Patents

Literature

213results about How to "Increase automation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

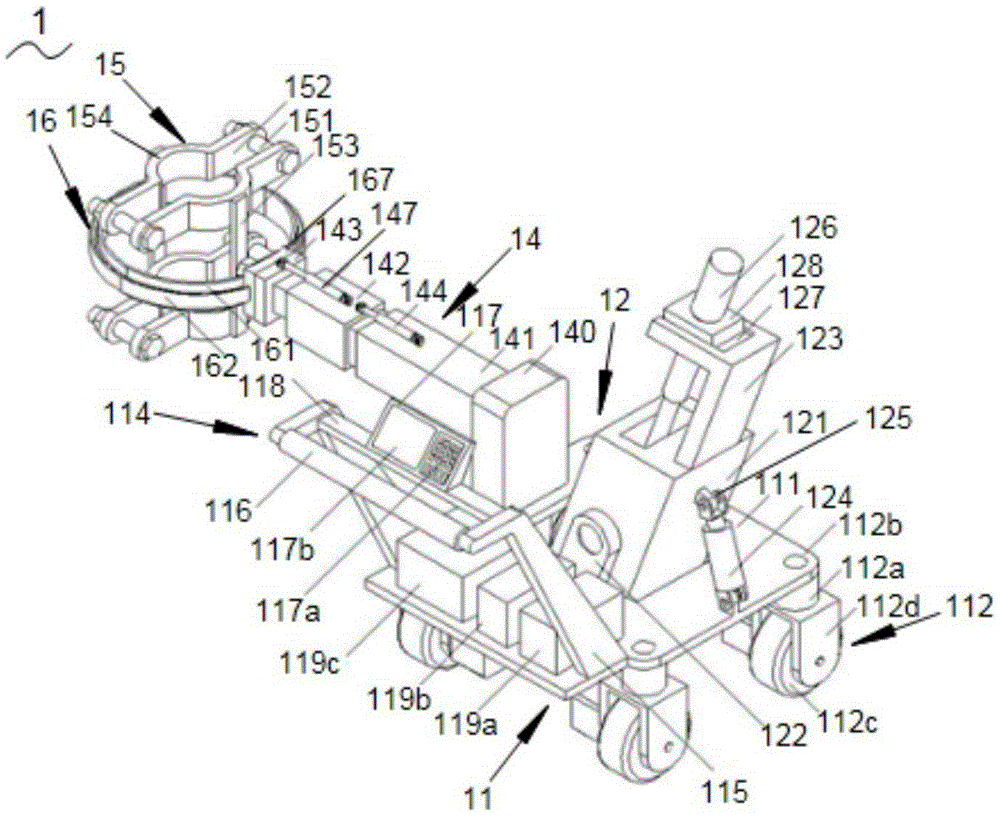

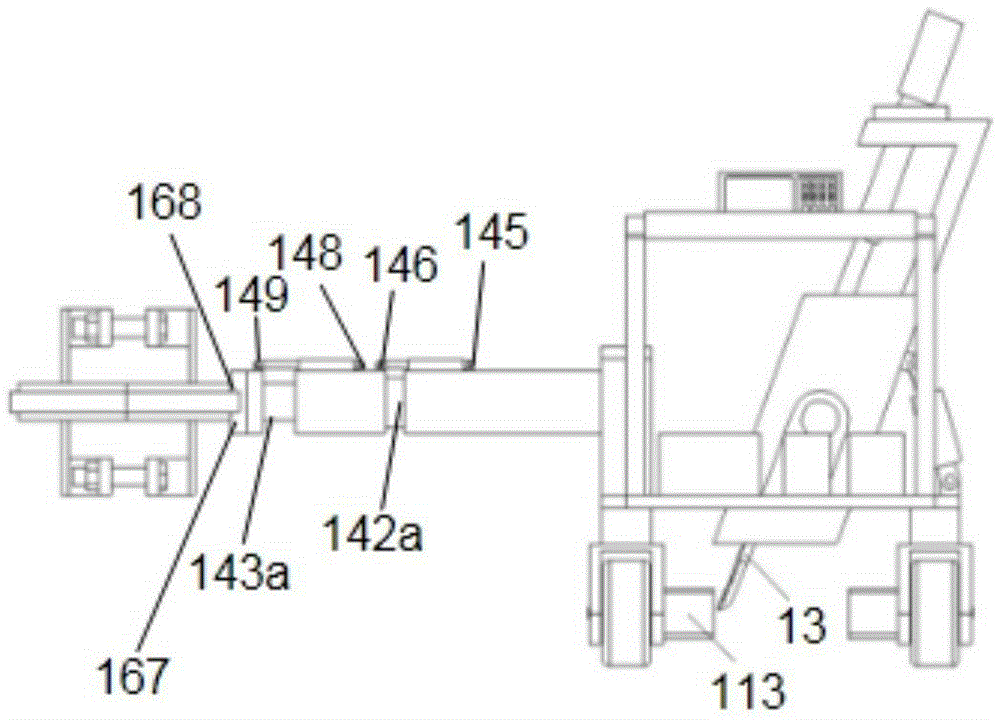

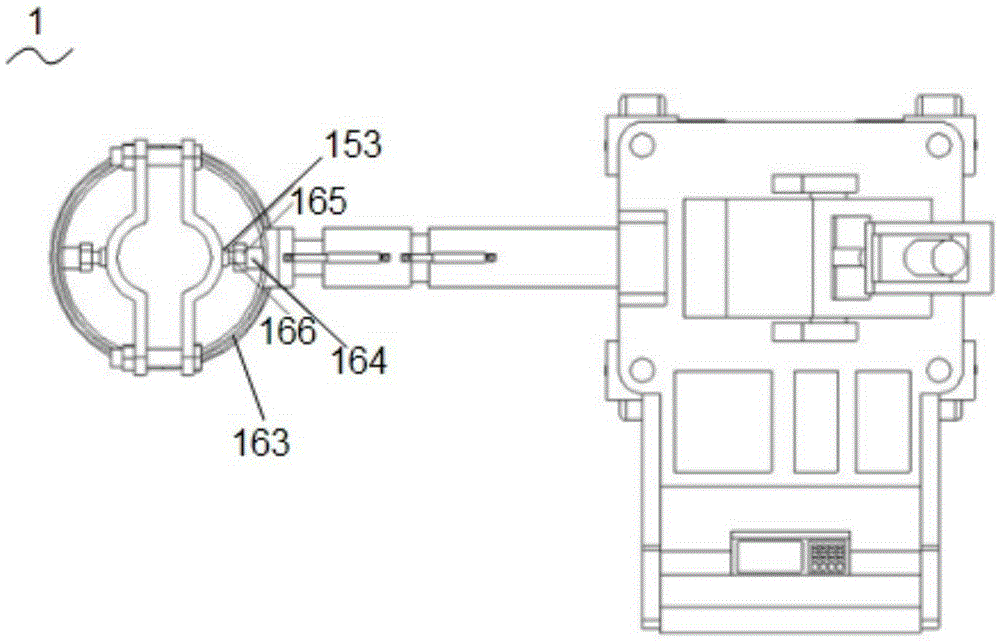

Tree transplanting device

A tree transplanting device comprises a moving unit, a hydraulic shovel unit, a moving shovel, a rotating arm, a rotating clamp and an annular rail. The moving unit further comprises a carrying platform, universal wheels, a hand-pushing portion, the carrying platform is used for carrying functional parts, the universal wheels are arranged on the bottom side of the carrying platform and driven by a motor, the hand-pushing portion is arranged on the carrying platform, a handle and a mounting platform of an operating panel are arranged at one end of one side of the hand-pushing portion at an interval, the hydraulic shovel unit is arranged on the carrying platform, a second piston rod of a second hydraulic cylinder of the hydraulic shovel unit is fixed to the moving shovel, the rotating arm is fixedly arranged on the carrying platform through a fixing block, and the annular rail further comprises a rail inner ring and a rail outer ring. The hydraulic shovel unit is utilized to replace manual digging, so that integral separation of root systems of seedlings to be transplanted is realized, adhesion of soil on the root systems is guaranteed, and loss of water and nutrition in the process of transplanting is lowered. In addition, labor intensity is reduced greatly, automation rate of garden tree transplanting is increased, and the tree transplanting device has extremely high popularization and application value.

Owner:SHANGHAI DIANJI UNIV

Preparation method of plecanatide

InactiveCN104211777ASimple and efficient operationIncrease automation ratePeptide preparation methodsBulk chemical productionPlecanatideSolvent

According to the invention, plecanatide is synthesized by a solid-liquid combination method. Two disulfide bonds are successively formed by an orientation method. Thus, mismatching of disulfide bonds is avoided, and it is beneficial to subsequent purification. The method provided by the invention has advantages of simple operation, high automation and few usage amount of a solvent, and is green and environmentally friendly.

Owner:HYBIO PHARMA

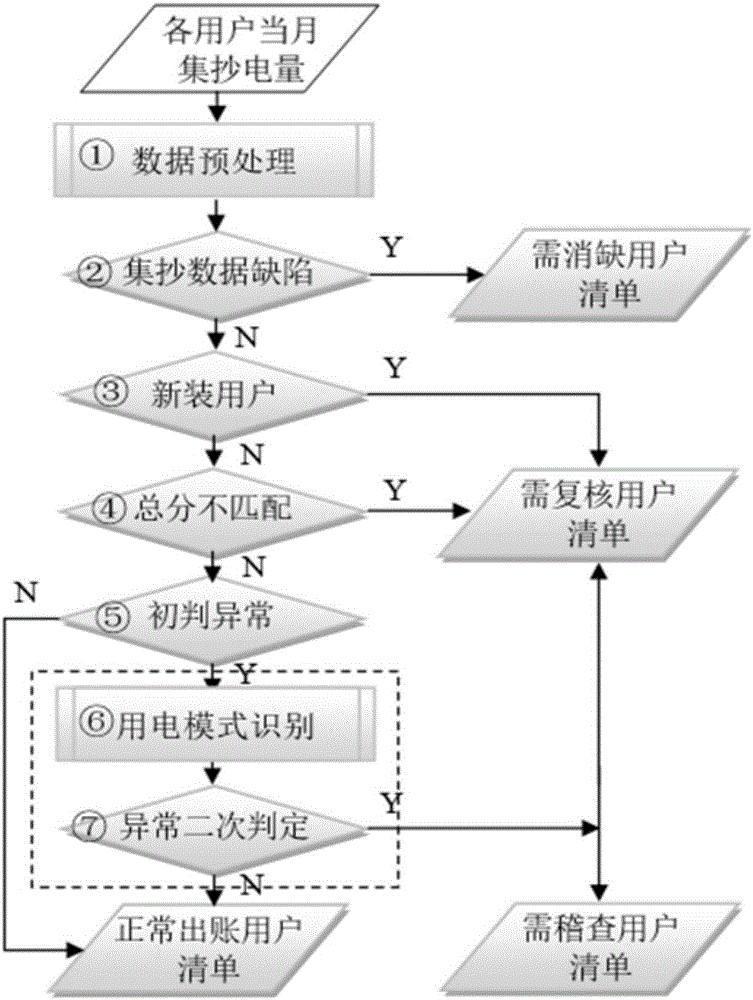

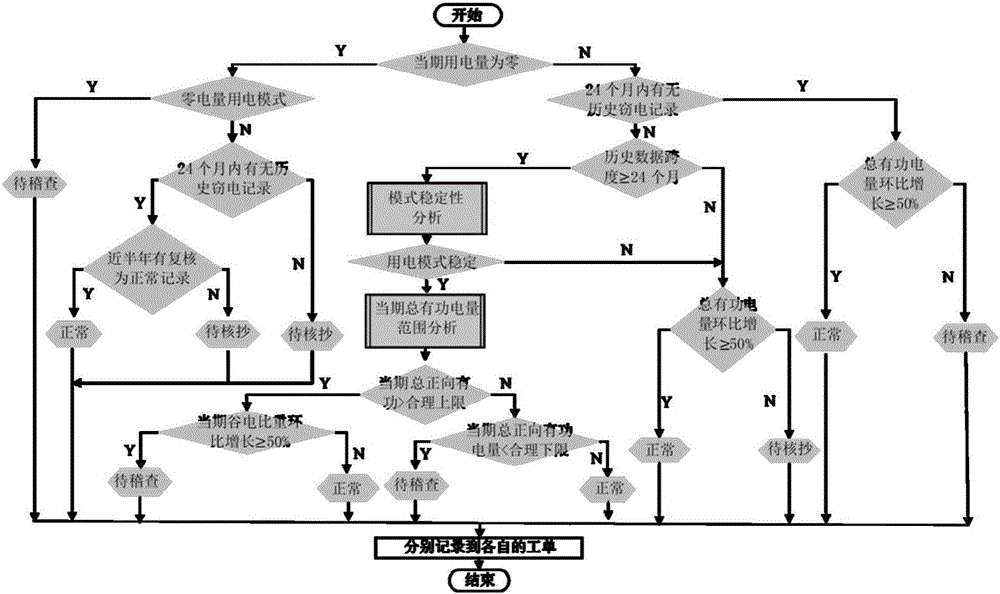

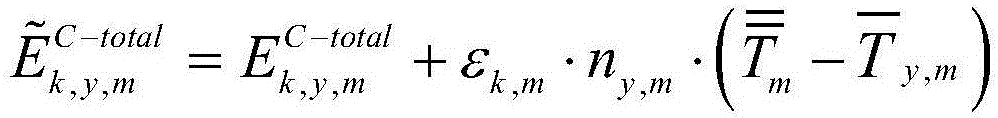

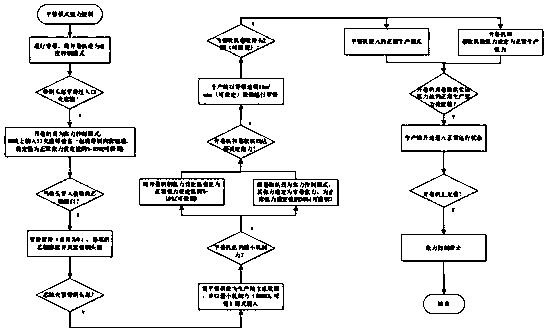

Method for determining stability of power mode based on gray relational analysis

InactiveCN106447534AContribute to automatic intelligent judgmentRefine the responsible departmentData processing applicationsInformatizationElectric consumption

The invention relates to a method for determining the stability of a power mode based on gray relational analysis and belongs to the field of power supply and distribution management. Based on a two-stage decision algorithm of mode recognition, the method defines a power mode time sequence by a 12-month coefficient for users with no historical electricity stealing records and having meter data more than two years, determines the power mode stability by a gray relational analysis method, predicts a reasonable range of current electricity consumption with reference to a historical power model so as to determine whether the user's current electricity consumption is abnormal. The reasonable range can improve the accuracy of the abnormal judgment without an increase in the workload of manual review, and can narrow the scope of the review, improve the efficiency of the review and the reliability of the meter data, promotes rapid improvement in the quality of a meter reading system by finding a weak link, promotes the development and operation of corresponding computer analysis software and, improve the automation and informatization level of service related to meter reading, can be widely used in the field of centralized meter reading management system design, operation and management.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

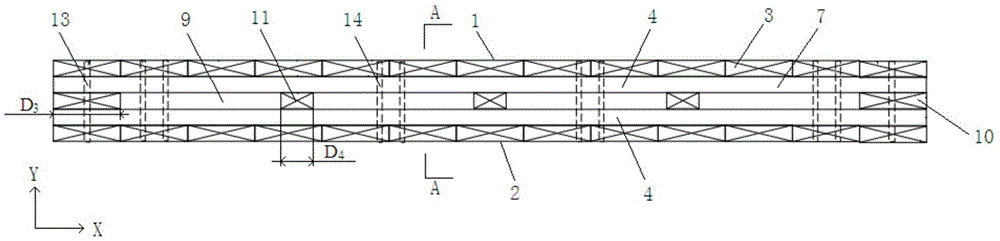

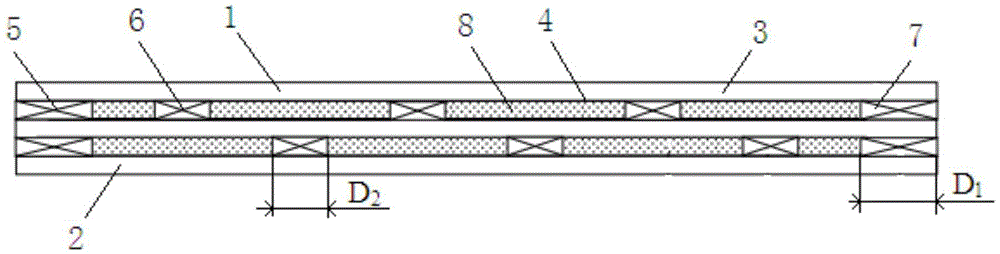

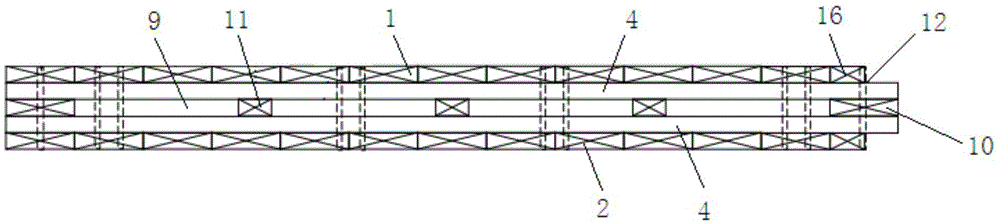

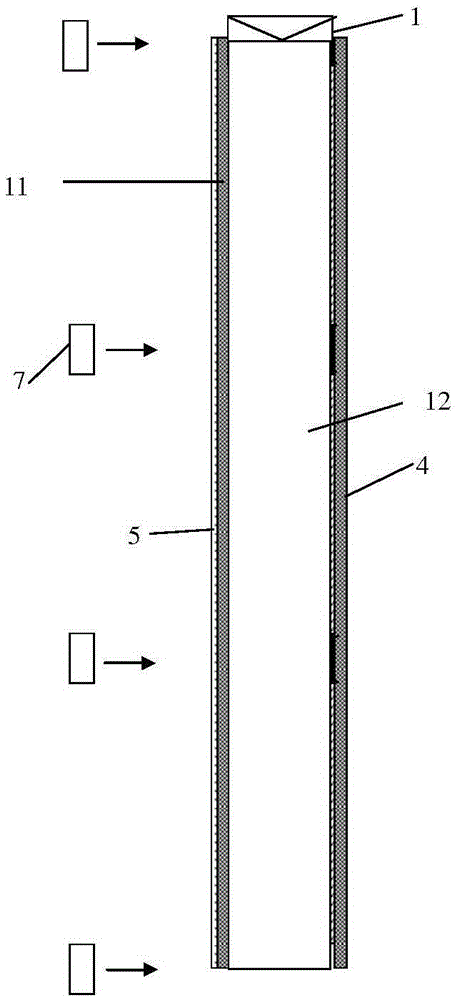

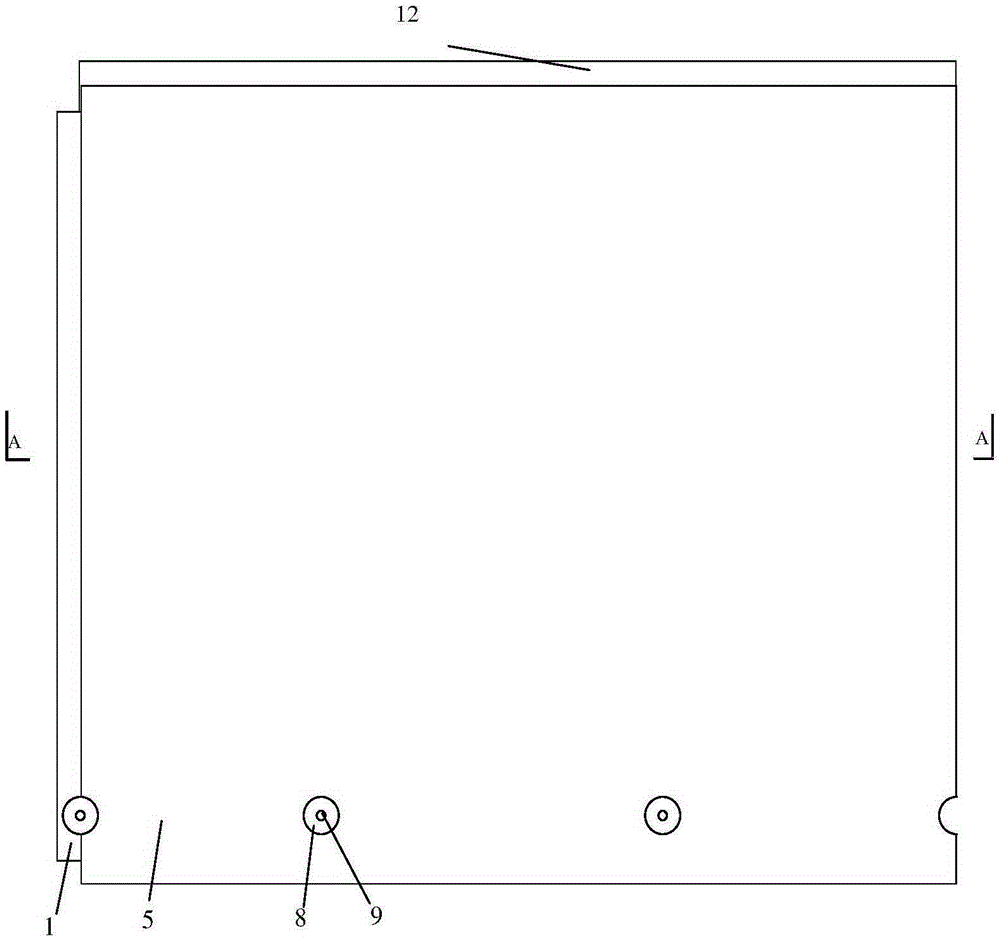

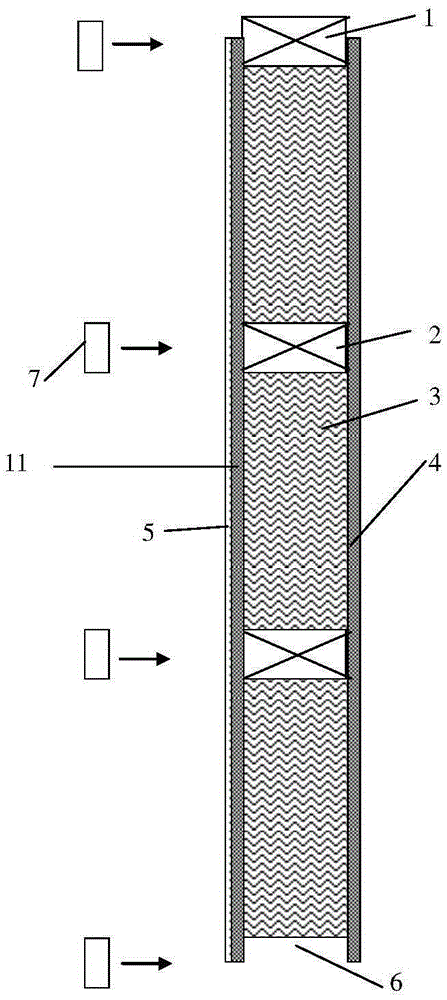

Hollow cross-ply laminated building block bearing plate

ActiveCN105544757AImprove mechanical performanceQuality improvementHeat proofingSound proofingInsulation layerPulp and paper industry

The invention relates to a hollow cross-ply laminated building block bearing plate which comprises an inner layer plate body and an outer layer plate body. At least two heat preservation or sound insulation layers are arranged in a first cavity formed between the inner layer plate body and the outer layer plate body. Each heat preservation or sound insulation layer comprises first wood boards arranged at the two ends of the first cavity, and second wood boards arranged in a cavity between the two first wood boards at intervals, cavities formed between every two second wood boards and between the first wood boards and the second wood boards are filled with non-bearing heat preservation boards or non-bearing sound insulation materials, a second cavity is formed between every two heat preservation or sound insulation layers, and third wood boards are arranged at the two ends of each second cavity respectively. The hollow design is adopted, and the heat preservation or sound insulation layers are embedded in plate bodies, so that good heat preservation performance or sound insulation performance is achieved, and heat preservation protection or sound insulation treatment does not need to be carried out outside the plate bodies any more; the boards in the plate bodies are distributed in a cross-ply mode, so that the plate bodies have good stress performance and are light and good in economic effect, the manufacturing cost is reduced, and environment pollution is effectively avoided.

