Patents

Literature

34results about How to "No leftovers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

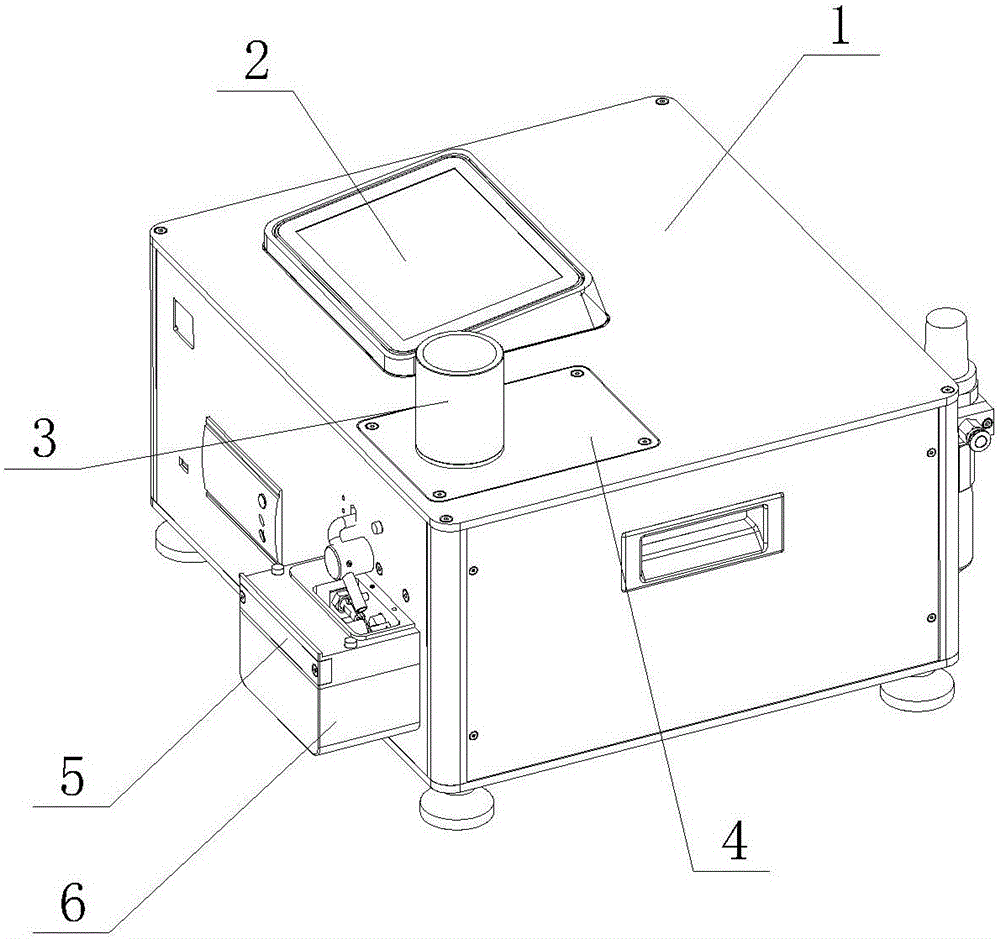

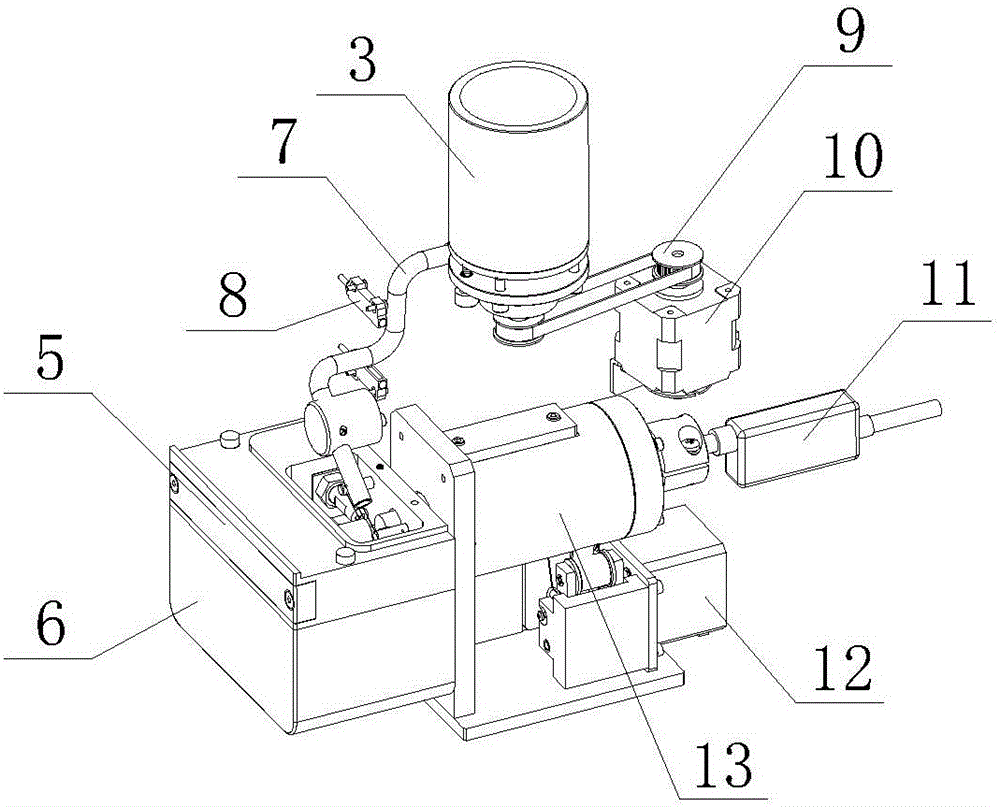

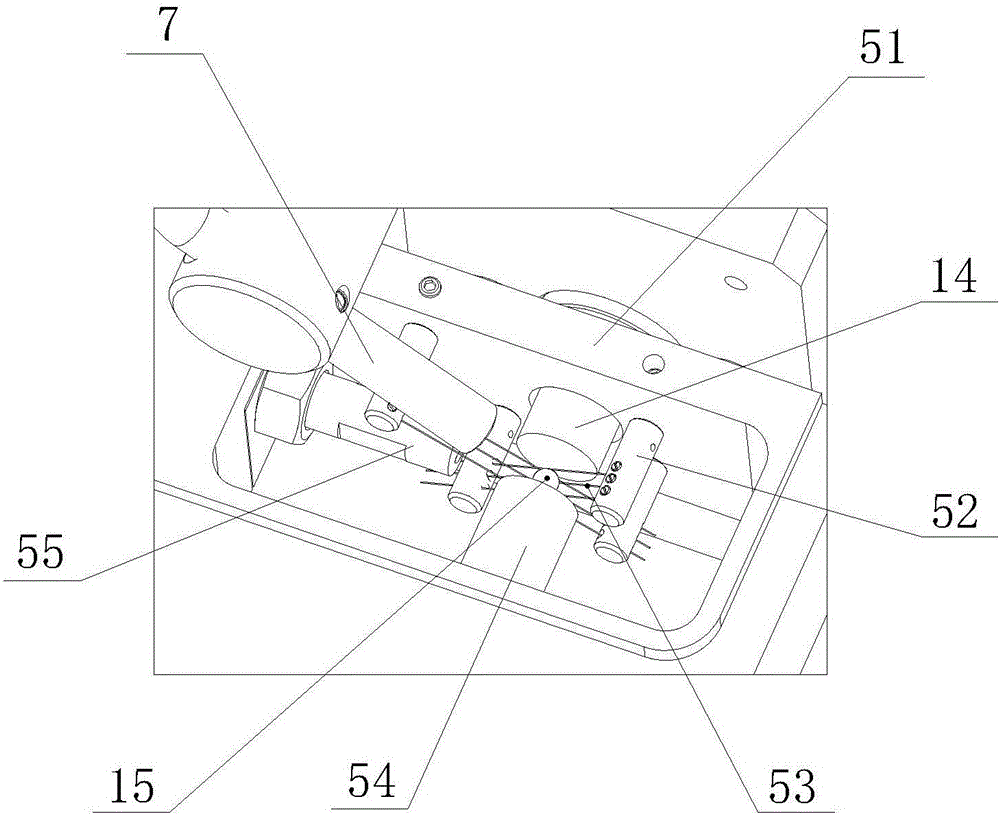

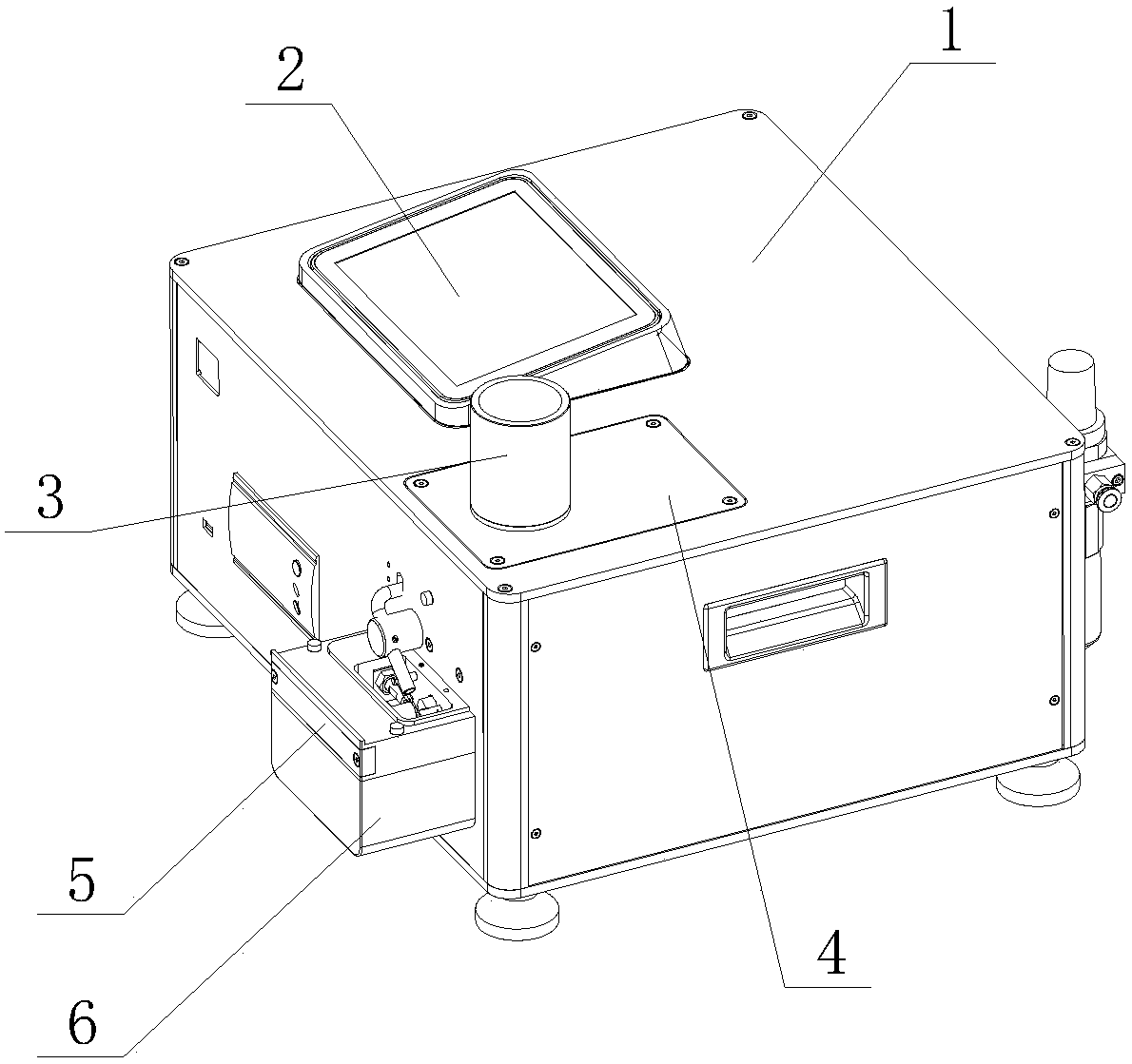

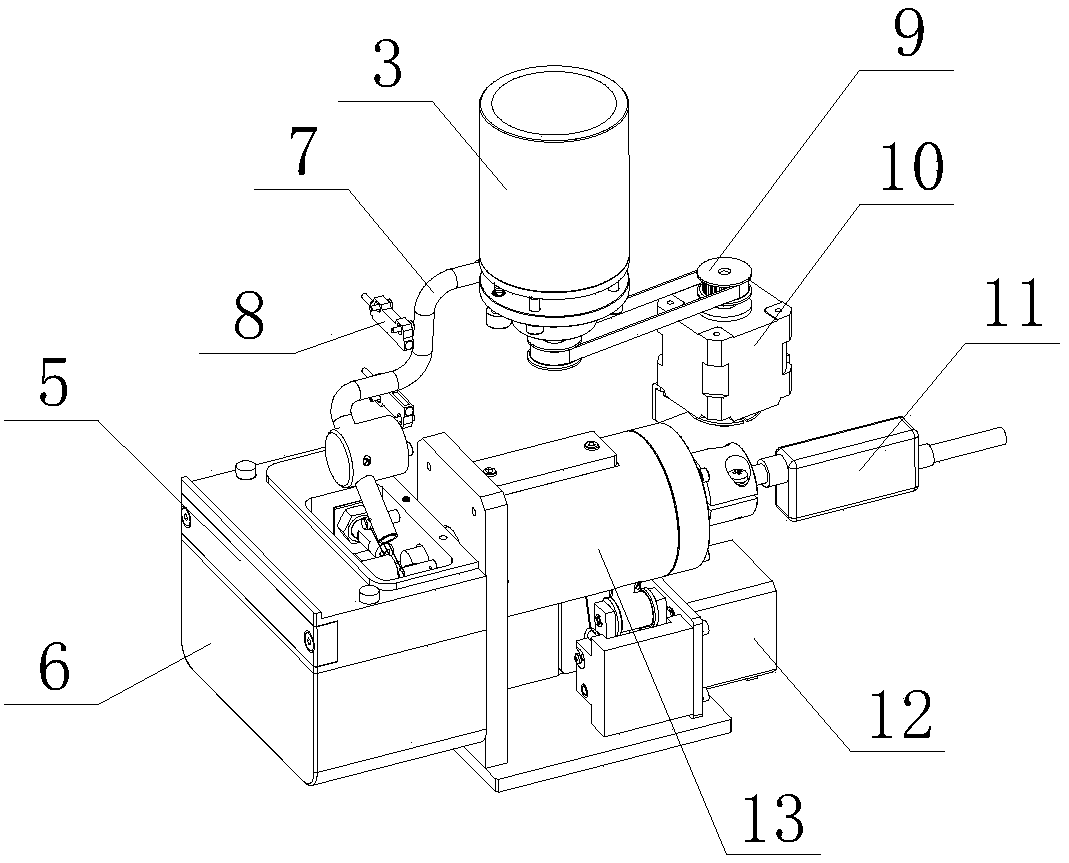

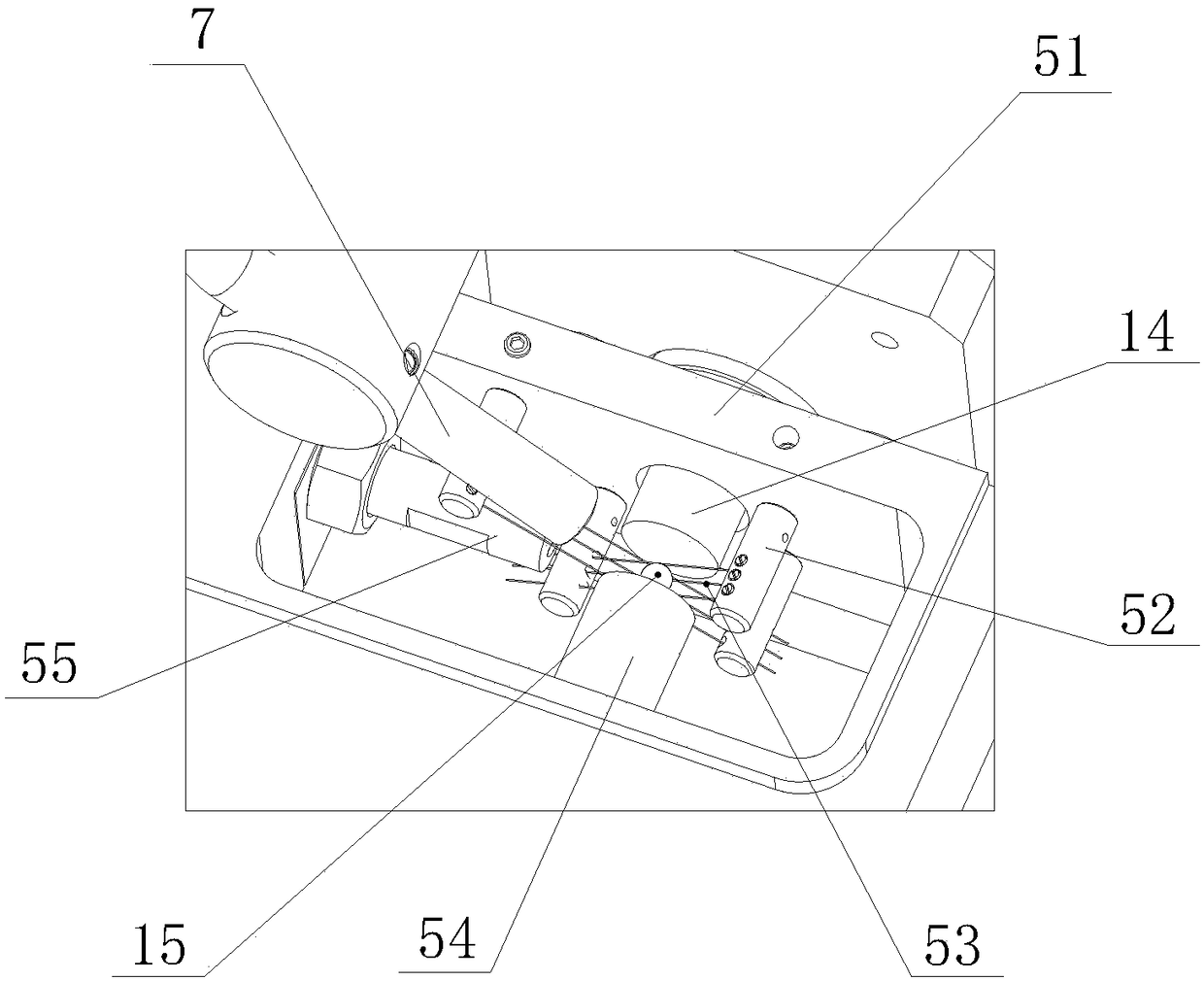

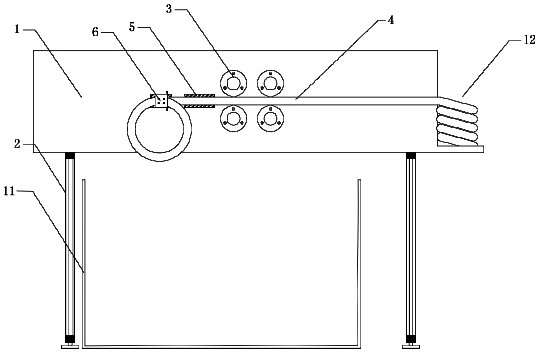

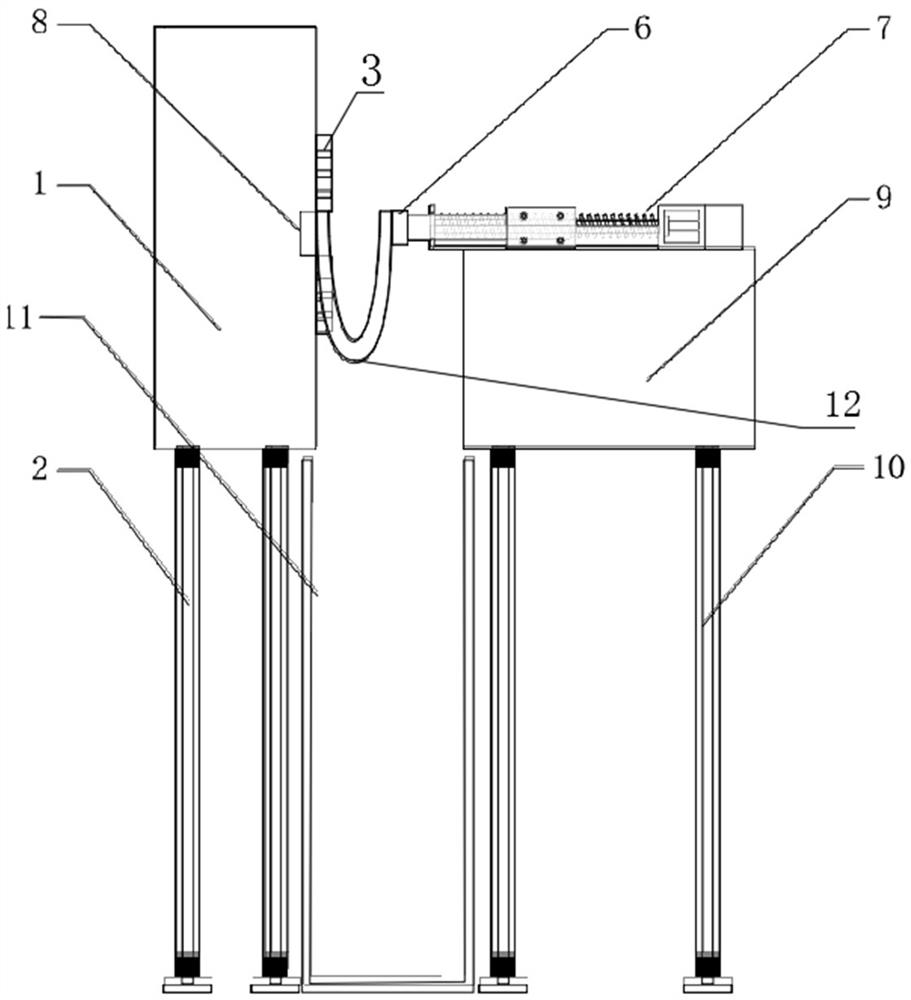

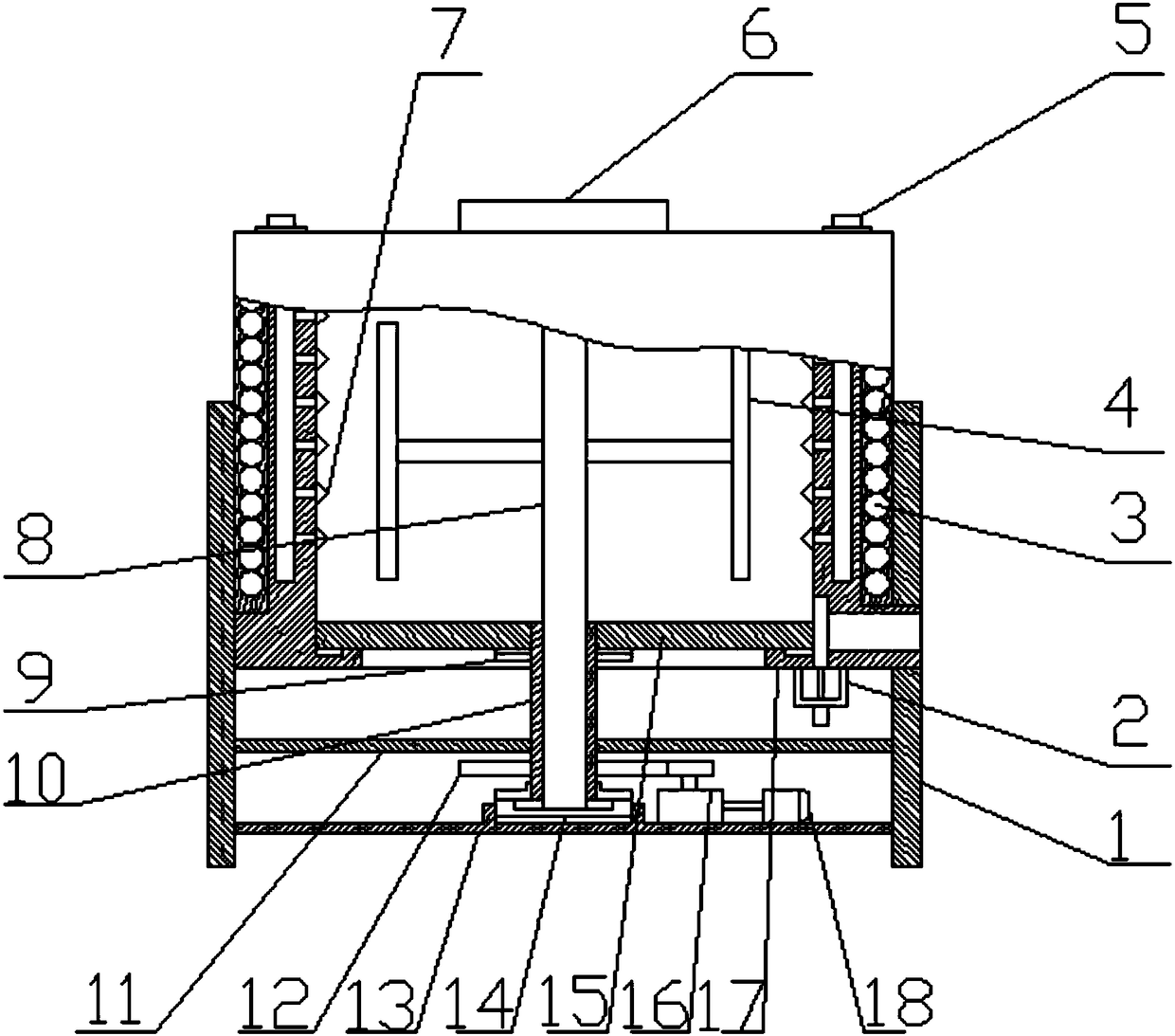

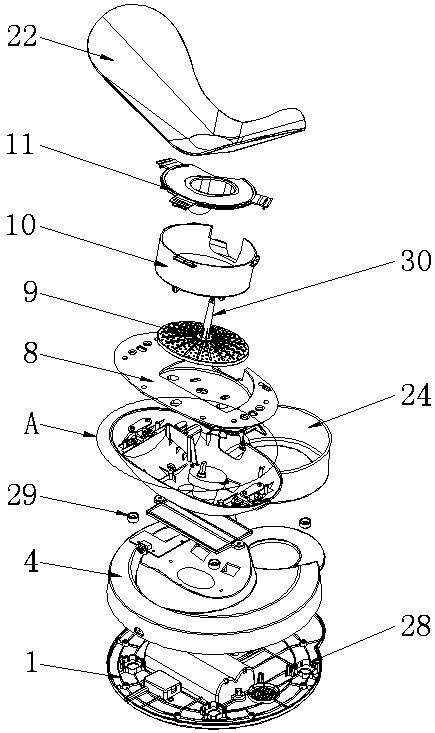

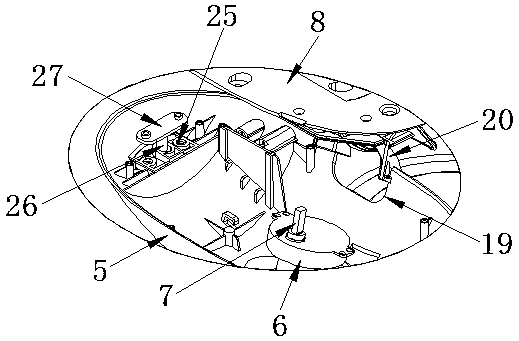

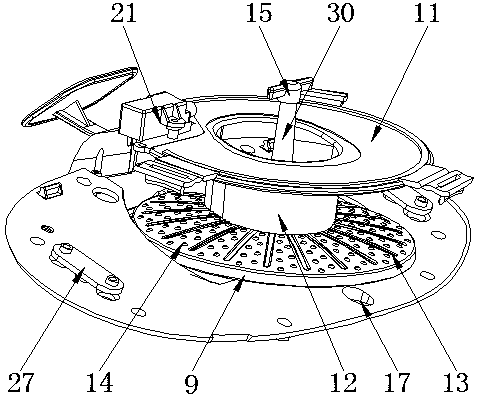

Popping bead strength testing instrument

ActiveCN105758729ASave labor efficiencySimple cuttingMaterial strength using tensile/compressive forcesEngineeringPressure sensor

The invention discloses a popping bead strength testing instrument which comprises a case.The case is provided with a controller and a feeding pressurizing mechanism.The feeding pressurizing mechanism comprises a material barrel, a carrying table, a pressure head, a compressing mechanism and a compressing motor, wherein the pressure head is fixed to the compressing end of the compressing mechanism, and the compressing motor is in driving connection with the compressing mechanism.The carrying table comprises a carrying table support, and the carrying table support is provided with an air blowing pipe, a pressure-bearing head, a pressure sensor and a steel wire groove, wherein the pressure-bearing head is in rigid connection with the pressure sensor, one end of the pressure head right faces the pressure-bearing head, a grating ruler is connected to the other end of the pressure head, the steel wire groove is located between the pressure-bearing head and the pressure head, a discharging port of the material barrel is provided with a flexible material guide pipe, an air blowing opening of the air blowing pipe faces the steel wire groove, a popping bead detector is arranged in a pipeline of the material guide pipe, and the pressure sensor, the grating ruler and the popping bead detector are electrically connected with the controller.The popping bead strength testing instrument is capable of saving manpower and high in efficiency, the discharging process is simple, the material barrel can be quickly replaced to be compatible to samples with different diameters, and material jamming and residual materials can be avoided.

