Vertical vacuum drying device

A vacuum drying device, vertical technology, applied in the direction of non-progressive dryers, heating devices, drying solid materials, etc., can solve the problems of high production cost, low heating efficiency, unclean discharge, etc., to reduce production costs, Improved productivity and shorter heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

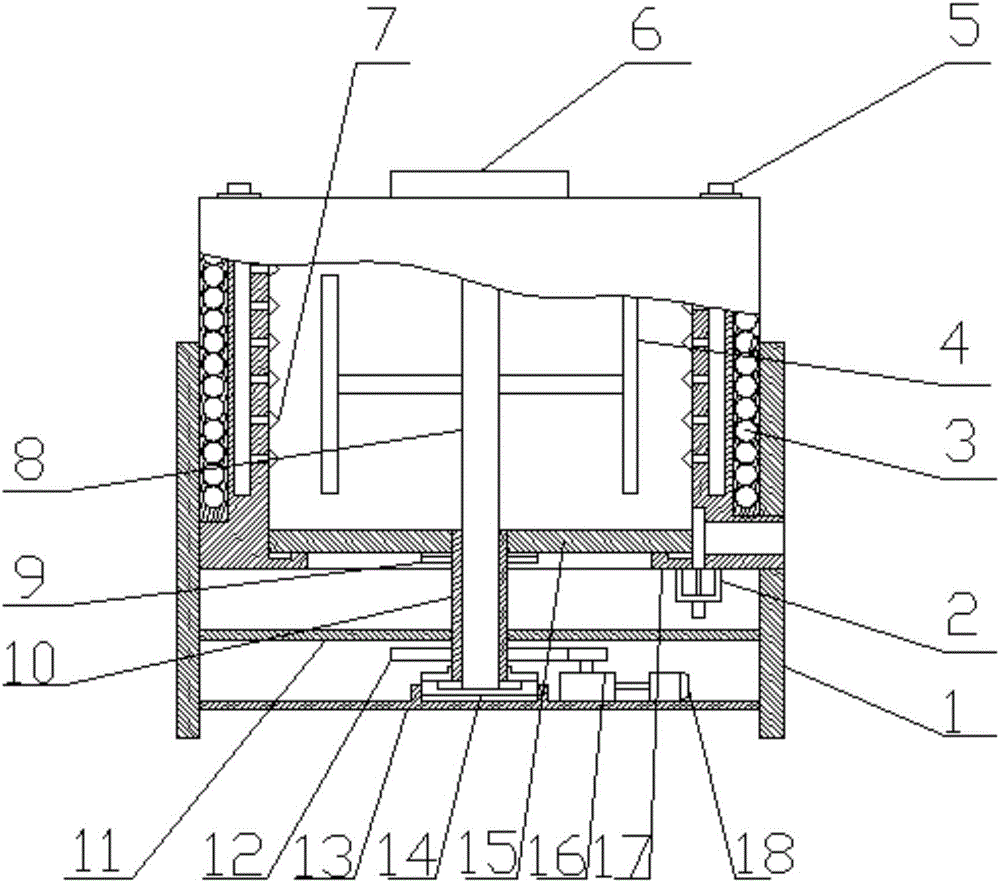

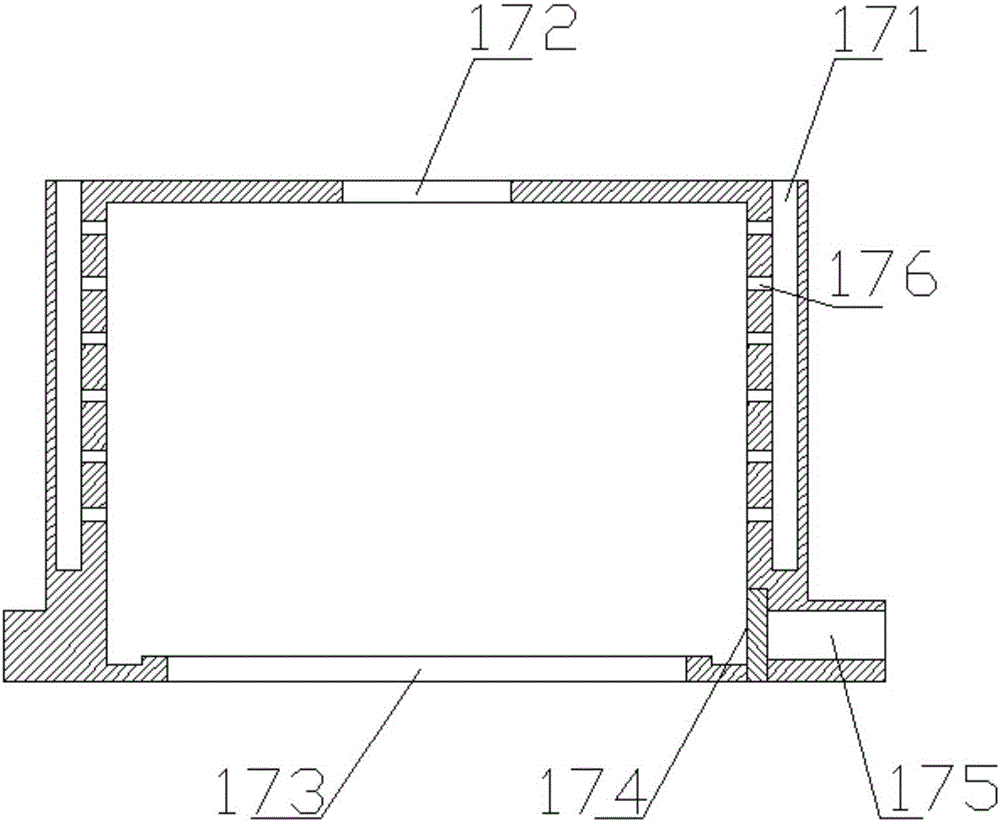

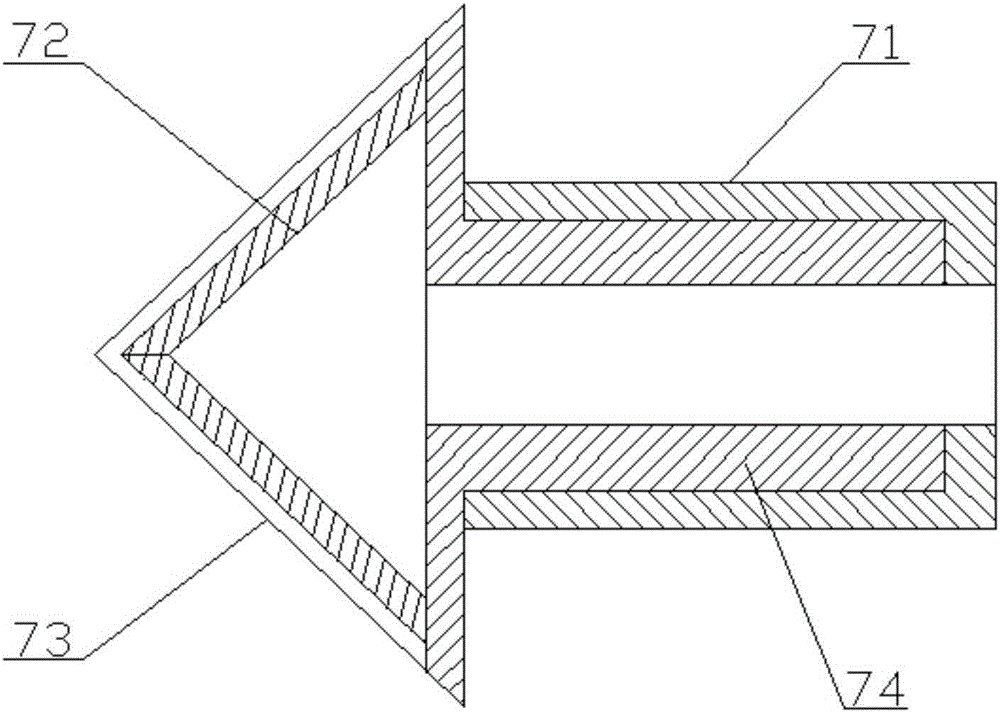

[0020] like figure 1 , figure 2 , image 3 A vertical vacuum drying device shown includes a frame 1, a tank body 17, a cover plate 6, a magnetic induction coil 3, a filter tip 7, a rotating shaft 8, a bushing 10, a supporting plate 15, a motor 18 and a supporting plate A11, The tank body 17 is a cylindrical cavity structure, the cover plate 6 is installed on the top surface of the tank body 17, the tank body 17 is vertically installed on the frame 1, and the magnetic induction coil 3 is installed on the tank body 17, the filter tip 7 is installed on the inner wall of the tank body 17, and the stirring blade 4 is installed in the tank body 17, and the stirring blade 4 is installed on the rotating shaft 8, and the rotating shaft 8 is installed on the lining In the sleeve 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com