Owner:张延年

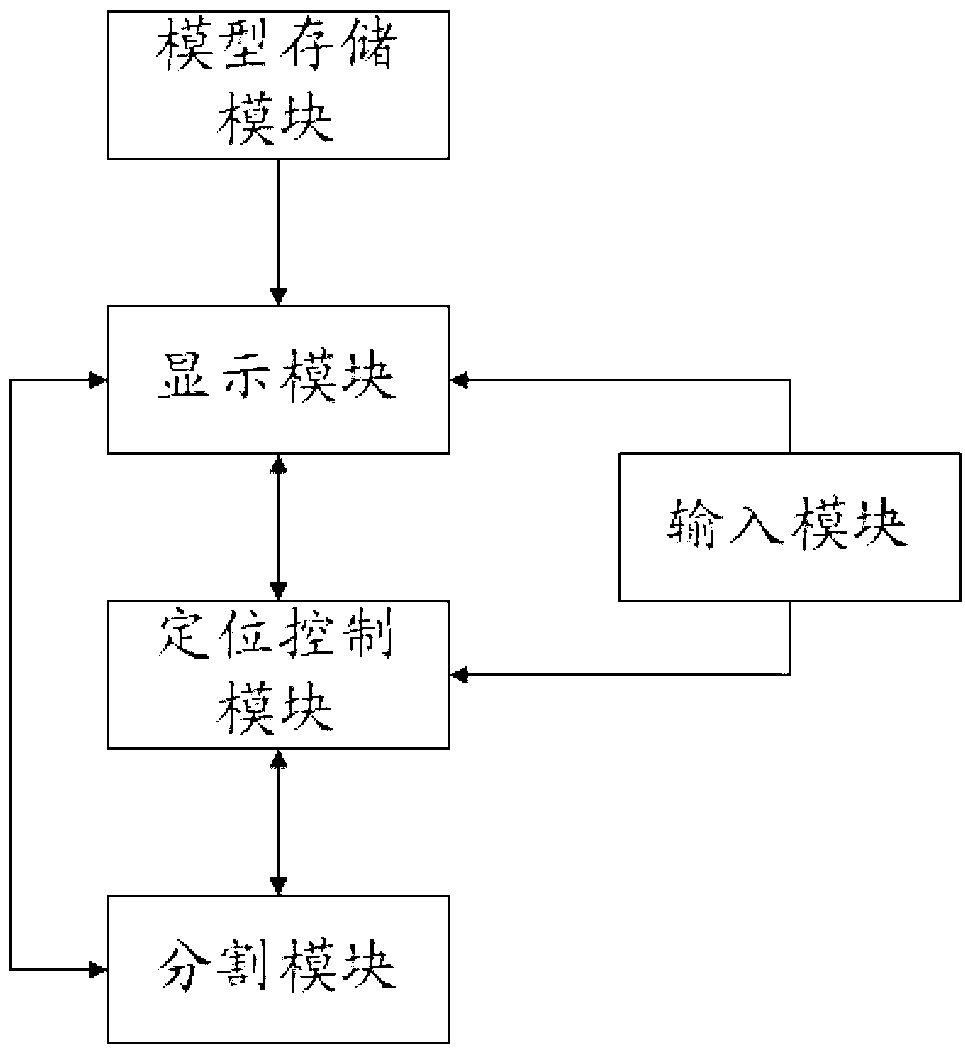

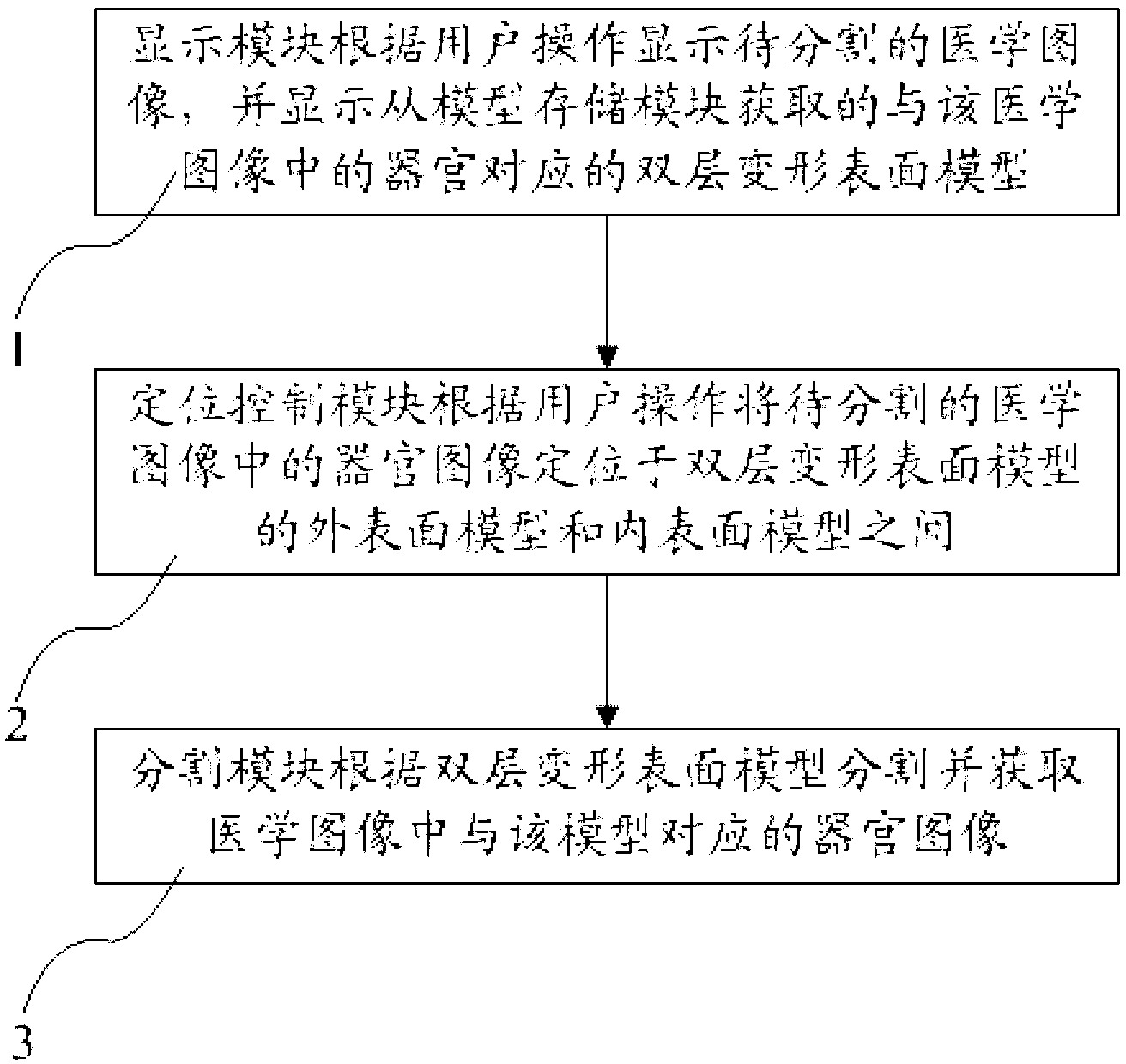

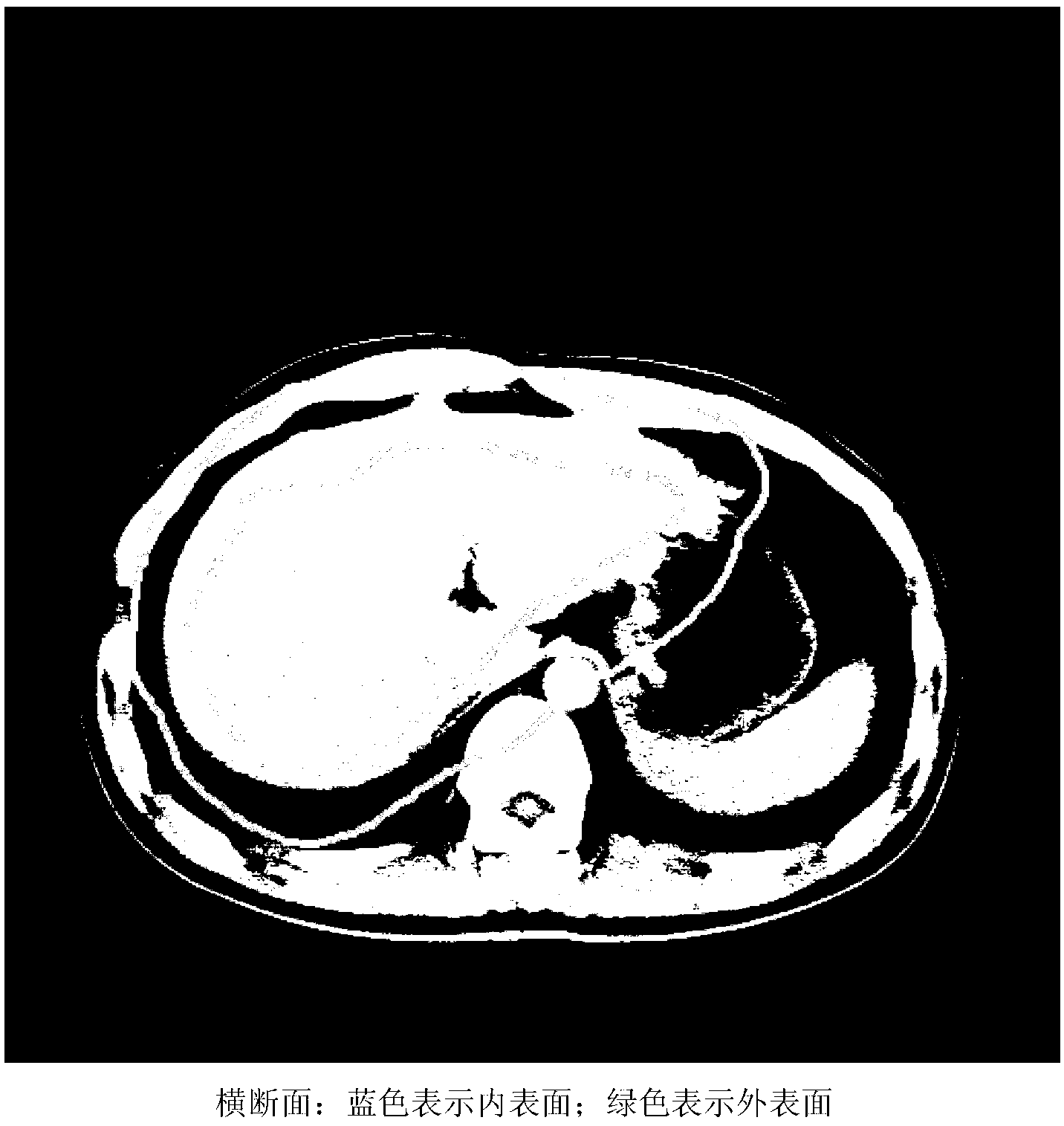

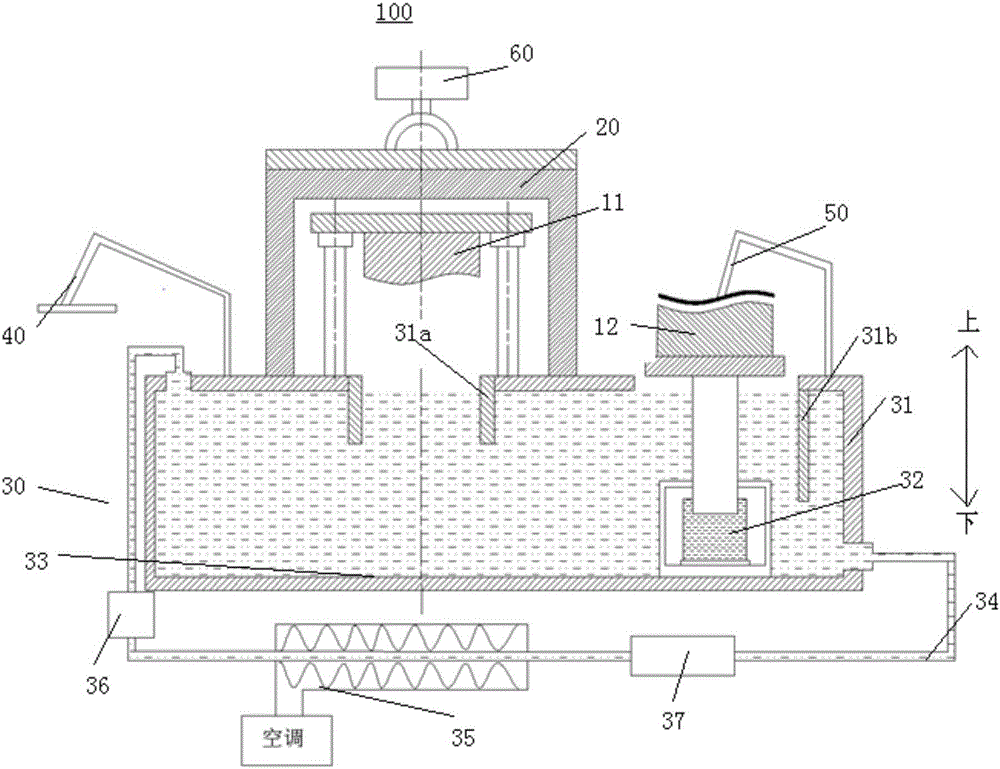

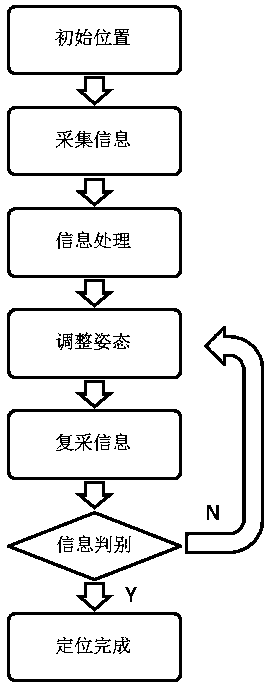

Medical image segmentation system and medical image segmentation method based on deformation surface models

InactiveCN103295234AImprove accuracyIncrease automation rateImage analysisImaging processingImage segmentation

The invention relates to a medical image segmentation system and a medical image segmentation method based on deformation surface models, and belongs to the technical field of image processing. The medical image segmentation system comprises a model storing module, an input module, a display module, a locating control module and a segmenting module, so that the displaying module can be utilized to display medical images to be segmented based on user operation, and then displays double-layer deformation surface models corresponding to organs in the medical images acquired from the model storing module; the locating control module is utilized to locate the organ images in the medical images to be segmented between outer surface models and inner surface modules of the double-layer deformation surface models; and finally the segmenting module is utilized to segment and acquire the organ images of the medical images corresponding to the double-layer deformation surface models according to the double-layer deformation surface models. Therefore, segmentation of the medical images based on the three-dimensional deformation surface models can be realized, accuracy and automation of the segmentation of the medical images are greatly improved, and difficulty on segmentation is effectively reduced.

Owner:SHANGHAI DATU MEDICAL SCI & TECH

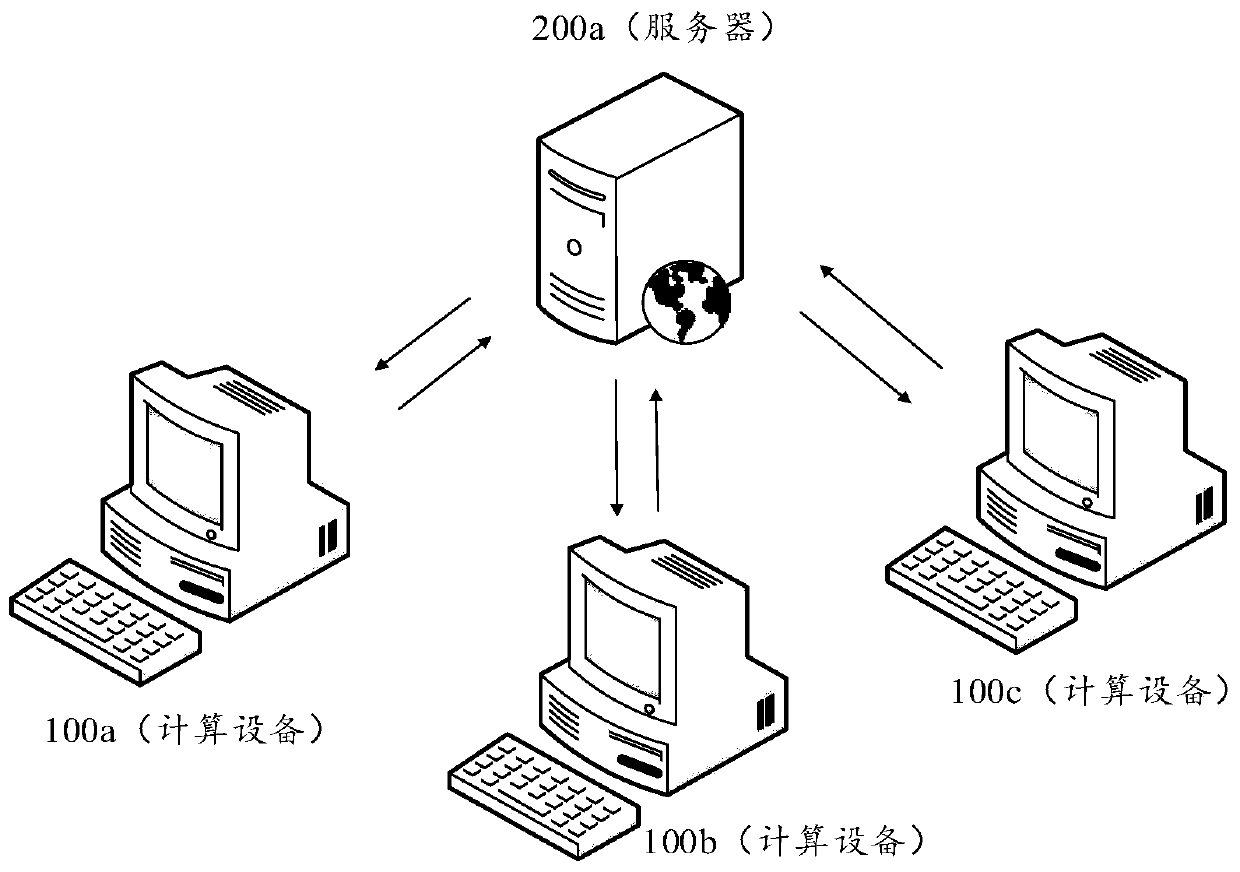

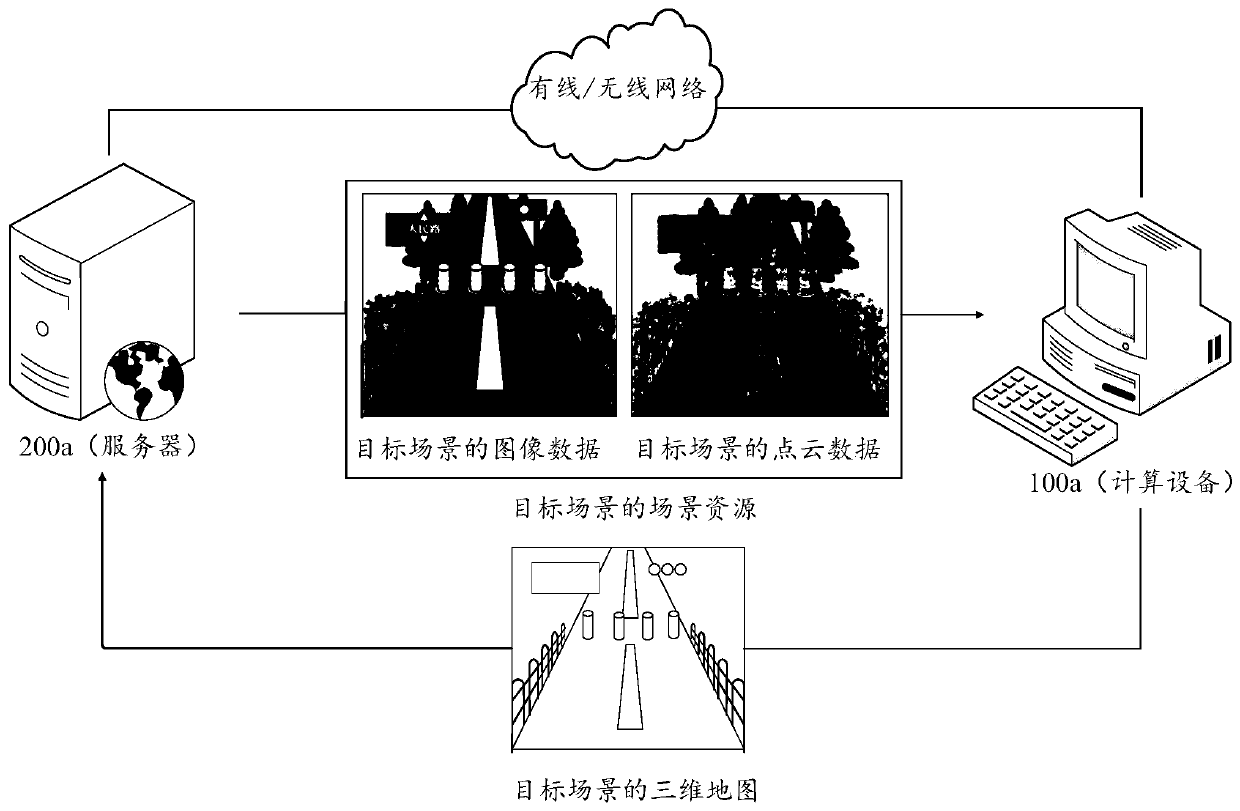

Map construction method and device, terminal and computer readable storage medium

