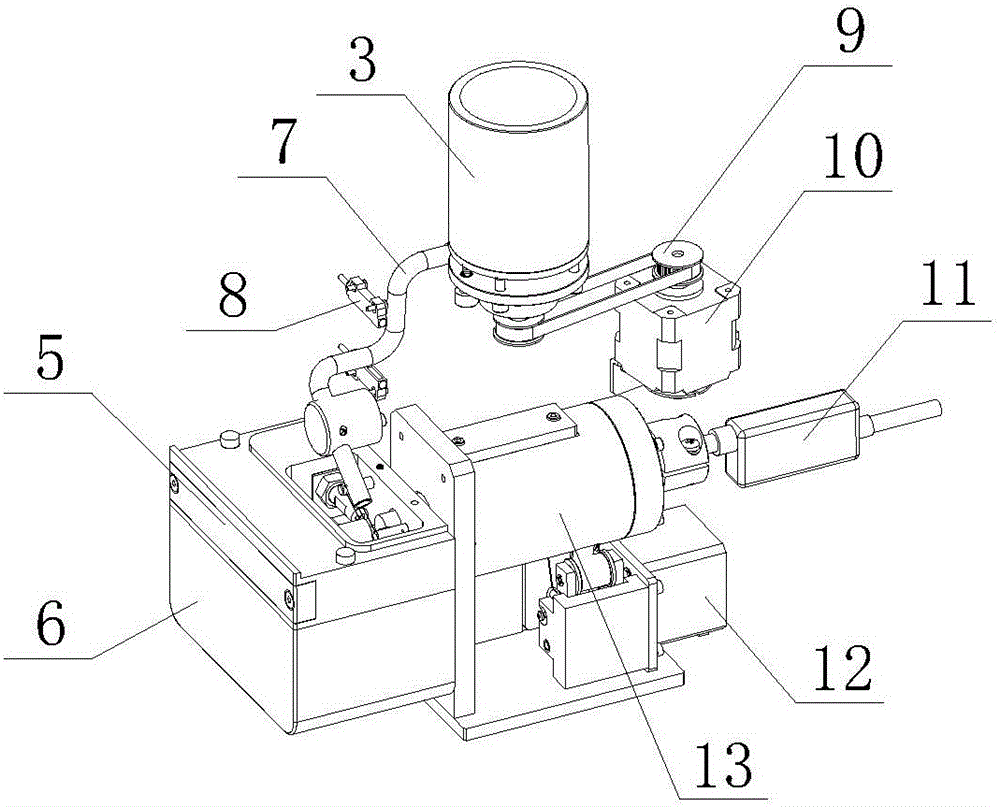

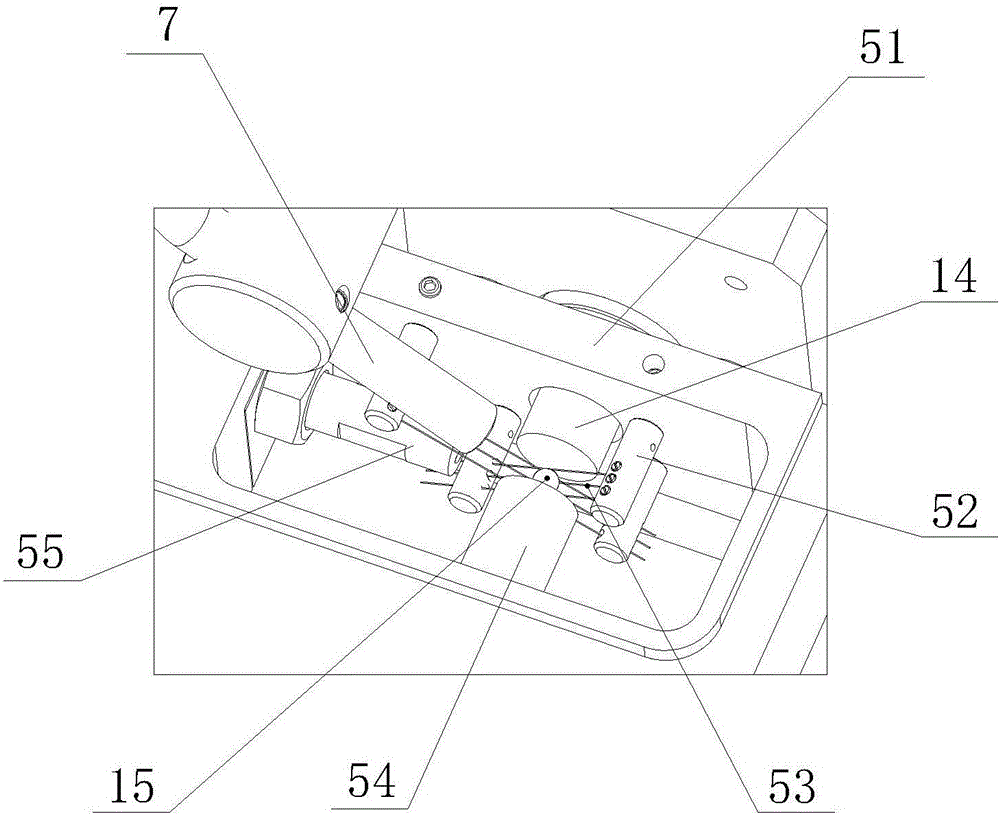

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a cabinet 1, the cabinet 1 is provided with a controller 2 and a feed pressurization mechanism, the feed pressurization mechanism includes a barrel 3, a stage 5, a pressure head 14, a compression mechanism 13 and a compression motor 12, The pressure head 14 is fixed on the compression end of the compression mechanism 13, and the compression motor 12 is driven and connected with the compression mechanism 13. The sensor and the steel wire groove used to position and support the explosive ball 15, the pressure head 54 is rigidly connected with the pressure sensor, one end of the pressure head 14 faces the pressure head 54, and the other end of the pressure head 14 is connected with a grating ruler 11, and the steel wire groove is located at Between the pressure head 54 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com