Rack box bottom side beam, manufacturing method thereof and method for manufacturing rack box

A manufacturing method and technology of bottom and side beams, which are applied in the field of containers, can solve problems such as damage to bottom and side beams, instability of web plates, and excessive scraps, and achieve the effects of improving production efficiency and product quality, increasing stability, and increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

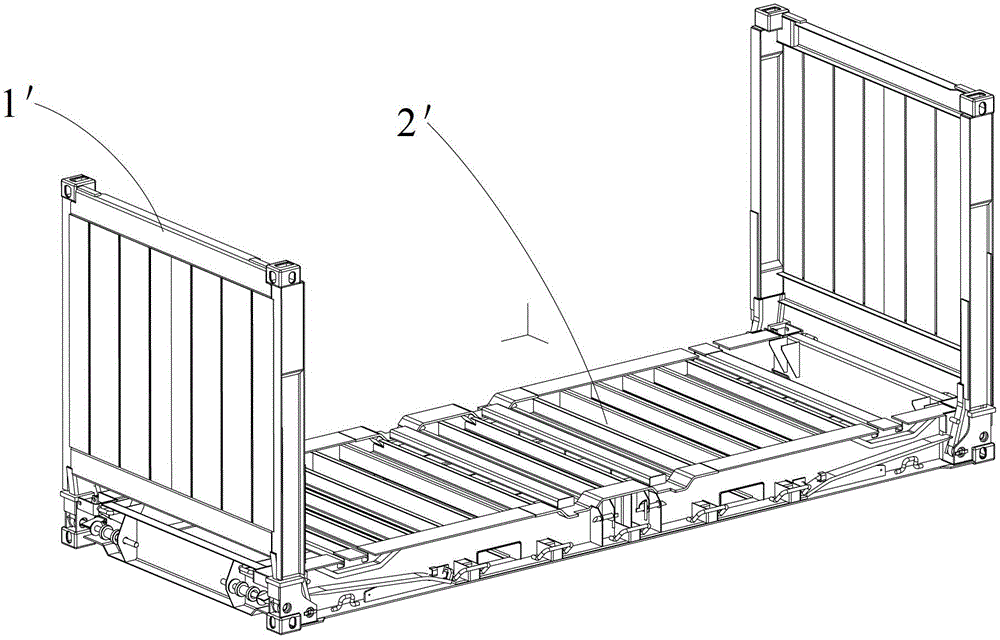

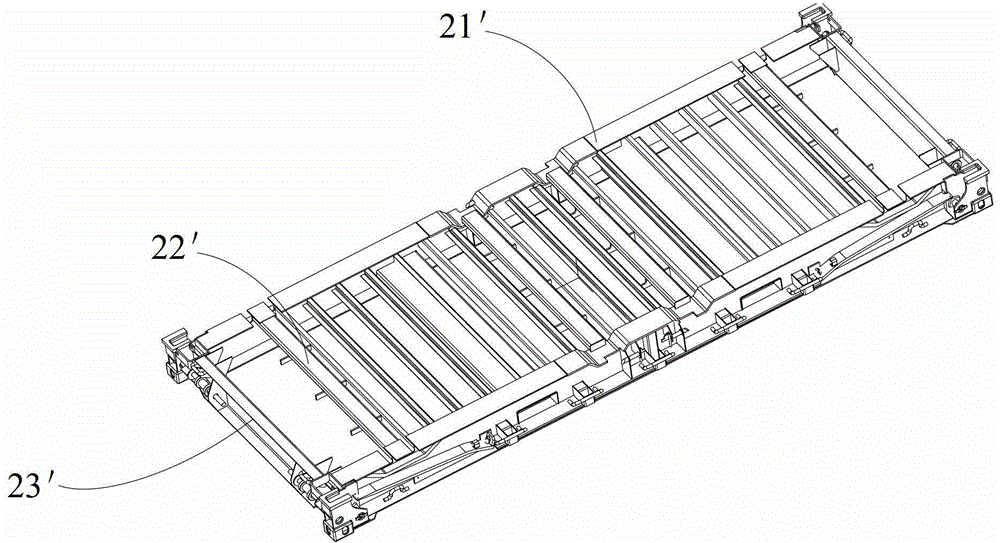

[0033] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0034] see Figure 6 , the present invention provides a method for manufacturing the side girder of the box bottom of the platform, the manufacturing method includes: step S1, making a web with a corrugated shape in the longitudinal direction; in this embodiment, step S1 includes step S11: making a web with a preset width a Web; step S12: making a web with a corrugated longitudinal direction.

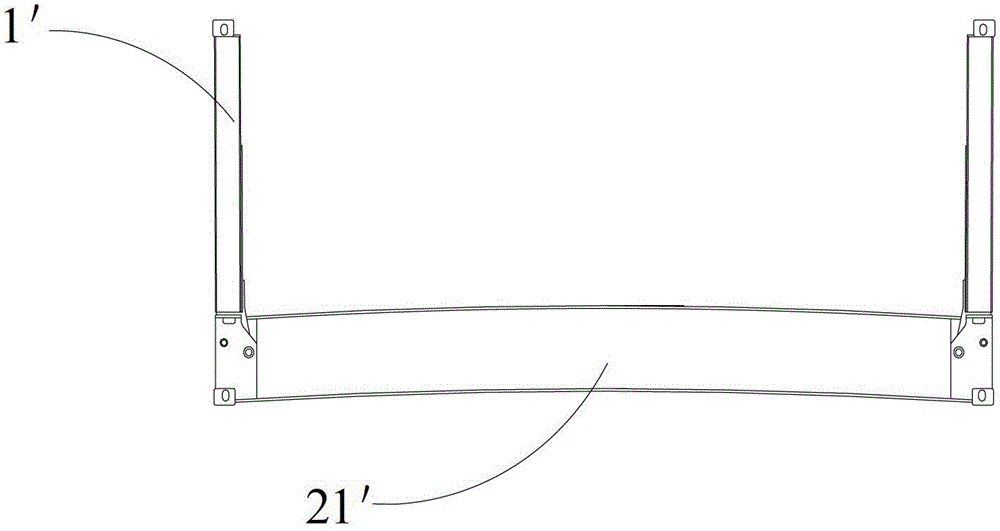

[0035] Such as Figure 7 , Figure 8 and Figure 9 As shown, the longitudinal direction of the web 213 is corrugated. In this embodiment, the web 213 can be produced by cutting. Compared with processing by large-scale CNC plasma (or flame) cutting machine in the prior art, the advantage of using shearing method is that it can avoid the generation of scraps, thereby sav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com