ActiveCN110796714AEfficient editingEditing work is accurate and convenientImage analysisDrawing from basic elementsData packPoint cloud

The embodiment of the invention discloses a map construction method and device, a terminal and a computer readable storage medium. The map construction method comprises: acquiring scene resources, thescene resources comprising image data and point cloud data of a target scene, the image data comprising two-dimensional image data of the target scene, and each point in the point cloud data comprising three-dimensional space coordinate data; determining first point cloud distribution of the first map element based on the image data; determining second point cloud distribution of the second map element based on the point cloud data; and constructing a three-dimensional map of the target scene according to the first point cloud distribution and the second point cloud distribution. By adoptingthe embodiment of the invention, map element editing work can be more efficient, accurate and convenient, so that the automation rate of map construction work is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

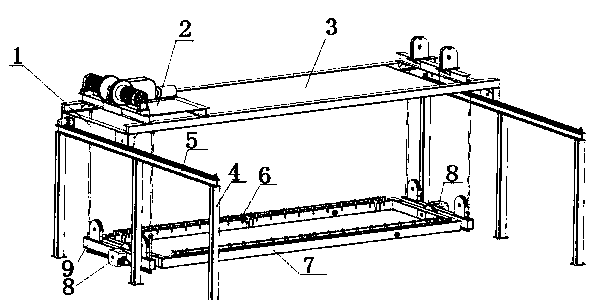

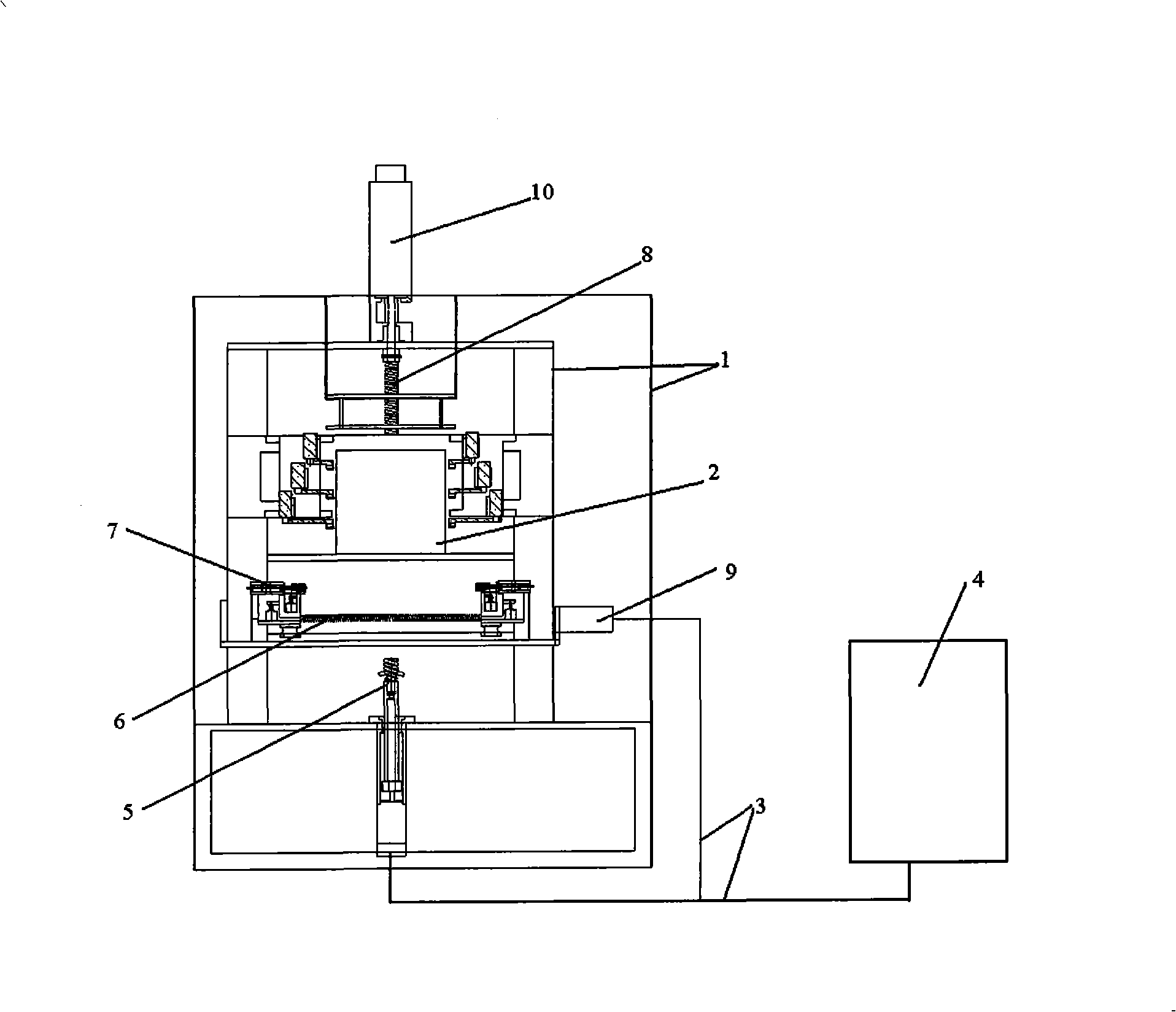

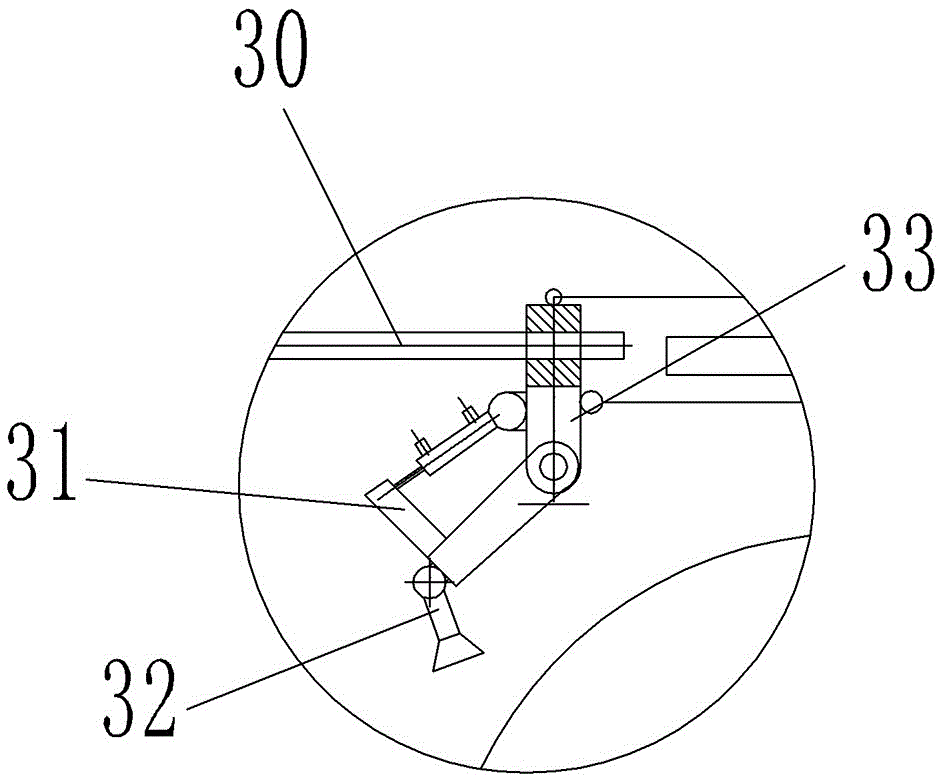

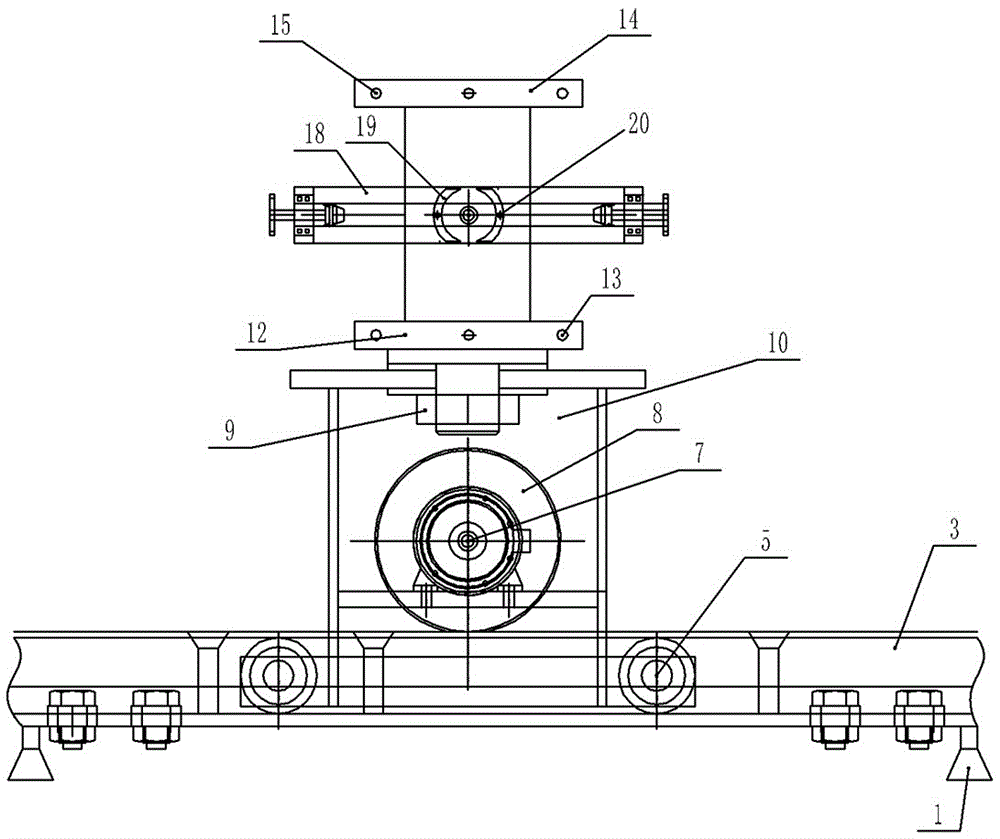

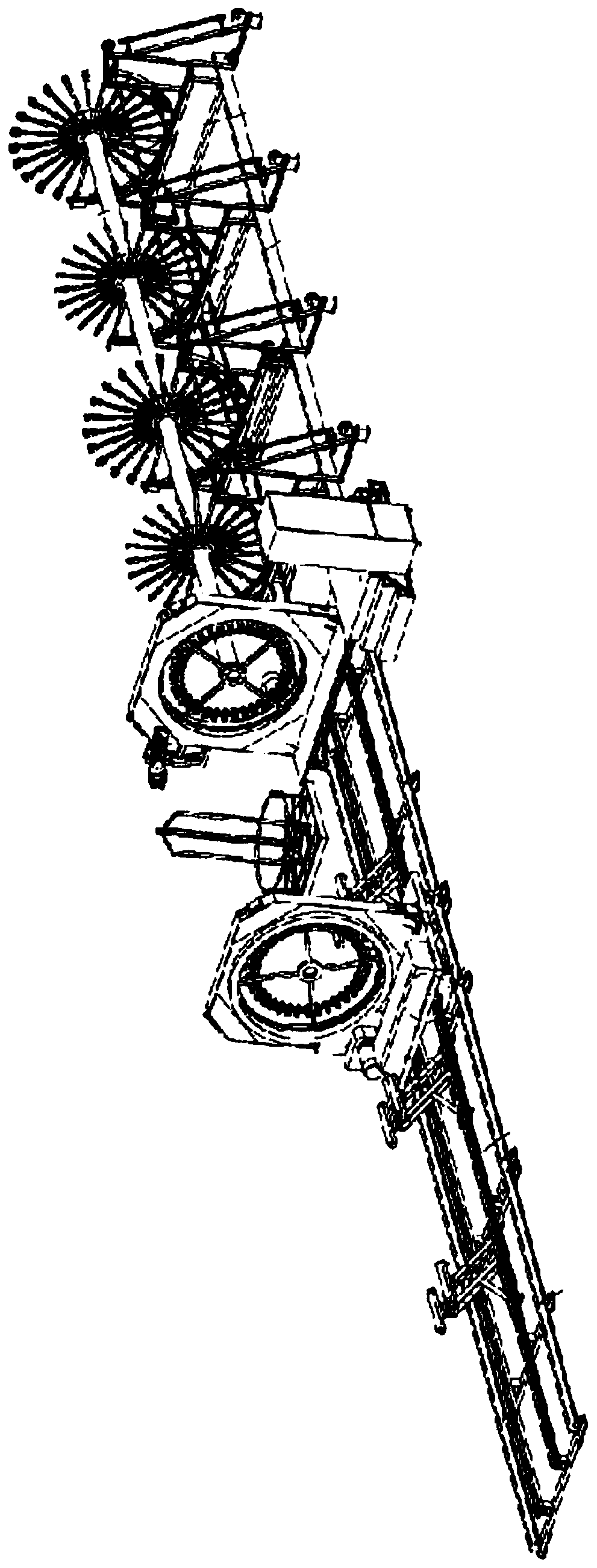

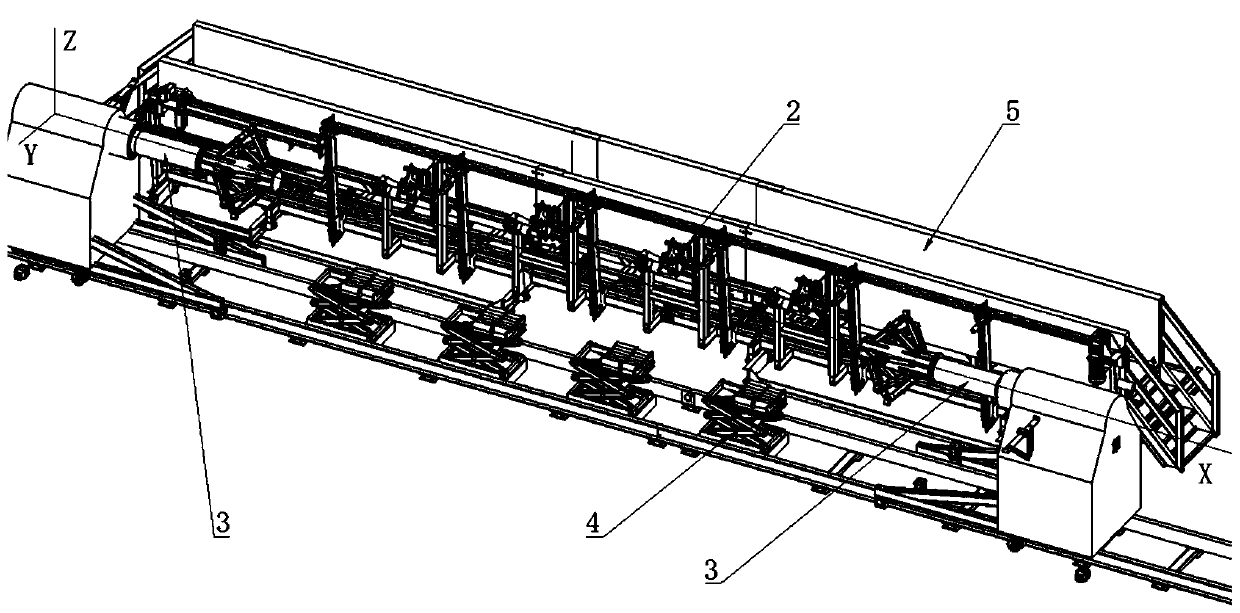

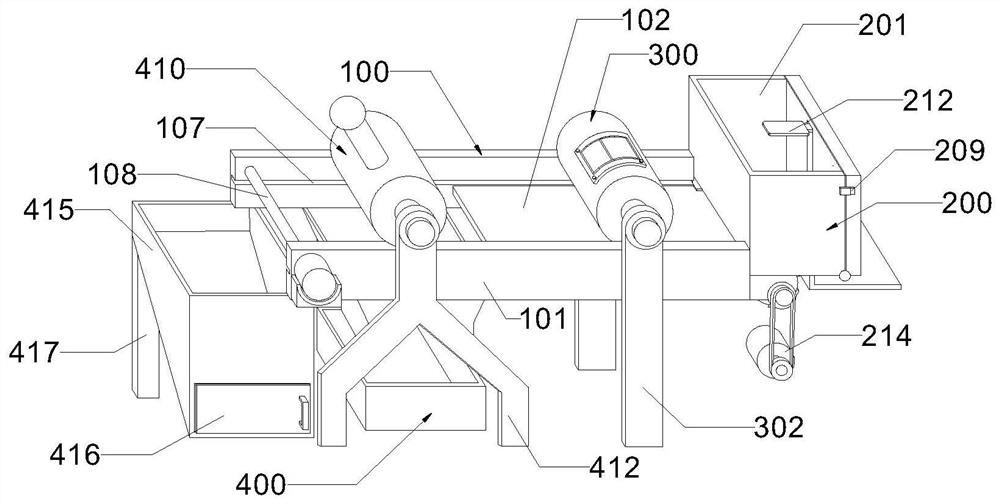

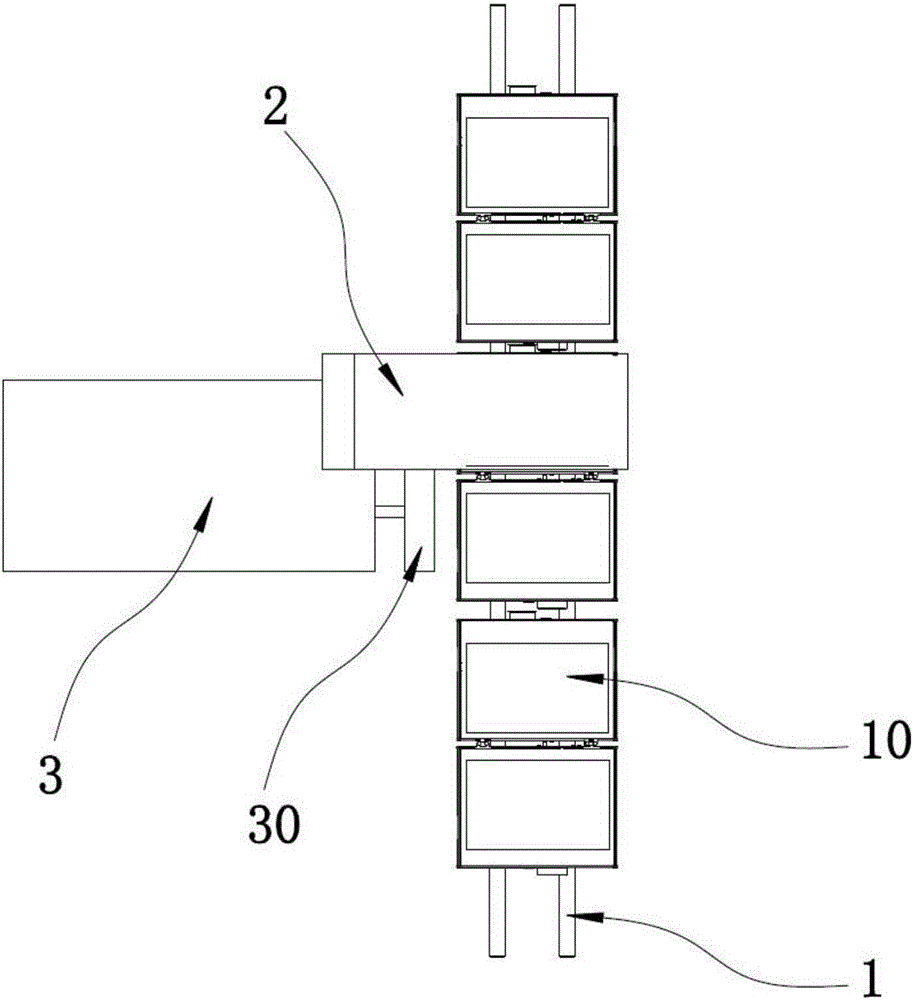

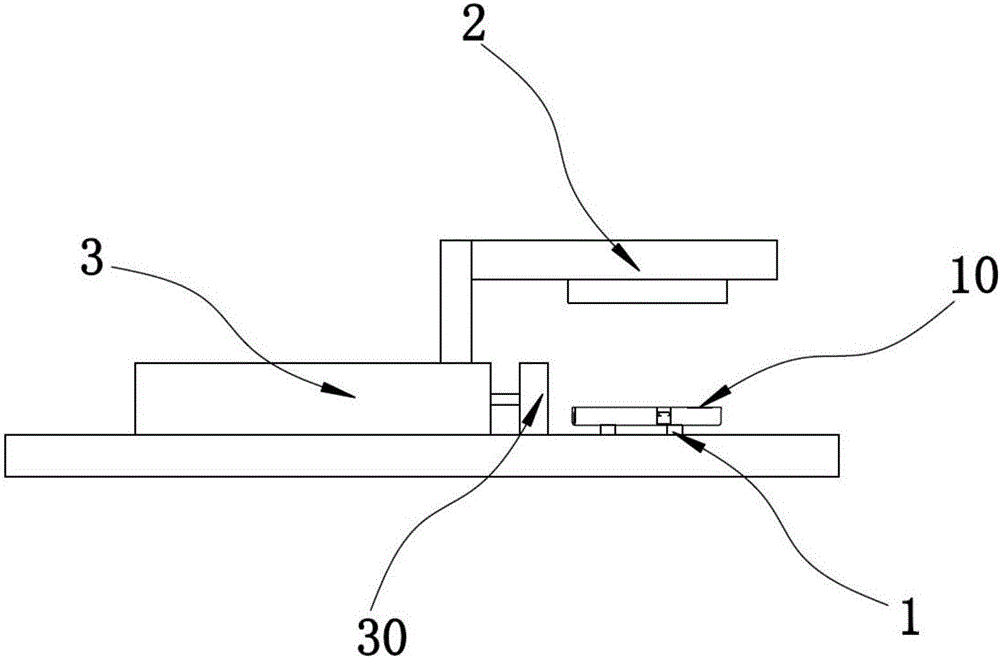

Laminated slab upending machine

ActiveCN103449151AAdvanced production technologyFully mechanizedConveyor partsIndustrial engineeringPrefabrication