Owner:CHENGDU RETOOL SCI & TECH CO LTD

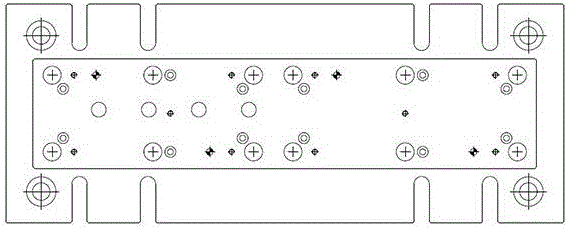

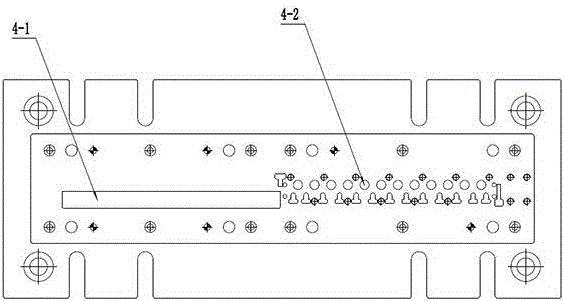

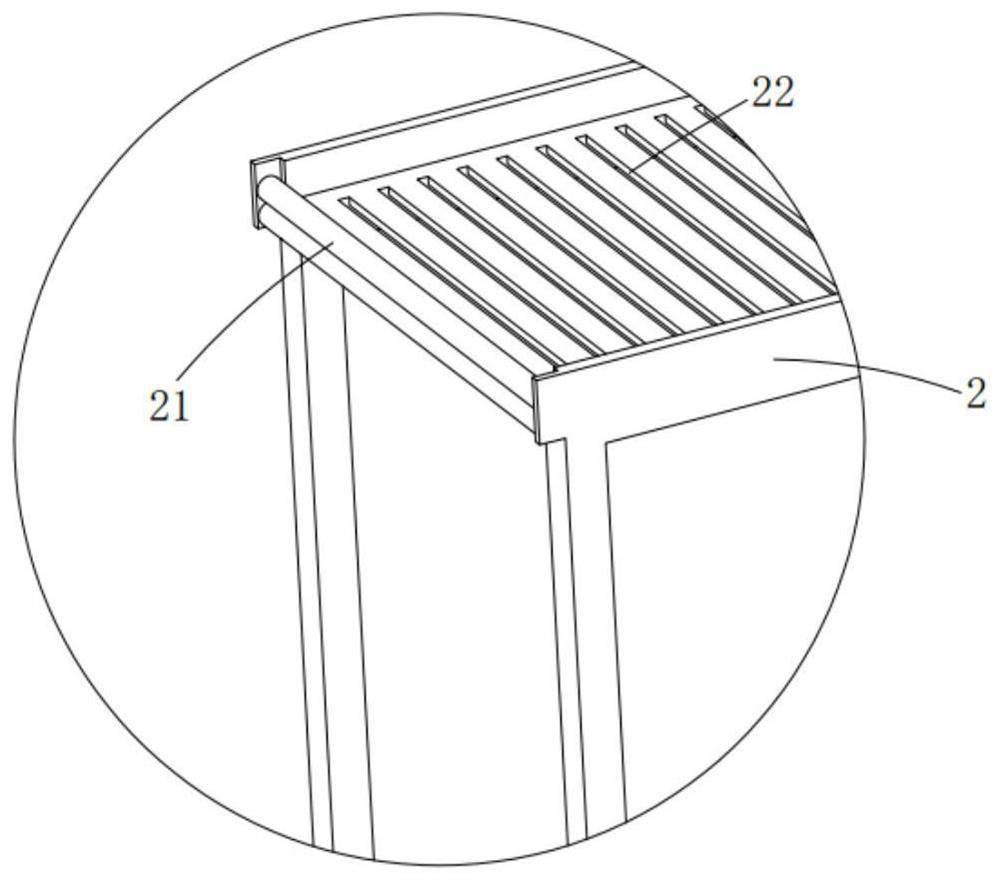

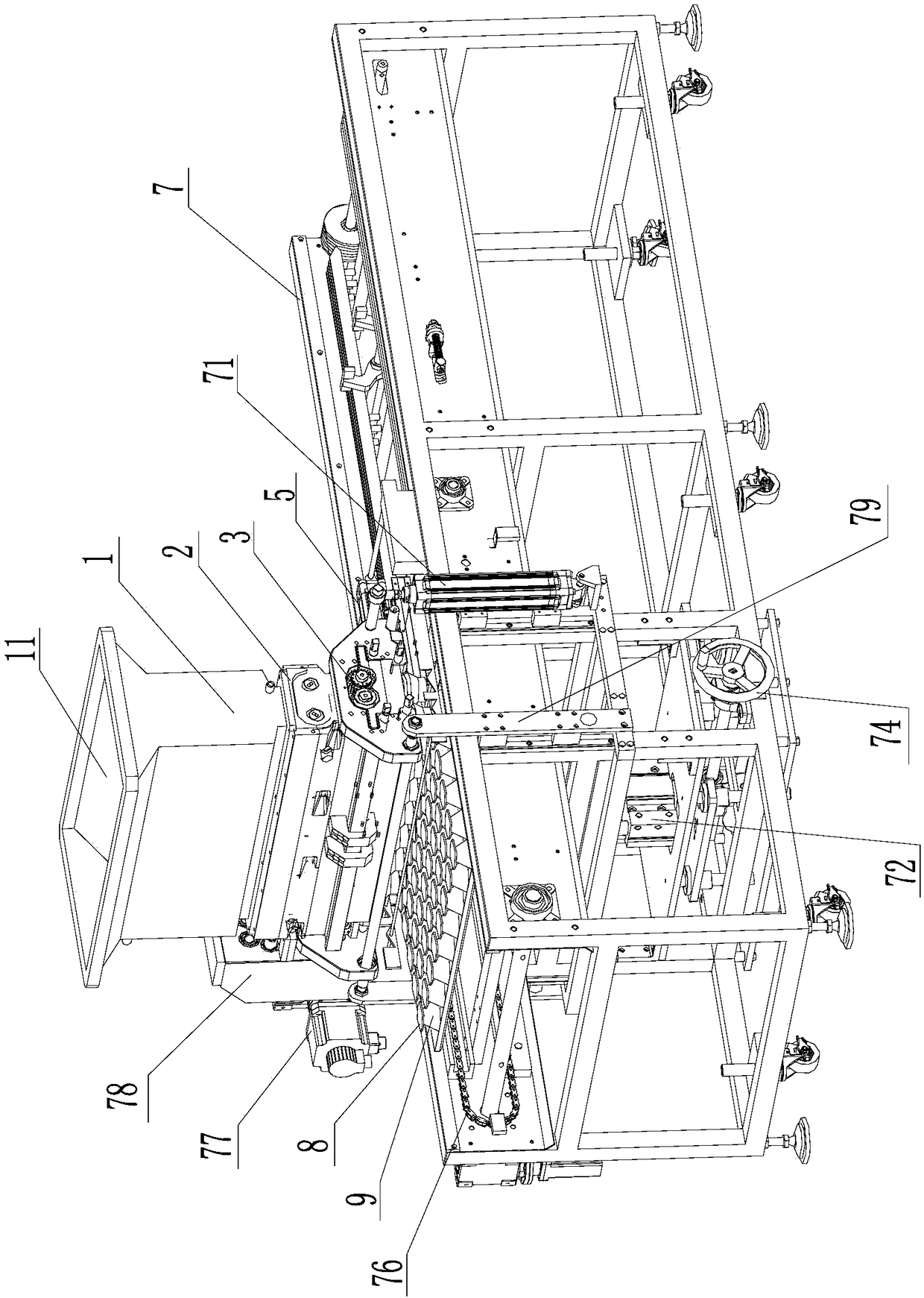

Fixed angle iron waste-material-free punching forming method, mold and production line

The invention discloses a fixed angle iron waste-material-free punching forming method, mold and production line, and belongs to the technical field of fixed angle iron manufacturing equipment, mold and manufacturing method. The forming method provided by the invention is characterized in that direct outsourcing steel belt rollers are mainly used as raw materials; the punching forming is performed by a material conveying mechanism and a punching mechanism. A punching mold is invented on the basis of the method; the front half part of a female template of the mold is a hole punching female mold used for punching holes in raw materials; the back part of the female mold of the mold is a bending female mold used for bending material sheets subjected to the hole punching; a hole punching head is fixed in a position, corresponding to the hole punching female mold, of the punching head fixing plate; a bending punching head is fixed in a position corresponding to the bending female mold; a cutting punching head used for cutting the material sheets is arranged on the punching head fixing plate corresponding to a position between the hole punching female mold and the bending female mold. The invention also provides a punching protection line based on the mold. The method, the mold and the production line provided by the invention have the advantages that the punching bending forming work procedures are simple and convenient; the forming speed is high; the production efficiency is greatly improved; no leftover is left; the production cost is greatly reduced.

Owner:CANGZHOU ORBON ELECTRICAL & MECHANICAL PROD MAKING

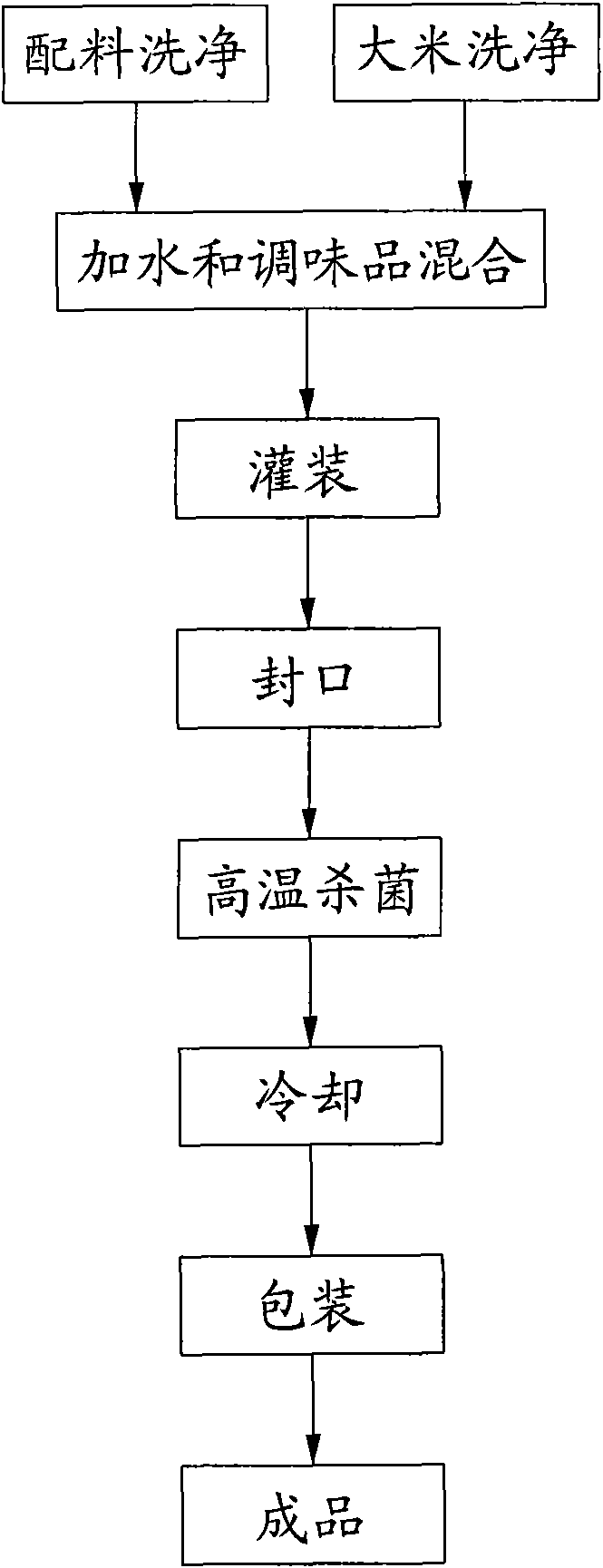

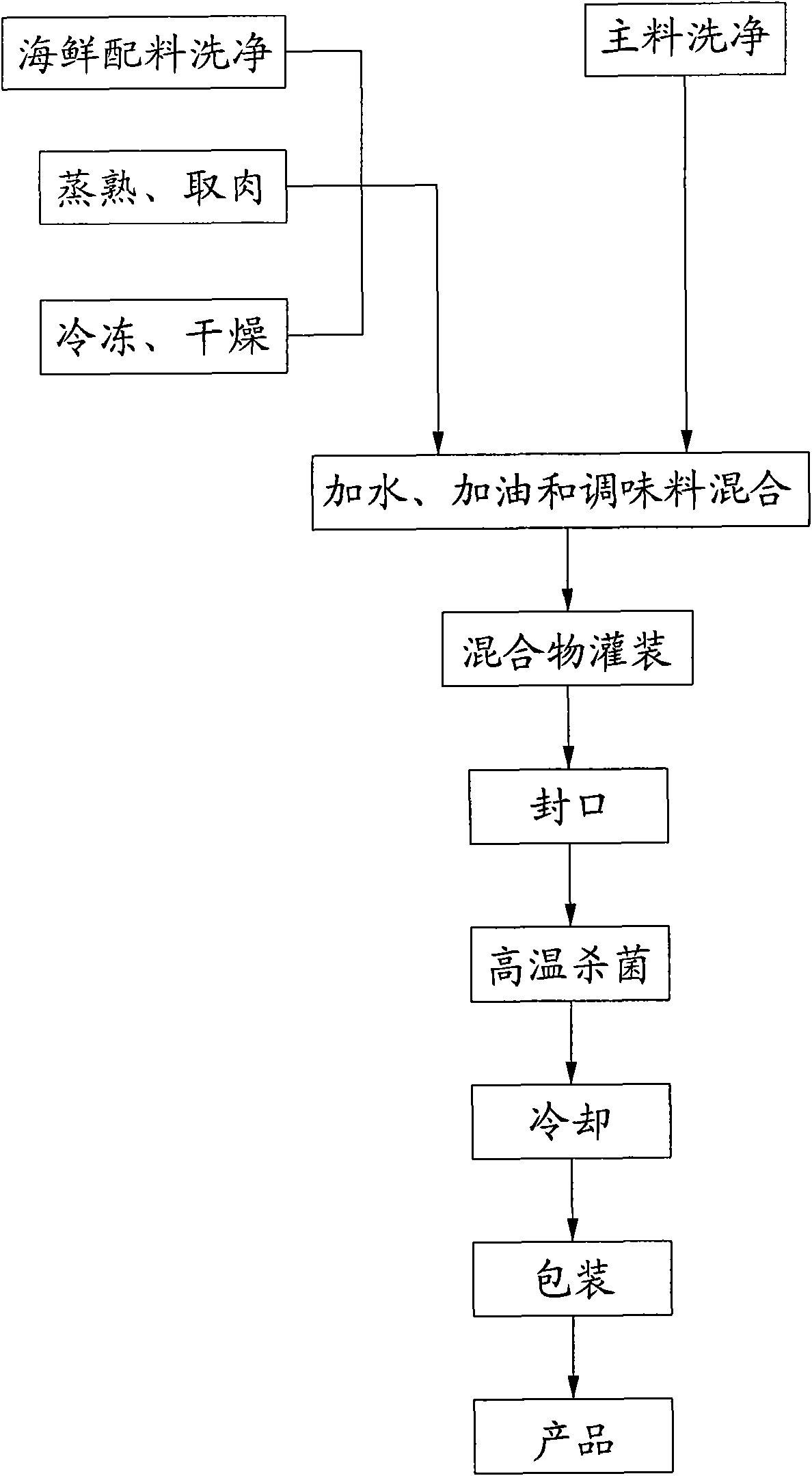

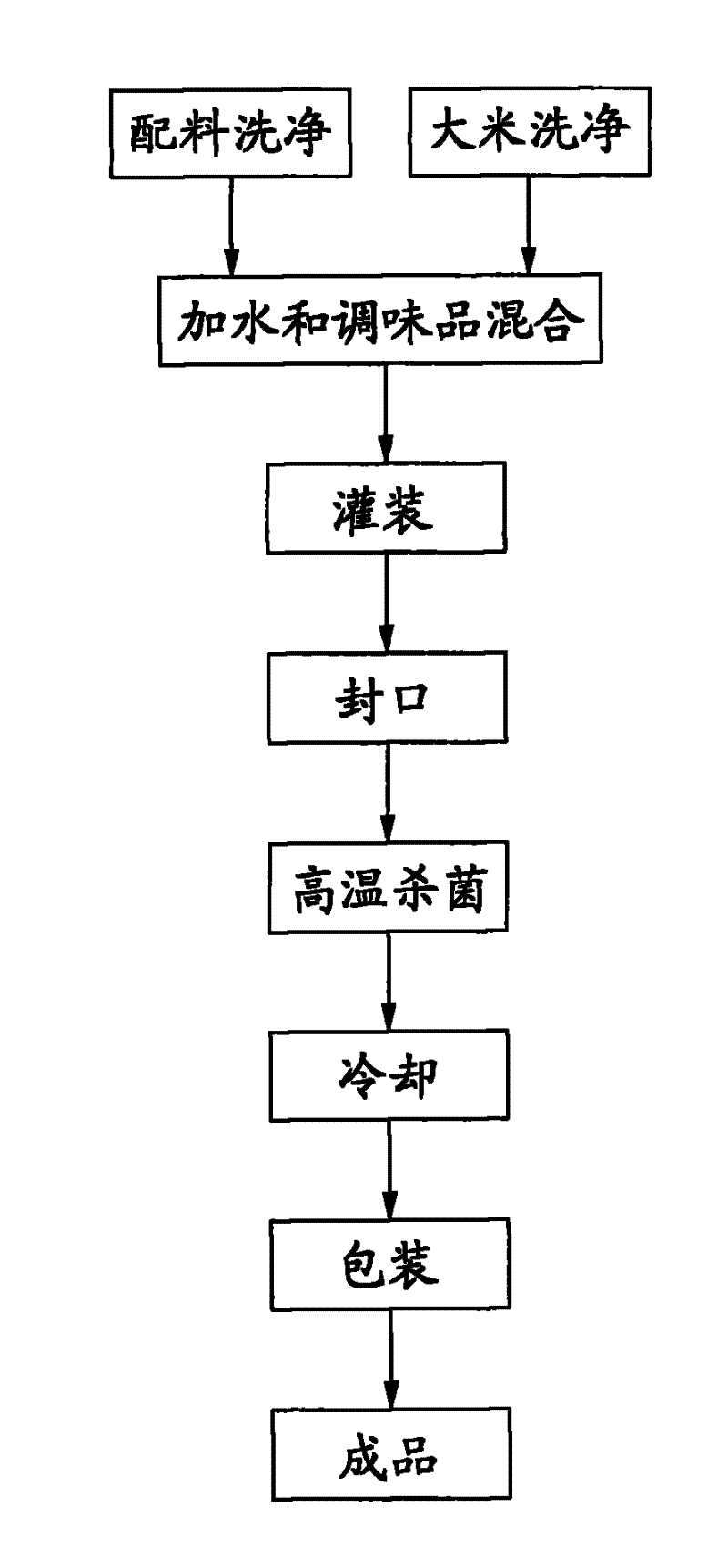

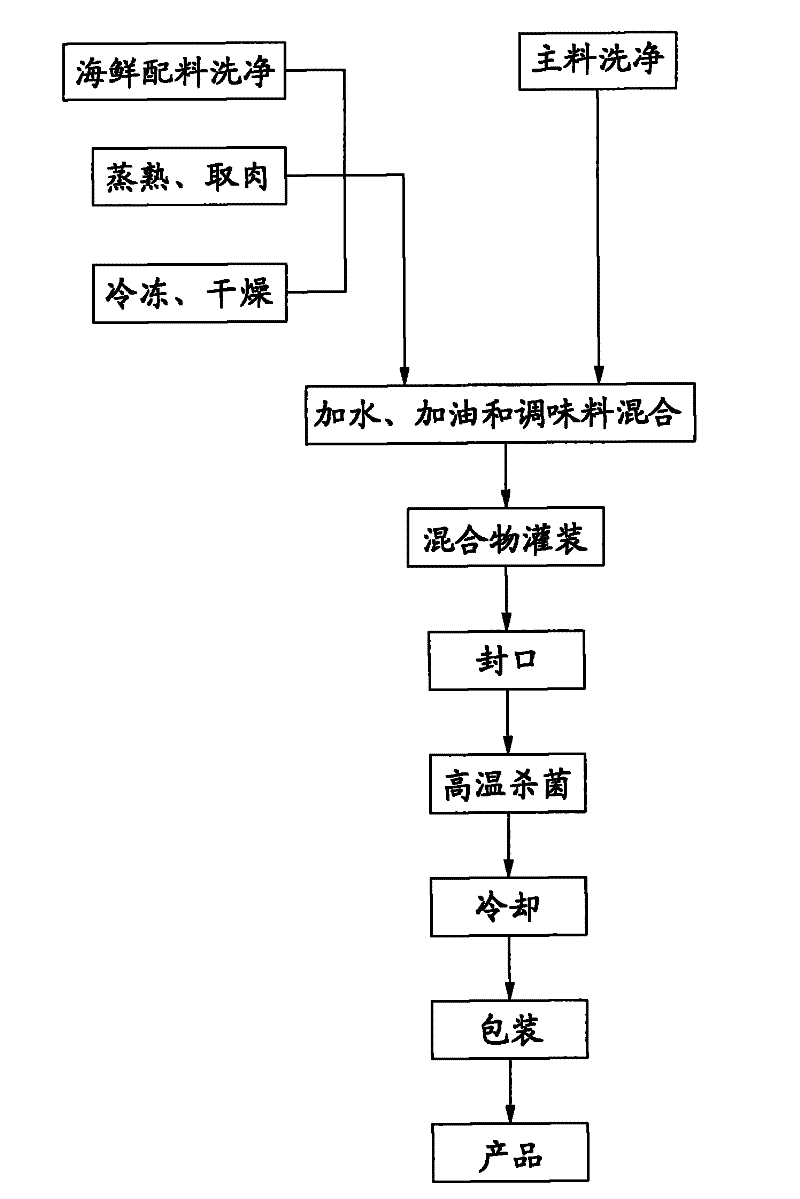

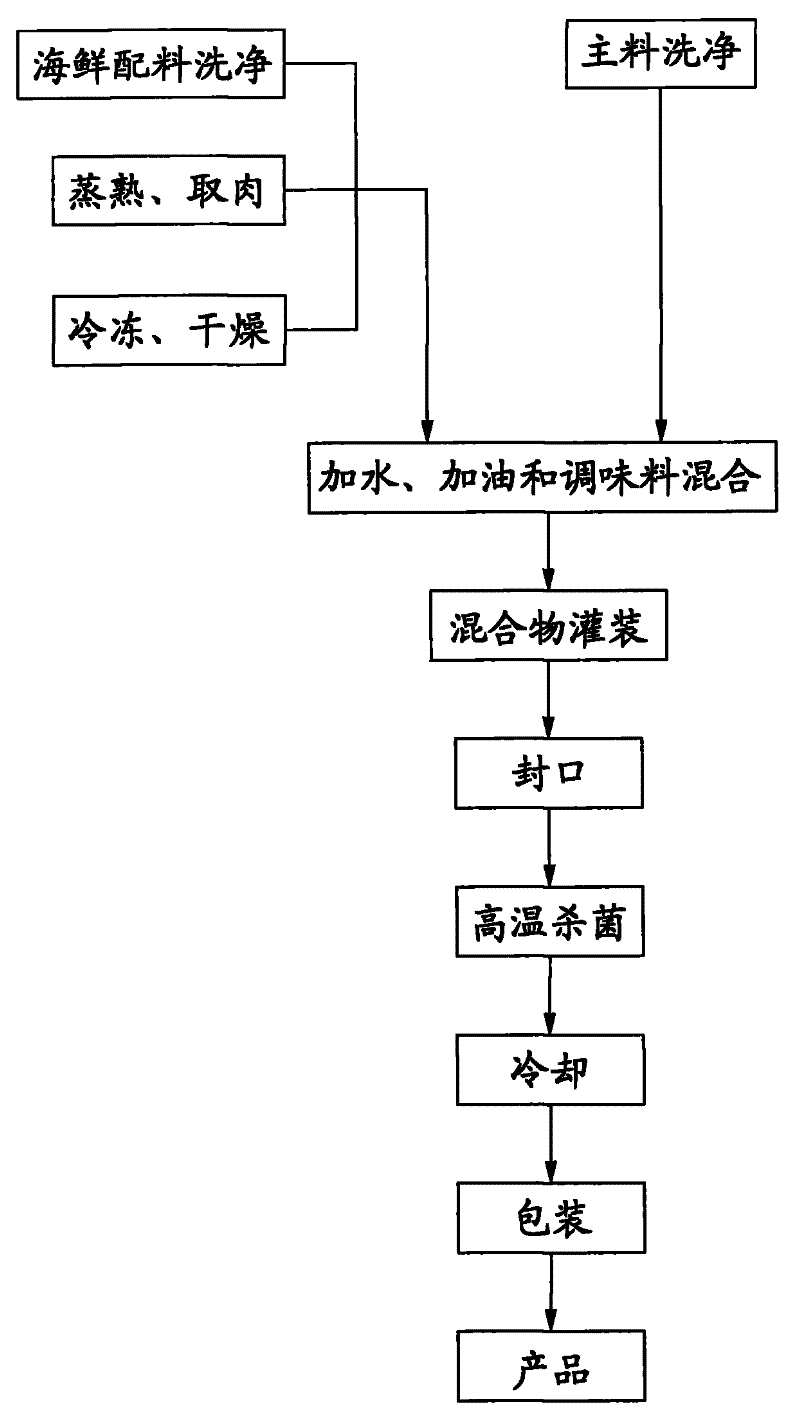

Processing method of seafood instant congee

The invention discloses a processing method of seafood instant congee, comprising the steps as follows: washing the main ingredients for standby use; washing and steaming the seafood ingredients, taking out the meat, refreezing and drying the meat for standby use; taking the washed main ingredients and refrozen and dried seafood ingredient, adding water, oil and flavoring for mixture; filling and sealing the mixture; sterilizing the mixture at high temperature, cooling and packaging the mixture, thus obtaining the product. In the method, the seafood ingredients are first steamed and then the meat is taken, refrozen and dried, so that the odors of the seafood ingredients are removed and freshness is improved, thereby ensuring delicate flavor of the seafood. In addition, the dried seafood ingredients can not be boiled out and become pasty but are still in cakes, thereby ensuring mouthfeel and color of the seafood; therefore, the product produced by the method is good in color, aroma and taste; the processing and production courses are environment-friendly and sanitary and the leftovers can be comprehensively utilized, thus having little pollution and high social and economic benefits.

