Production and automatic production equipment for building dry powder and mortar

A technology of dry powder mortar and production process, which is applied to clay preparation devices, chemical instruments and methods, and mixing operation control devices, etc. It can solve the problems that cement mortar is easy to solidify, must be used immediately, and cannot be stored for a long time, so as to achieve complete blanking. , easy to expand, and realize the effect of staged investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

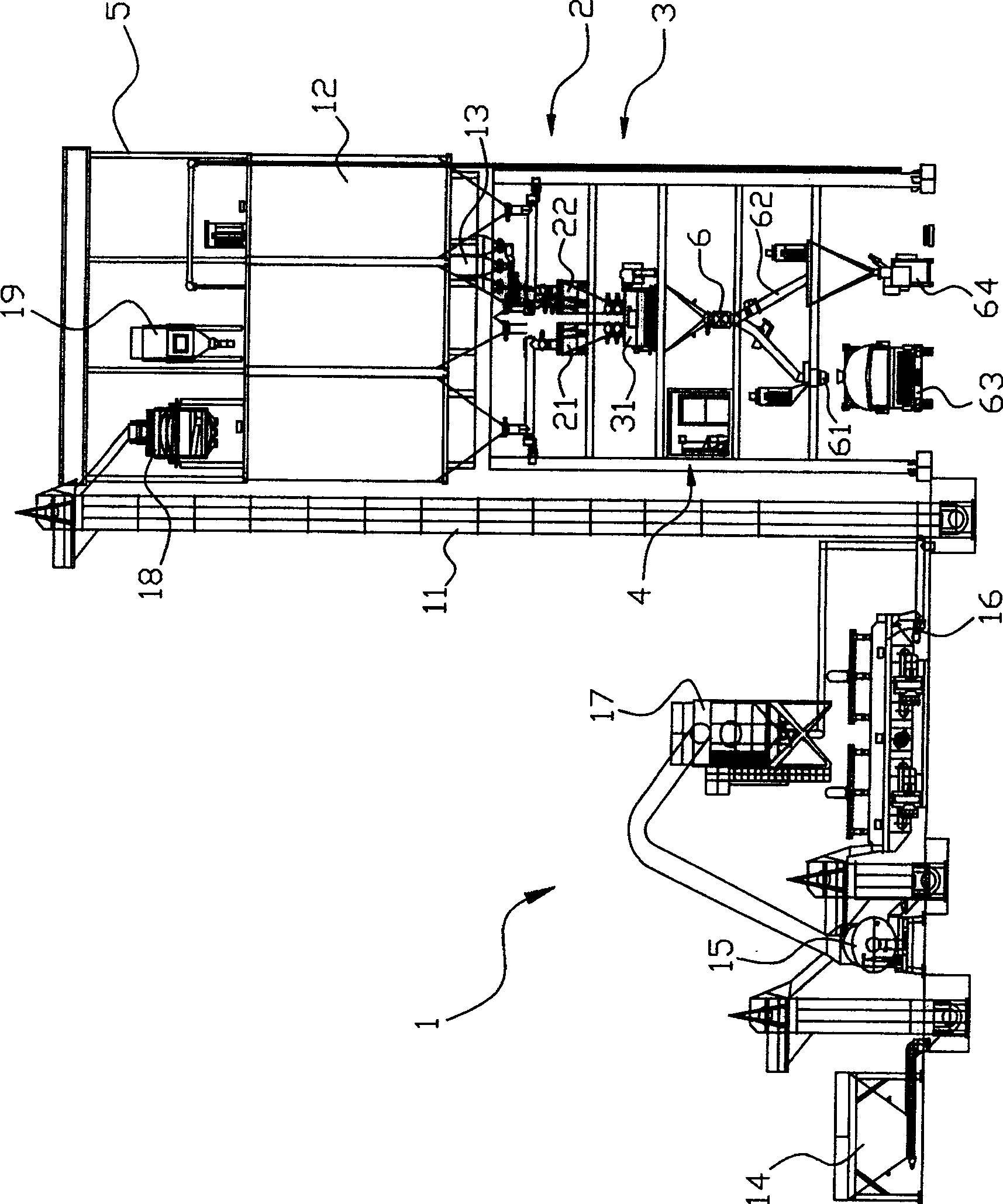