The invention provides a laminated slab upending machine. Upright columns are fixedly installed on the ground; supporting beams are installed on the upper ends of the upright columns; a main beam or a walking board is guided to walk on the supporting beams by a walking mechanism; a dual-drum winding and lifting mechanism is installed on the main beam or the walking board; a fixing frame is installed on the dual-drum winding and lifting mechanism in a lifting way through steel ropes and a pulley; an upending framework and upending machines are installed on the fixing frame; the upending machines are connected with and drive the upending framework; a hydraulic clamping device for clamping a steel trolley and a workpiece is installed on the upending framework. By the adoption of the laminated slab upending machine, the fully mechanical automation can be realized; therefore, the production efficiency is improved greatly, as well as the prefabrication rate of a plant with industrialized dowelling.

Owner:QINGDAO SHANGLIU YUANDA HOUSE IND CO LTD

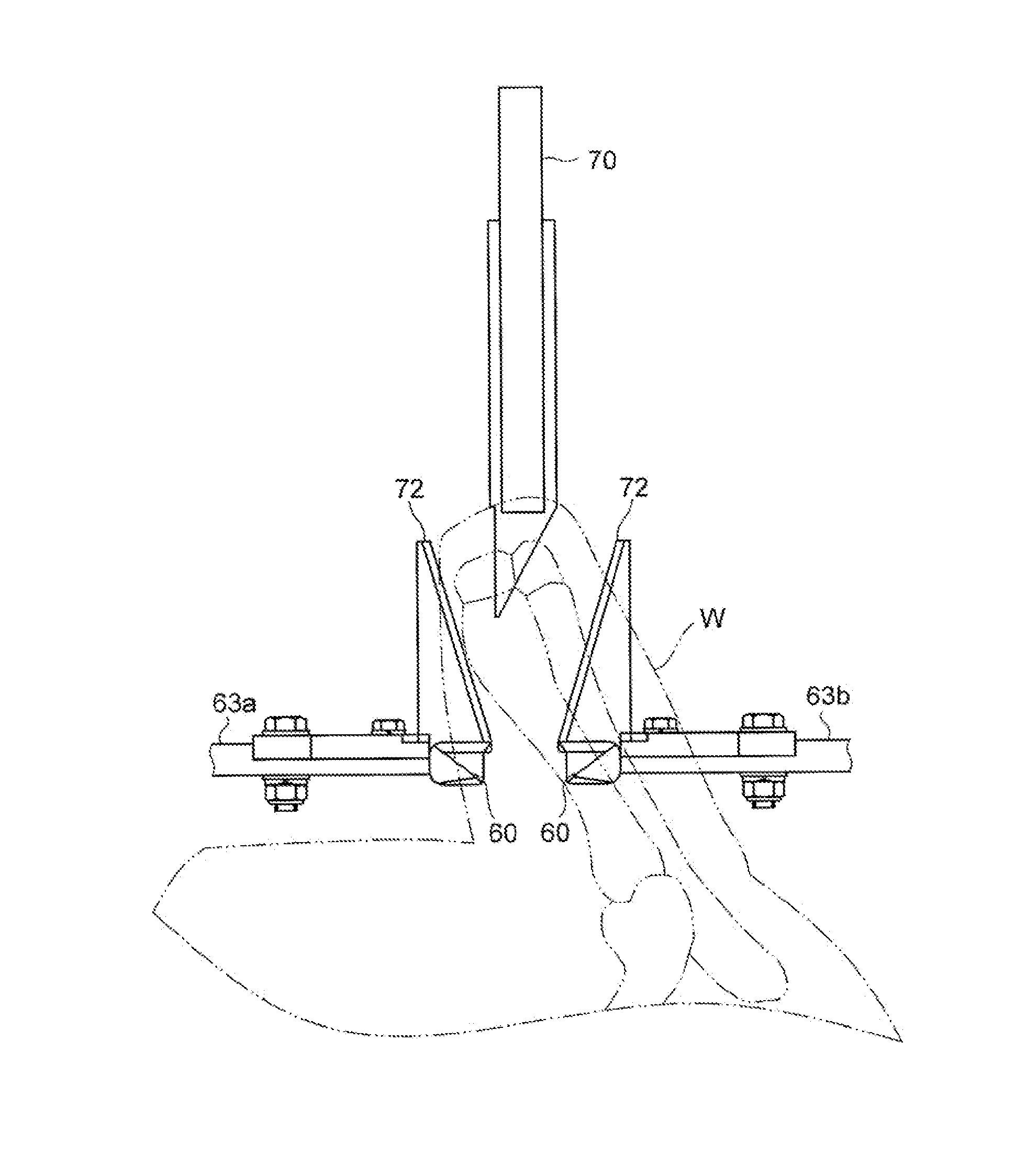

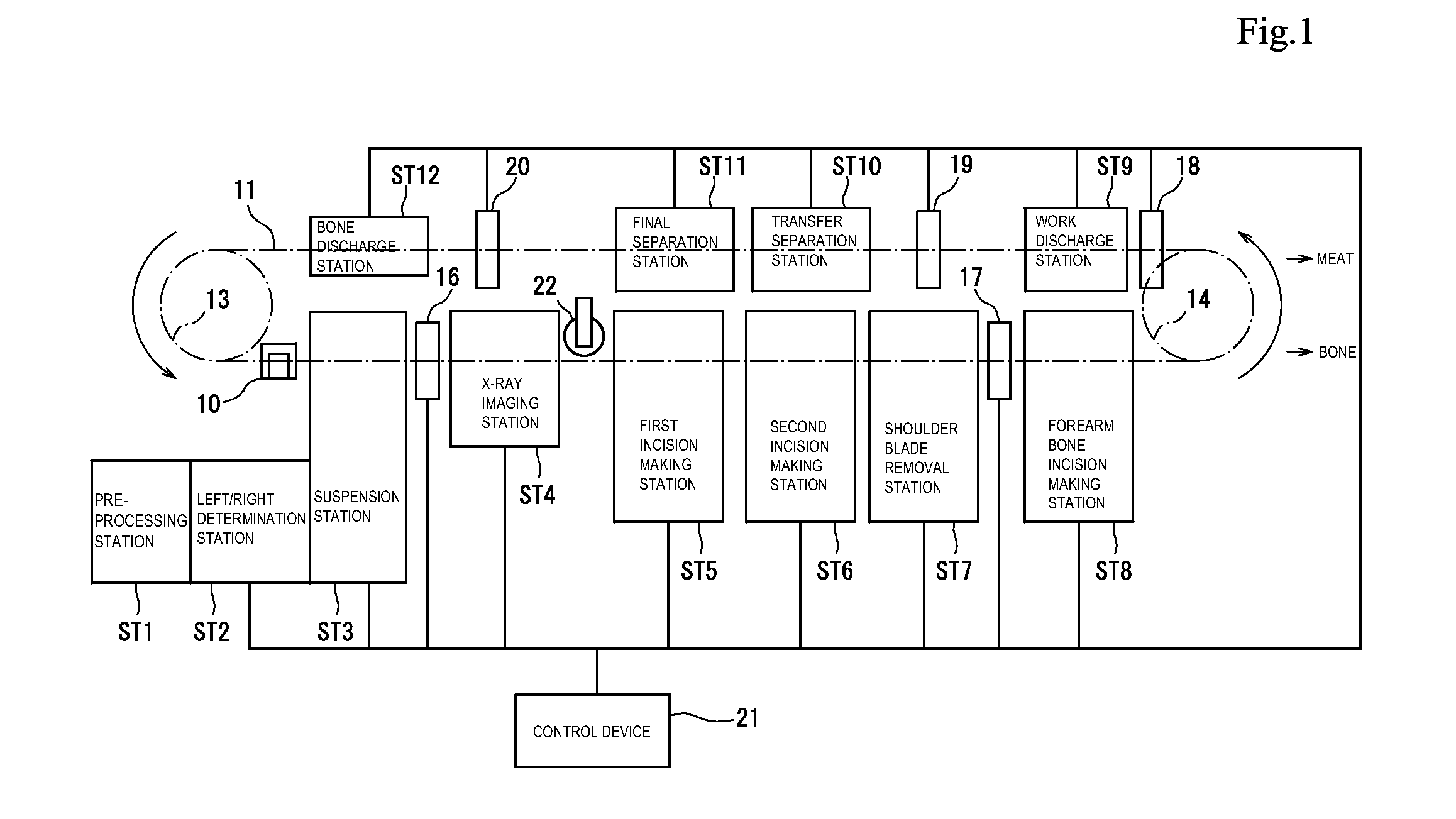

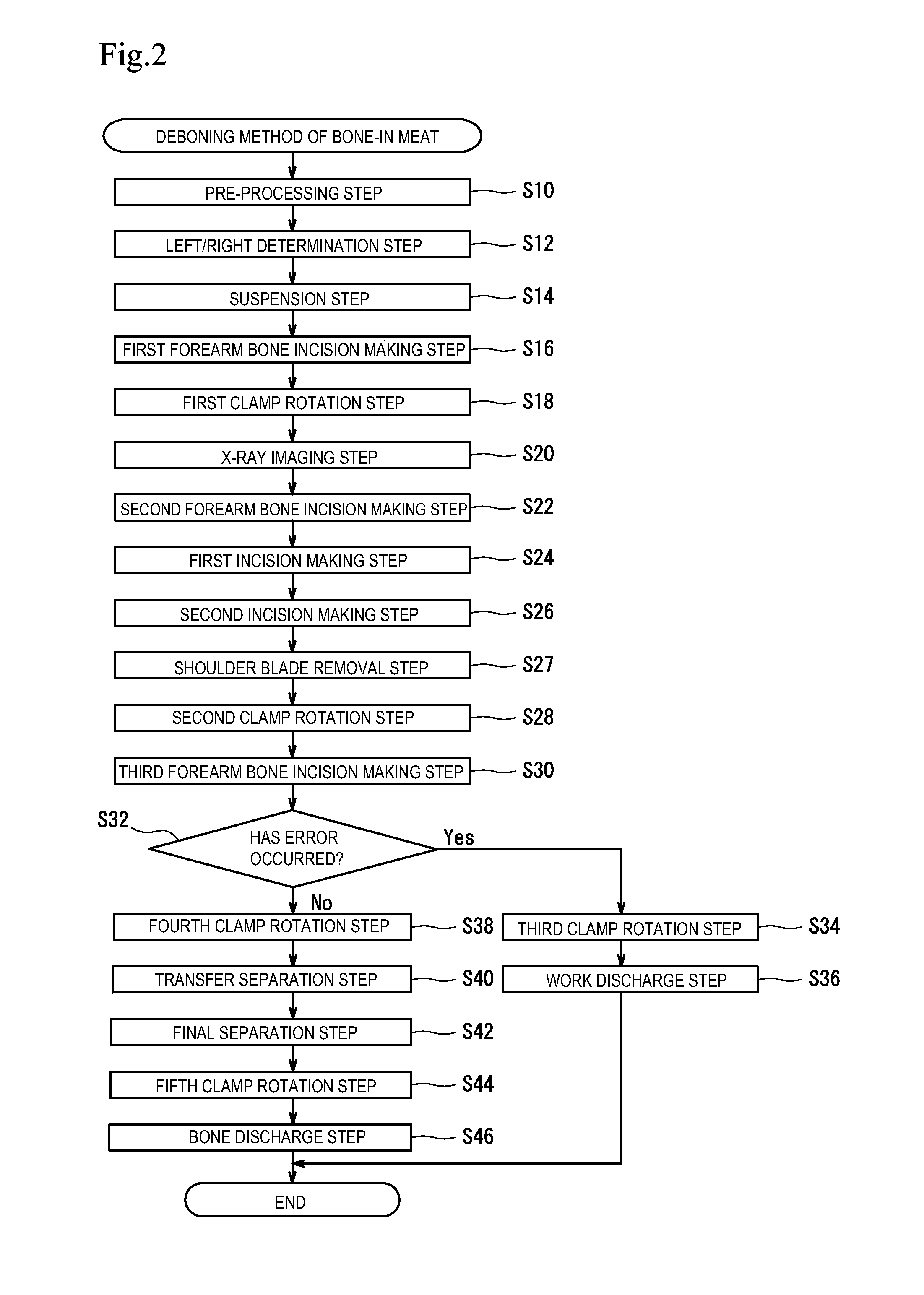

Device and method for conveying bone-in meat and deboning system of bone-in meat including the device

ActiveUS20150004892A1Increase automation rateMeat/sausage hanging-upSlaughtering animals fettering apparatusBand shapeActuator

Two hooking members of a hooking unit used in a device for conveying bone-in meat respectively have belt-like main body parts, blade-like pointed ends provided at ends on one side of the main body parts, and barbs provided on first sides of the main body parts to be continuous with the points. The hooking members are supported so as to be in parallel with each other with an elastically changeable interval therebetween and to be rotatable about rotation axes along longitudinal axes of the main body parts. Further, the hooking unit has an actuator which rotates the hooking members about the rotation axes.

Owner:MAYEKAWA MFG CO LTD

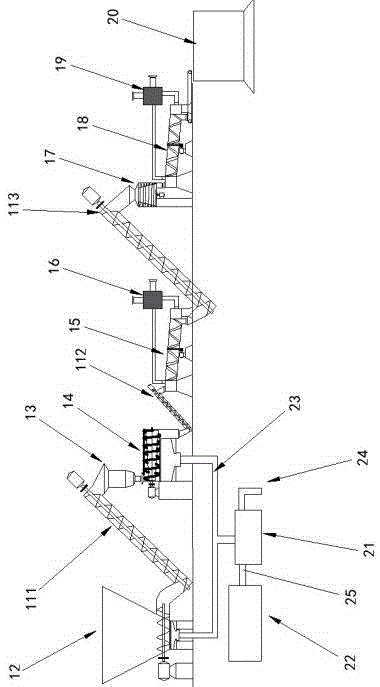

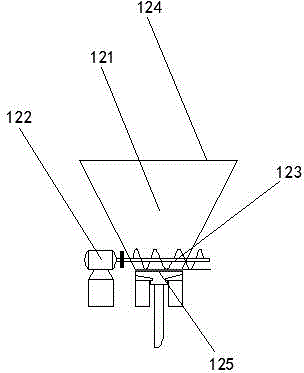

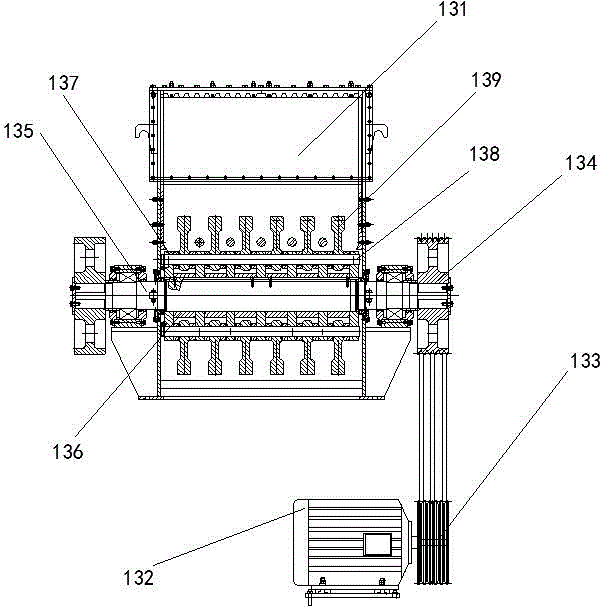

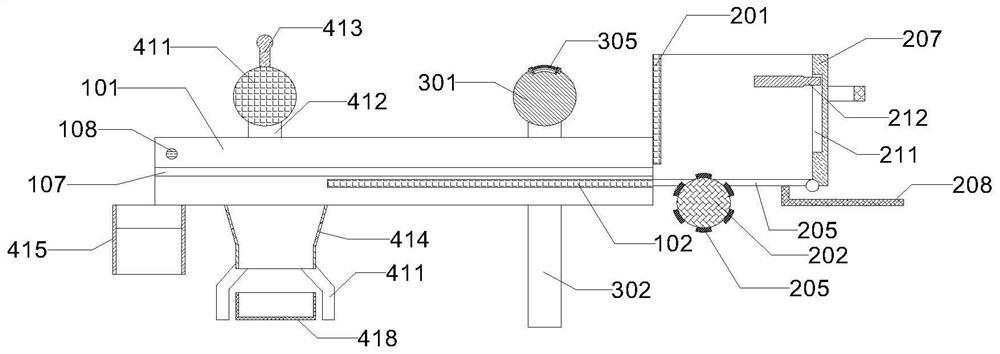

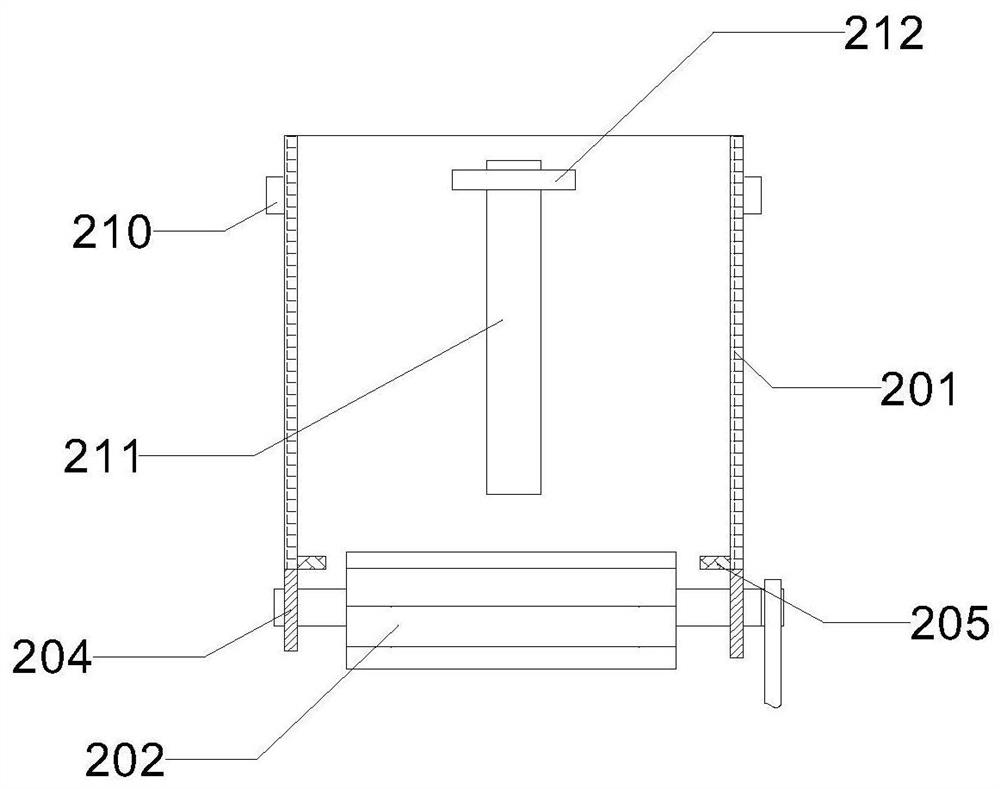

Kitchen waste recovery and treatment system

InactiveCN104690072AImprove water removal rateAvoid churnSolid waste disposalClimate change adaptationSlagFuel tank

The invention discloses a kitchen waste recovery and treatment system. The kitchen waste recovery and treatment system comprises a waste storage tank, a crusher, a screw press, a first dryer, a fertilizer storage tank, an oil-water separator, an oil storage tank, a conveying mechanism, a screw granulator and a second dryer, wherein a discharging hole of the waste storage tank is communicated with one end of the crusher through the conveying mechanism, the other end of the crusher is connected with a feeding hole of the screw press, a slag hole of the screw press is communicated with one end of the first dryer through the conveying mechanism, the other end of the first dryer is communicated with one end of the screw granulator through the conveying mechanism, the other end of the screw granulator is connected with one end of the second dryer, the other end of the second dryer is connected with the fertilizer storage tank, a filtering water outlet of the waste storage tank and an oil outlet hole of the screw press are connected with the oil-water separator through connecting pipes, and the oil-water separator is communicated with the oil storage tank through an oil pipe. An organic fertilizer prepared by recycling kitchen waste is high in quality.