Owner:XIAMEN BAOLINTAI SEAFOOD FOODSTUFF

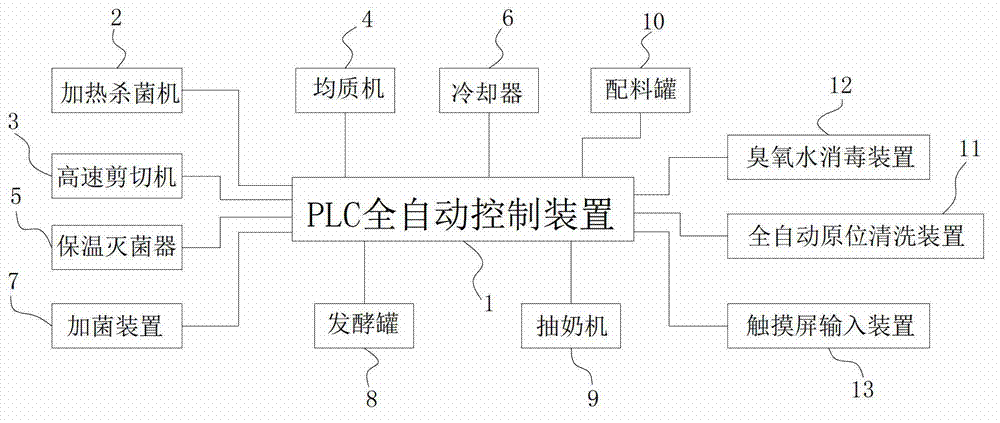

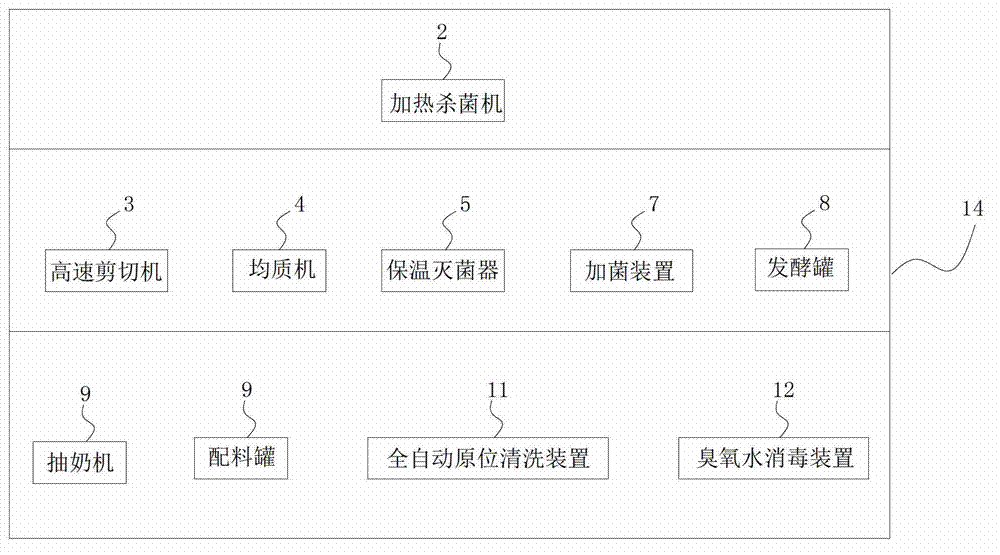

Full-automatic yoghourt integrated machine

InactiveCN102823647ASmall footprintNo leftoversMilk preparationAutomatic controlProgrammable logic controller

The invention relates to a yoghourt machine, and in particular discloses a full-automatic yoghourt integrated machine. PLC (Programmable Logic Controller) full-automatic control devices, and a heating sterilization machine, a high-speed shearing machine, a homogenizer, a heat preservation sterilization machine, a cooler, a bacterium adding device, a fermentation tank, a milk pumping machine, a make-up tank, a full-automatic in-situ washing device and an ozone water disinfection device which are connected with and controlled by the PLC full-automatic control devices are integrated inside the integrated machine in upper, middle and lower layers. By adoption of the yoghourt machine, not only is the yoghourt production is transferred to a custom terminal so as to prevent the pollution of the yoghourt during the production, transportation and storage processes, but also the yoghourt machine has the characteristics of being small in energy consumption, complete in function and small in occupied space.

Owner:GANSU TIANFANG FOOD CO LTD

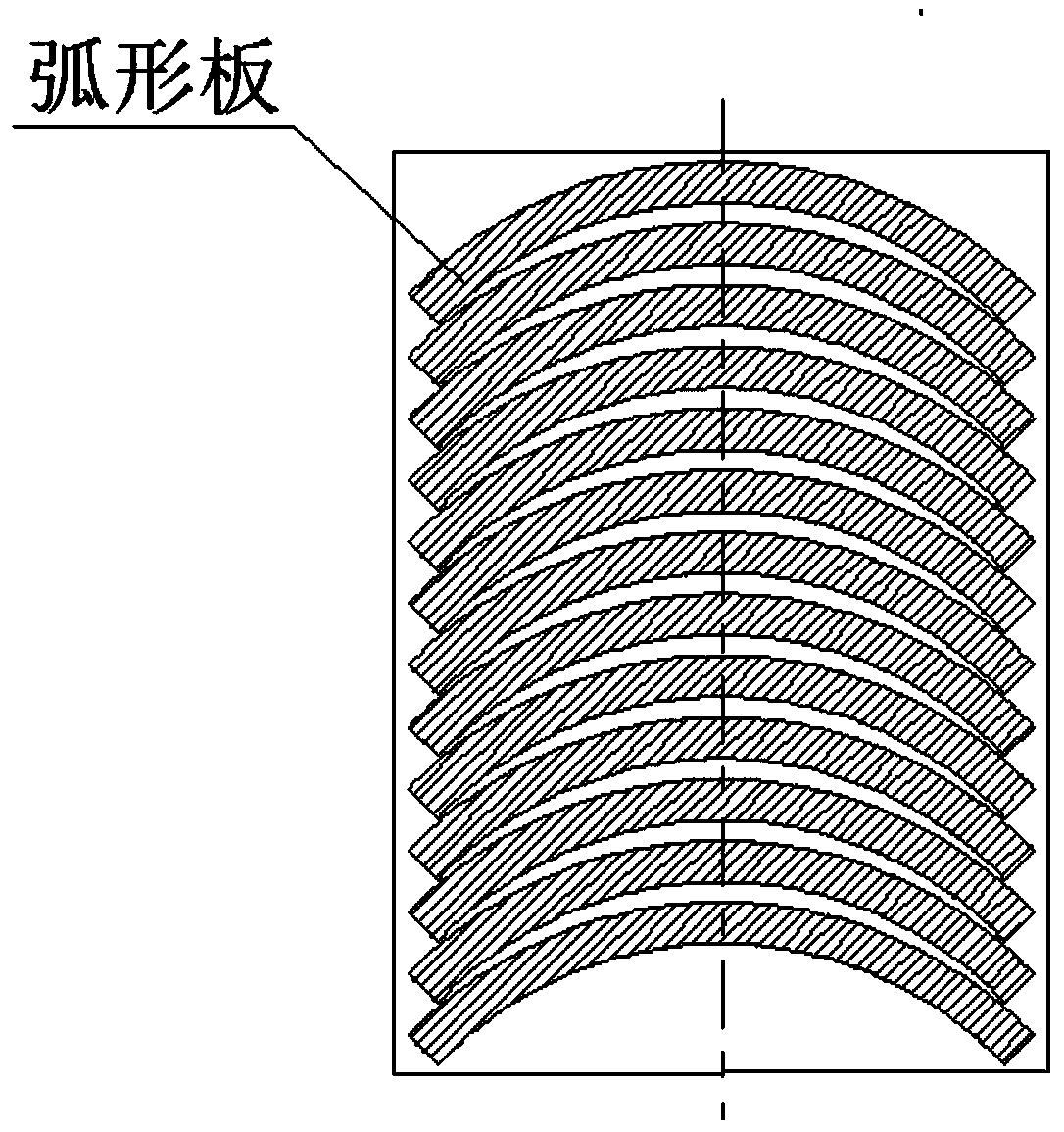

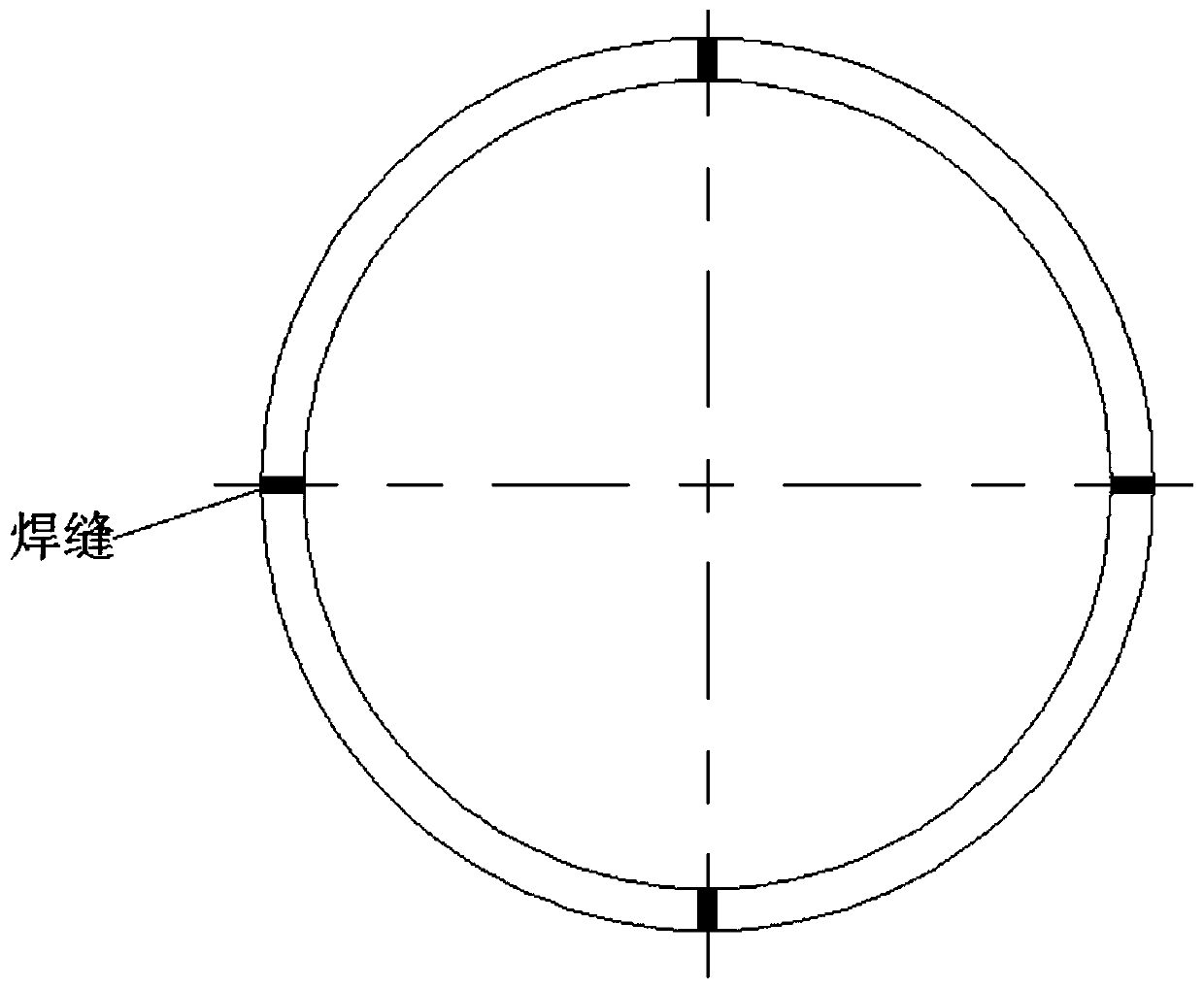

Manufacturing method of large-diameter thin-wall circular ring of pressure bearing equipment

The invention provides a manufacturing method of a large-diameter thin-wall circular ring of pressure bearing equipment and relates to a manufacturing method of the thin-wall circular ring. The purpose is to solve the problems that the production efficiency of an existing discharging, tailor welding and forming method for a multi-section arc plate steel plate of the large-diameter thin-wall circular ring is low, and the material cost and the manufacturing expense are high. The method comprises the steps that the steel plate is discharged, a longitudinal joint groove is machined, the steel plate is rolled into a cylinder body and subjected to tailor welding, a rigid supporting assembly is installed in the cylinder body in a welding manner, and the cylinder body is cut into multiple circularrings by a turning cutter on a turning lathe. According to the method, the number of machined grooves and the number of weld joints are reduced remarkably, the production efficiency is high, corner excess materials are not generated, the material utilization rate is increased, and the material cost and the manufacturing expense are reduced. The method is applicable to manufacturing of a large-diameter thin-wall circular ring part structure in the pressure bearing equipment.

Owner:HARBIN BOILER

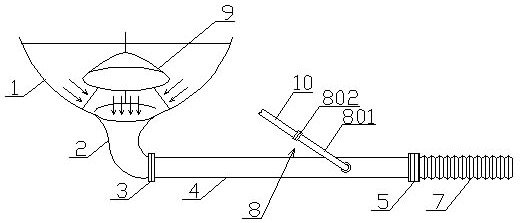

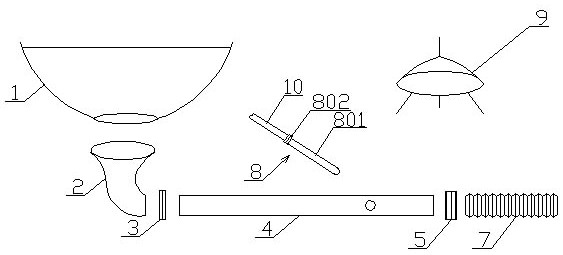

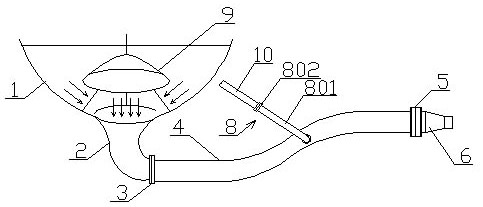

Lower discharging device of powder and particle material transport vehicle

PendingCN112109621AReasonable designSimple structureTank vehiclesLoading/unloading vehicle arrangmentButterfly valvePipe

The invention provides a lower discharging device of a powder and particle material transport vehicle and belongs to the technical field of manufacturing of powder and particle material transport vehicles. The lower discharging device structurally comprises a reducing elbow arranged on a tank body; the reducing elbow is arc-shaped; the diameter of one end of the reducing elbow is relatively small;the diameter of the other end of the reducing elbow is relatively large; the large-diameter of the reducing elbow communicates with the bottom of the tank body; the small-diameter end of the reducingelbow communicates with the feeding end of a connecting material pipe through a flange; the discharging end of the connecting material pipe is connected with a quick coupling or a discharging hose through a discharging butterfly valve; a material boosting device is arranged on the connecting material pipe; and a gas collection dustproof device is arranged right above the joint of the reducing elbow and the tank body in the tank body. The lower discharging device has the advantages of reasonable design, simple structure, small size, smooth discharging, convenience in use and the like.

Owner:张法英

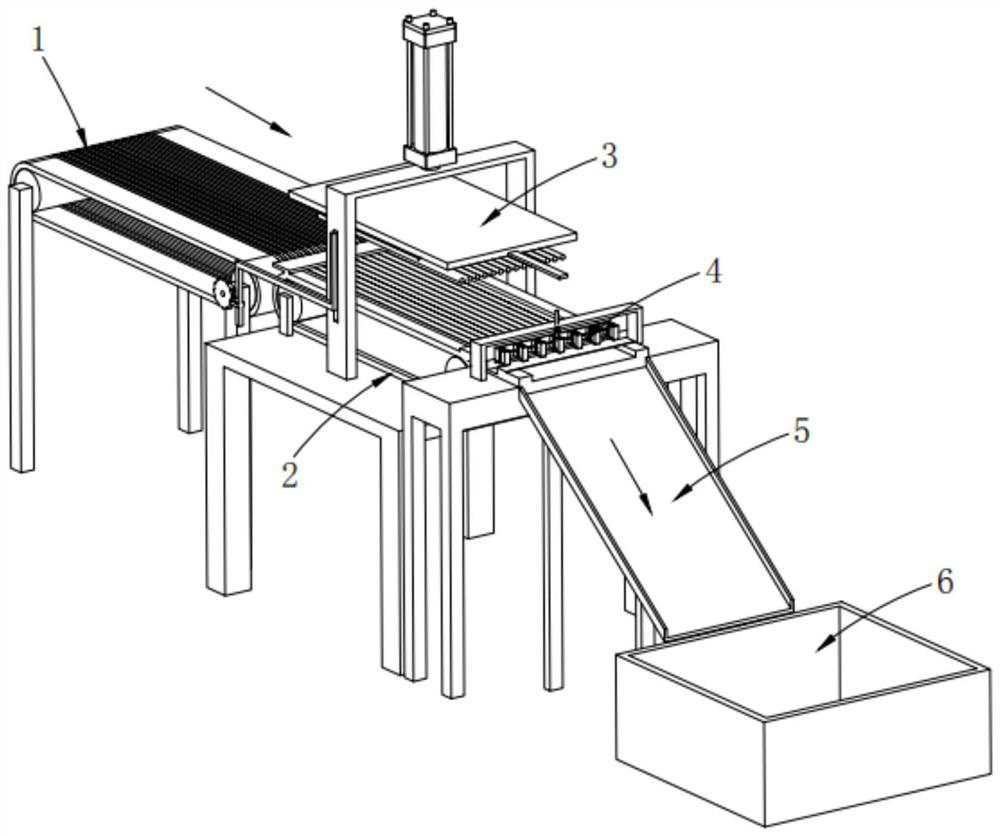

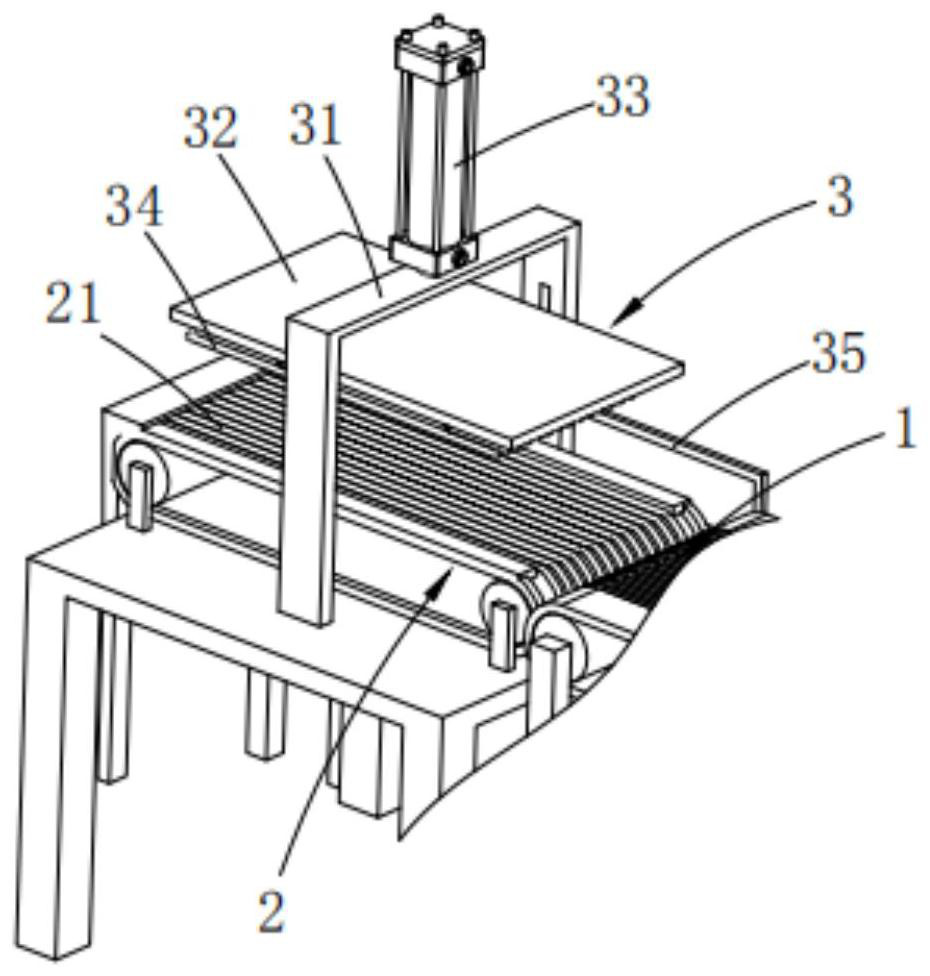

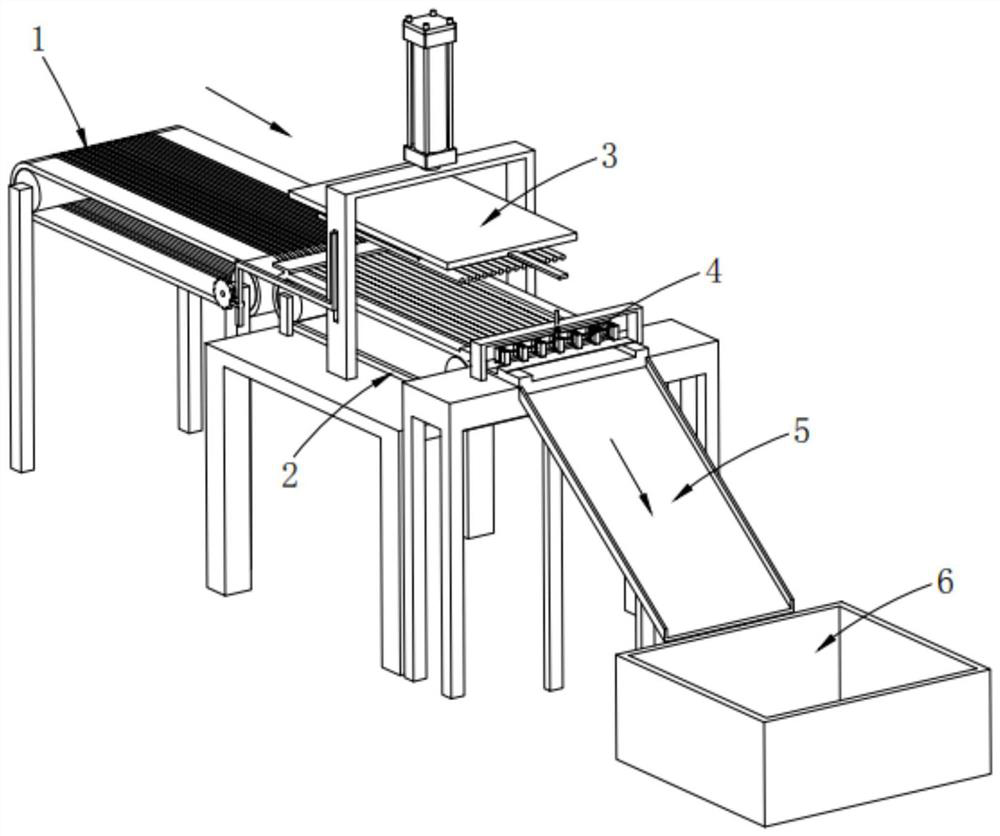

Processing and production method of dough sheets

InactiveCN112042699AIncrease profitImprove product qualityDough shaping and cutting apparatusDough processingProcess engineeringMechanical engineering

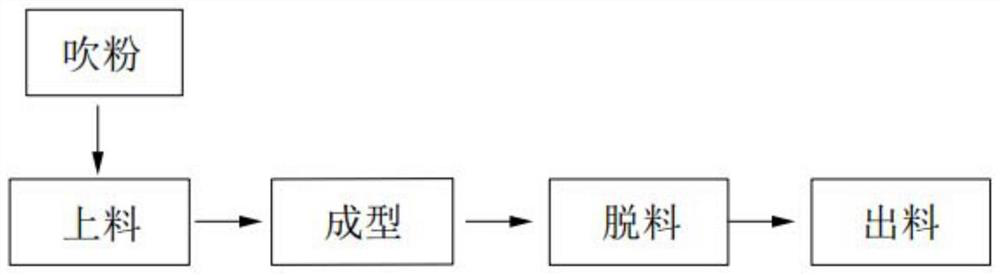

The invention relates to the technical field of food processing equipment, and particularly relates to a processing and production method of dough sheets. The processing and production method comprises the following steps of step 1, a loading working procedure: conveying dough sheets by a first conveying mechanism in the conveying direction; step 2, a powder blowing working procedure: performing powder blowing on the bottoms of the dough sheets by a powder blowing device under a second conveying mechanism; step 3, a shaping working procedure: conveying the dough sheets to a first base by the second conveying mechanism; step 4, a material stripping working procedure: driving a first shaping piece and a second shaping piece to move downwards by a driving piece, so that the shaped dough sheets are separated from the first shaping piece and the second shaping piece; and step 5, a discharging working procedure: cutting off the shaped dough sheets by a second cutter to obtain a butterfly shape. According to the processing and production method disclosed by the invention, the first shaping piece and the second shaping piece are matched, so that the dough sheets are pressed until side edges are in M shapes, besides, through mutual movement of shaping rods, the dough sheets at a first notch and a second notch are mutually adhered, and then the dough sheets on a discharging mechanism arecut and discharged.

Owner:马胜男

Novel process for producing complex sugared pomelo peel food

The invention belongs to the technical field of food production processes and relates to a novel process for producing a complex sugared pomelo peel food. The food is prepared by the following process steps: (1) debitterizing pomelo peel; (2) treating tremella; (3) blending complex paste; (4) mixing; (5) forming; and (6) packaging and sterilizing. The raw material in the invention is special in formula and has innovativeness, the process is innovative, resource-saving, low in energy consumption, high in yield and high in quality, and the product is tasty, elastic, soft, non-sticky and low in calorie and has multiple health functions.