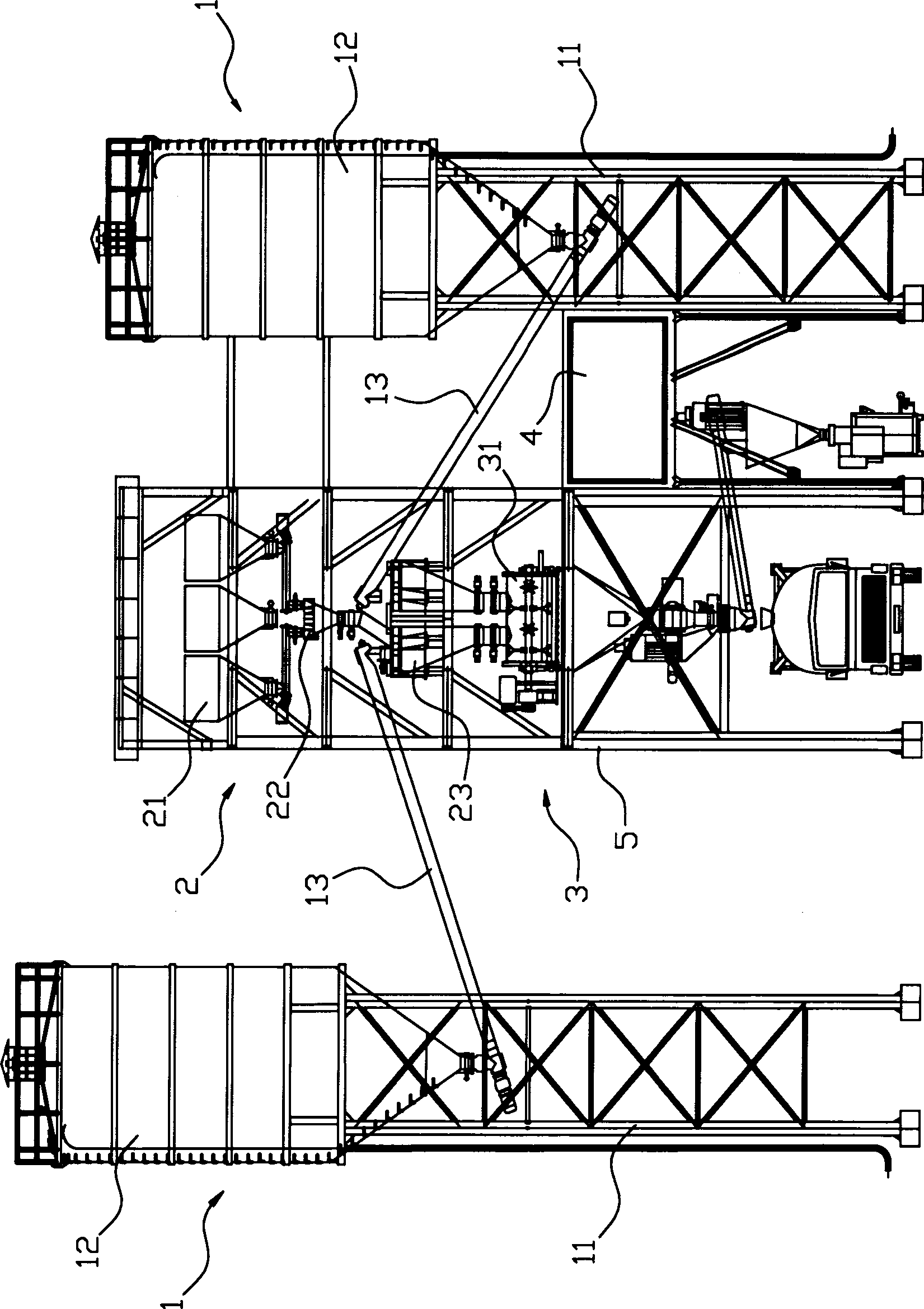

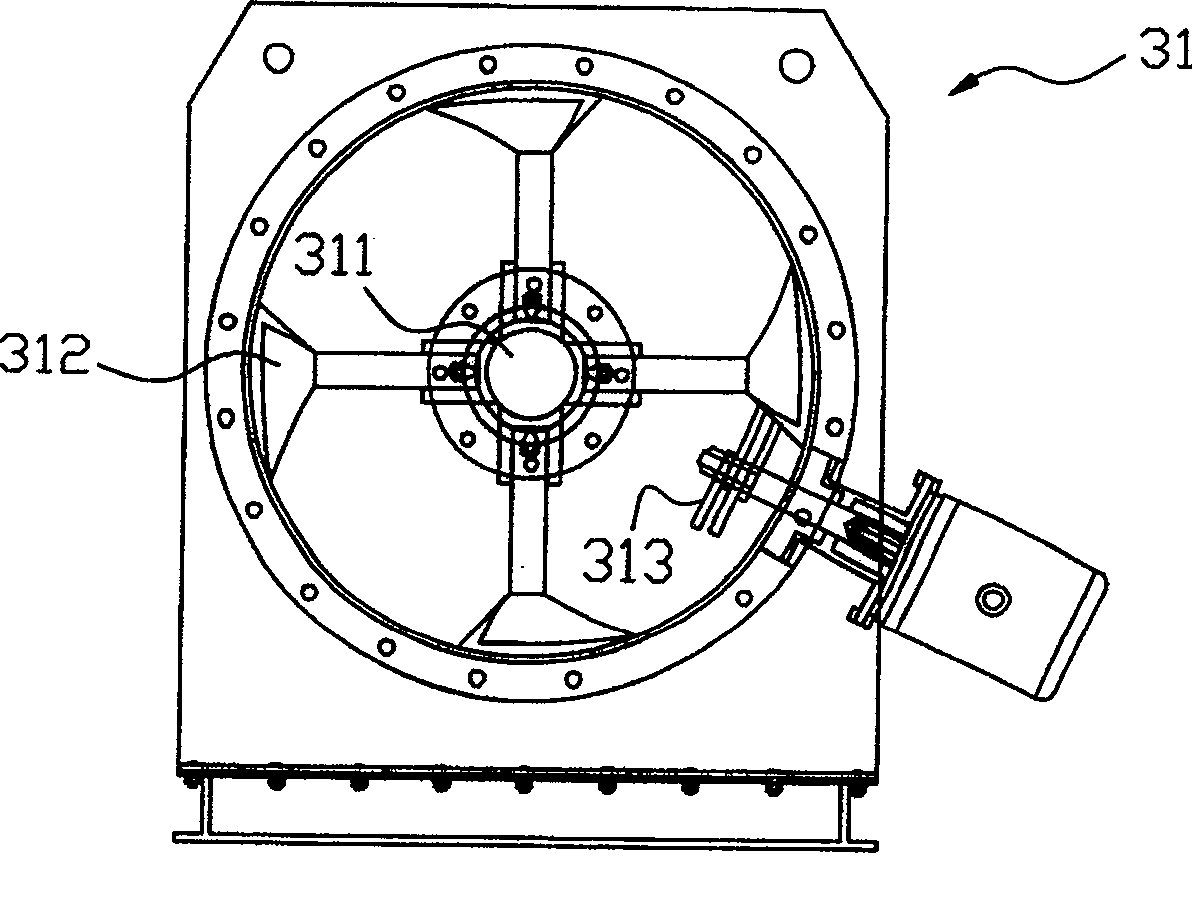

[0046] Specific embodiment two of the present invention, refer to figure 2 , including: a material preparation system 1, including a number of storage bins 12 for storing dry powder materials fixed at a certain height through a steel structure 11 and a corresponding dry powder material conveying mechanism 13; a batching system 2, including additive storage bins 21, dry powder material metering Device 23 and additive metering device 22, dry powder material metering device 23 is connected with the outlet of aforementioned dry powder material conveying mechanism 13, additive metering device 22 is connected below additive storage bin 21; Mixing system 3 includes a dry powder material metering device 23 and the stirring equipment 31 below the additive metering device 22; the automatic control system 4 is used to automatically control the above-mentioned material preparation system 1, the batching system 2 and the mixing system 3 to work harmoniously; the steel structure main buildi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com