Owner:深圳格林斯玛特科技有限公司

Automatic manufacturing device for spiral tube and producing method

InactiveCN101337765ARealize CNC automationEasy temperature controlVessels or leading-in conductors manufactureGlass reforming apparatusNumerical controlEngineering

The invention relates to an automatic production device and a production method of a spiral lamp tube. The automatic production device comprises a machine frame, as well as a heating furnace, an inflated claw and a coil pipe mould which are mounted on the machine frame; a spiral groove is arranged on the outer surface of the coil pipe mould, and can rotate and lift relatively to the machine frame; and the inflated claw is connected with the machine frame through a transversal movement mechanism and a longitudinal movement mechanism. The automatic production device further comprises a control device; the control device is composed of a console, a control circuit and a drive device; the console is connected with the drive device through the control circuit; the drive device controls the action of the inflated claw and the coil pipe mould to be mutually connected during the manufacturing process of the lamp tube. The automatic production device can ensure that the production of the lamp tube realizes numerical control automation, so that the temperature, the speed, the position and other parameters during the production process achieve fine control, and an operator can be far away from the operating environment with high temperature.

Owner:陈伯川

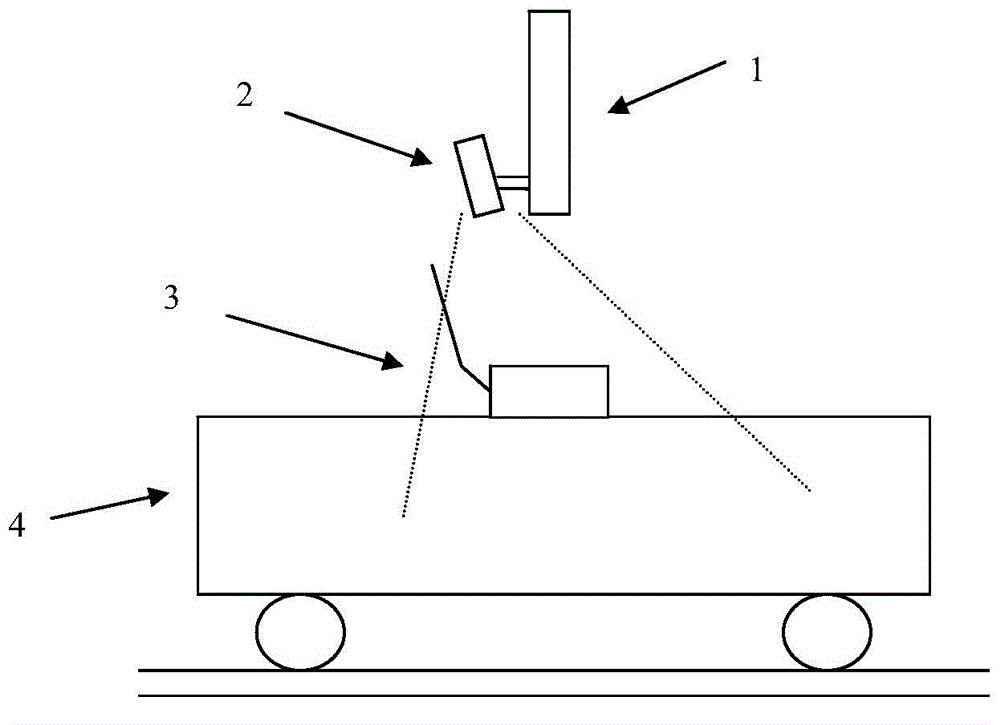

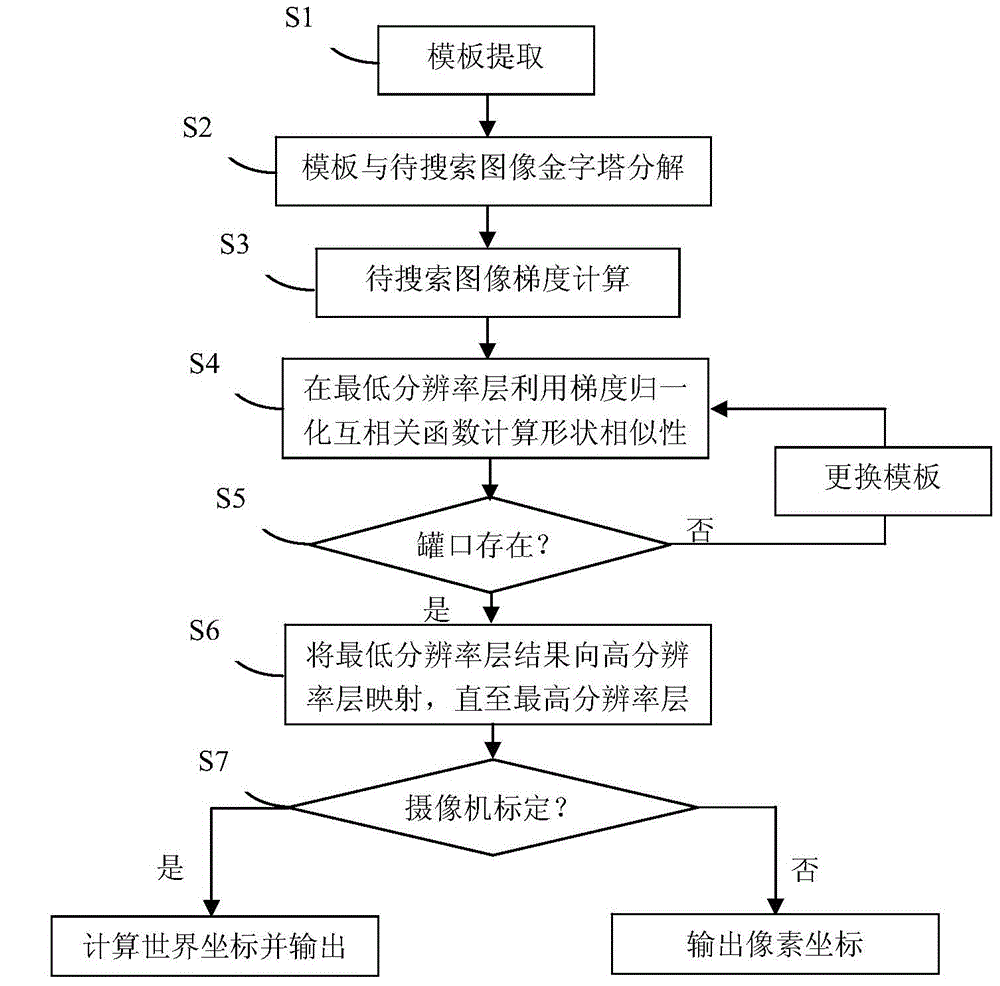

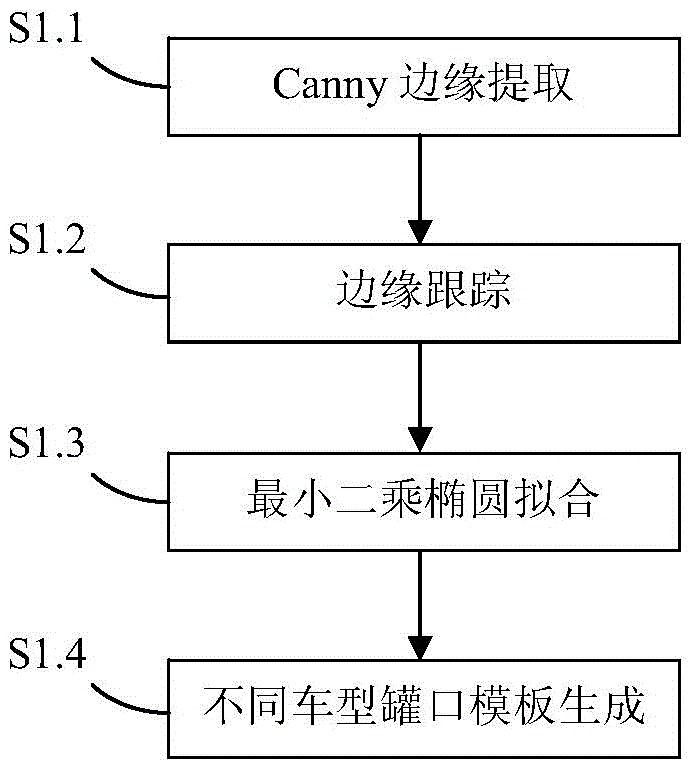

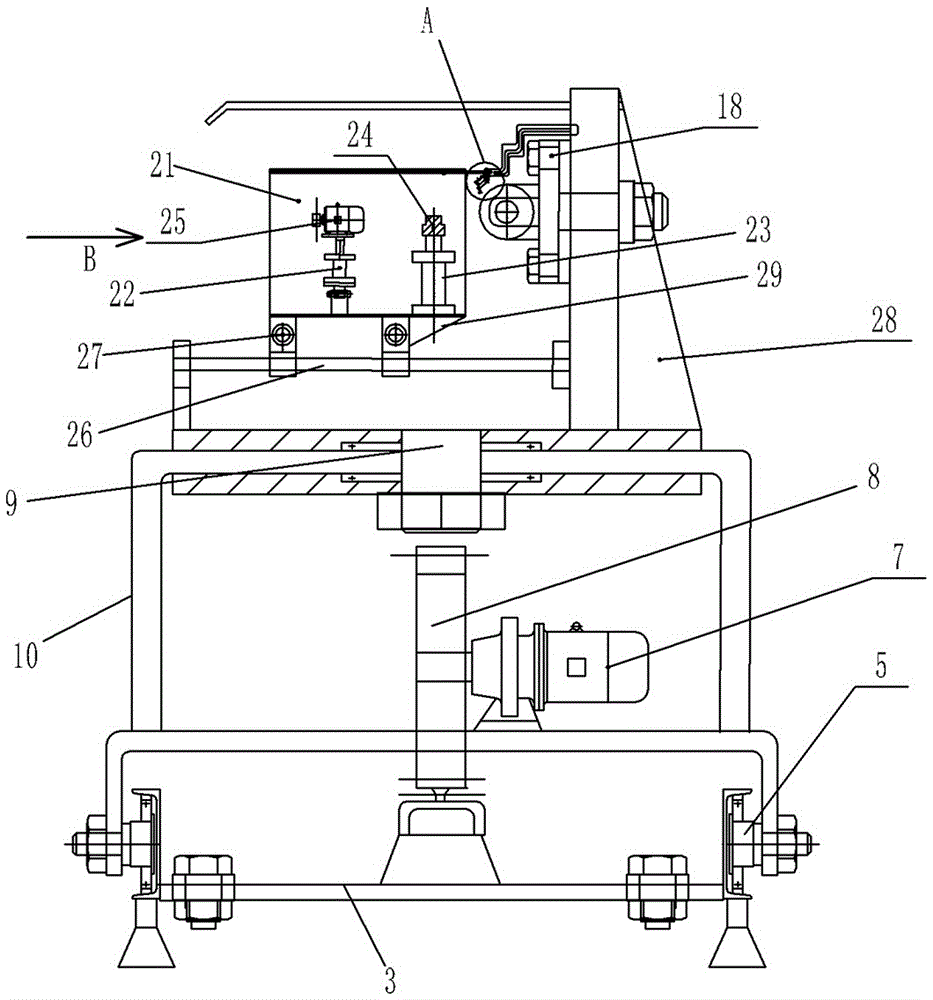

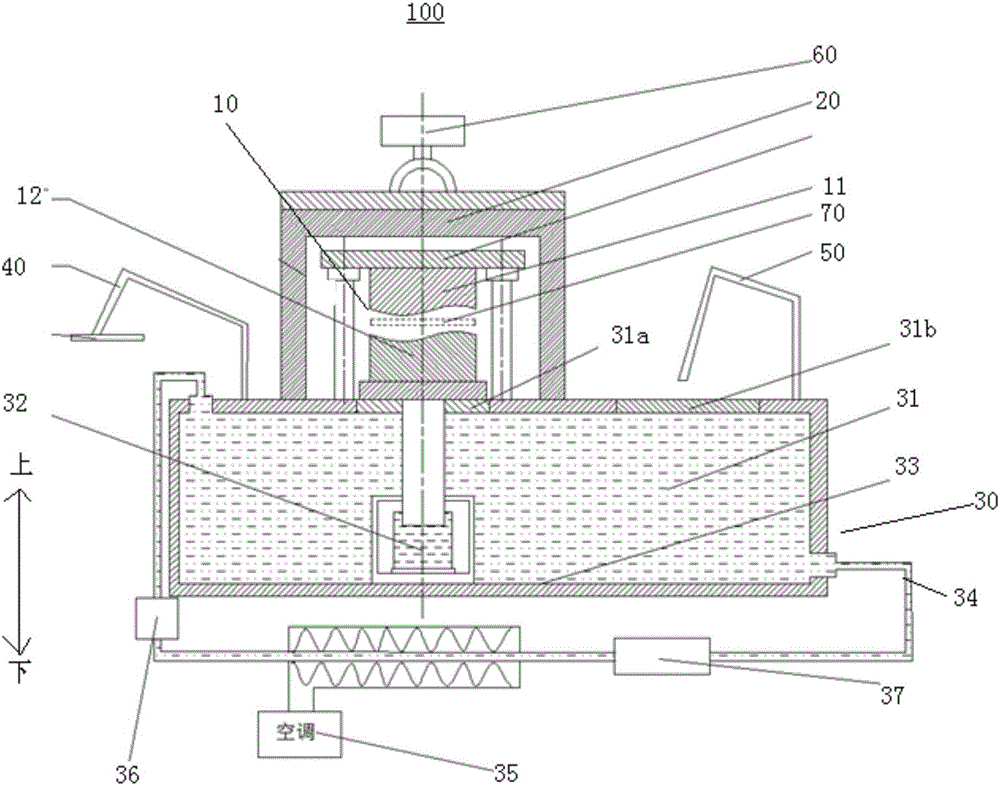

Method for visually positioning tank mouth of railway oil tank truck

ActiveCN103559704AFast positioningAvoid missing edgesImage analysisGeometric image transformationShape matchingLoading arm

The invention discloses a method for visually positioning a tank mouth of a railway oil tank truck. The method includes the steps that the single-pixel edge of the tank mouth is extracted from an image obtained when a large loading arm just faces the tank mouth and is fit to an oval, and the coordinates and the gradient of the edge of the tank mouth are calculated through an oval formula to be fit to a shape template; image pyramid decomposition is carried out on the template and an image to be searched for; the gradient information in all pyramid layers of the image to be searched for is calculated; an interesting region matched with the tank mouth and a shape matching threshold value are set, and on the decomposed layer with the lowest image resolution ratio of the pyramid, the tank mouth is positioned with the normalized gradient mutual correlation as a shape similarity metric function. The method for visually positioning the tank mouth of the railway oil tank truck has the advantages of being high in reliability, low in implementation, high in automation degree and the like.

Owner:HARBIN ENG UNIV

Preparation device for preparing anticorrosive coating on outer surface of pipeline

InactiveCN105835352AQuality improvementImprove uniformityCorrosion preventionPipe protection against corrosion/incrustationEngineeringUltimate tensile strength

The invention relates to a preparation device for preparing an anticorrosive coating on the outer surface of a pipeline. The preparation device comprises a bottom frame which is used for being movably assembled on a track extending in the axial direction of the pipeline in a guiding mode. The bottom frame is provided with a cloth roll installing rack used for installing a cloth roll and further provided with a paint spraying mechanism. The paint spraying mechanism comprises a primer spraying mechanism body used for spraying primer on the peripheral surface of the rotating pipeline and / or an outer-layer paint spraying mechanism body used for spraying outer-layer paint on a cloth belt wound on the peripheral surface of the pipeline. Primer spraying, cloth belt winding and outer-layer paint spraying can be achieved at the same time, the efficiency is high, and too much manual intervention is not needed, so that the labor intensity is relieved; and meanwhile, the rotating pipeline and the movable bottom frame are matched with each other, accordingly, the paint spraying thickness and the cloth belt winding thickness can be accurately controlled, and the uniformity and the quality of the prepared anticorrosive coating can be effectively improved.

Owner:郑州工业技师学院

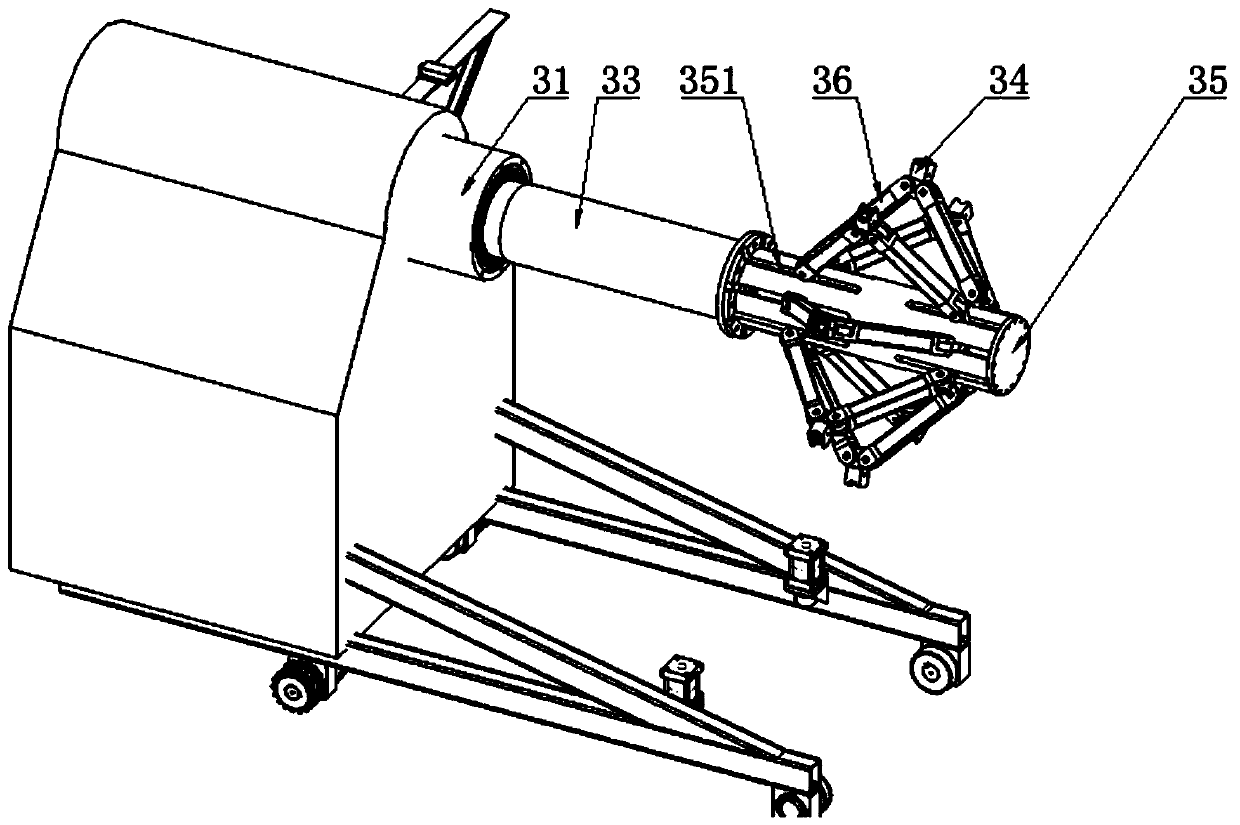

Use method of reinforcement cage seam welder

ActiveCN110000459AReduce labor intensityIncrease productivityWelding/cutting auxillary devicesWelding with roller electrodesWinding machineEngineering

The invention discloses a use method of a reinforcement cage seam welder and belongs to the field of manufacturing of reinforcement cages. The use method comprises steps as follows: the sum of main reinforcing bars is set to be A, and the included angle alpha between every two adjacent main reinforcing bars is determined; a plurality of inner-supporting bars are arranged and supported along a first straight line by an inner-supporting bar supporting device of the reinforcement cage seam welder; the main reinforcing bars are fed, specifically, one main reinforcing bar is conveyed to outer sidewalls of a plurality of inner-supporting bars by a main reinforcing bar feeding rack, and meanwhile, the number i of the conveyed main reinforcing bars is equal to i plus one; the main reinforcing bars on the main reinforcing bar feeding rack are welded to the outer side walls of the inner-supporting bars by a welder; an inner-supporting bar rotation driving device drives the inner-supporting barsto rotate; whether welding of the main reinforcing bars is completed is judged, the inner-supporting bar rotation driving device drives the inner-supporting bars to rotate around the first straight line at a constant speed if the answer is positive, meanwhile, a moving bar winding machine moves along a five straight line parallel to the first straight line, and wound bars in the moving bar winding machine are welded to the main reinforcing bars by the welder; manufacturing of a reinforcement cage is completed and if not, the main reinforcing bar feeding step is repeated. With the adoption ofthe reinforcement cage seam welder, the manufacturing efficiency of the reinforcement cages is significantly enhanced.