Owner:DONGGUAN MENGCHUANG HEALTH CARE TECH CO LTD

Vertical vacuum drying device

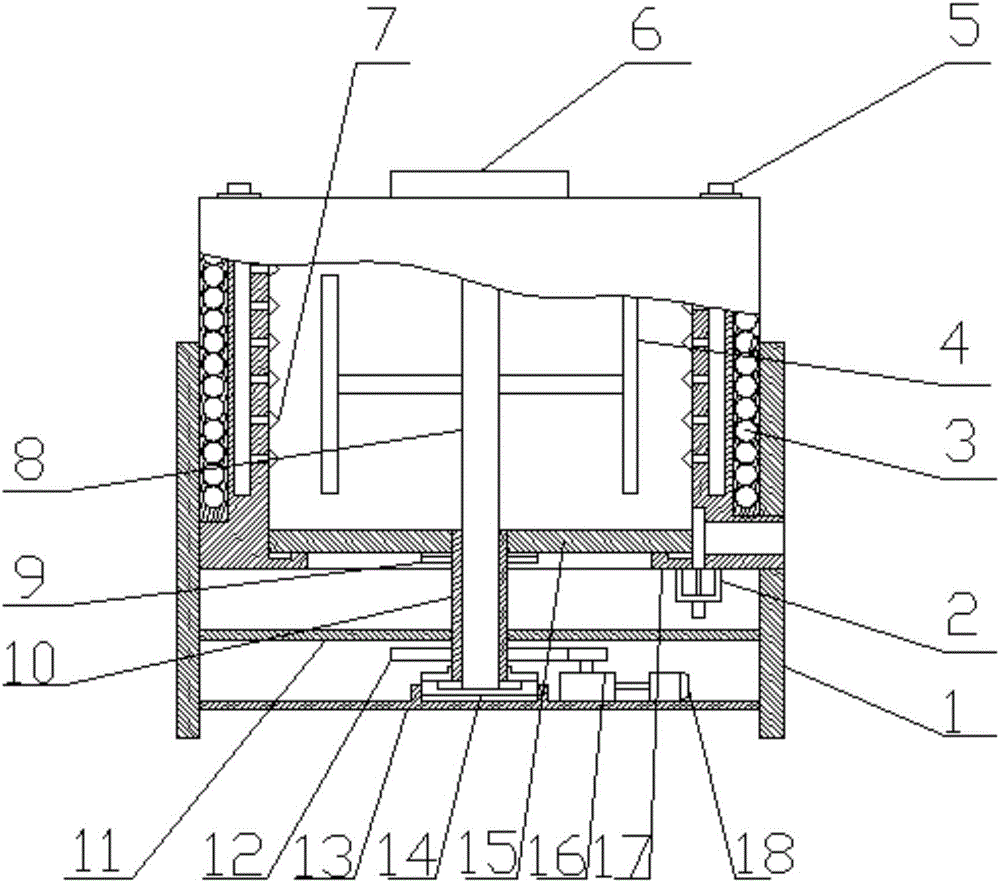

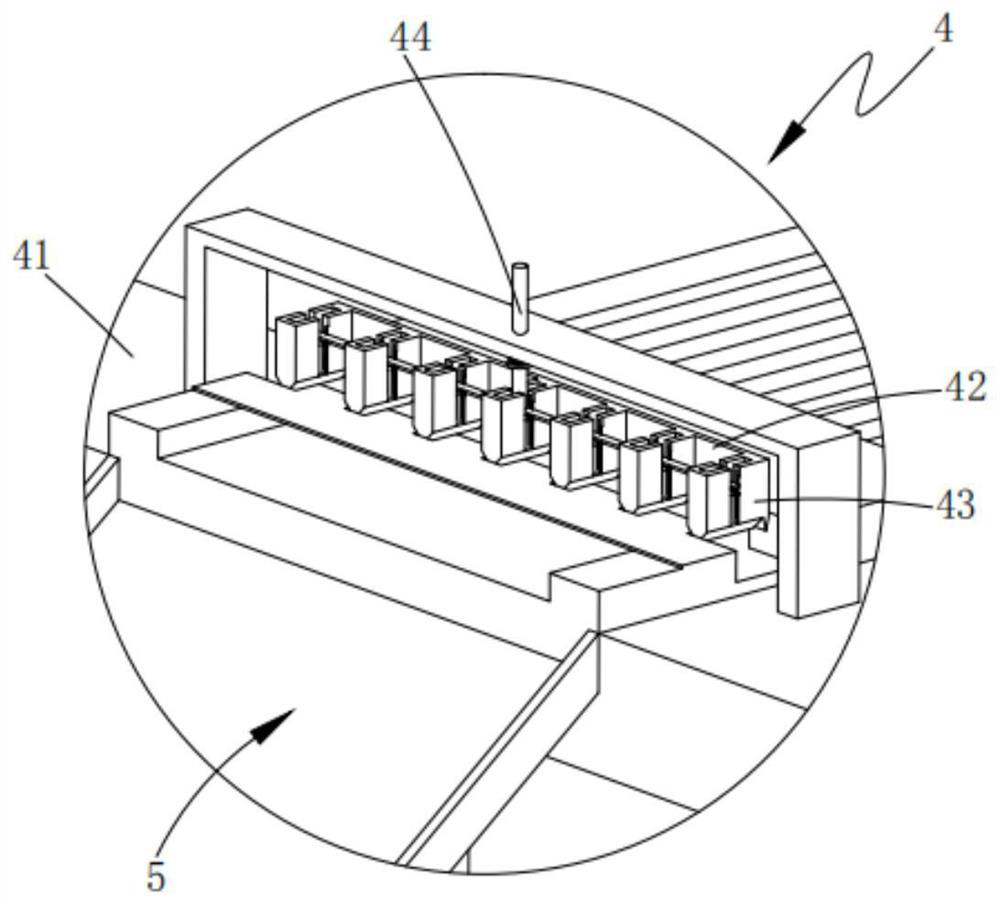

ActiveCN106152743AShort heating timeImprove heating efficiencyDrying using combination processesDrying solid materials with heatClutchInduction coil

The invention discloses a vertical vacuum drying device. The vertical vacuum drying device comprises a rack, a tank body, a cover plate, magnetic induction coils, filter tips, a rotating shaft, a bushing, a supporting plate, a motor and a support plate A, wherein the tank body is of a cylindrical cavity structure; the cover plate is arranged on the upper top surface of the tank body; the tank body is vertically arranged on the rack; the magnetic induction coils are arranged on the outer wall of the tank body; the filter tips are arranged on the inner wall of the tank body; stirring blades are arranged in the tank body and are also arranged on a rotating shaft; the rotating shaft is arranged in the bushing; the upper end of the bushing is arranged on the supporting plate; the lower end of the bushing is arranged on the support plate A; the supporting plate is arranged on the lower bottom surface of the tank body; a clutch A is arranged between the bushing and the supporting plate; a clutch B is arranged between the bushing and the rotating shaft; the bushing is connected with the motor; and the motor is arranged on the rack. The vertical vacuum drying device disclosed by the invention is high in drying efficiency and low in production cost.

Owner:贵州省印江县依仁食品有限公司

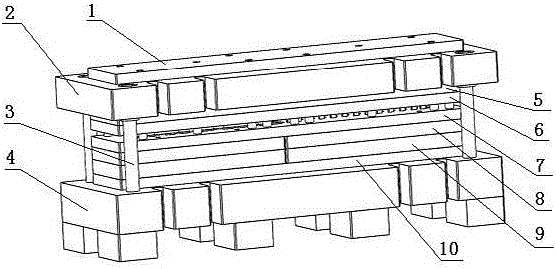

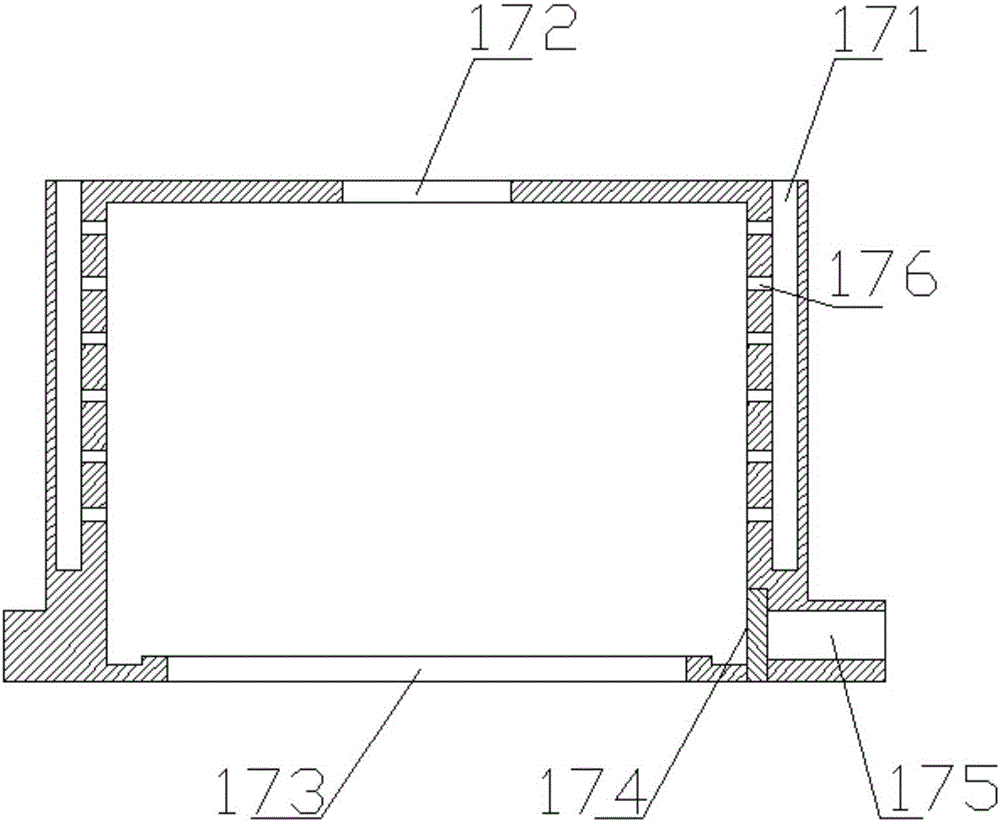

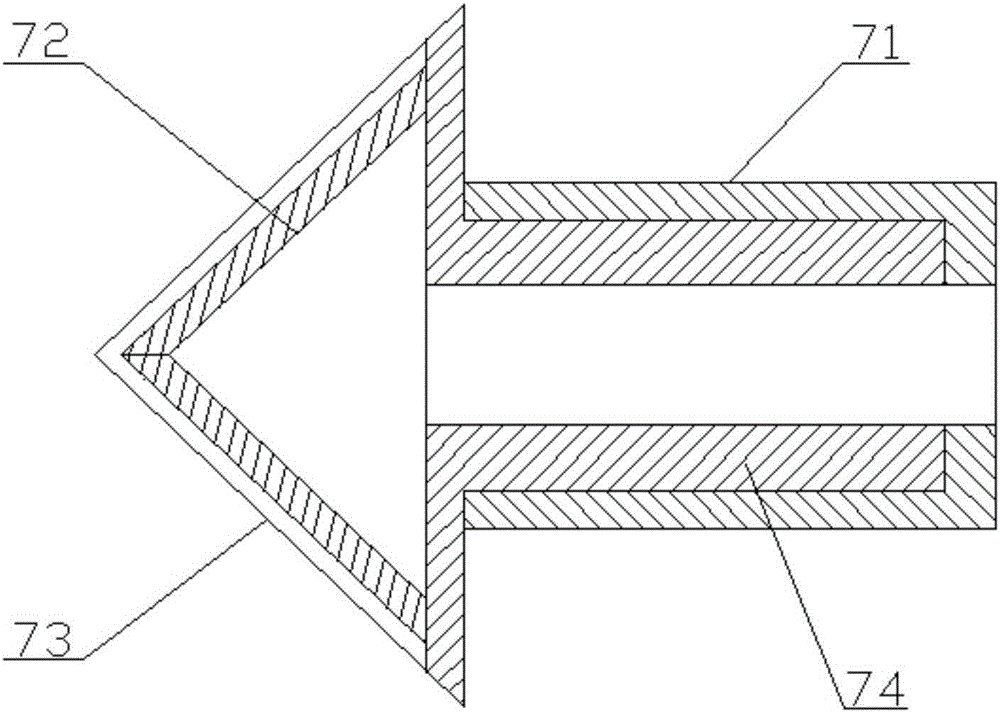

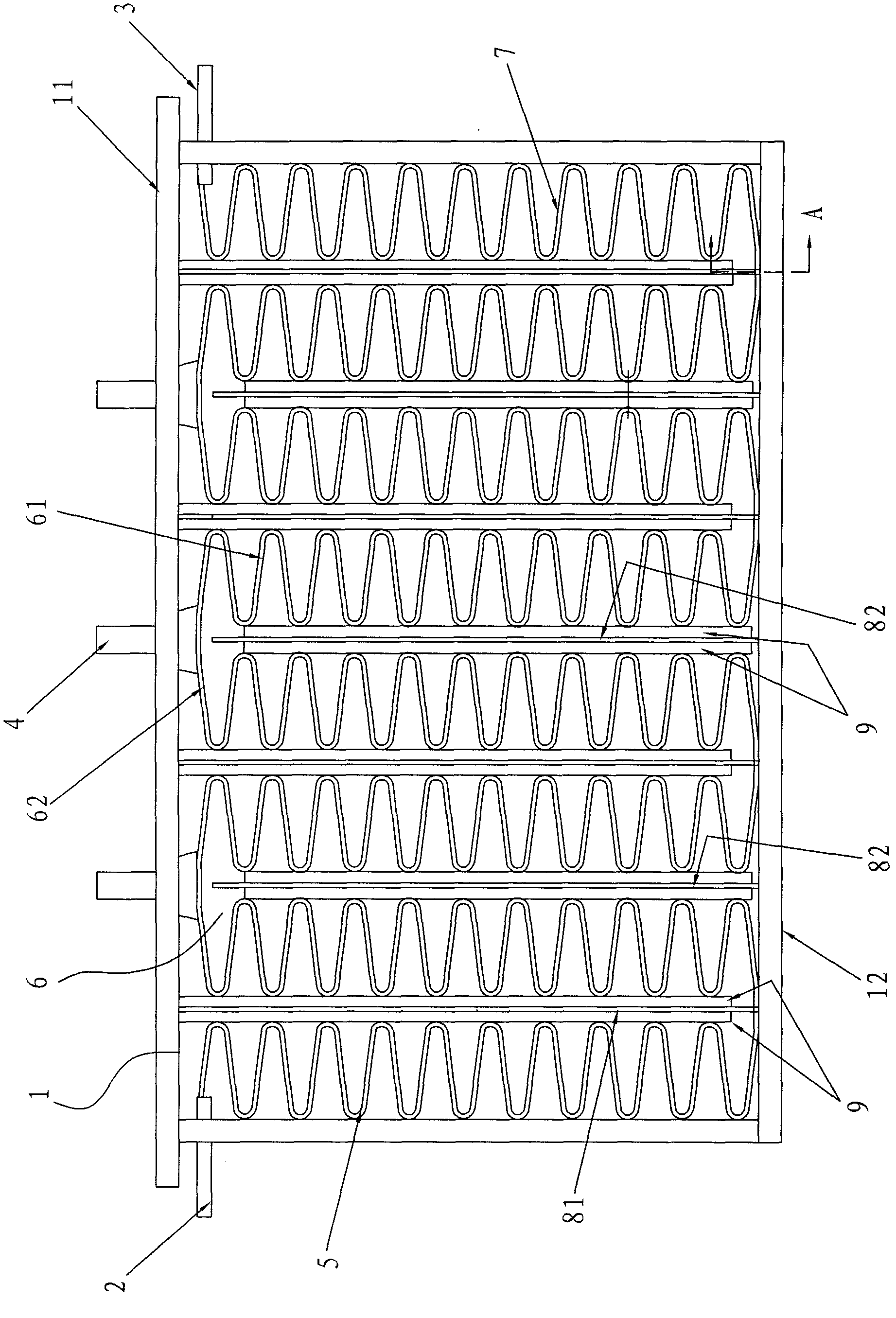

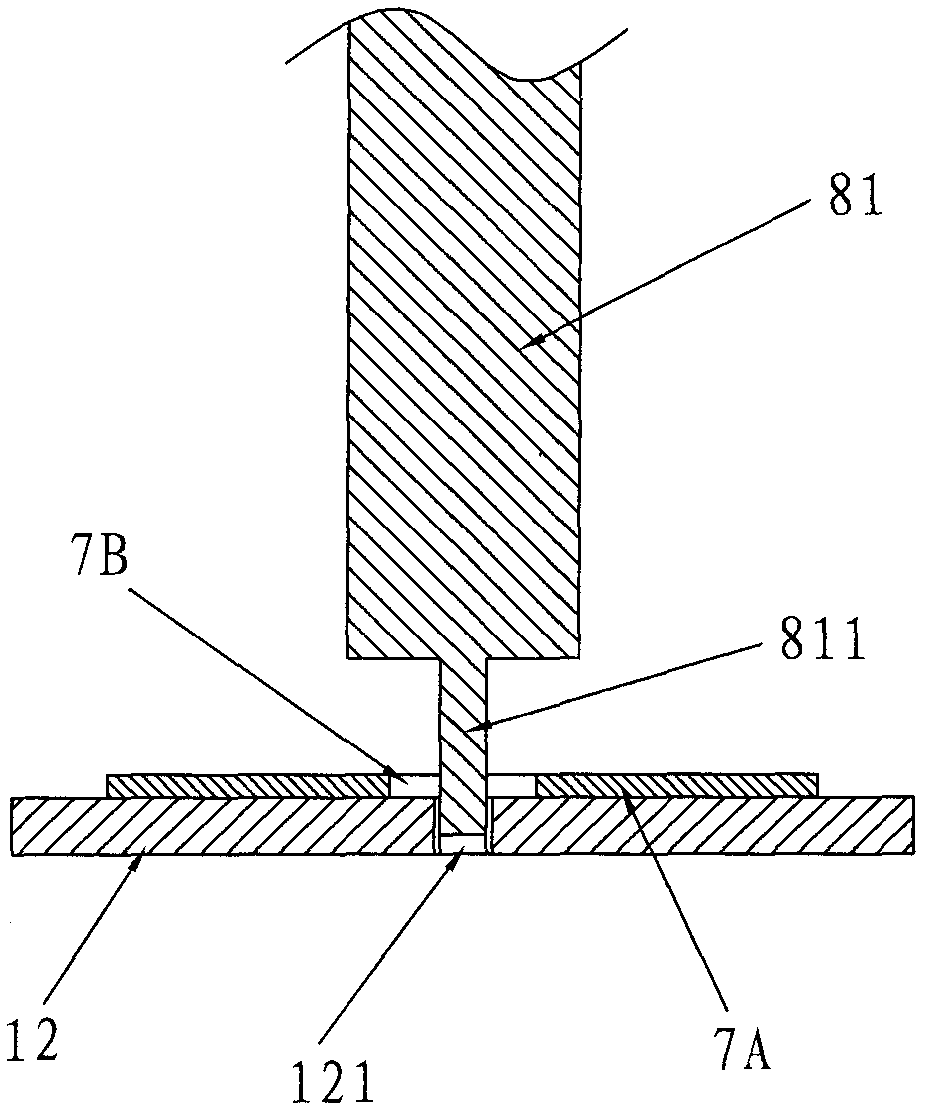

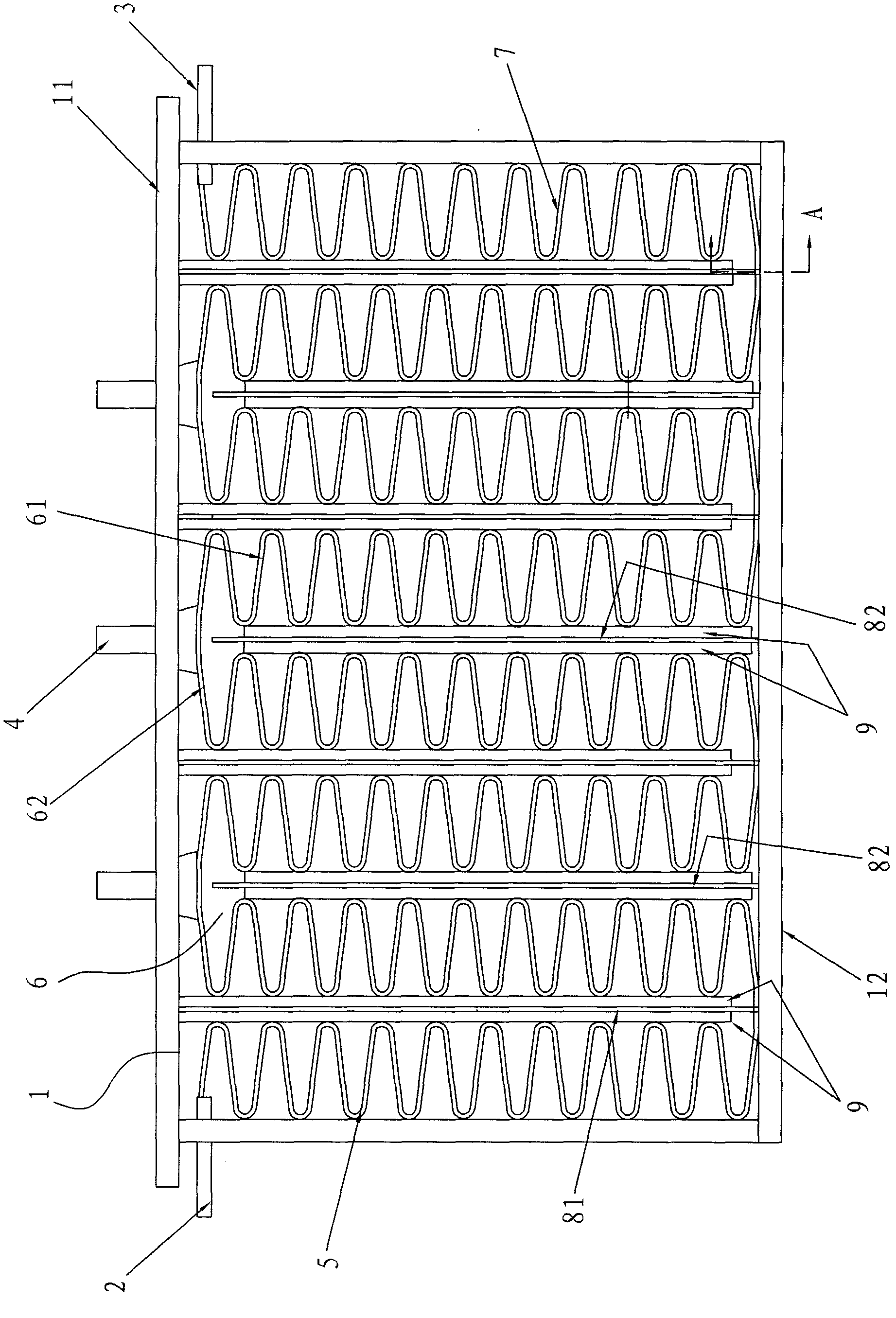

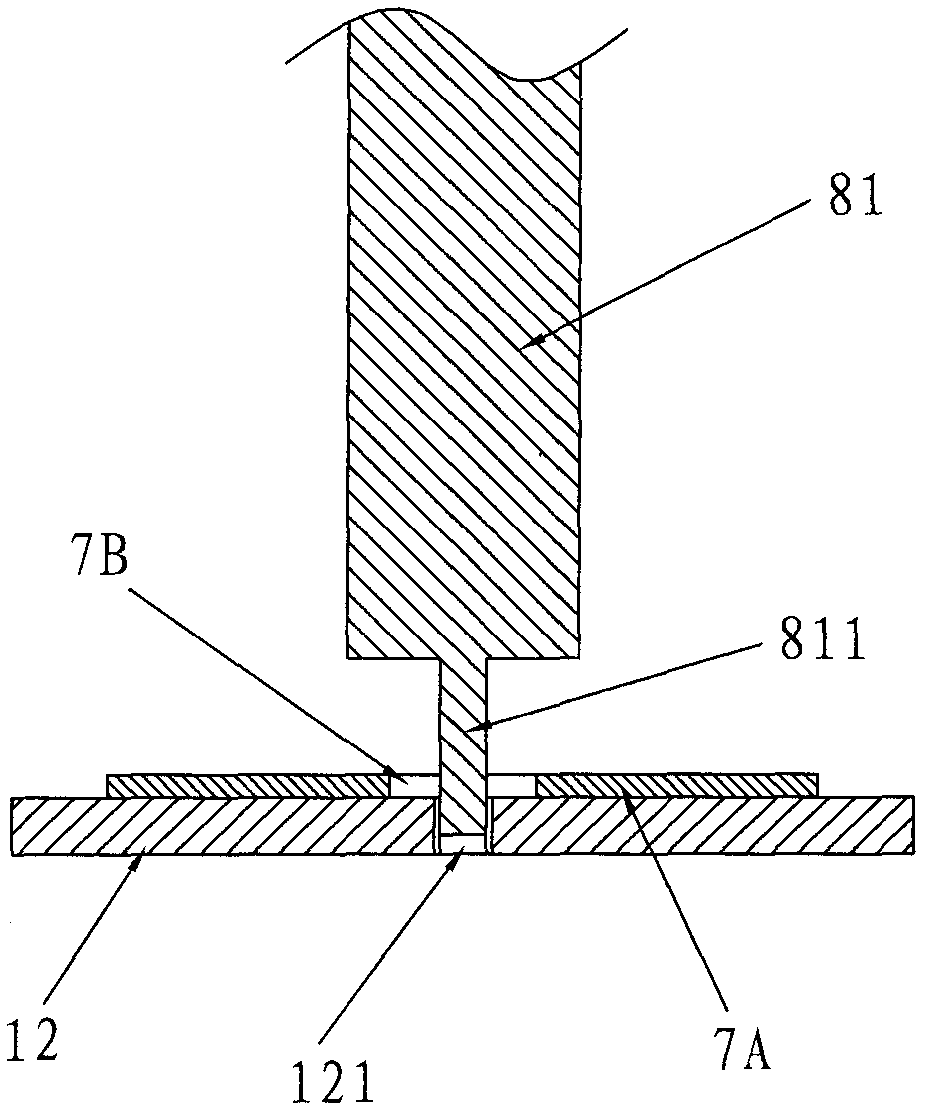

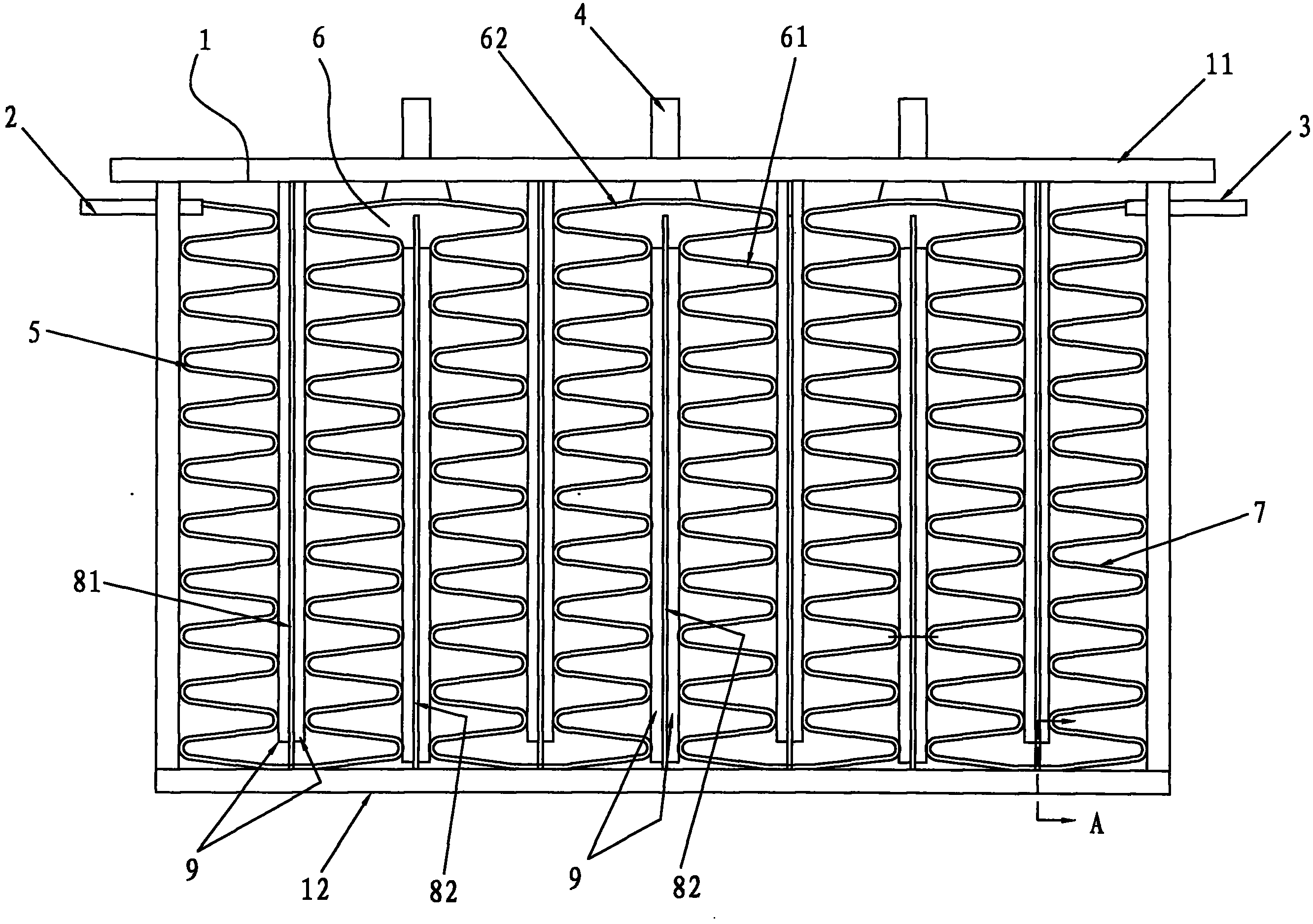

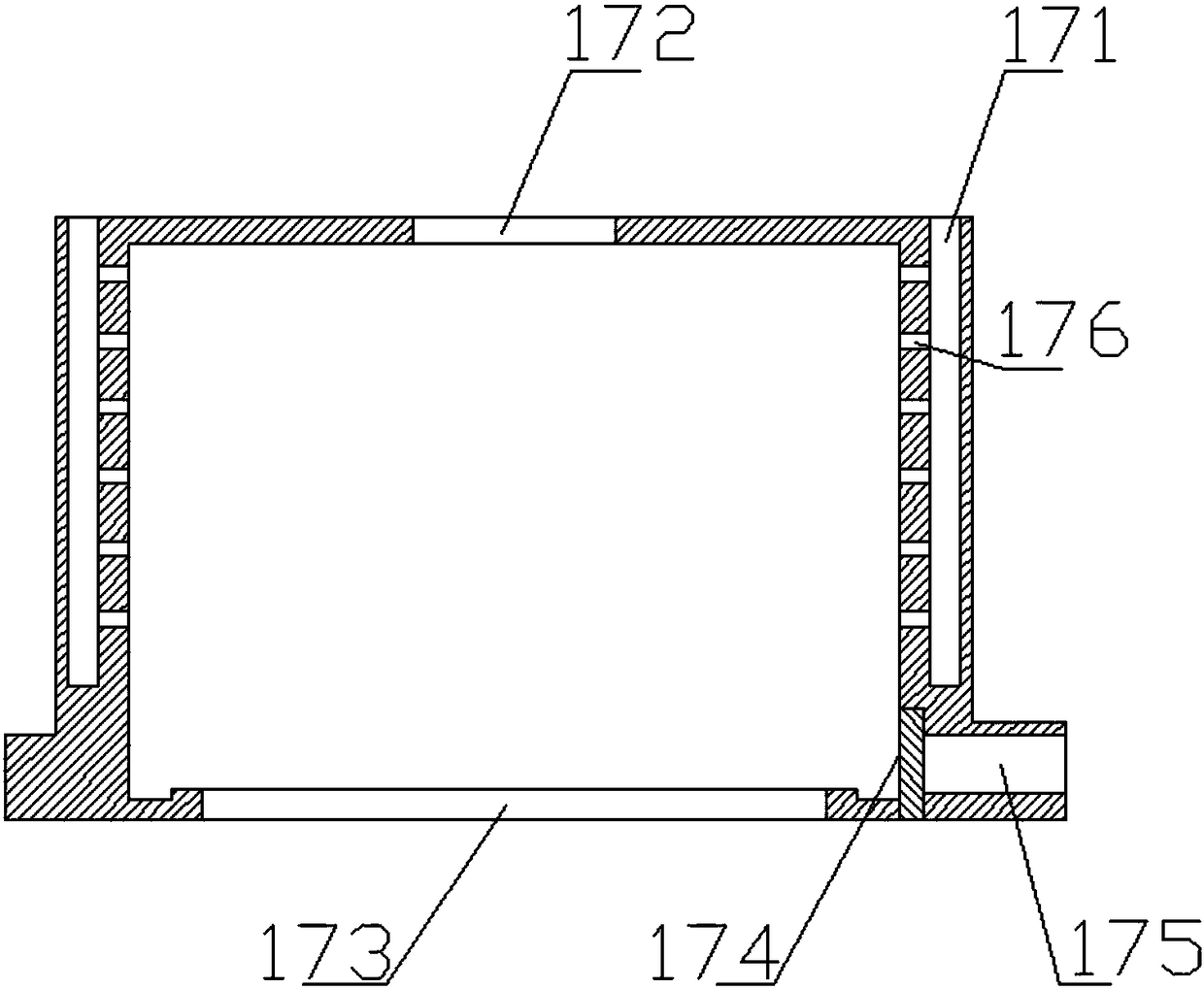

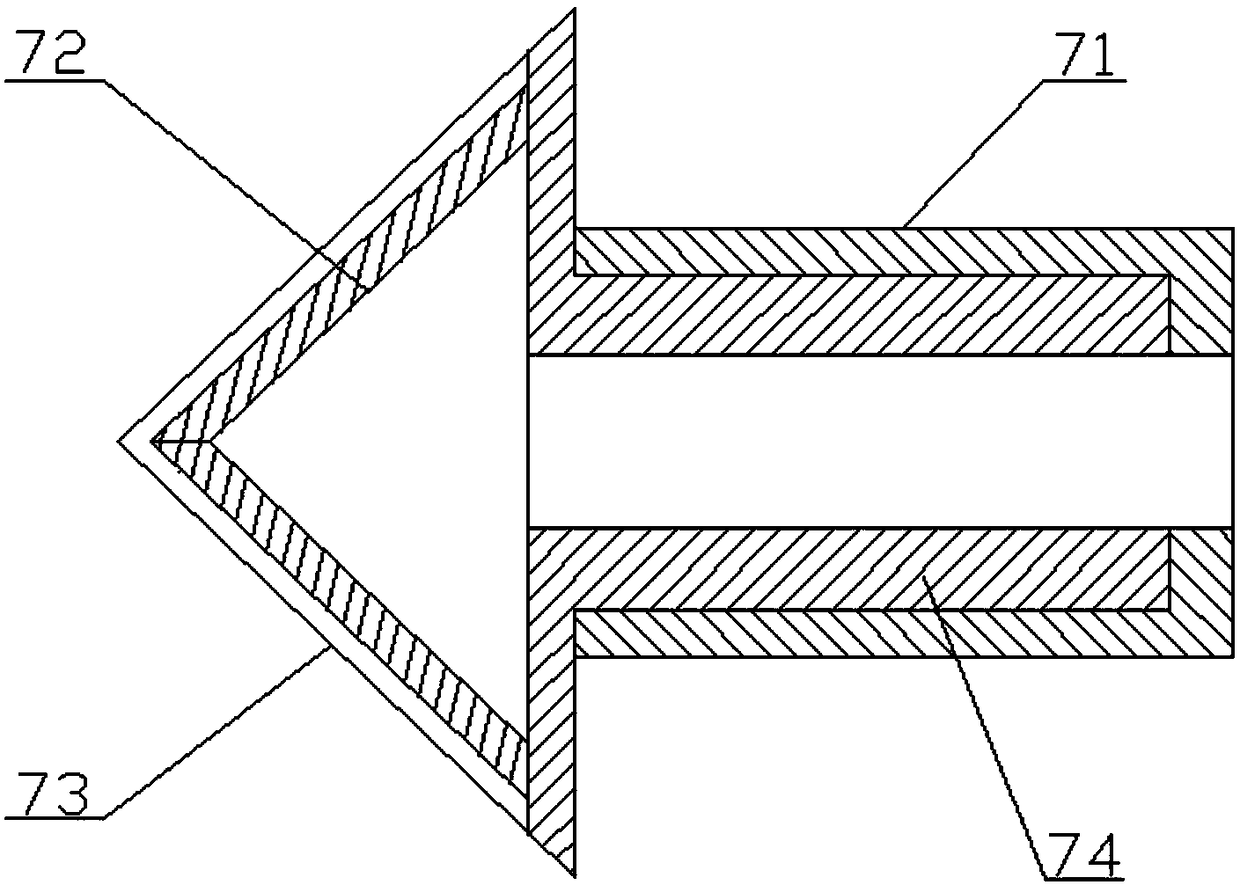

Resistor with wavelike resistor discs

InactiveCN102436882BSave man hoursNo leftoversResistor mounting/supportingZig-zag/sinusoidal resistive elementsWave shapeResistor

The invention discloses a resistor with wavelike resistor discs. The resistor with wavelike resistor discs comprises an insulating frame, resistor discs, an input terminal, an output terminal and a central tapping terminal. The resistor discs comprise a head resistor disc, a middle resistor disc and an end resistor disc. The head resistor disc, the middle resistor disc and the end resistor disc are made from a steel disc having certain width. The head resistor disc and the end resistor disc have wave shapes. The head resistor disc is fixedly connected to one side of the insulating frame. The end resistor disc is fixedly connected to the other side of the insulating frame. The middle resistor disc has a lower frame shape. Two sides of the middle resistor disc have wave shapes. The top of the middle resistor disc is fixedly connected to a top plate of the insulating frame. In the invention, based on the structure, a collared steel sheet is directly cut into a small collared steel sheet of which width is the same as resistor disc width and then the cut small collared steel sheet can be directly utilized for resistor disc manufacture. Compared with the prior art which is characterizedin that a collared steel sheet is bought back and then is cut into multiple small steel discs, the resistor with wavelike resistor discs saves working time and does not produce offcuts.

Owner:王爱民

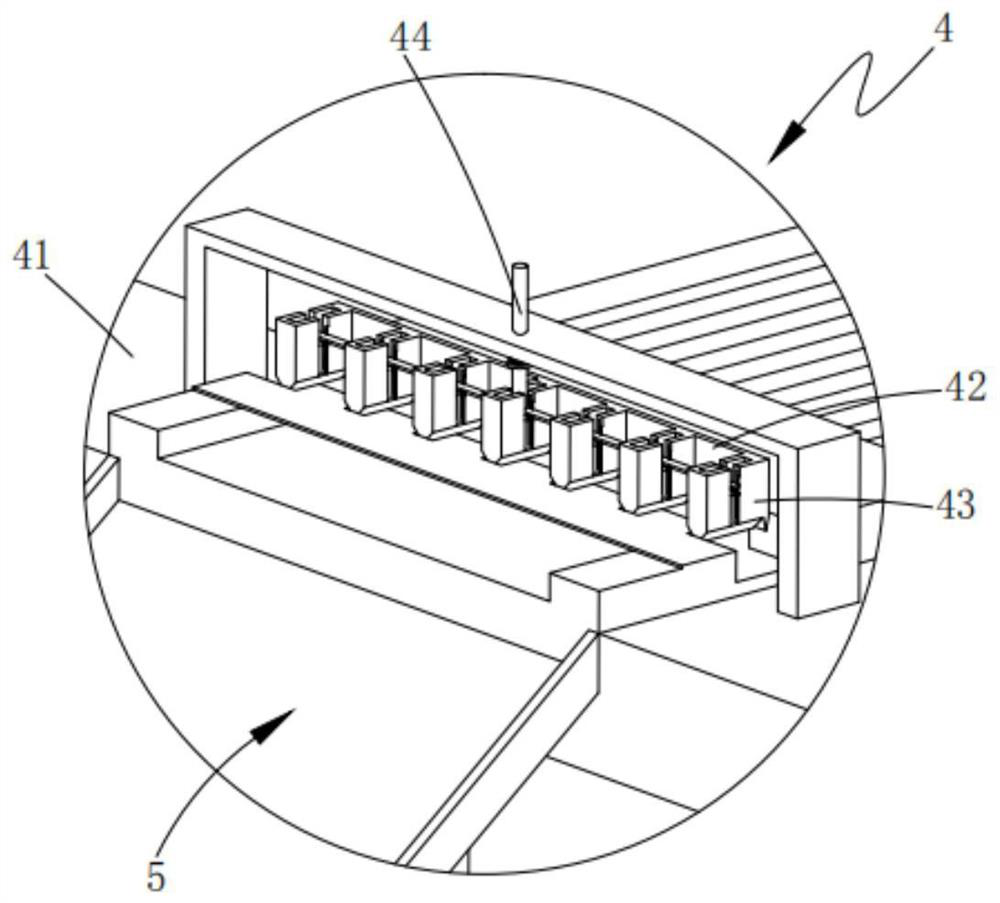

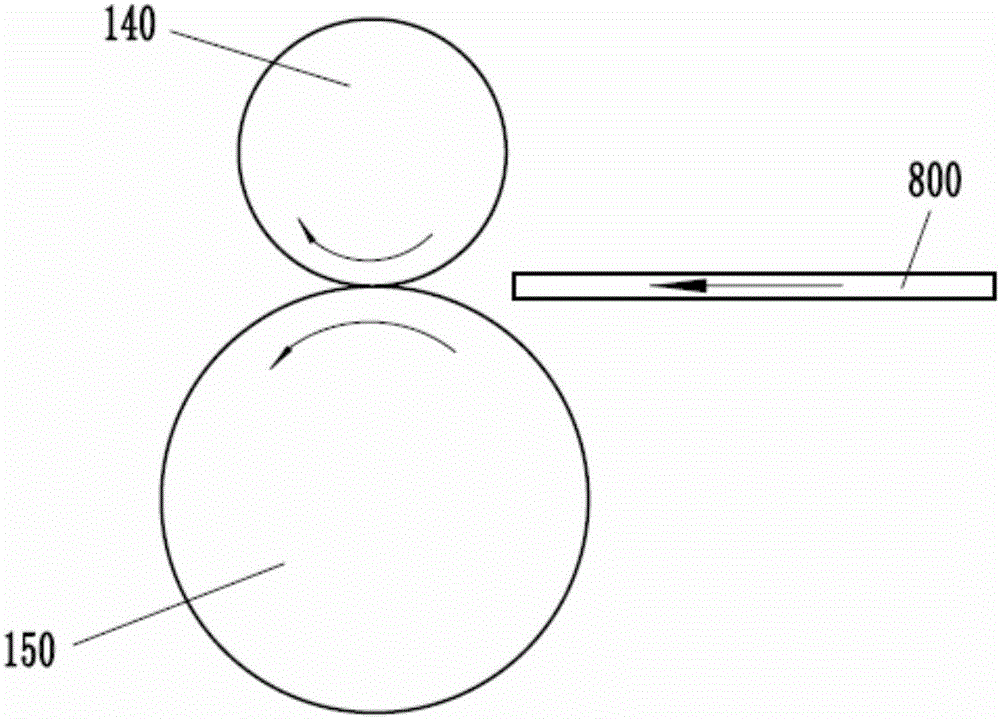

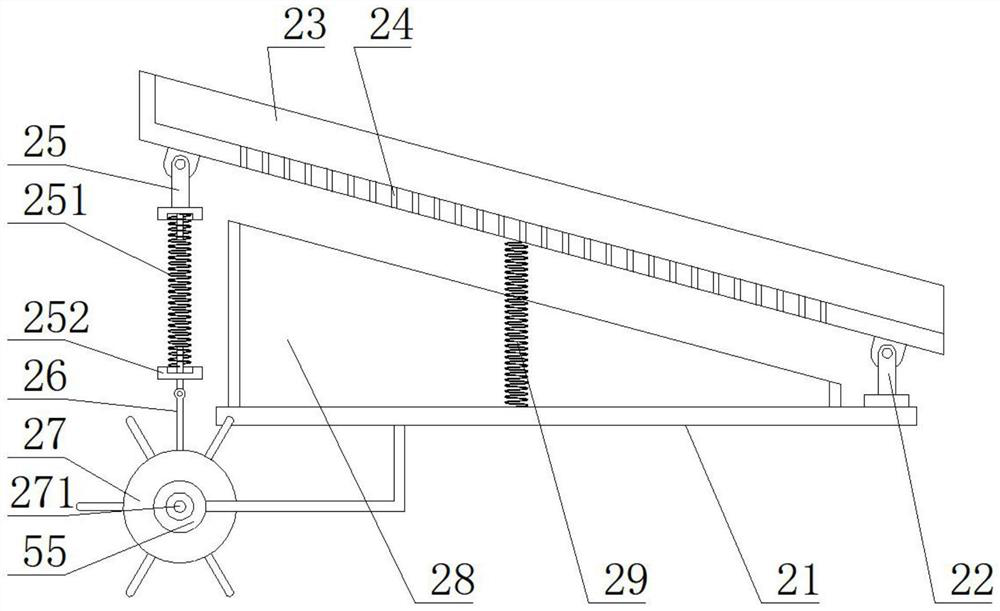

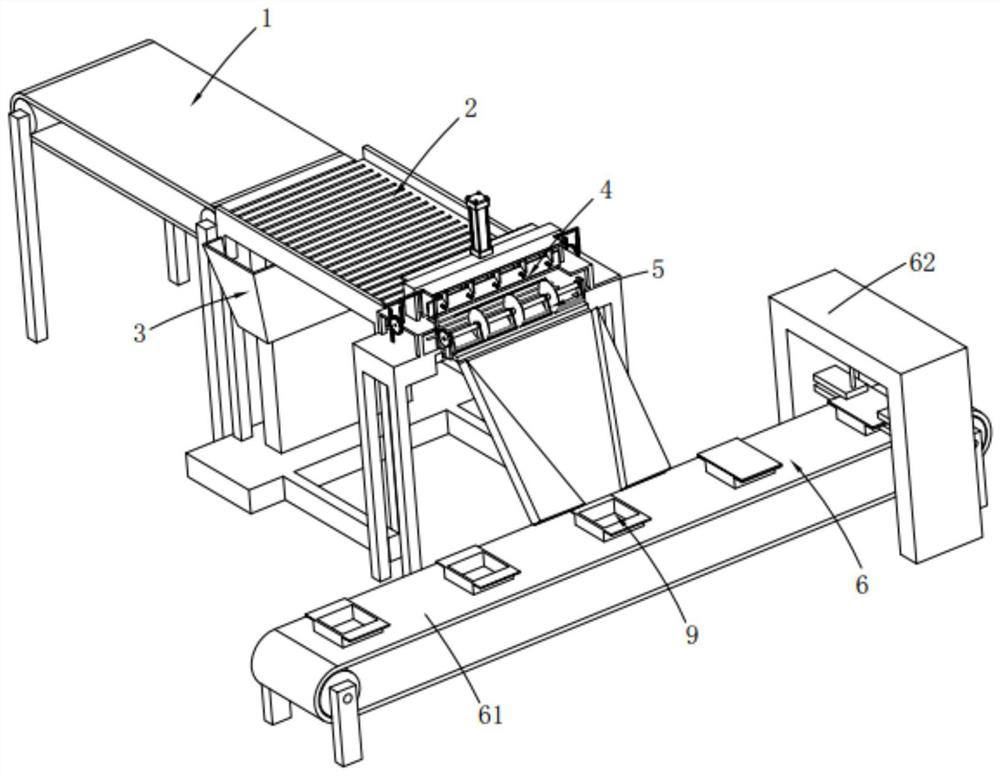

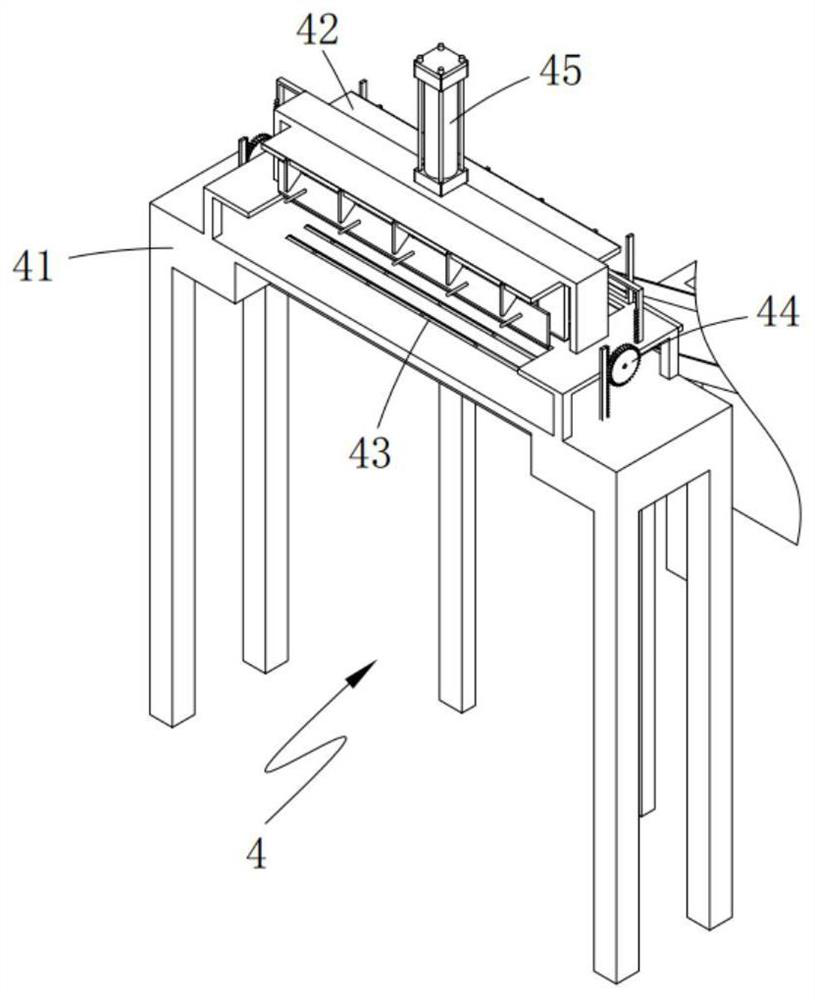

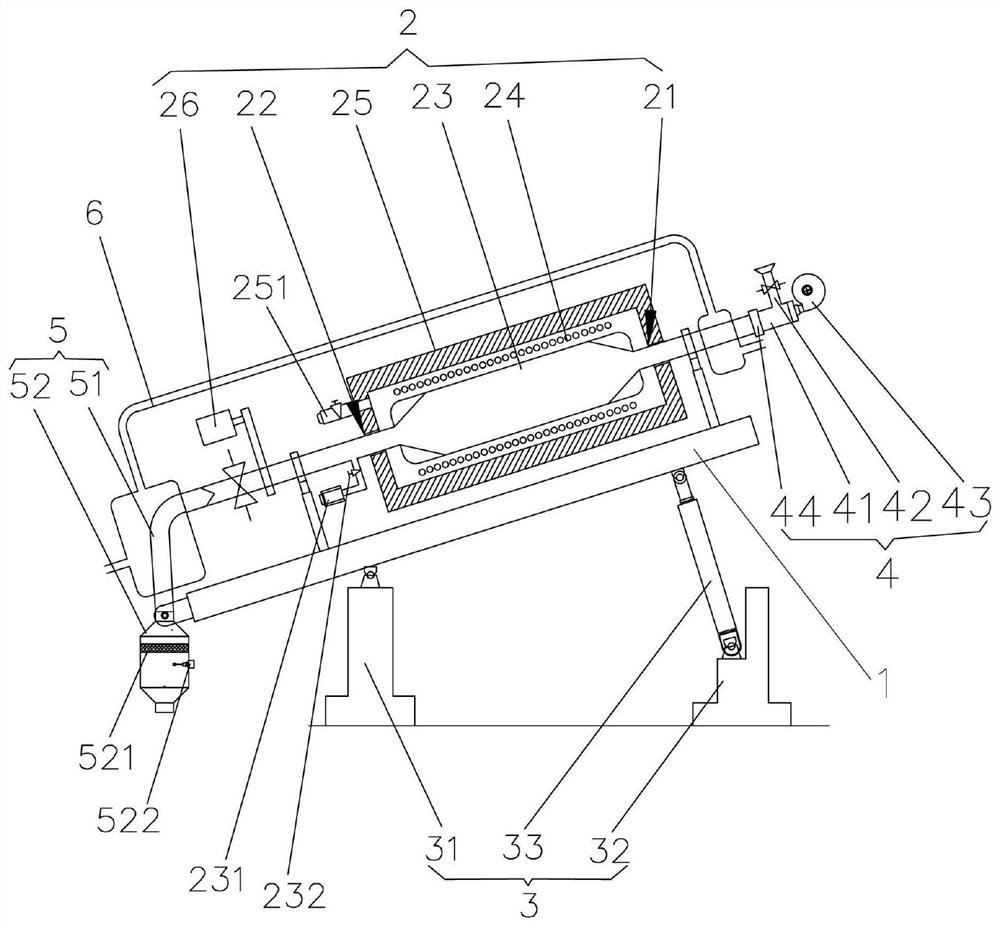

Automatic wrapper production line

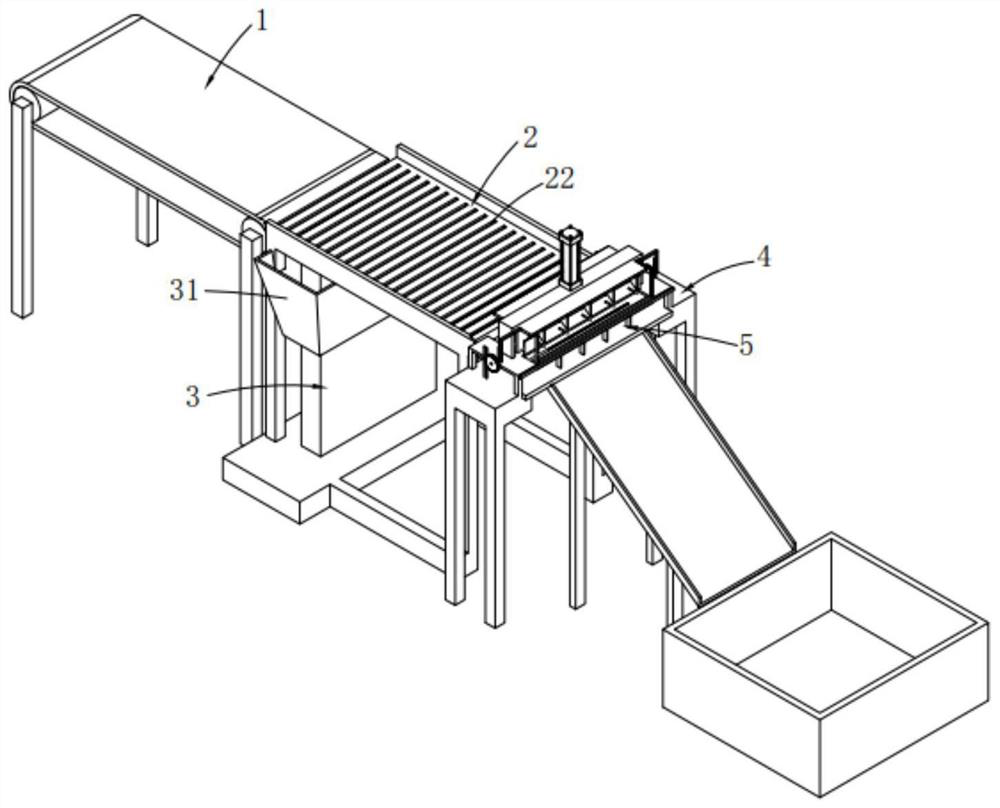

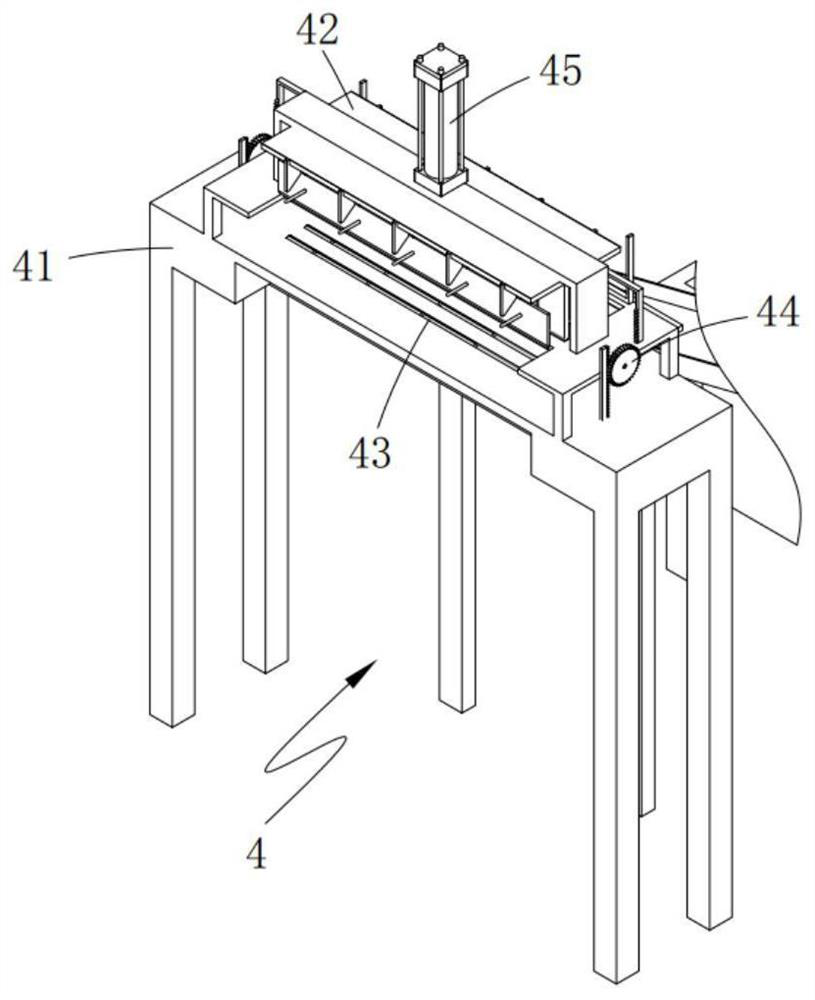

ActiveCN111771932AIncrease productivityImprove product qualityDough shaping and cutting apparatusProduction lineIndustrial engineering

The invention relates to the technical field of food processing equipment, in particular to an automatic wrapper production line which comprises a first conveying mechanism. A second conveying mechanism is arranged at the output end of the first conveying mechanism in the conveying direction of the first conveying mechanism. A forming mechanism is arranged above the second conveying mechanism; a cutting mechanism is arranged at the output end of the second conveying mechanism in the conveying direction of the second conveying mechanism. The cutting mechanism comprises a first base, a first cutter, a cutter assembly and a cutting assembly. The cutter assembly is arranged on the first cutter in an array mode in the length direction of a first cutter, and the cutting assembly is arranged on the first base in a sliding mode in the height direction of the first base. The first conveying mechanism and the second conveying mechanism are linked with the first cutter to transversely cut off thewrappers in the process of conveying the wrappers at intervals, and then the cutter assembly is used for longitudinally cutting off the wrappers to extrude and form the single M-shaped wrappers, so that the production efficiency and the production quality are improved.