Owner:CHENGDU GUTE MACHIENRY WORKS

Wood-structure bearing heat preservation wallboard

The invention relates to a wood-structure bearing heat preservation wallboard and belongs to the technical field of buildings. The heat preservation wallboard comprises a wood beam, a connector bearing wood column, an internally-arranged bearing wood column, an inner side regenerative board, an outer side regenerative board and a waterproof air-permeable membrane. The assembling efficiency is high and can reach 100%; materials are single and high in standardization and generalization; workability is high, and the automation rate of production of workshop components is high; moulds or casting or curing is not needed, and time, labor and money are saved for processing; machine tool program control operation is adopted in the whole processing process, and the processing precision is high; the wood-structure bearing heat preservation wallboard is light and more orderly in appearance; the assembling speed is high, and the construction period can be shortened by folds; installation operation is obviously simplified, and requirements for workers are low; heat preservation wallboard is good in integrity, definite in force transmission, simple in structure, safe, reliable, capable of saving materials, convenient to construct, high in integration, good in heat preservation effect and durability, high in bearing force and good in economical effect, complex operation in the construction process is avoided, and the manufacturing cost is greatly reduced.

Owner:太仓市梅林印刷感光材料有限公司

Die cutting equipment for carton processing and working method thereof

InactiveCN111805969AAvoid flippingImprove production and processing efficiencyPaper-makingBox making operationsCartonPaperboard

The invention discloses die cutting equipment for carton processing and a working method thereof. The die cutting equipment comprises a conveying mechanism; a feeding mechanism, a die cutting mechanism and a collecting mechanism are sequentially arranged on the conveying path of the conveying mechanism; the feeding mechanism comprises an accommodating box for carrying out posture restraint on a paperboard and a feeding roller for carrying out feeding operation on the paperboard; the collecting mechanism comprises a separating mechanism and a material collecting piece; the separating mechanismis used for separating the board and waste after die cutting of the paperboard; and the material collecting piece is used for collecting the board and waste. According to the die cutting equipment forcarton processing and the working method thereof, the feeding process is continuous and stable to improve the automation rate of the overall machining process, and the board part and the waste part of the paperboard after die cutting are separated, so that the trouble of setting the separating procedures separately is avoided, and the producing and processing efficiency of a factory is improved.

Owner:孙同昂

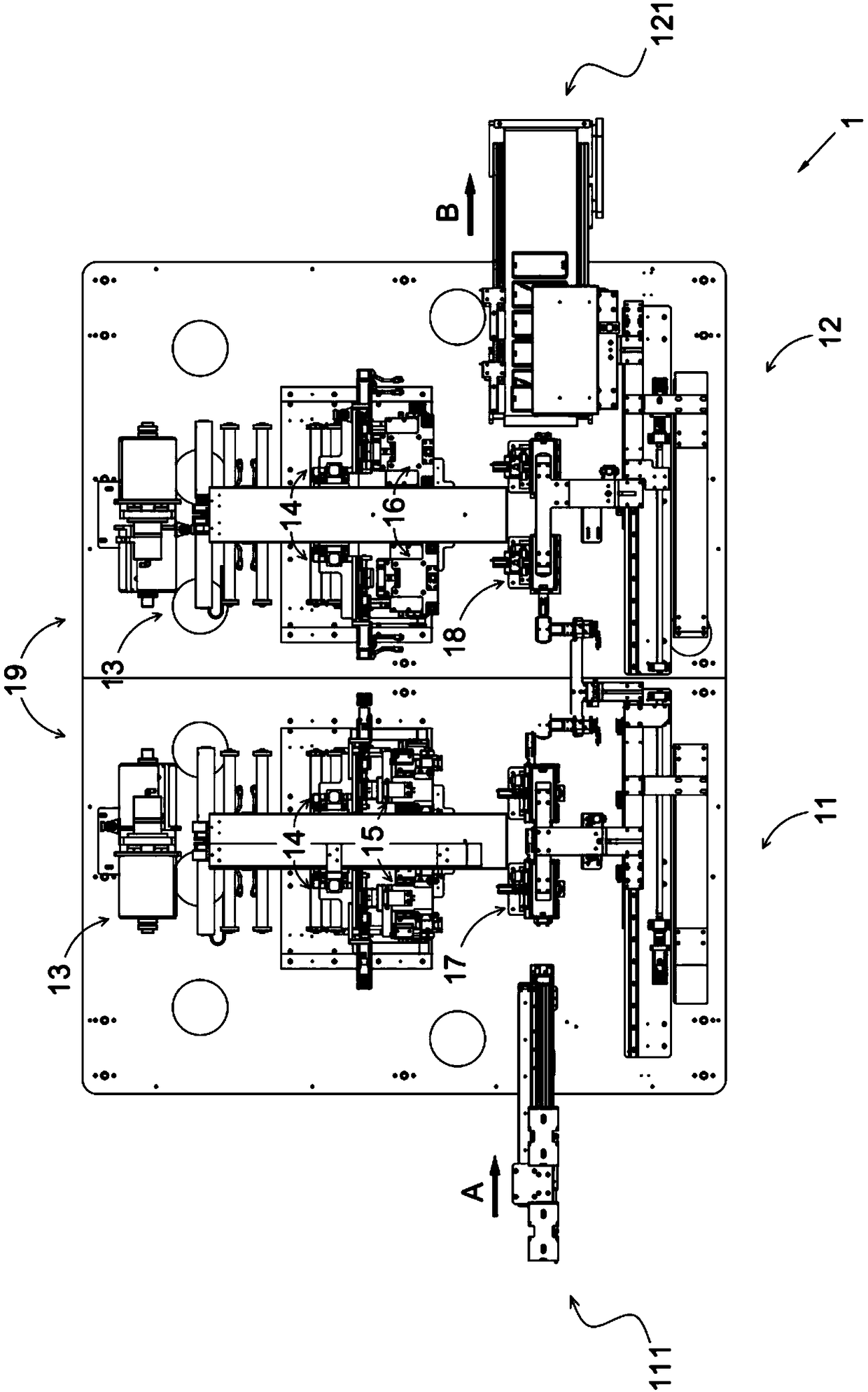

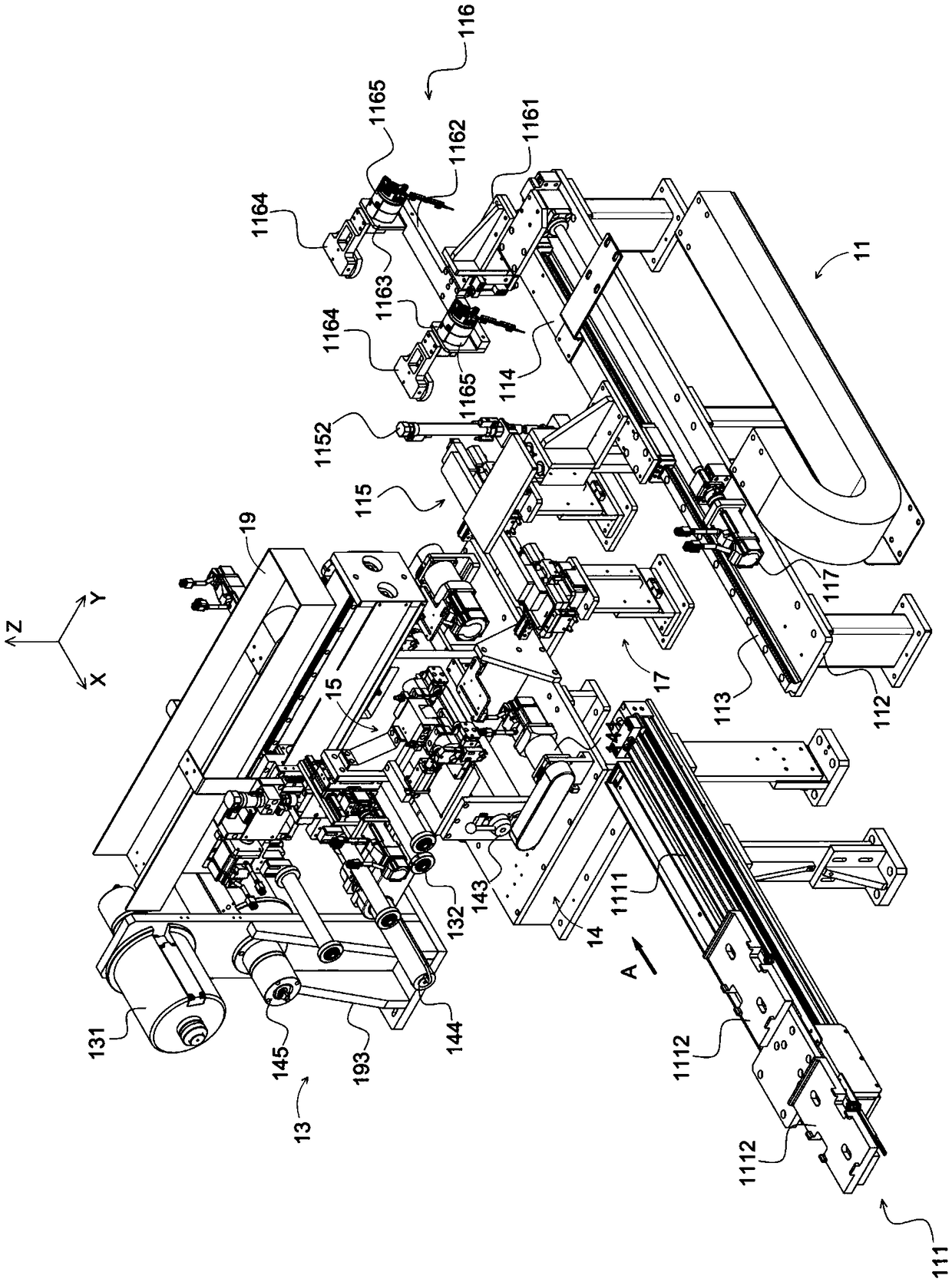

Full-automatic film coating assembly line for 3D curved glass and film coating method of full-automatic film coating assembly line

The invention discloses a full-automatic film coating assembly line for 3D curved glass and a film coating method of the full-automatic film coating assembly line. The full-automatic film coating assembly line comprises a concave face synchronous transfer assembly, a convex face synchronous transfer assembly in butt joint with the concave face synchronous transfer assembly, a concave face film coating device and a convex face film coating device. The concave face film coating device and the convex face film coating device are arranged beside the concave face synchronous transfer assembly and the convex face synchronous transfer assembly correspondingly. The full-automatic film coating assembly line is high in automation rate, a concave face film coating procedure and a convex face film coating procedure are integrated on one assembly to be carried out, the circulating cycle of the 3D curved glass is saved, surface contamination and scratches caused in the transferring and circulating process to the 3D curved glass are avoided, and the film coating efficiency and film coating quality are greatly improved. In addition, the film coating automation rate is increased, meanwhile, a filmsuction plate and a film press roll can be prevented from interference during film coating, a protection film is pasted more fully, the film coating efficiency and film coating quality are further improved, and wide market application prospects are achieved.

Owner:SUZHOU RS TECH

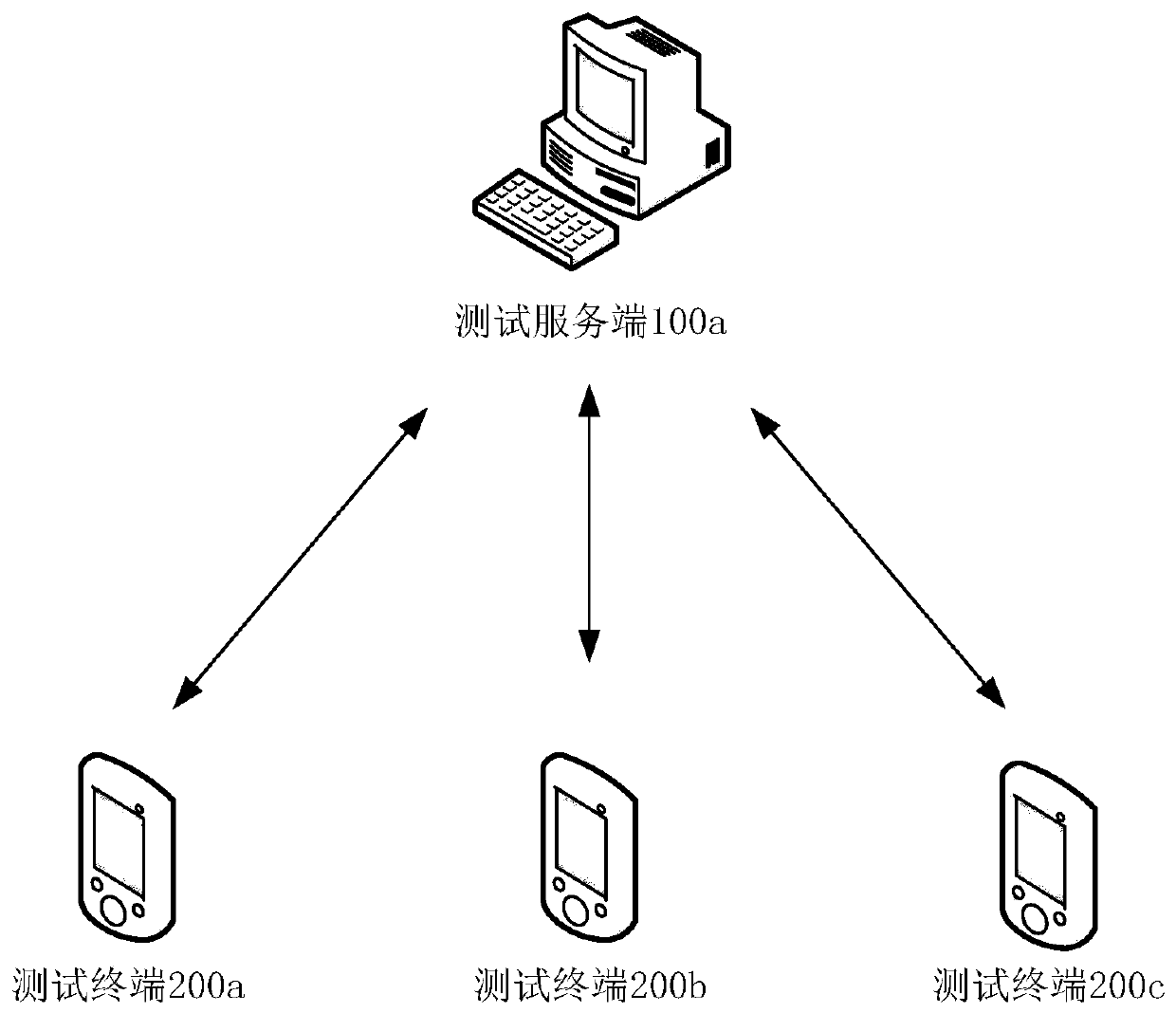

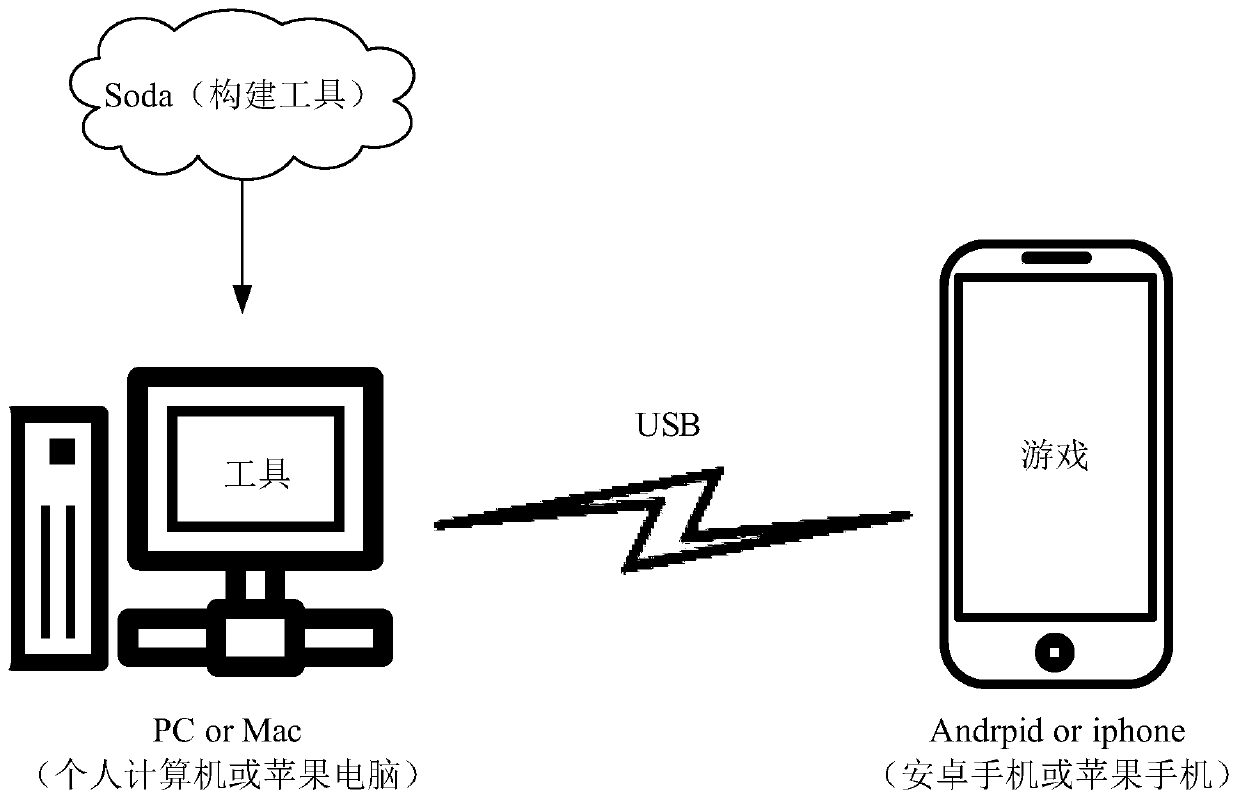

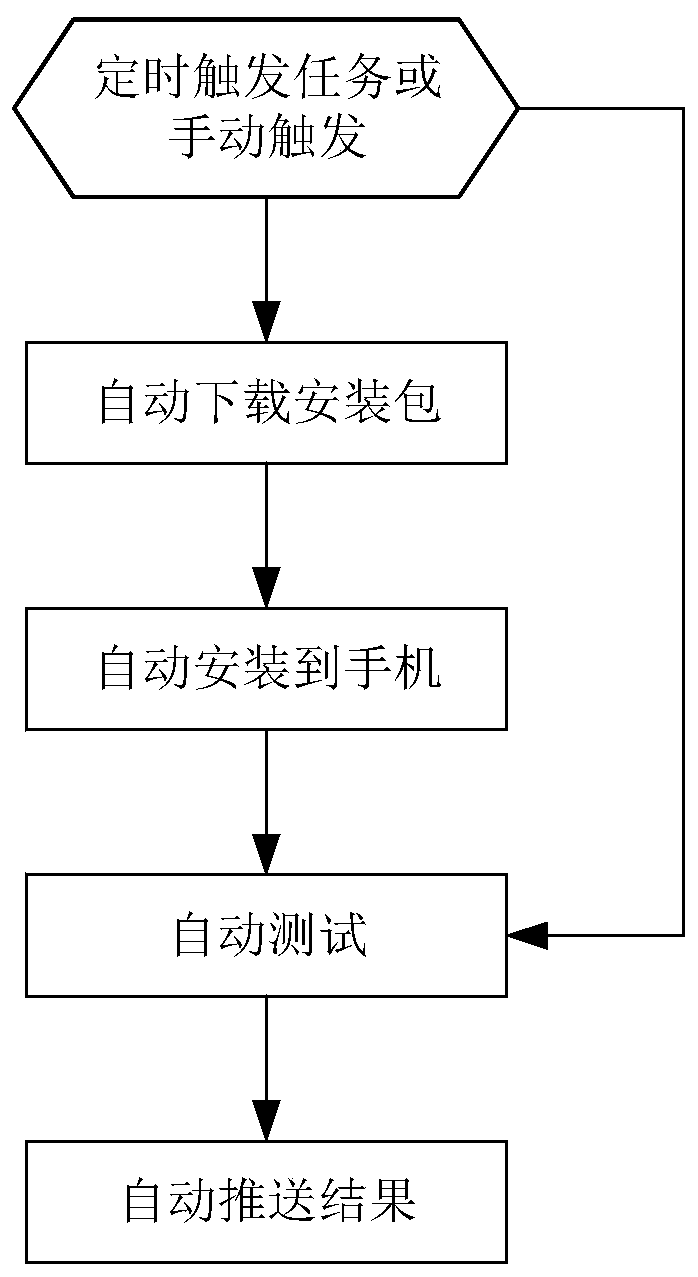

Game automation test method and device, terminal and computer storage medium

ActiveCN110781085AImplement automated testingFully automatedSoftware testing/debuggingVideo gamesTest efficiencyTest script

The embodiment of the invention discloses a game automation test method and device, a terminal and a computer storage medium. The game automation test method comprises the steps of obtaining an installation package, a test case and a test framework of a to-be-tested game according to description information of the to-be-tested game; according to a test script command matched with the to-be-testedgame, sending the installation package to at least one test terminal, controlling the at least one test terminal to install the installation package, sending the test case to the at least one test terminal, and controlling the at least one test terminal to execute at least one operation event for the game to be tested; and generating a test report of the to-be-tested game according to a test result of executing at least one operation event for the to-be-tested game by the at least one test terminal. By adopting the embodiment of the invention, various games can be automatically downloaded, installed and tested, and the test result can be pushed, so that the game test efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

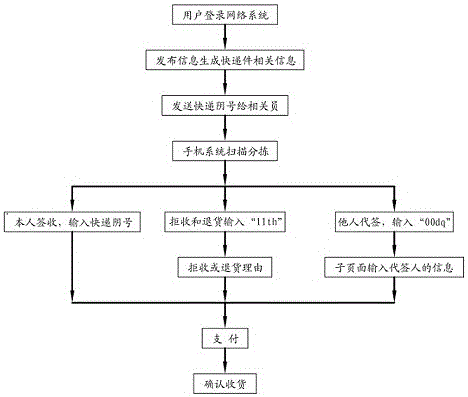

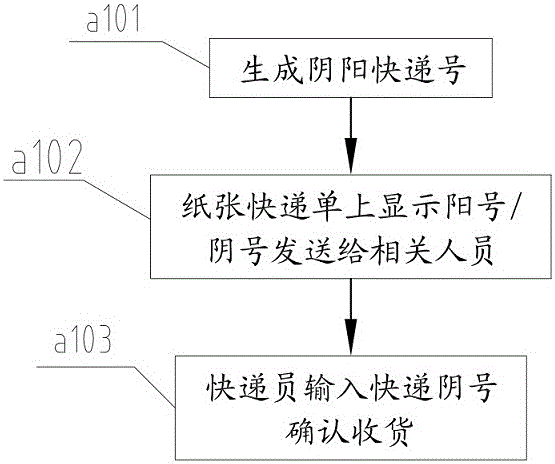

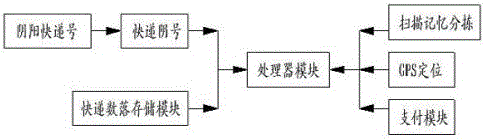

Internet plus express delivery system and yin-yang express number network signing

The invention relates to an Internet plus express delivery system so as to realize express delivery order network signing. The system comprises an information release module, a scanning module, a GPRS positioning module, a network signing module, a payment module and a processor module, and information connection among a merchant platform, an express delivery company, a sender and a receiver through yin-yang express numbers of an express delivery order. According to the invention, the express delivery system is accessed through a networked mobile phone, and functions of express delivery network signing, information release, network payment on delivery, express delivery scanning and the like are realized. The express delivery system changes an existing paper express delivery order manual signing mode and an express delivery POS machine network signing mode, adopts a network signing technology, and reduces a link that a courier affirms goods reception by rescanning; the process of delivering parcels by scattered users is reconstructed, and an express delivery order automatic generation technology is adopted to replace manual writing of an express delivery order at present; and meanwhile, express delivery information can be queried at any time and places by adopting a GPRS query technology. The express delivery system provided by the invention improves the accuracy, the safety, the reliability and the confidentiality of an existing express delivery system, and the cost of express delivery is reduced at the same time.