Owner:临泉县康寿面业有限公司

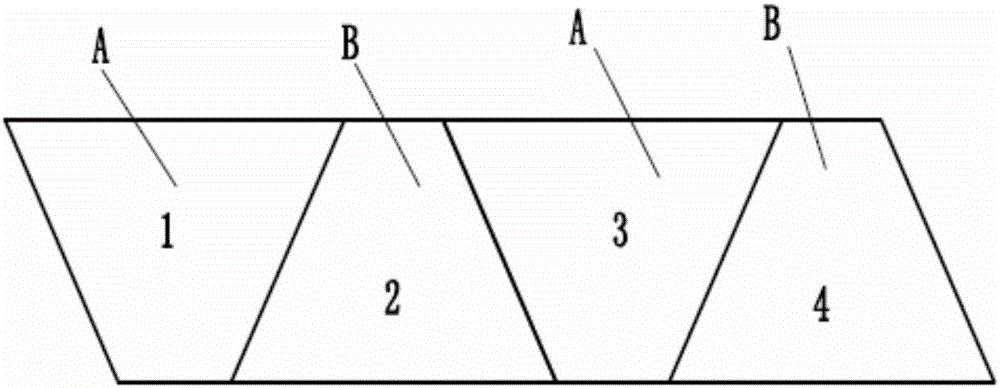

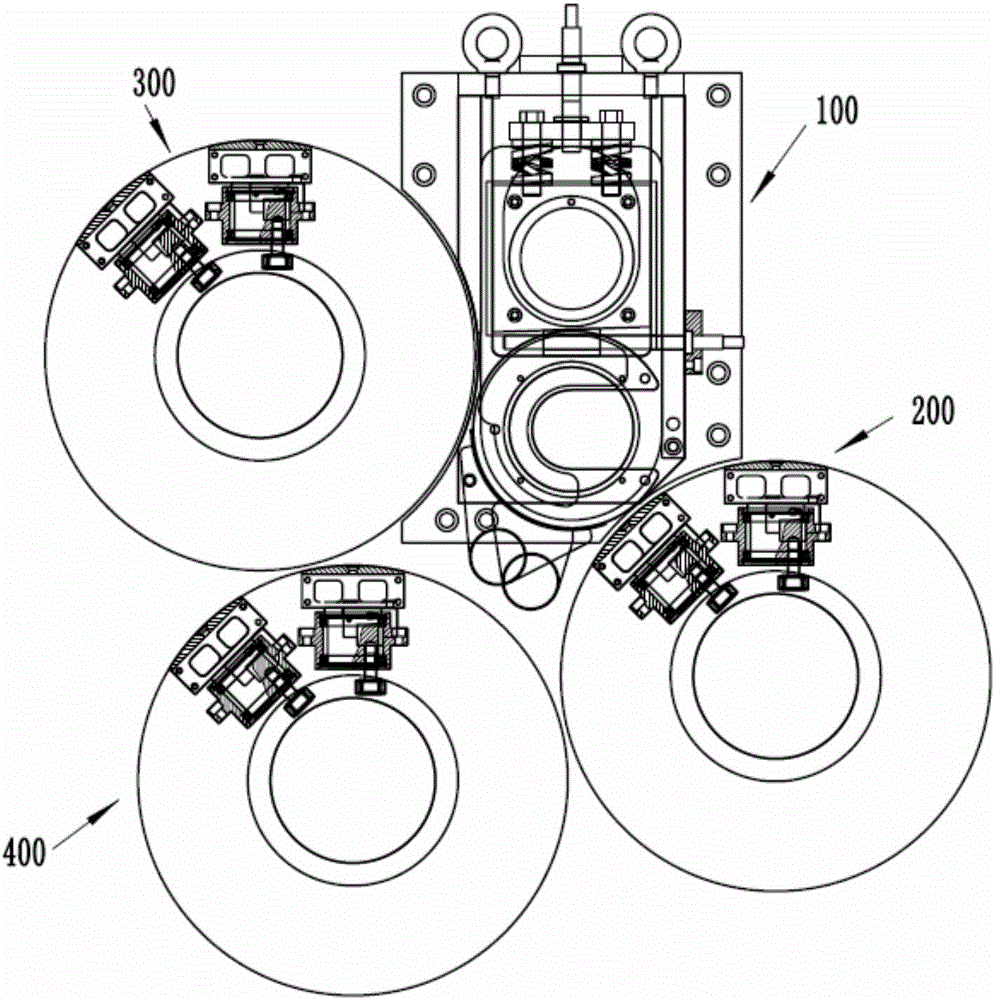

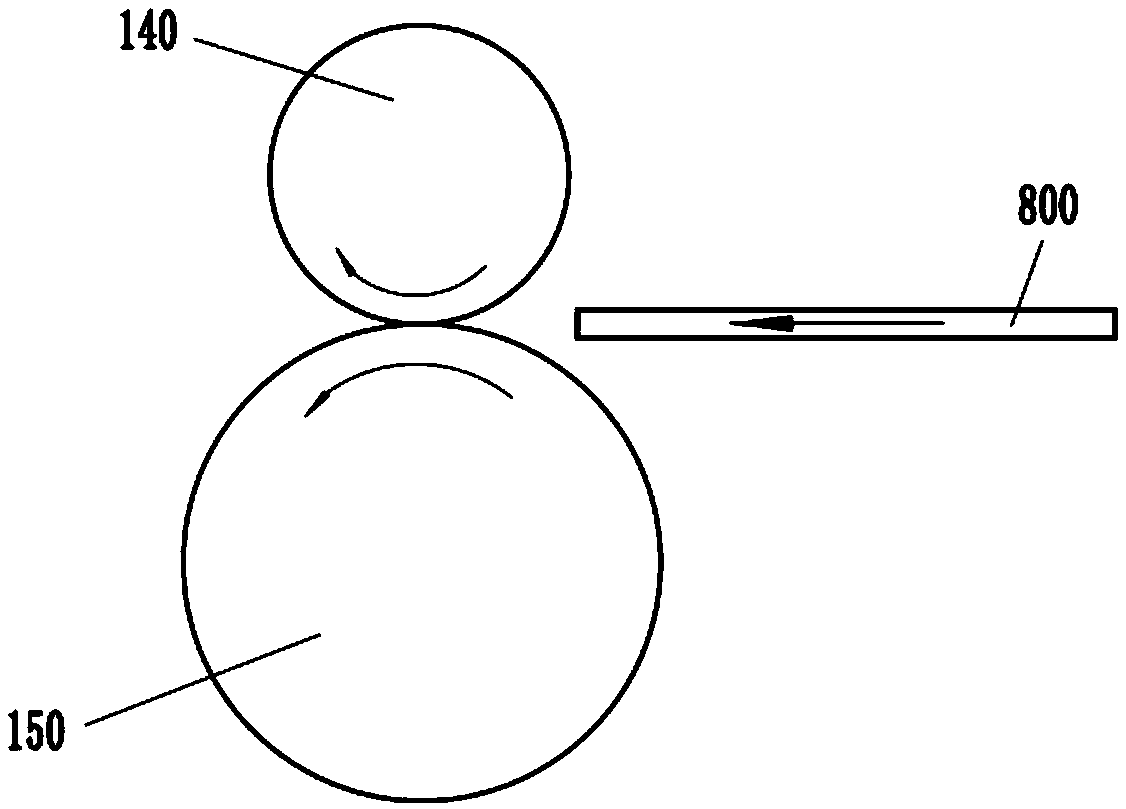

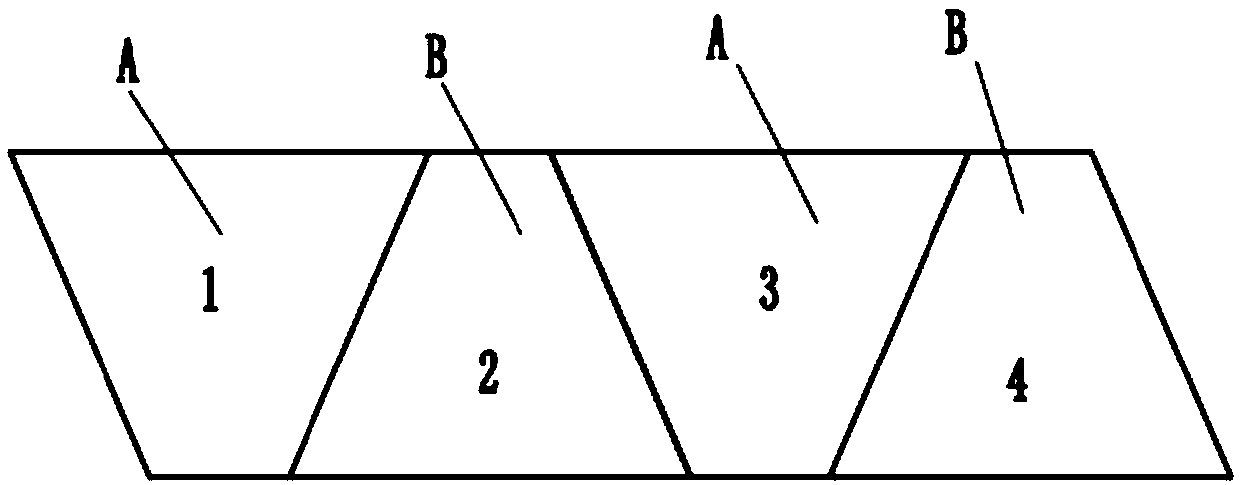

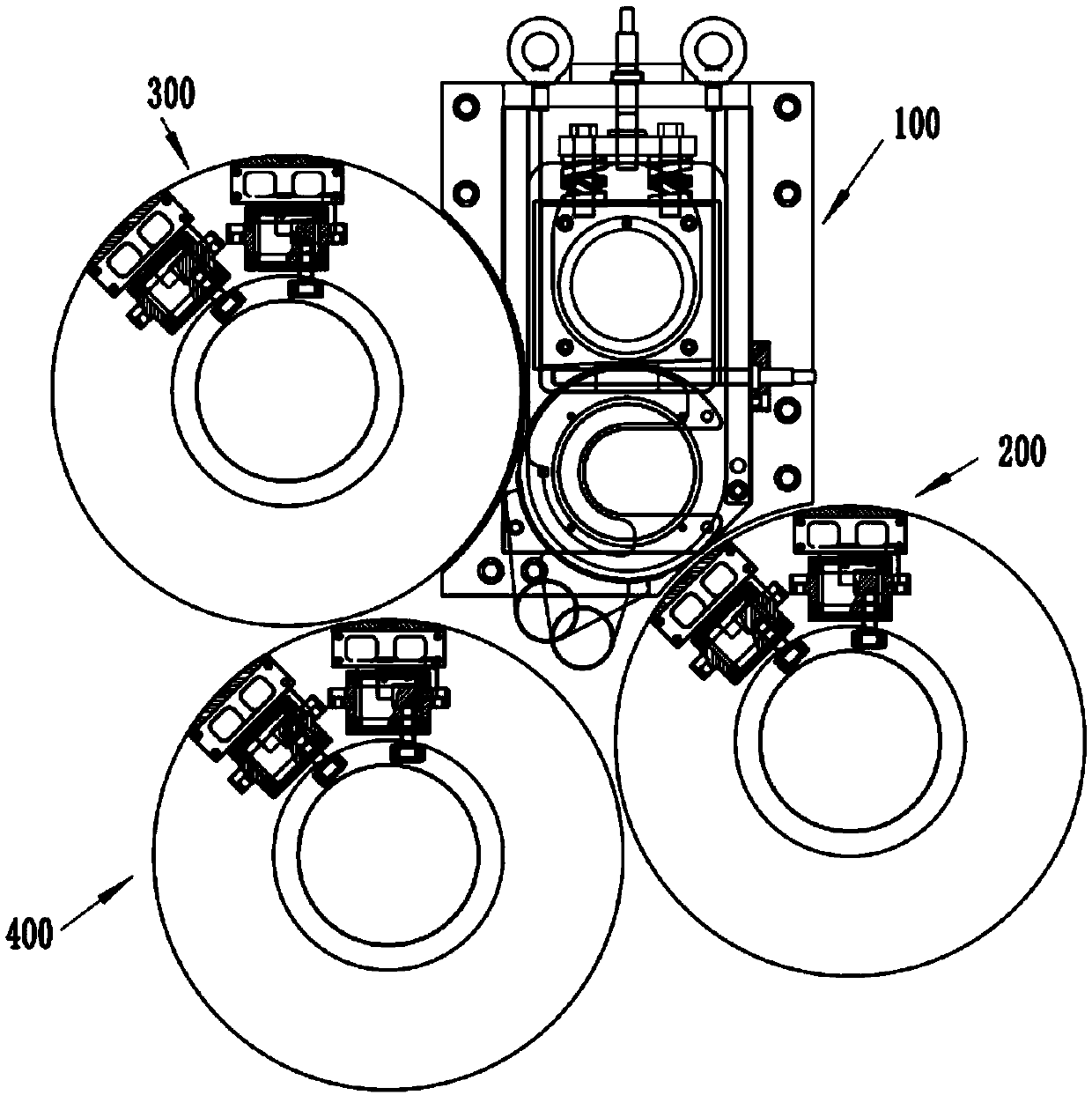

Large paper diaper lug part short-cutting longitudinal pitching method and system for realizing method

ActiveCN106361500AReasonable structural designCompact layoutAbsorbent padsBaby linensEngineeringRaw material

The invention discloses a large paper diaper lug part short-cutting longitudinal pitching method. The method comprises the following steps: S10, carrying out continuous and sequential slitting on a large lug part material belt by adopting a lug part short-cutting device, thus forming a left lug part A and a right lug part B; and S20, adsorbing the cut left lug part A and right lug part B by a first adsorbing cutter anvil and a second adsorbing cutter anvil, respectively, and enabling the cut left lug part A and right lug part B to rotate along with the first adsorbing cutter anvil and the second adsorbing cutter anvil. The invention further provides a system for realizing the large paper diaper lug part short-cutting longitudinal pitching method. The system comprises the lug part short-cutting device, a transmission-side longitudinal pitching device, an operation-side longitudinal pitching device and a left-right side lug part pitching device, and the transmission-side longitudinal pitching device and the operation-side longitudinal pitching device are respectively arranged at the outer side of the lug part short-cutting device. The method and the system have the advantages that the structure is simple, the use is convenient, the stability is good, and the waste caused by raw material cutting can be effectively avoided.

Owner:SONGJIA QUANZHOU MACHINERY

A method and system for short-cutting longitudinal distance changing of large ear pieces of diapers

ActiveCN106361500BEffective variable pitchMake sure the size specificationAbsorbent padsBaby linensManufactured materialStructural engineering

Owner:SONGJIA QUANZHOU MACHINERY

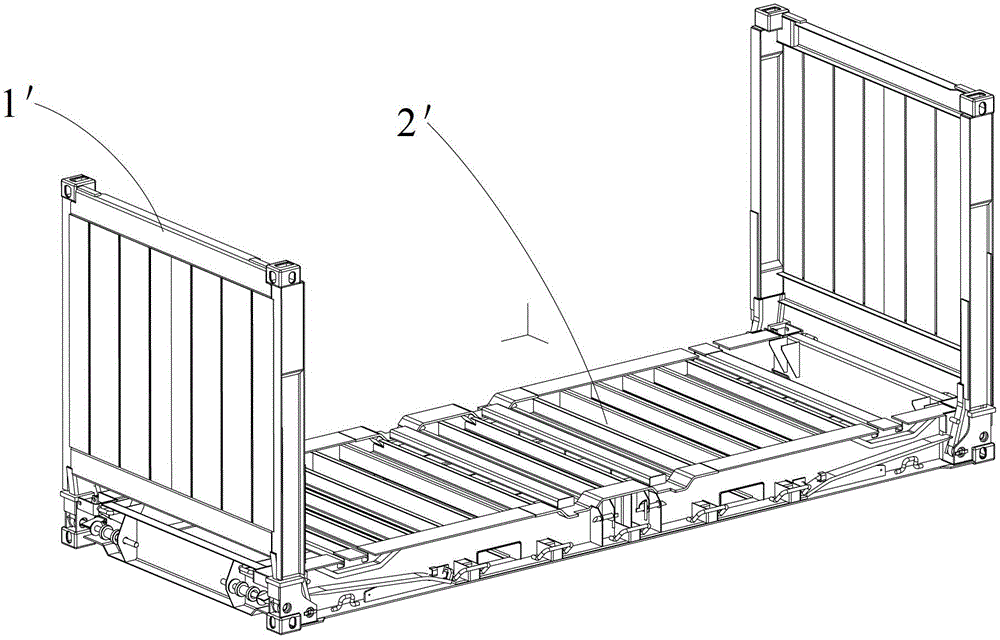

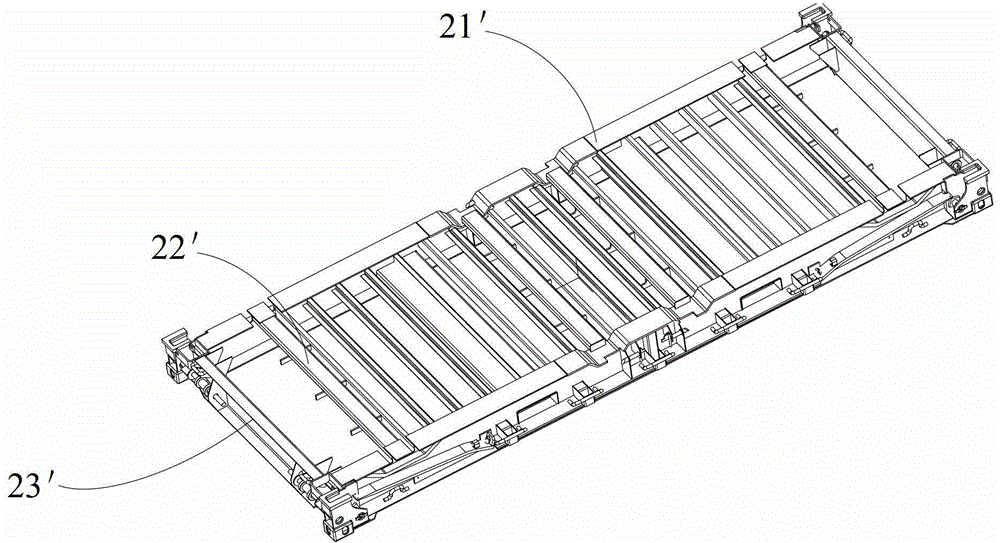

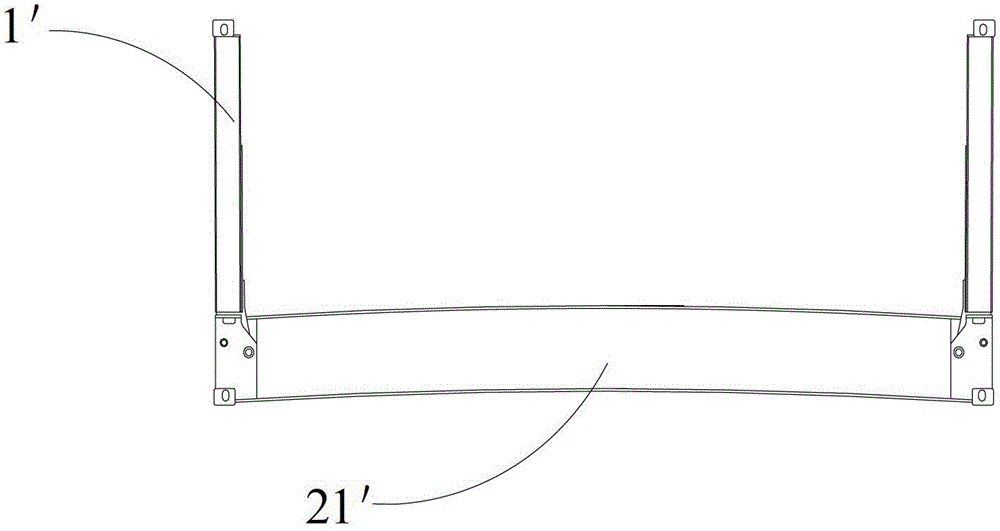

Rack box bottom side beam, manufacturing method thereof and method for manufacturing rack box