Owner:李昱成

Clip type feeding mechanism

PendingCN108408389AIncrease automation rateShorten feeding intervalMetal working apparatusConveyor partsEngineeringSurface plate

The invention discloses a clip type feeding mechanism which comprises a mounting panel, a clip type material box arranged on the mounting panel, and an ejection assembly for periodically eject workpieces in the clip type material box in sequence. The multiple workpieces to be fed are arranged in the clip type material box, the ejection assembly is arranged beside the clip type material box, and the clip type material box can slide on the mounting panel in a reciprocating manner and can selectively ascend and descend in the vertical plane. The ejection direction of the ejection assembly is perpendicular to the sliding direction of the clip type material box. The clip type feeding mechanism has the high automation rate, the feeding interval is greatly shortened, feeding efficiency is greatlyimproved, and the subsequent processing or assembling procedure can be carried out fast and orderly.

Owner:SUZHOU RS TECH

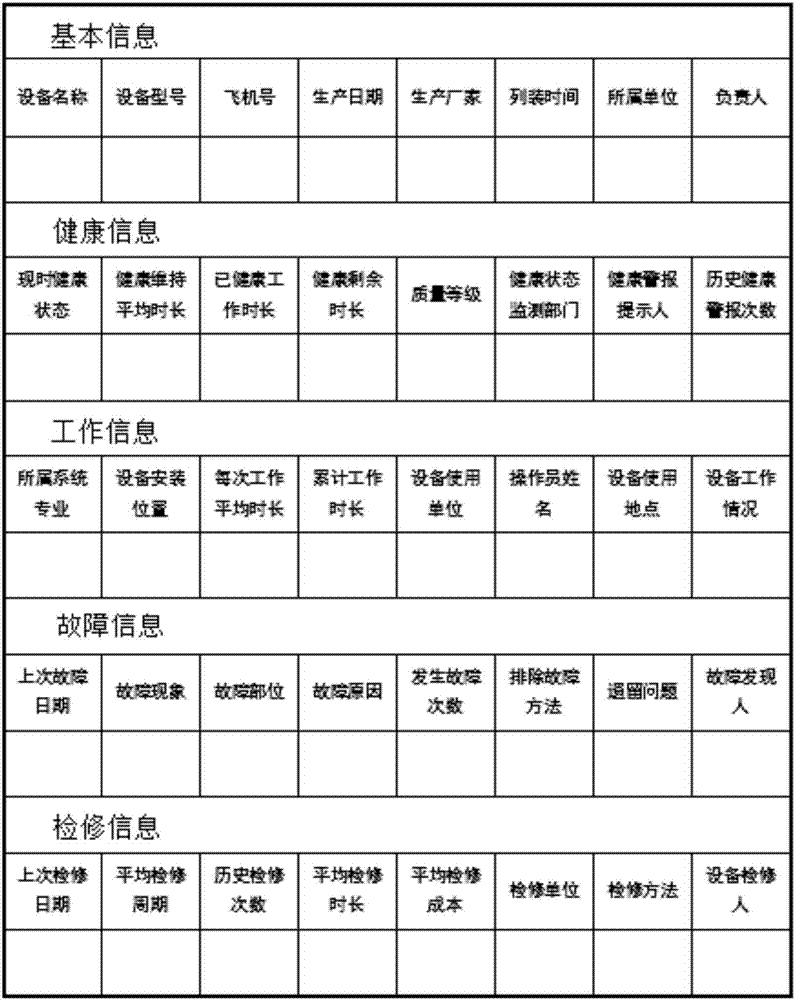

Aircraft equipment electronic resume system and application method

InactiveCN107015809AImprove securityImprove acceleration performanceRegistering/indicating working of vehiclesSoftware engineeringData setData management

The invention relates to an aircraft equipment electronic resume system and an application method. The technical problems of low safety, accuracy and efficiency in the prior art are mainly solved. Based on flight big data analysis and application, the system is established on a row data management and control platform, information data corresponding to all pieces of equipment of an aircraft is automatically extracted by traversing aircraft flight information input by a user on the platform and uploaded files, a corresponding data set is generated in a fixed format and uploaded to a background data server, and all equipment resumes stored originally are automatically updated. While it is ensured that all the aircraft equipment resumes are safely stored and conveniently used, an automatic resume management and control and application mechanism technical scheme is provided for the user, the problem is solved better, and the aircraft equipment electronic resume system can be applied to aircraft ground support equipment.

Owner:QINGDAO CAMPUS AVIATION ENG COLLEGE OF THE PEOPLES LIBERATION ARMY NAVY

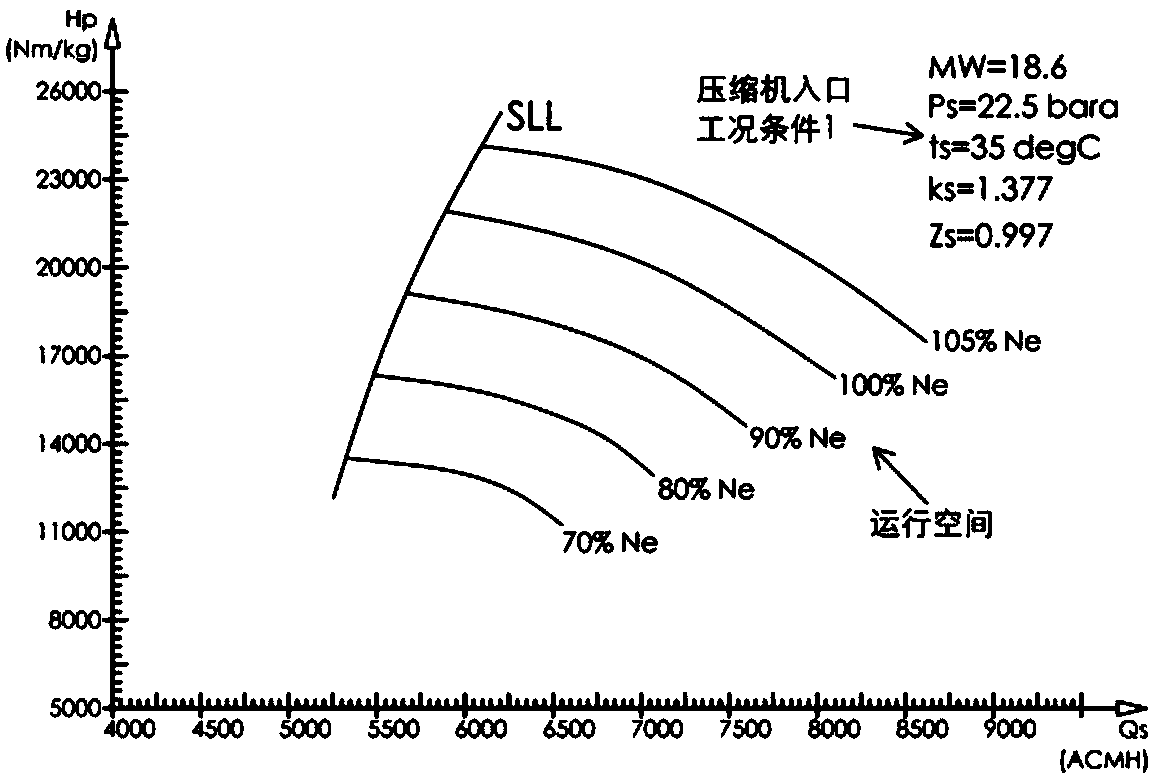

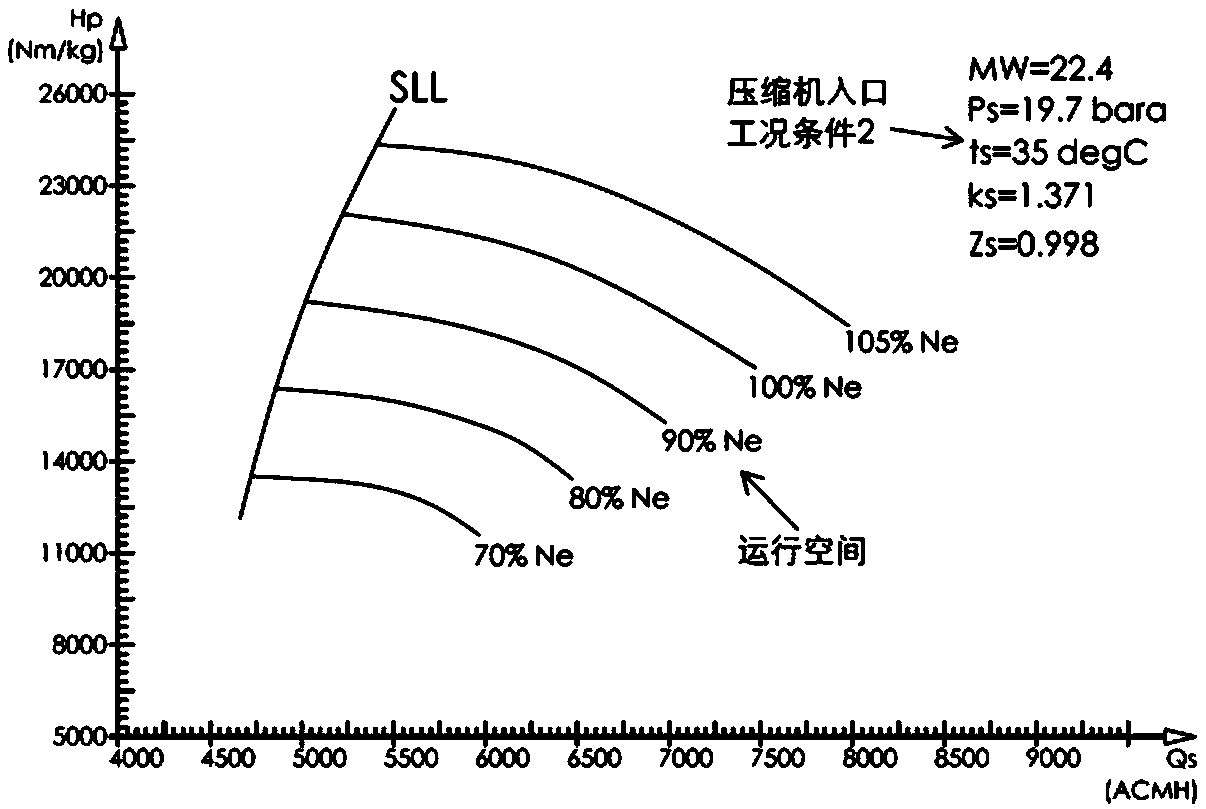

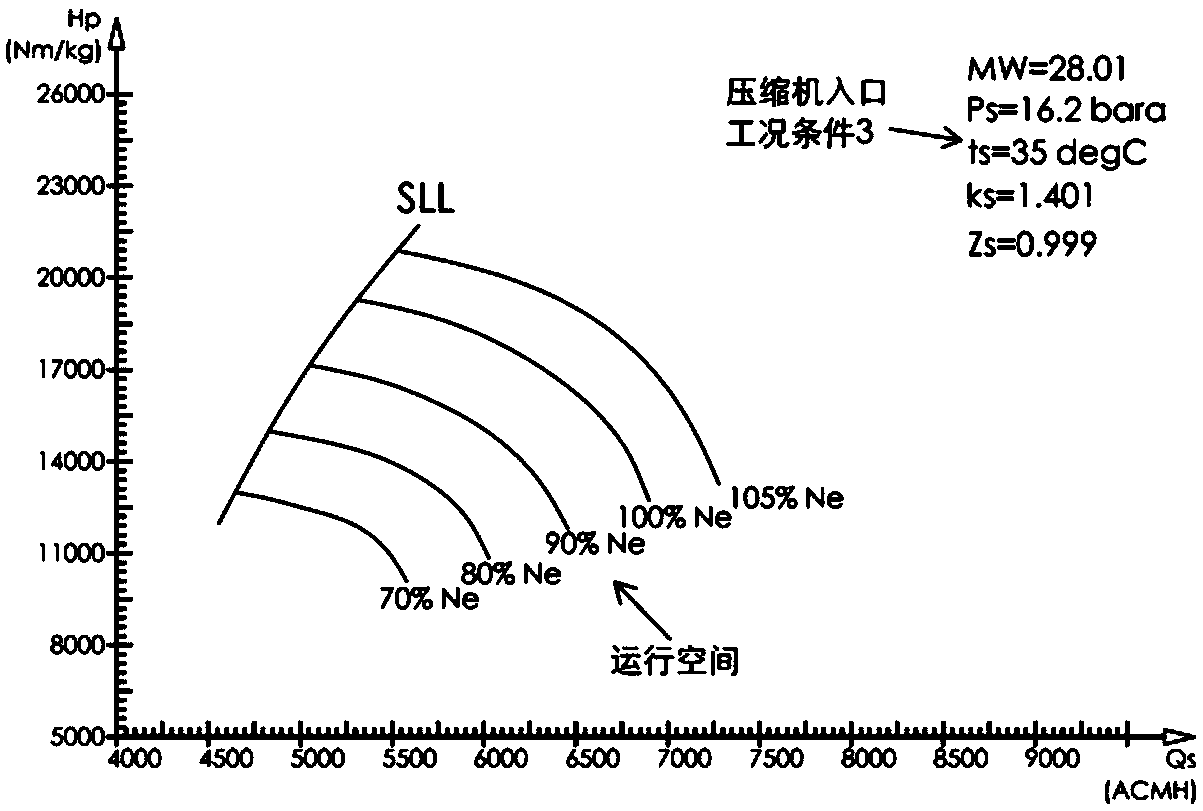

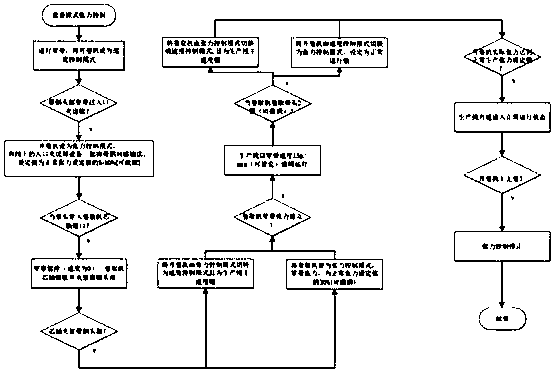

Compressor dynamic anti-surge control method based on variable working condition running

InactiveCN109209979AAccurate dynamic anti-surge controlEfficient dynamic anti-surge controlPump controlNon-positive displacement fluid enginesEngineeringStreamflow

The invention provides a compressor dynamic anti-surge control method based on variable working condition running. The method comprises the steps that S1, points are uniformly acquired on a surge limit line SLL in performance curves of a compressor, and a simplified polytropic head hr is calculated according to the type of vertical coordinates of the performance curves; S2, a simplified flow square qr<2> is calculated; S3, a dimensionless coordinate system (qr<2>, hr) is established by using the simplified flow square qr<2> as the horizontal coordinate and using the simplified polytropic headhr as the vertical coordinate; and S4, compressor running spaces and SLLs of the centrifugal compressor under different inlet running working conditions are subjected to normalization treatment in thedimensionless coordinate system, so that the only one SLL is formed, specifically, the mechanical structure and an internal flow channel of the centrifugal compressor are constant. The compressor dynamic anti-surge control method based on variable working condition running can achieve accurate, efficient and safe centrifugal compressor dynamic anti-surge control and remarkably improve the automation rate of compressor unit control.

Owner:北京一诺先科装备技术有限公司

Online detecting and sorting device

InactiveCN106000907AImprove product qualityWill not affect the next processSortingAssembly lineCommunicating Junction

The invention relates to the technical field of sorting equipment, in particular to an on-line detection and sorting device, which includes an assembly line for transmitting magnetic needle boxes and a controller. The assembly line for transmitting magnetic needle boxes transmits magnetic needle boxes. A pushing device is installed on one side of the assembly line of the needle box, and an imaging device is installed on the pushing device, the probe of the imaging device is located directly above the magnetic needle box, and the output end of the pushing device is provided with a push plate through a push rod , the controller stores a standard image database in the memory and communicates with the image signal data captured by the probe of the imaging device. If the plugged foam or soft magnet is skewed, the production quality of the assembly is good, and the next process will not be affected. No quality inspection personnel are required to test, the labor intensity is small, the automation rate is high, and the production cost is low.