Owner:GUANGDONG XINHUI CIMC SPECIAL TRANSPORT EQUIPS +1

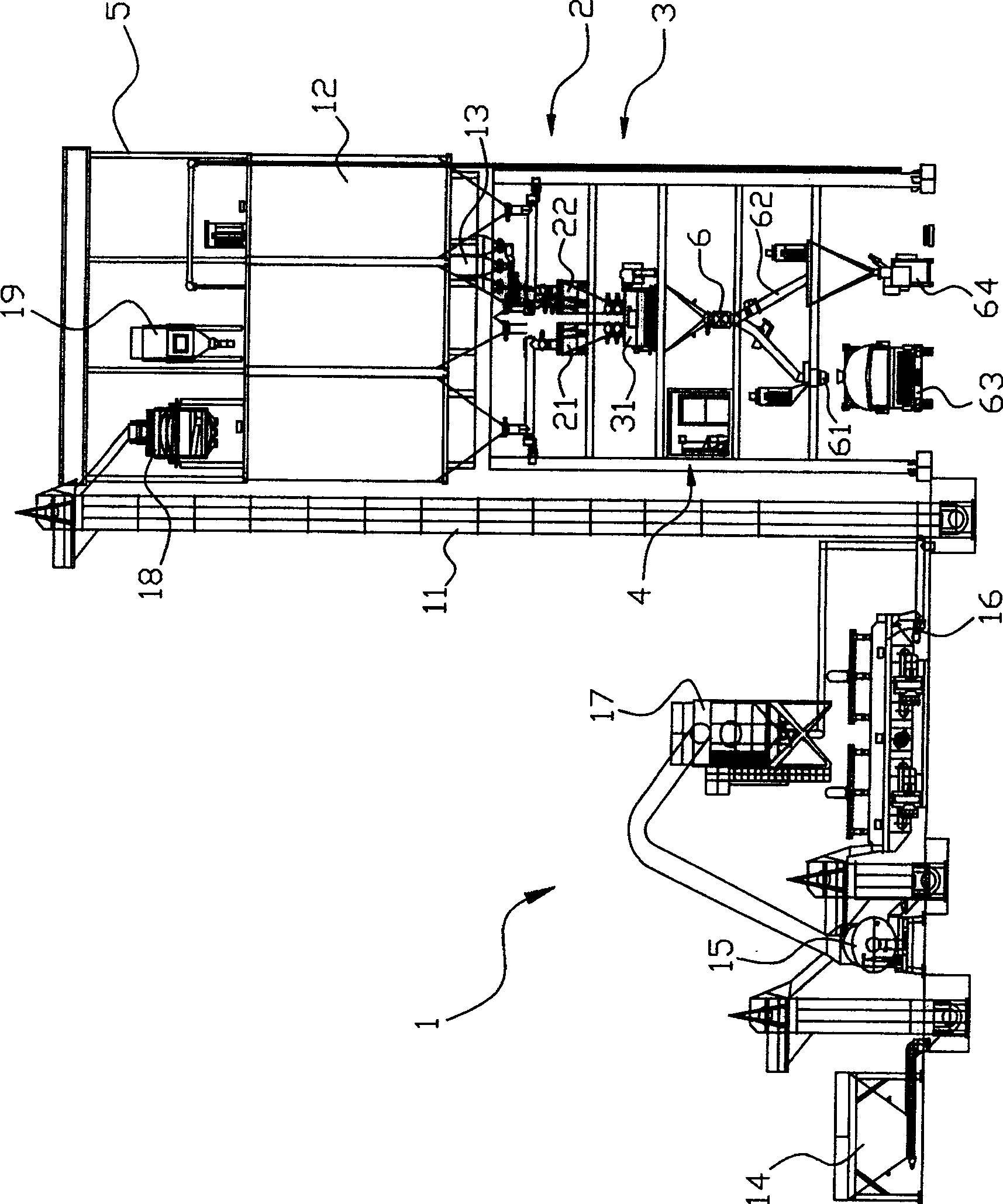

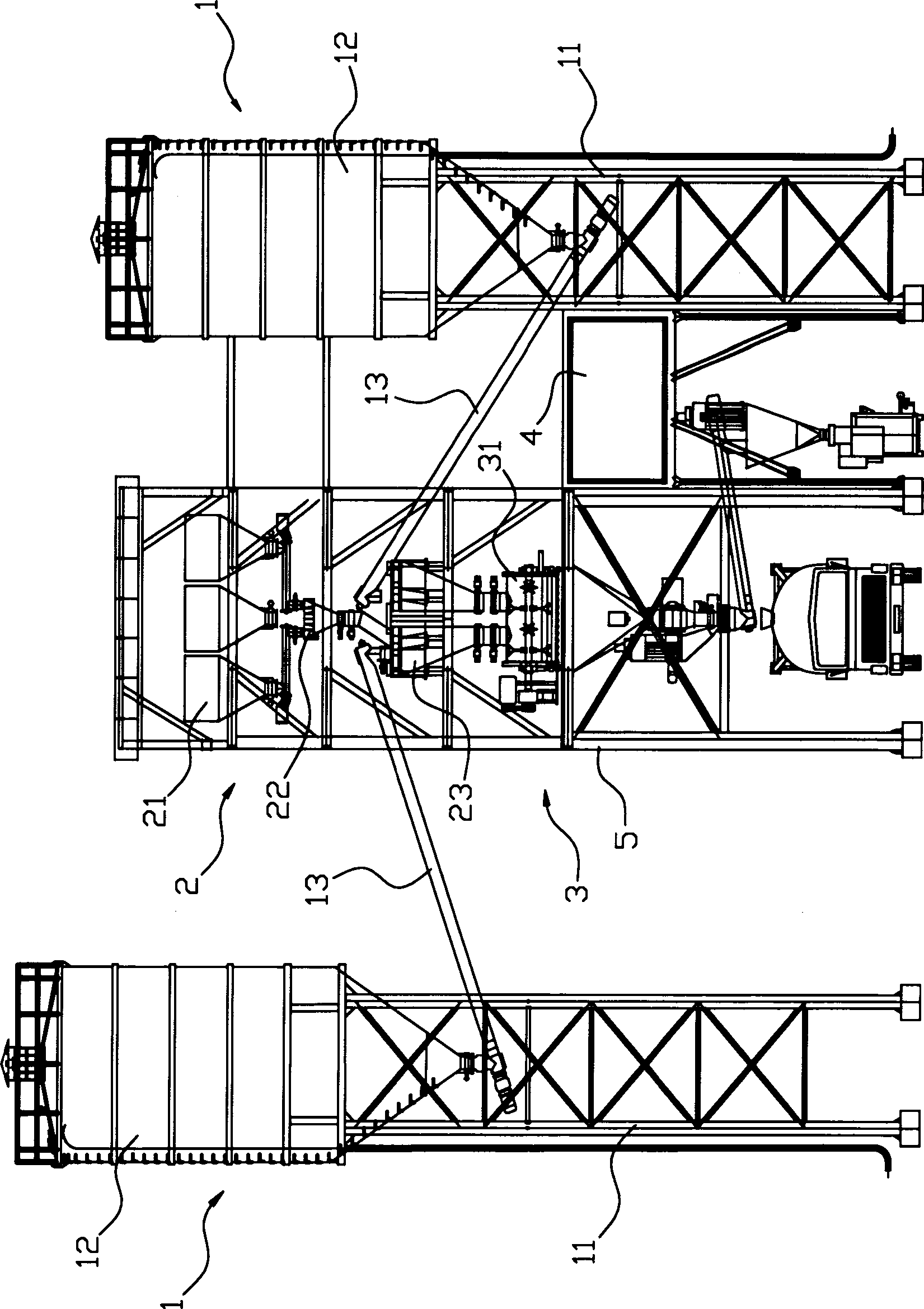

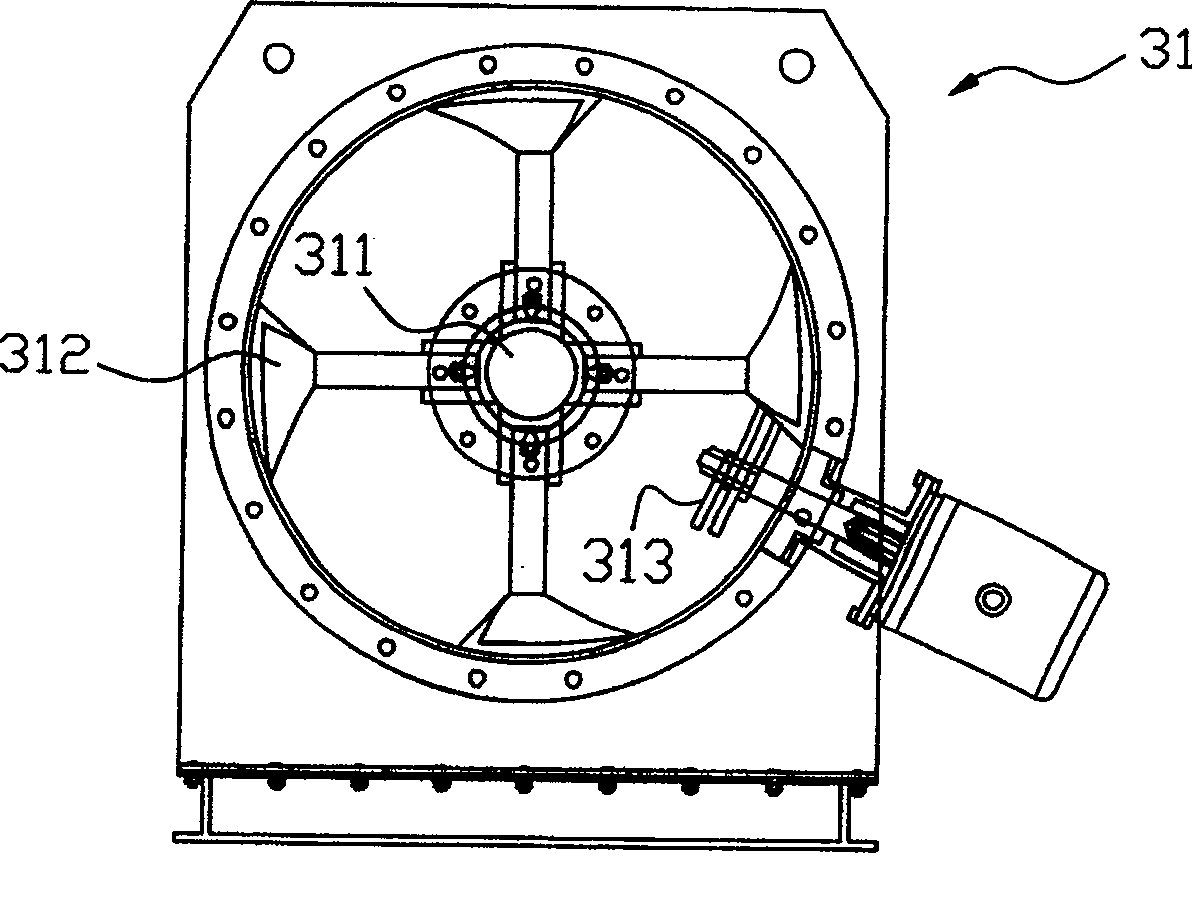

Production and automatic production equipment for building dry powder and mortar

ActiveCN100532047CAchieve standardizationImprove standardizationMixing operation control apparatusAutomatic controlHybrid system

A production process of dry powder mortar for construction, including: 1) material preparation, transporting various dry powder materials to a certain height; 3) feeding, so that various weighed dry powders fall into a mixing container at a lower position; 4) mixing, mixing the dry powders in the mixing container evenly, and obtaining dry powder mortar from the bottom of the mixing container. Its production equipment includes material preparation system, batching system, mixing system, automatic control system, and steel structure main building. The invention realizes the automatic production of dry powder mortar by adopting a complete set of equipment, and at the same time, facilitates the standardization of the distribution ratio control of each component of the dry powder mortar.

Owner:QUANGONG MACHINERY

Waste tire thermal cracking reaction device

ActiveCN114214085APrevent affecting pyrolysis effectAvoid interferenceLiquid hydrocarbon mixture productionProcess engineeringCracking reaction

The invention discloses a waste tire thermal cracking reaction device and a thermal cracking process thereof, and relates to the technical field of waste recycling, the waste tire thermal cracking reaction device comprises a stirring device, the stirring device comprises a feeding barrel, the inner wall of the feeding barrel is movably connected with a rotating wheel through a pin shaft, the bottom of the stirring device is provided with a screening and conveying device, and the screening and conveying device comprises a fixed bottom plate; a short support is fixedly connected to the right side of the top of the fixed bottom plate, a guide screen groove is movably connected to the top of the short support through a pin shaft, filtering holes are formed in the bottom of the middle of the guide screen groove at equal intervals, and a short vibration connecting rod structure is movably connected to the left side of the guide screen groove through a pin shaft. The tire particles are heated and cracked to generate non-condensable gas, and the particles in a closed space formed by the blocking block, the material plate, the fixed isolation plate and the movable isolation plate enter the bottom of the inner wall of the anti-escape barrel, so that in the whole feeding process of the device, oil gas in the heating tank cannot escape into the atmosphere from the feeding device, and the atmospheric environment is protected.

Owner:湖南睿熙达新材料科技有限公司

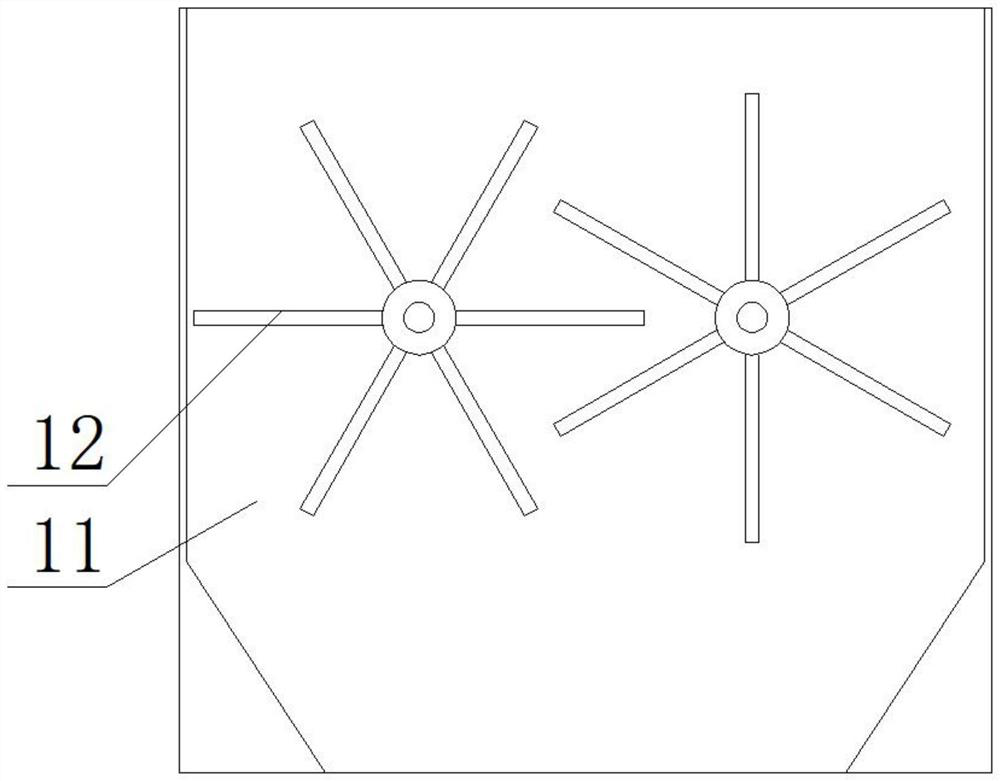

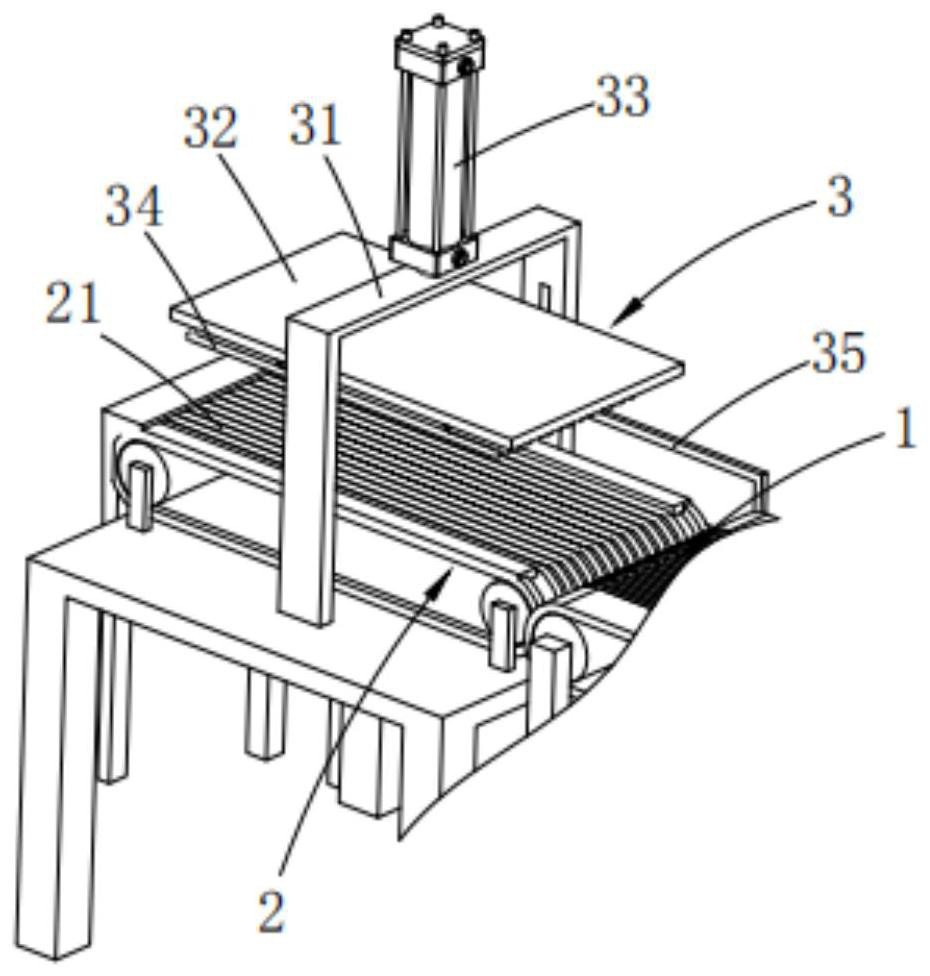

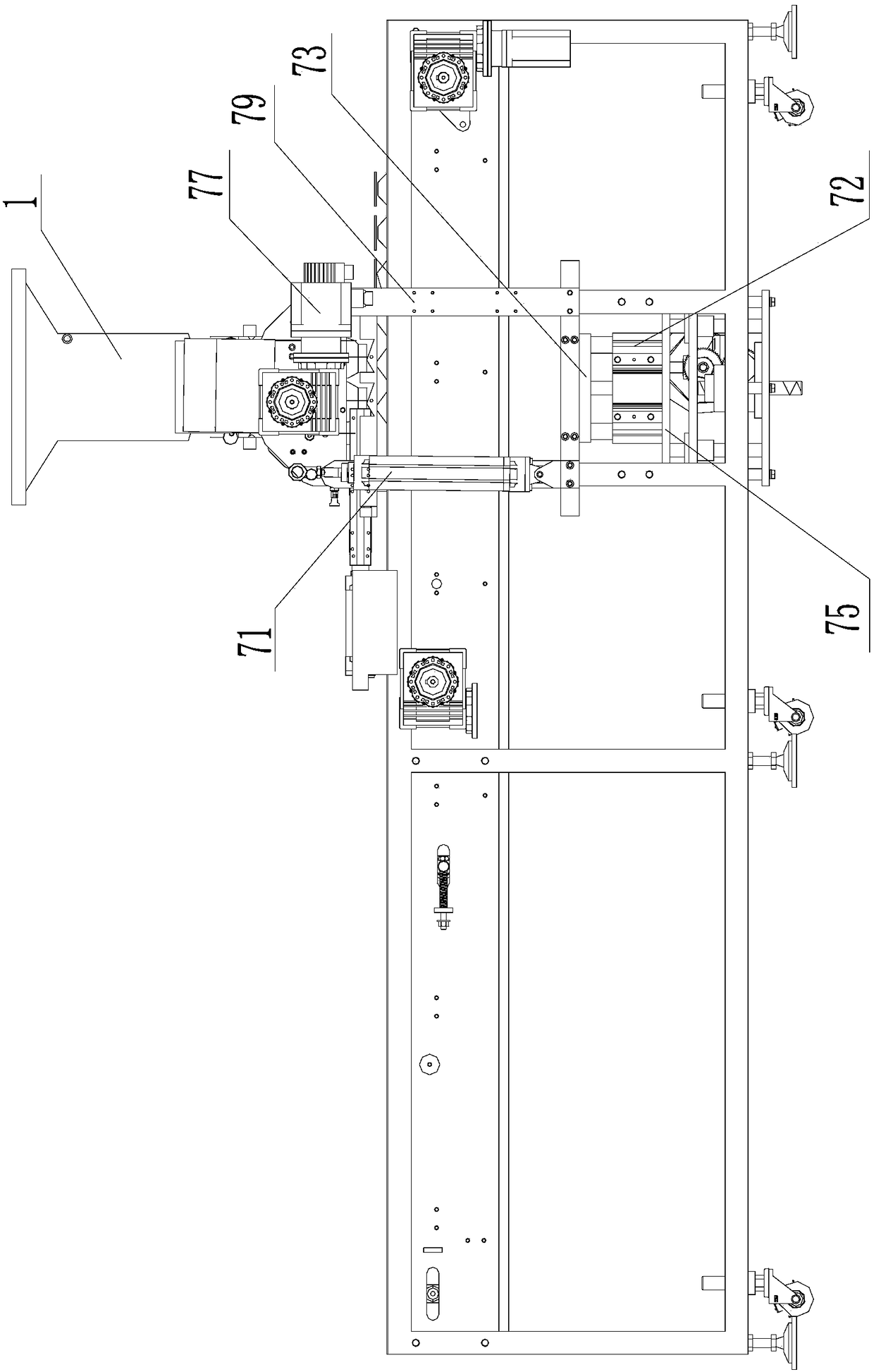

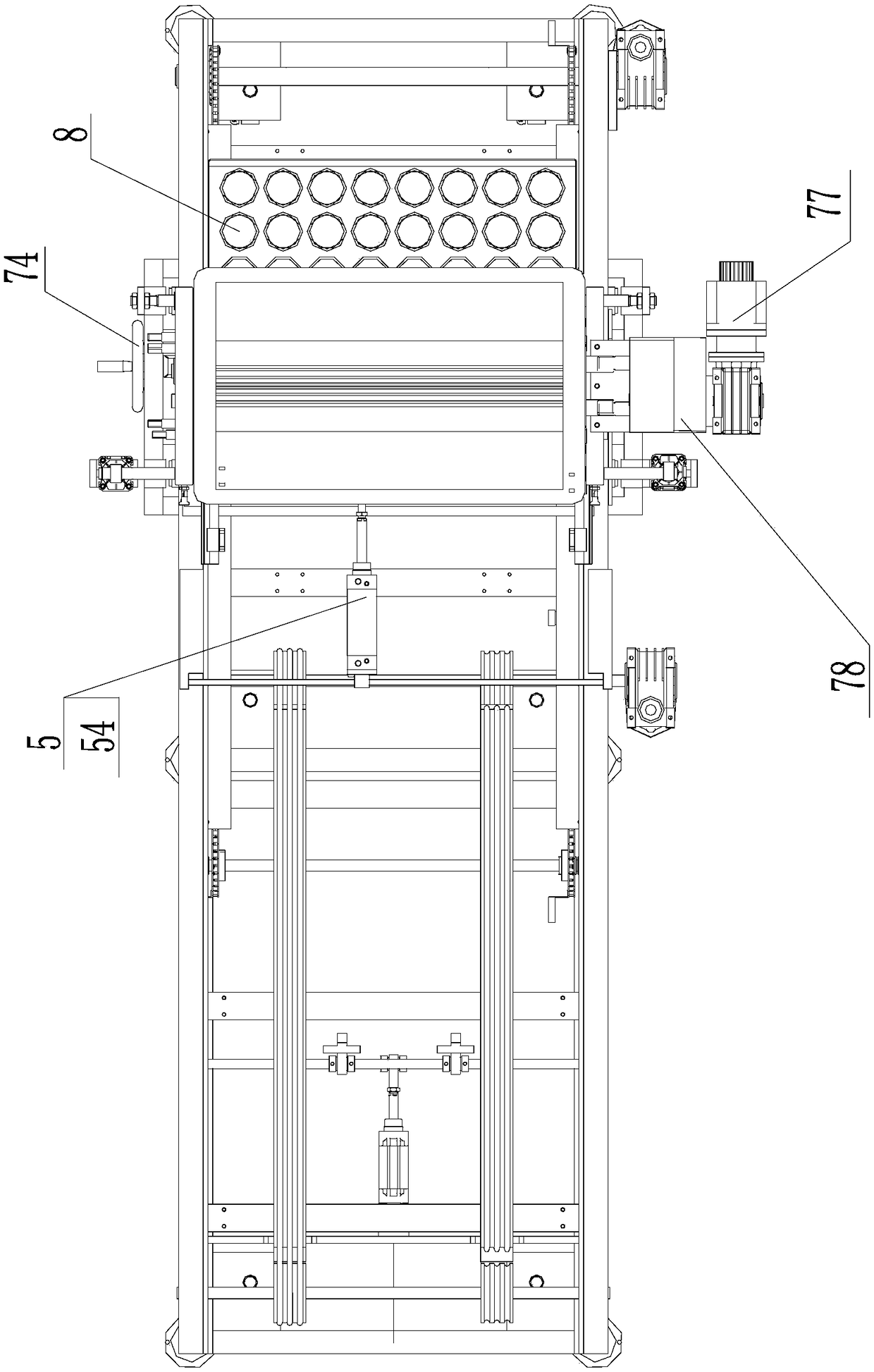

Automatic processing and forming production device of farfalle

InactiveCN112056339ARealize automatic production packagingIncrease profitWrapper twisting/gatheringSolid materialWaste materialIndustrial engineering

The present invention relates to the technical field of food processing devices and particularly to an automatic processing and forming production device of farfalle. The automatic processing and forming production device of farfalle comprises a first conveying mechanism, a second conveying mechanism arranged at an output end of the first conveying mechanism, a forming mechanism arranged at an output end of the second conveying mechanism in a conveying direction of the second conveying mechanism, a discharging mechanism arranged at an output end of the forming mechanism, and a packaging mechanism arranged at an output end of a material chute. Through cooperation of a first forming part and a second forming part, dough skins are pressed into side-edge M shapes, meanwhile, the dough skins atfirst notches and second notches are bonded through mutual movements of forming rods, then the formed farfalle enters packaging boxes through the material chute, the packaging boxes and box covers are nailed together through a stapling assembly after the box covers are additionally arranged on the packaging boxes through an external mechanical arm, packaging is finished, automatic production andpackaging of the farfalle are achieved, and production quality and a utilization rate of waste materials are improved.

Owner:马胜男

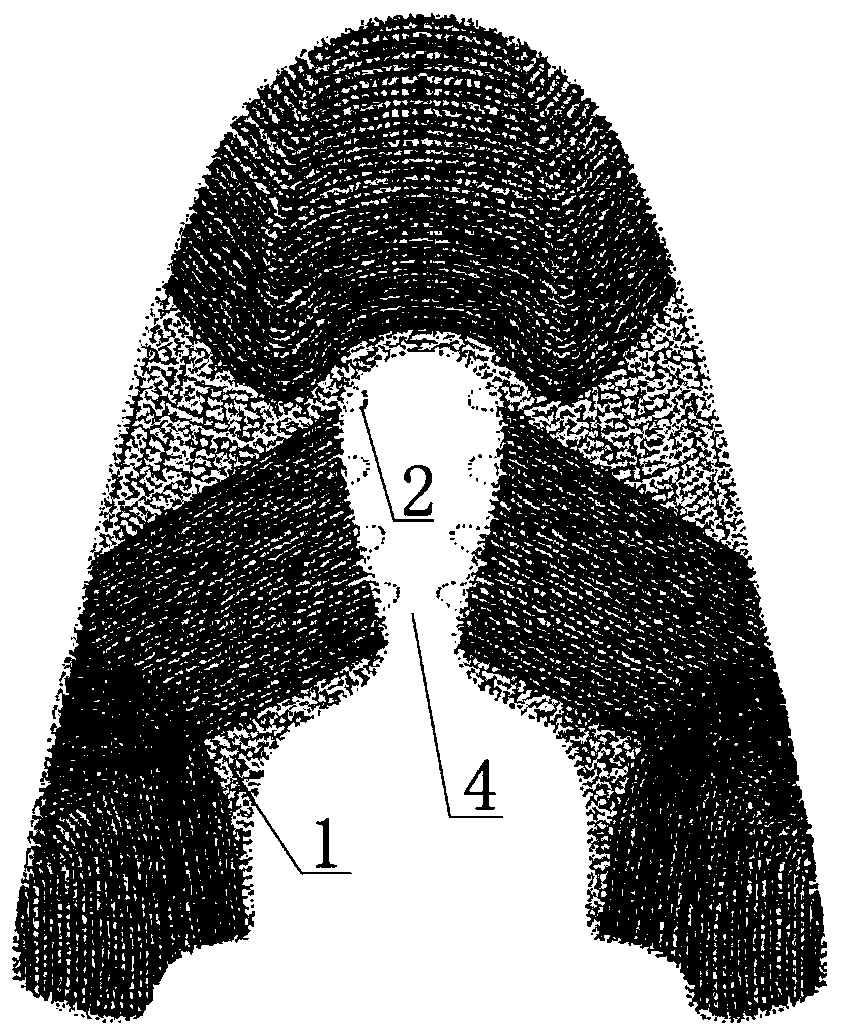

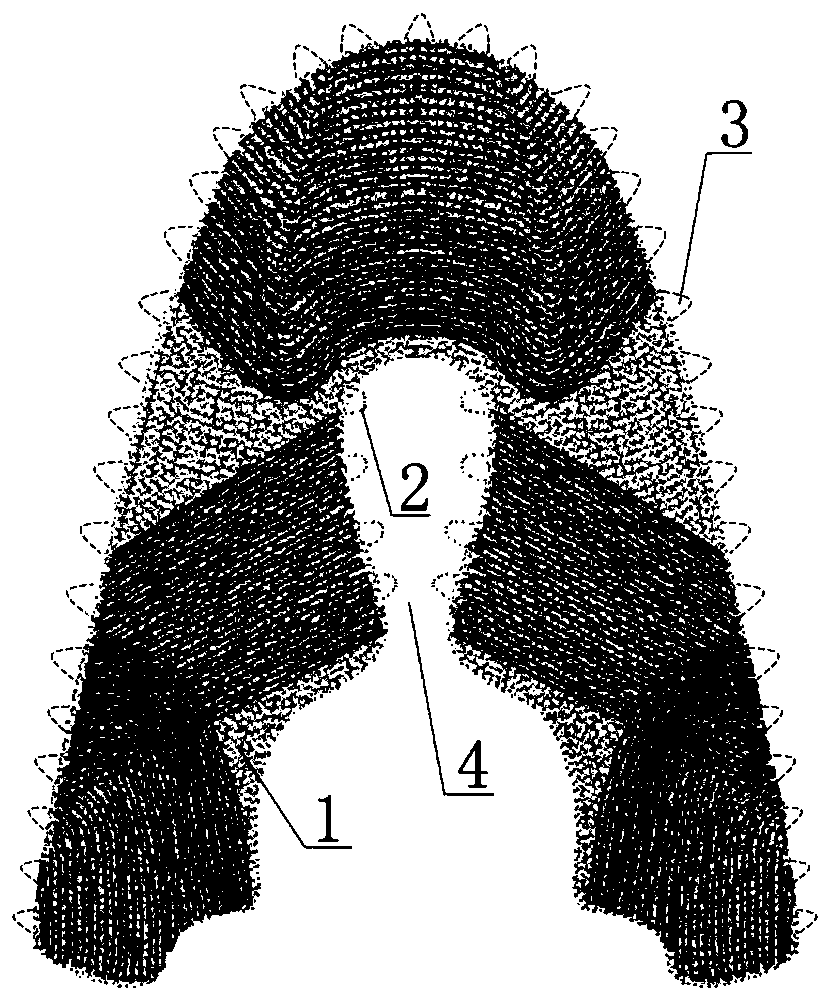

A method for making computer embroidery shaped shoe uppers

ActiveCN107460666BHigh degree of automationFast productionAutomatic machinesYarnIndustrial engineering

The invention discloses a production method of a computer-aided embroidery-formed vamp. The production method comprises the following steps: designing a plane template of the computer-aided embroidery-formed vamp, designing an embroidery pattern of the computer-aided embroidery-formed vamp, embroidering the computer-aided embroidery-formed vamp on a machine, and post-finishing the computer-aided embroidery-formed vamp and the like. By the production method, a computer-aided embroidery machine is used for embroidering a wrapped yarn into the one-piece formed vamp, and tailoring and sewing are not required for once forming, so that the conventional vamp producing technology is overturned; the production process is environmentally friendly, material-saving and high in degree of automation; the produced vamp has the characteristics of lightness, thinness, breathability, comfort, foot fitness, customizability and the like.

Owner:CHENGDU TEXTILE COLLEGE

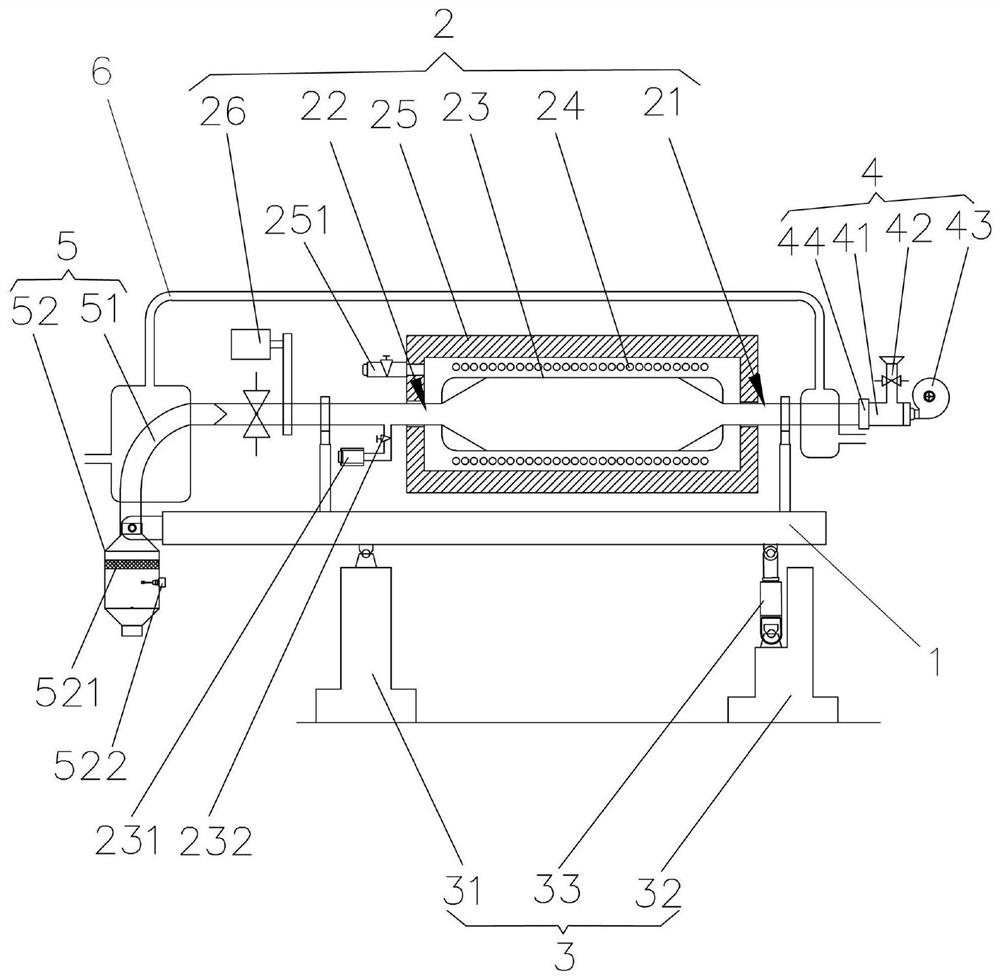

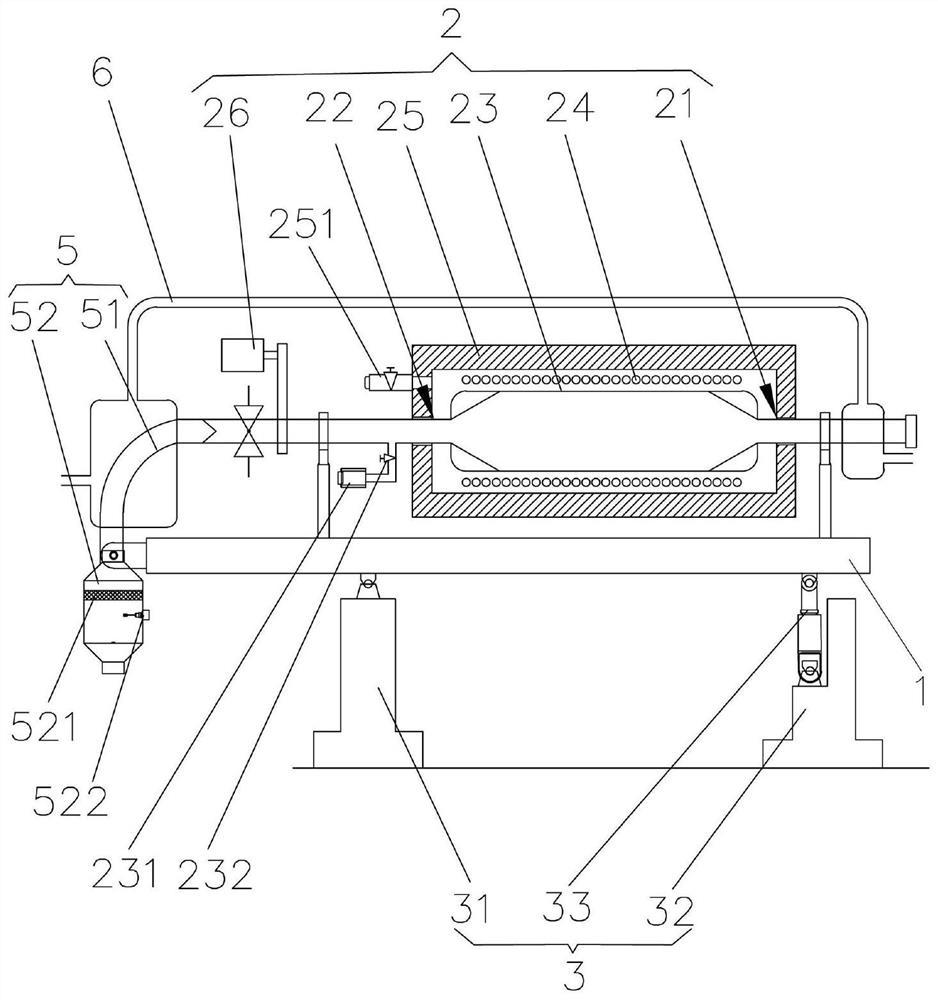

Rotary sintering furnace

PendingCN113915993ASmooth dischargeComplete dischargeRotary drum furnacesMaintainance of heating chambersMetallurgyGas supply

The invention belongs to the technical field of sintering furnaces, and particularly relates to a rotary sintering furnace. The rotary sintering furnace comprises a base, a furnace body rotationally arranged on the base and a first driving device used for driving the furnace body to obliquely rise, a feeding port is formed in one end of the furnace body, and a discharging port is formed in the other end of the furnace body. The first driving device is used for obliquely lifting one end of the feeding port of the furnace body, and the furnace body is provided with a positive pressure air supply adjusting device. The rotary sintering furnace has the advantages of being smooth in discharging, thorough in discharging and free of residual materials, meanwhile, the furnace pressure can be controlled, high-quality positive pressure sintering can be conducted on materials, and the sintering effect is good.

Owner:上海锦源晟新能源材料有限公司 +1

Noble metal seamless tube and manufacturing method and manufacturing equipment thereof

The invention discloses a noble metal seamless tube which is composed of a plurality of metallic elements, wherein the metallic elements comprise Au, Ag and Cu at the following ratio: 70-80% of Au, 4-16% of Ag and 9.8-21% of Cu. The invention also provides a manufacturing method thereof comprising the following steps: 1) under the anaerobic condition, putting metal mixture into a smelting furnace, heating the metal mixture in the smelting furnace by a medium-frequency heating power supply; 2) leading the heated metal mixture into a tube mould, cooling by a cooler, and shaping to a seamless tube preforming product; 3) leading the cooled seamless tube preforming product out of the tube mould; and 4) stretching the seamless tube preforming product to deform under high pressure to form the finished product of the noble metal seamless tube with different specifications. The manufacturing method is simple to operate, has high yield, can completely eliminate the defects, such as missing solder, perforation, irregular roll film butt joint and the like, improves seamless tube quality and lowers manufacturing cost. The invention also provides equipment for manufacturing the noble metal seamless tube.

Owner:陈海东

A kind of dough automatic production line

ActiveCN111771932BIncrease productivityImprove product qualityDough shaping and cutting apparatusMolding machineManufacturing line

Owner:临泉县康寿面业有限公司

Resistor with wavelike resistor discs

InactiveCN102436882ASave man hoursNo leftoversResistor mounting/supportingZig-zag/sinusoidal resistive elementsWave shapeResistor

The invention discloses a resistor with wavelike resistor discs. The resistor with wavelike resistor discs comprises an insulating frame, resistor discs, an input terminal, an output terminal and a central tapping terminal. The resistor discs comprise a head resistor disc, a middle resistor disc and an end resistor disc. The head resistor disc, the middle resistor disc and the end resistor disc are made from a steel disc having certain width. The head resistor disc and the end resistor disc have wave shapes. The head resistor disc is fixedly connected to one side of the insulating frame. The end resistor disc is fixedly connected to the other side of the insulating frame. The middle resistor disc has a lower frame shape. Two sides of the middle resistor disc have wave shapes. The top of the middle resistor disc is fixedly connected to a top plate of the insulating frame. In the invention, based on the structure, a collared steel sheet is directly cut into a small collared steel sheet of which width is the same as resistor disc width and then the cut small collared steel sheet can be directly utilized for resistor disc manufacture. Compared with the prior art which is characterizedin that a collared steel sheet is bought back and then is cut into multiple small steel discs, the resistor with wavelike resistor discs saves working time and does not produce offcuts.

Owner:王爱民

Bead Strength Tester

ActiveCN105758729BOptimize layoutQuick changeMaterial strength using tensile/compressive forcesGratingPressure sensor

The invention discloses a popping bead strength testing instrument which comprises a case.The case is provided with a controller and a feeding pressurizing mechanism.The feeding pressurizing mechanism comprises a material barrel, a carrying table, a pressure head, a compressing mechanism and a compressing motor, wherein the pressure head is fixed to the compressing end of the compressing mechanism, and the compressing motor is in driving connection with the compressing mechanism.The carrying table comprises a carrying table support, and the carrying table support is provided with an air blowing pipe, a pressure-bearing head, a pressure sensor and a steel wire groove, wherein the pressure-bearing head is in rigid connection with the pressure sensor, one end of the pressure head right faces the pressure-bearing head, a grating ruler is connected to the other end of the pressure head, the steel wire groove is located between the pressure-bearing head and the pressure head, a discharging port of the material barrel is provided with a flexible material guide pipe, an air blowing opening of the air blowing pipe faces the steel wire groove, a popping bead detector is arranged in a pipeline of the material guide pipe, and the pressure sensor, the grating ruler and the popping bead detector are electrically connected with the controller.The popping bead strength testing instrument is capable of saving manpower and high in efficiency, the discharging process is simple, the material barrel can be quickly replaced to be compatible to samples with different diameters, and material jamming and residual materials can be avoided.

Owner:CHENGDU RETOOL SCI & TECH CO LTD

Automatic forming method and device for rubber sealing ring blank

ActiveCN114851500AHigh degree of automationIncrease automation rateDomestic articlesBobbinKnife blades

The invention relates to the technical field of rubber sealing ring blank forming, in particular to an automatic rubber sealing ring blank forming method and device.A cutting blade is fixedly connected to the surface of a blank forming assembly, a second equipment body is fixedly connected to a sliding table module, and a second supporting rod is fixedly connected to the surface of the second equipment body; the inner side surface of the second supporting rod is fixedly connected with a blank box, and the tail end of the long blank strip is fixedly connected with a blank thread shaft. The device has the advantages that the automation degree is high, blank strips conveyed from the blank spool pass through the guide wheels and the guide grooves and are automatically pressed into rings through the combined action of the blank forming assembly and the cutting blade, feeding is conducted in a continuous blank strip introduction mode, automatic forming of the blank rings is achieved through the action of the automation assembly, and the production efficiency is improved. Except that the blank long strip of the blank bobbin is used up and the blank bobbin is replaced, the other processes are all completed by the machine, and the automation rate is high.

Owner:CHENGDU HOLY AVIATION SCI & TECH CO LTD

Processing method of seafood instant porridge

The invention discloses a processing method of seafood instant congee, comprising the steps as follows: washing the main ingredients for standby use; washing and steaming the seafood ingredients, taking out the meat, refreezing and drying the meat for standby use; taking the washed main ingredients and refrozen and dried seafood ingredient, adding water, oil and flavoring for mixture; filling and sealing the mixture; sterilizing the mixture at high temperature, cooling and packaging the mixture, thus obtaining the product. In the method, the seafood ingredients are first steamed and then the meat is taken, refrozen and dried, so that the odors of the seafood ingredients are removed and freshness is improved, thereby ensuring delicate flavor of the seafood. In addition, the dried seafood ingredients can not be boiled out and become pasty but are still in cakes, thereby ensuring mouthfeel and color of the seafood; therefore, the product produced by the method is good in color, aroma and taste; the processing and production courses are environment-friendly and sanitary and the leftovers can be comprehensively utilized, thus having little pollution and high social and economic benefits.

Owner:XIAMEN BAOLINTAI SEAFOOD FOODSTUFF

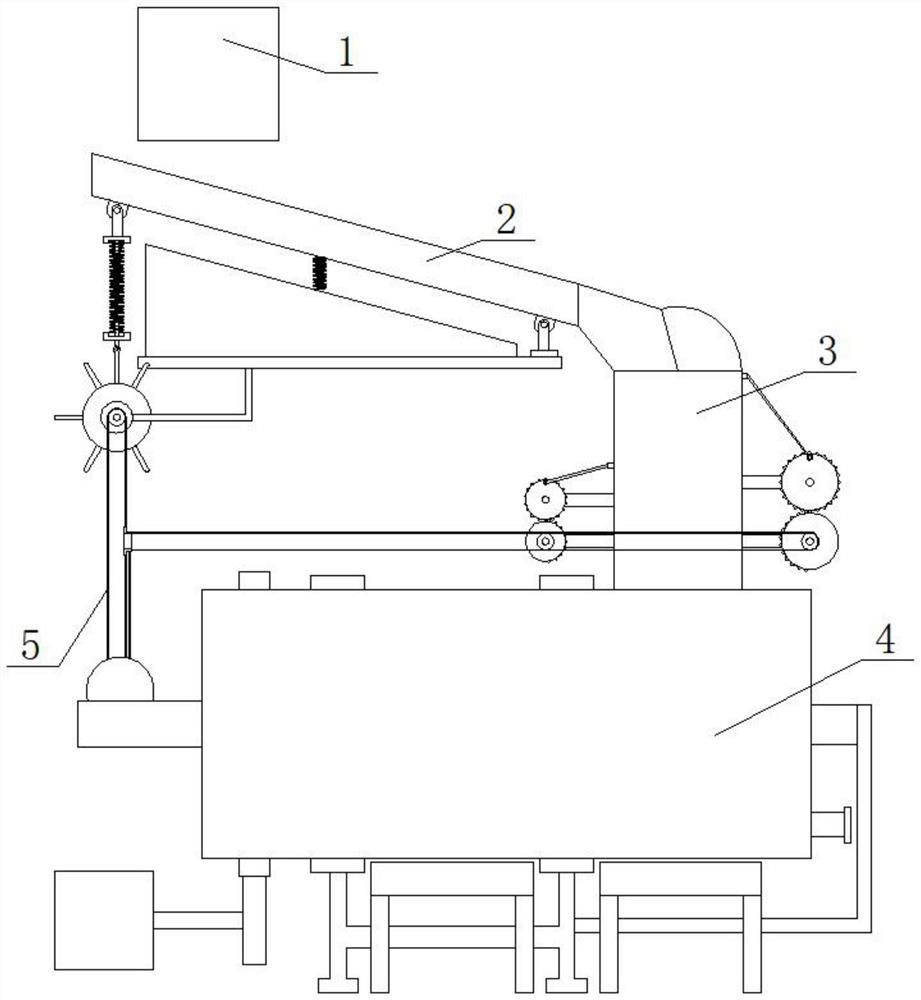

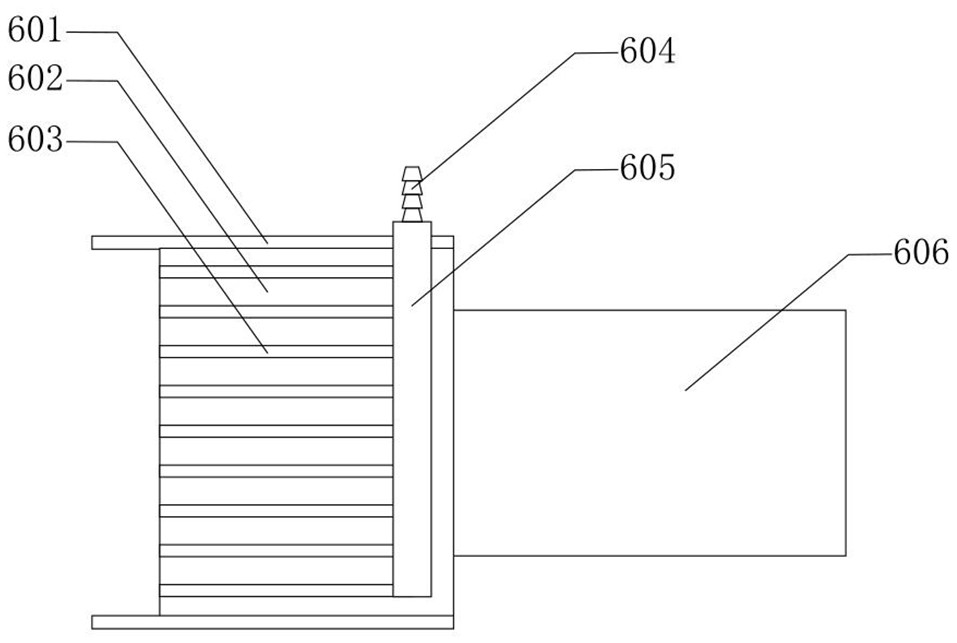

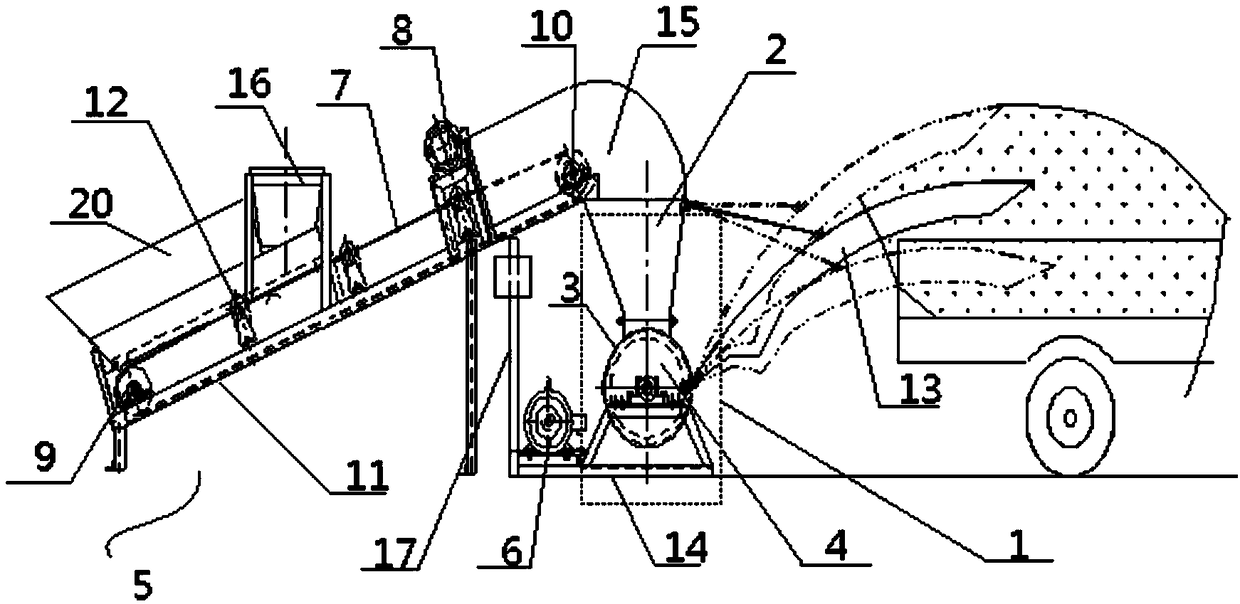

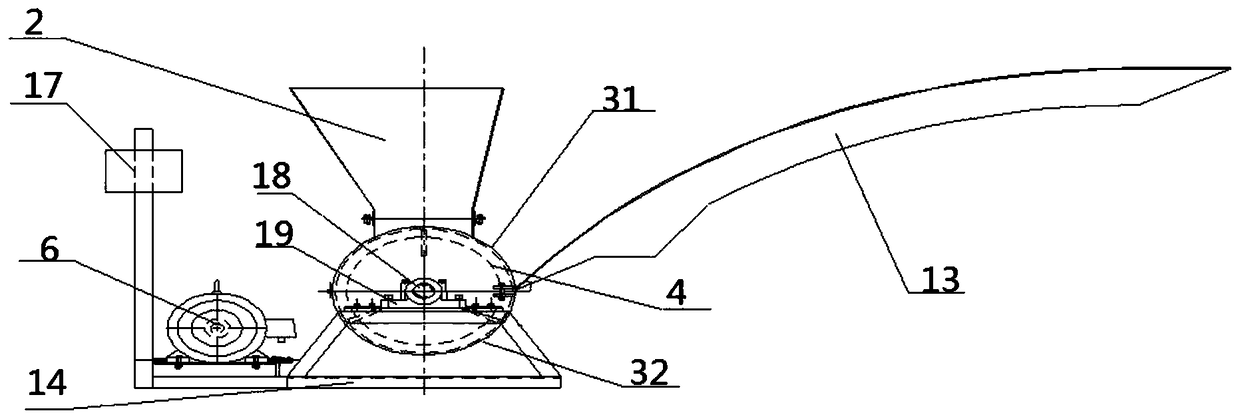

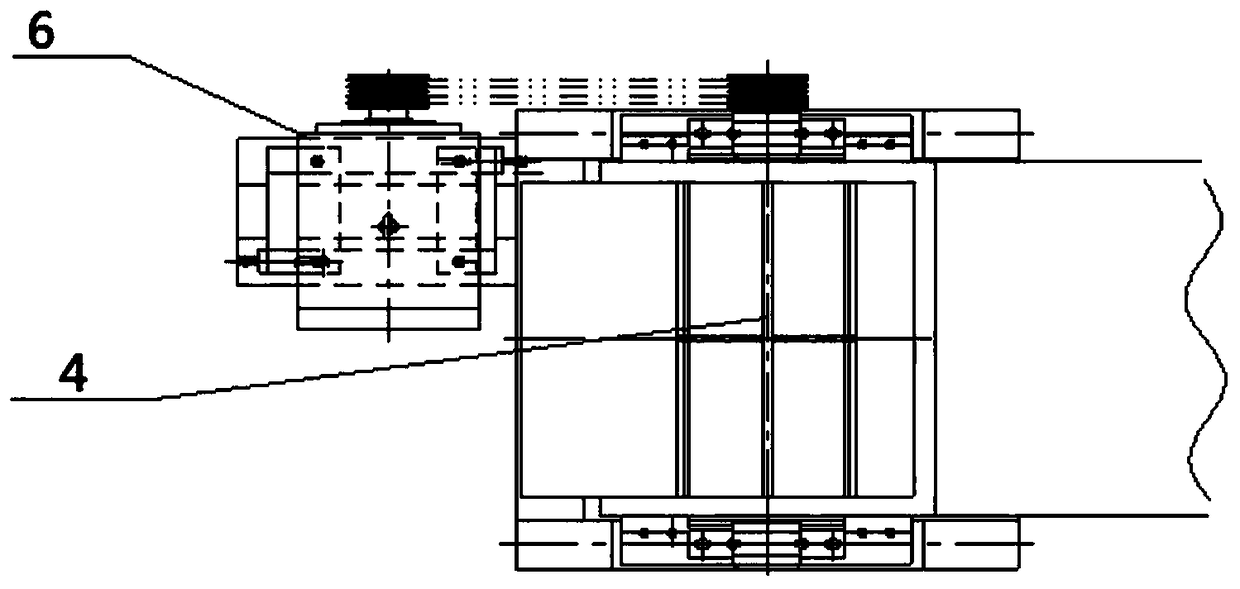

Total mixed rations (TMR) crushing and stirring integrated machine

The invention discloses a total mixed rations (TMR) crushing and stirring integrated machine. The TMR crushing and stirring integrated machine comprises a stirring main machine, a material transporting device and a first driving motor, wherein the material transporting device is connected with the stirring main machine, and is used for continuously transporting coarse materials and fine materialsto the stirring main machine; the first driving motor is used for driving the stirring main machine to continuously operate; the stirring main machine comprises a feeding hopper and a cylinder body which are sequentially arranged from top to bottom, and the cylinder body is connected with the feeding hopper, and is used for accommodating the coarse materials and the fine materials; a stirring unitis arranged in the cylinder body, and rotates at a high speed under the driving of the first driving motor, so that the coarse materials are cut into flocculence, and the fine materials are embeddedin the coarse materials, and a TMR feed in which the coarse materials and the fine materials are sufficiently mixed is formed; and a discharging opening for continuously discharging the TMR feed out of the cylinder body is arranged on one side of the cylinder body. Through the adoption of the TMR crushing and stirring integrated machine disclosed by the invention, the production efficiency is improved, the power consumption is low, the equipment cost is greatly reduced, the digestibility and nourishment absorbing rate of the TMR feed are increased, fattening time of livestock is shortened, income of raising households is increased, and the TMR crushing and stirring integrated machine has broad popularization prospects.

Owner:宋国亮

A vertical vacuum drying device

ActiveCN106152743BShort heating timeImprove heating efficiencyDrying using combination processesDrying solid materials with heatBiochemical engineeringVacuum drying

Owner:贵州省印江县依仁食品有限公司

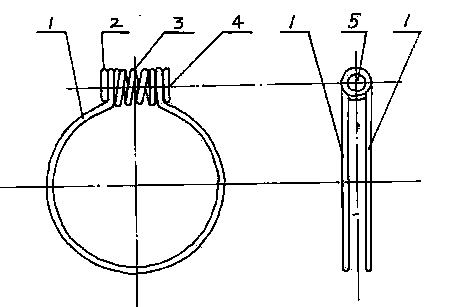

Pipe clamp

The invention relates to a fixing device for connecting pipes, in particular to a pipe clamp fixed on the outer diameter of a pipe. The pipe clamp is characterized in that a steel wire is wound to form a fixed end 2 and produce two steel wire strands which are wound to form the circumference of the pipe clamp, a fixed hole 5 is formed in the fixed end 2, two ends of the steel wire are respectively wound to form an auxiliary pipe clamp 3 and an end 4 to form another fixed end 2, and fixed holes 5 are formed in the auxiliary pipe clamp 3 and the end 4. A steel wire structure that the auxiliary pipe clamp and the pipe clamp are integrated is suitable for modern spring universal machining, the process is simple, and production efficiency is high. Offcut and excess materials are not produced, the unit pipe clamp cost is greatly reduced, the tightness of a fixing screw can be adjusted automatically by means of the spring type auxiliary pipe clamp, and connections like connection of rubber pipes are in kept in the normal fixing state all the time.

Owner:DALIAN YUJIAN TECH

Pet feeding machine with curved feeding structure

PendingCN110402832AImprove availability and reliabilityGood applicabilityAnimal feeding devicesElectric machineryEngineering

The invention discloses a pet feeding machine with a curved feeding structure and relates to the technical field of automatic feeding machines. The pet feeding machine comprises a bottom plate, a front shell and a rear shell, wherein the top of the bottom plate is fixedly connected with a base, the back side of the front shell is fixedly connected with the front side of the rear shell, the top ofthe base is fixedly connected with a bottom shell, and the bottom of the inner wall of the bottom shell is fixedly connected with a motor; one end of a motor output shaft is fixedly connected with a rotating rod, and a supporting plate is fixedly connected between the two sides of the inner wall of the bottom shell. According to the pet feeding machine with the curved feeding structure, the motorworks to drive a rotating disc to rotate, so that rotating blades are driven to rotate, food can be smoothly discharged from the feeding machine and fall into a food plate, and the phenomenon of material blockage is avoided; it is ensured that the feeding machine can work normally, the situation that pets cannot eat is avoided, and the practicability and the reliability are improved; the feeding machine can control the weight of food for feeding, is applicable to pets with different food intakes and has high applicability.

Owner:东莞广宇精密电子有限公司

Dough sheet production device and puff production equipment

PendingCN108338193AIncrease productivityIncrease profitDough shaping and cutting apparatusEngineeringReciprocating motion

The invention discloses a dough sheet production device and puff production equipment. The dough sheet production device comprises a hopper, a feeding roller, a feeding pump, a forming cup and a cutting device, wherein the hopper is provided with a feeding opening and a discharging opening; the feeding roller is close to the discharging opening of the hopper, and is used for extruding dough materials from the discharging opening and enabling the extruded dough materials to enter the feeding pump; the feeding pump is used for transporting the dough materials into the forming cup; a dough material forming device is jointly formed by the hopper, the feeding roller, the feeding pump, the forming cup and the cutting device; and a cutting knife can be in straight reciprocating motion at the outlet of the forming cup, so that the dough materials are cut into dough sheets. The dough sheet production device and the puff production equipment disclosed by the invention aim to solve the technicalproblems that a conventional dough sheet production device is complicated in production process, and can produce leftover materials, so that waste is generated; and the invention provides the dough sheet production device and the puff production equipment, through which the production working procedures are reduced, and in the production process, no leftover materials are produced.

Owner:BEIJING SHENCHEN MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com