Owner:江苏健裕健康医疗器械有限公司

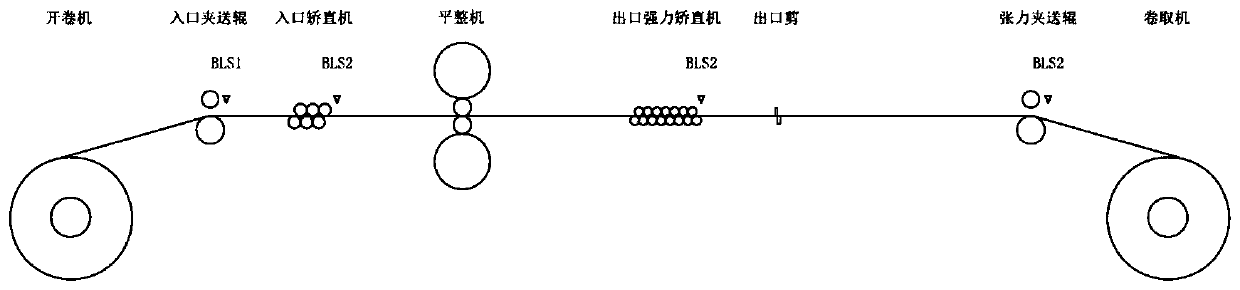

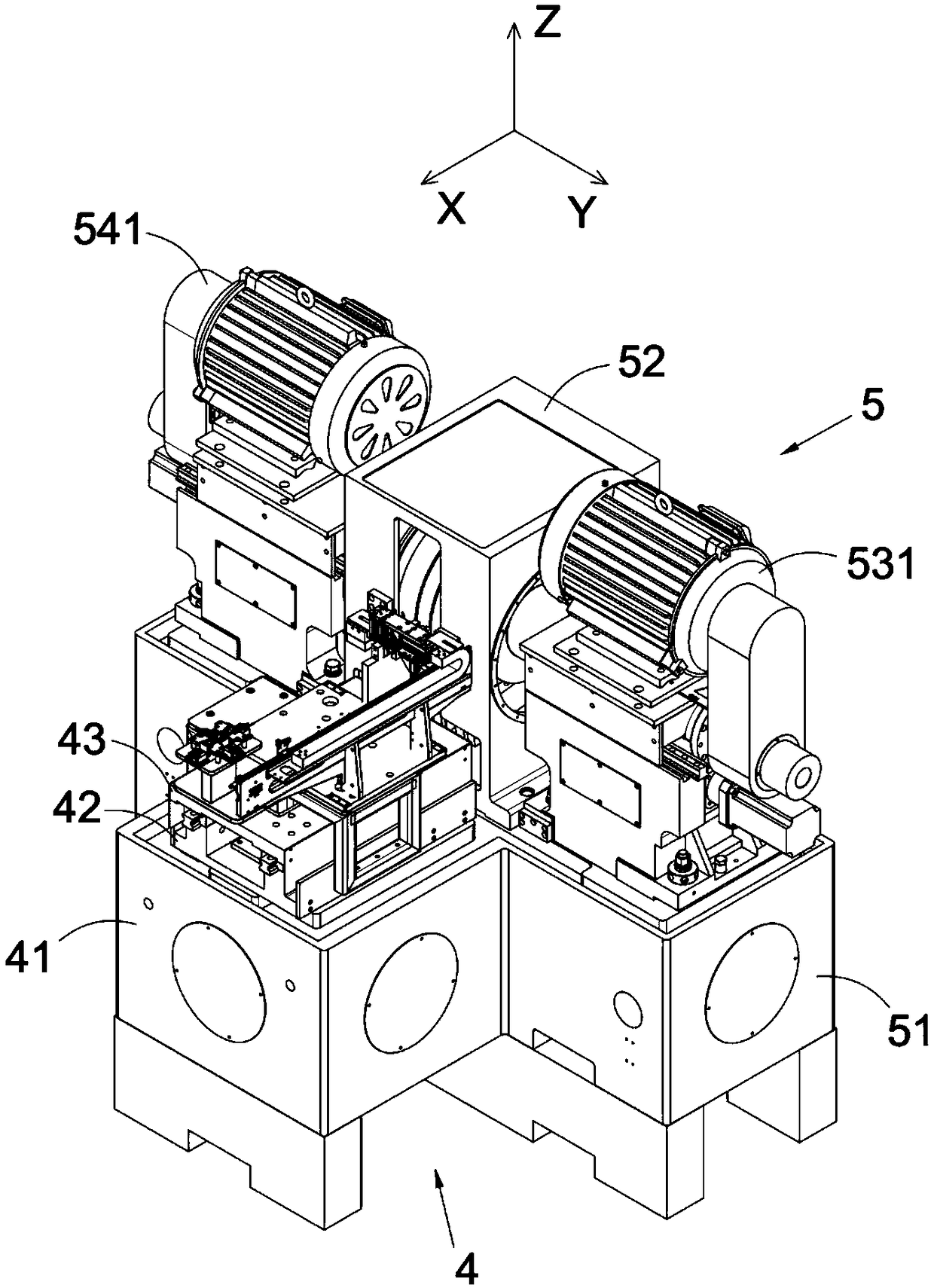

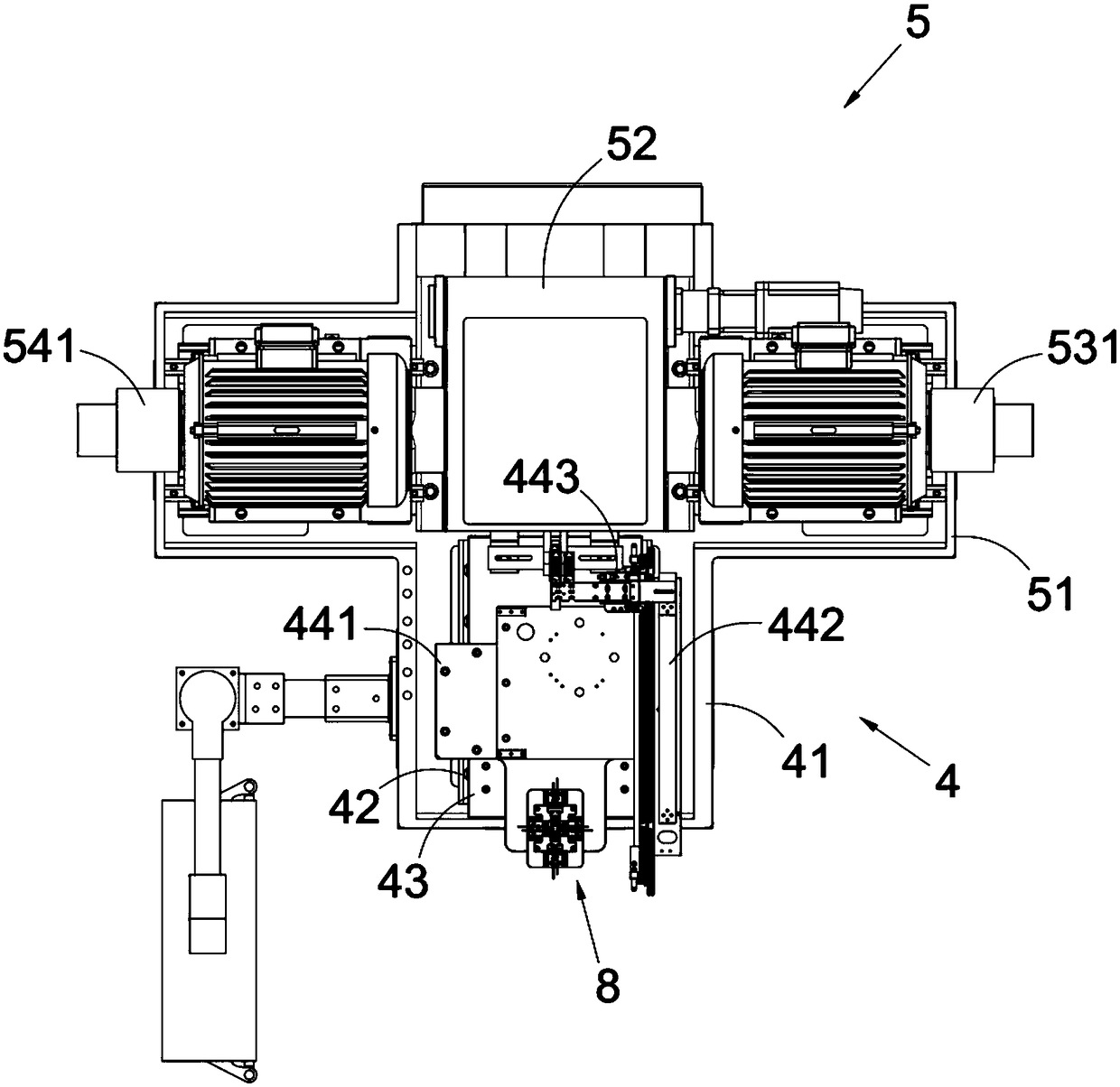

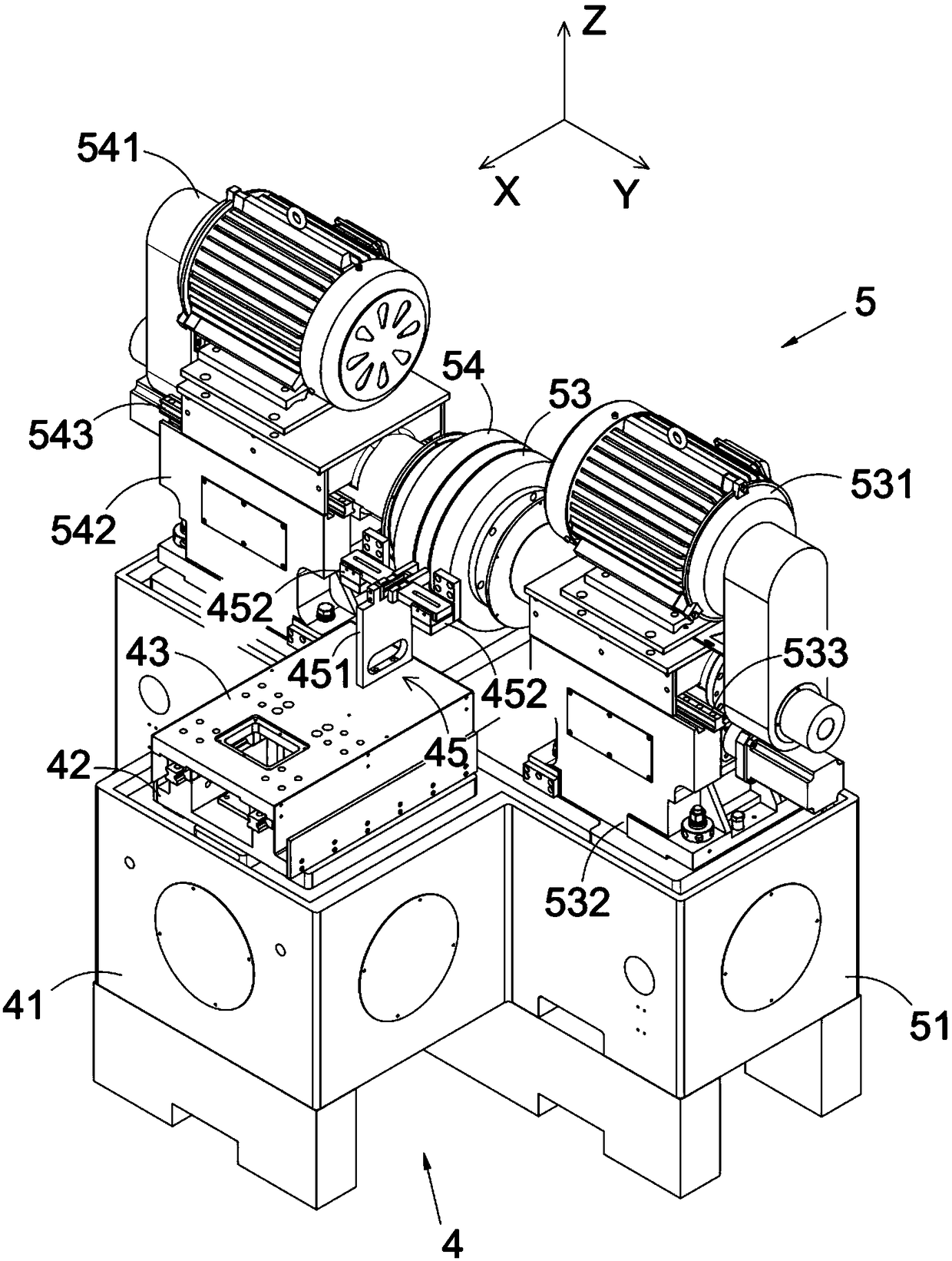

Tension control method for leveling and winding unit

ActiveCN109940048AAvoid large jitterAvoid easy scratches and other problemsTension/compression control deviceStrip steelTension control

The invention discloses a tension control method for a leveling and winding unit, and the tension control method has two working modes: rewinding and leveling. According to the tension control method,stable and controllable tension of the unit in the tape threading and operating process is achieved, and the problems that strip steel shakes severely and is liable to scratch and the like are solved; and powerful support is provided for achieving automatic tape threading of the unit and improving the automation degree as well as the product quality and the finished product rate of hot-rolled strip steel.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

Automatic locating type side face grinding device

PendingCN108655857AImprove loading and unloading efficiencyIncrease automation rateEdge grinding machinesGrinding carriagesDischarge efficiencyEngineering

The invention discloses an automatic locating type side face grinding device. The automatic locating type side face grinding device comprises a side face grinding machine and a transverse moving mechanism in butting connection with the side face grinding machine; wherein a secondary locating mechanism is arranged on the transverse moving mechanism; the transverse moving mechanism comprises a supporting bottom plate, a supporting top plate arranged on the supporting bottom plate and slidably connected with the supporting bottom plate and a transverse moving assembly arranged on the supporting top plate in a straddling mode; the secondary locating mechanism is arranged at the front end of the supporting top plate; a workpiece bearing assembly is arranged at the tail end of the supporting topplate. Through the automatic locating type side face grinding device, the feeding and discharging efficiency is improved, and the automatic rate of the grinding process is further increased; meanwhile, a workpiece can be located secondarily before grinding, the grinding accuracy is further improved, and the automatic locating type side face grinding device has broad market application prospects.

Owner:SUZHOU RS TECH

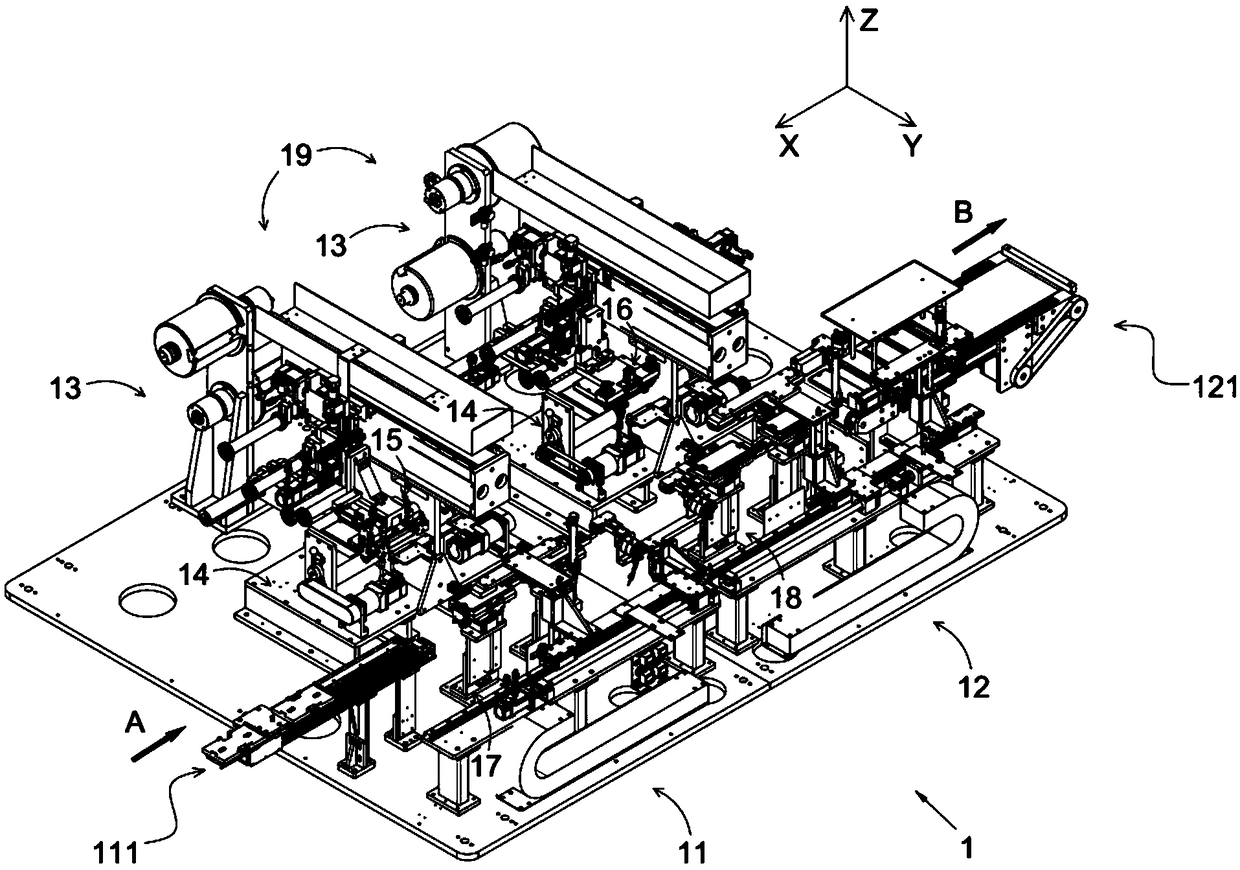

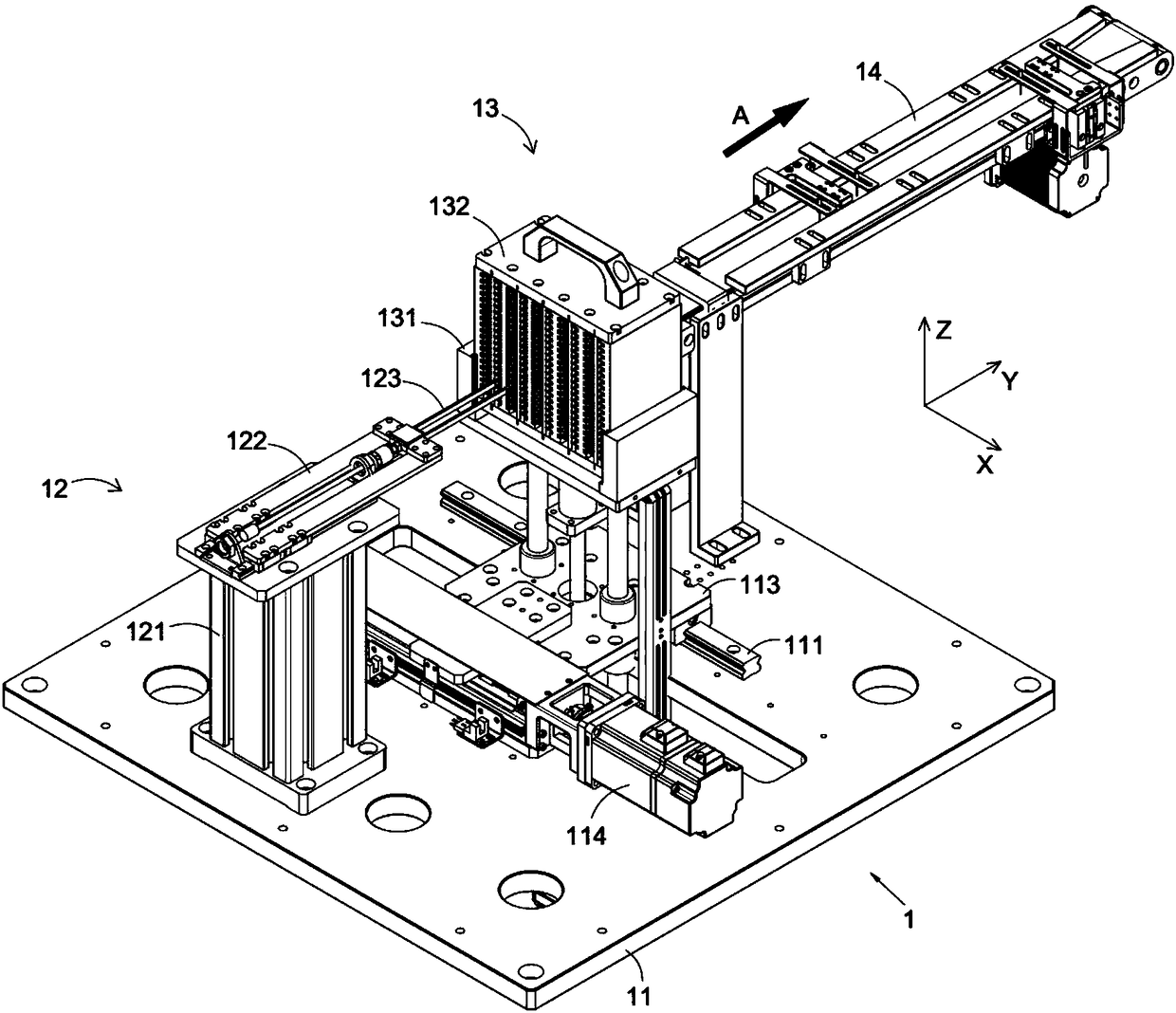

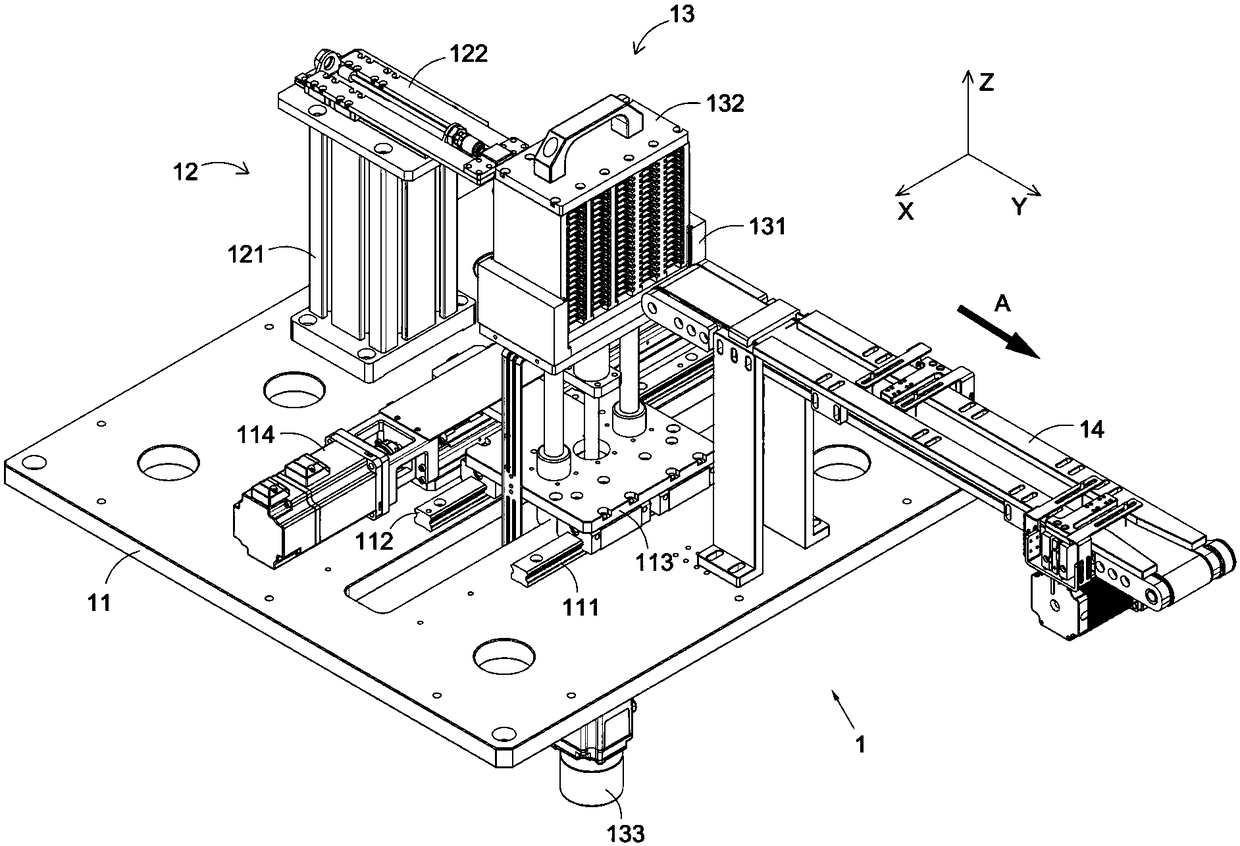

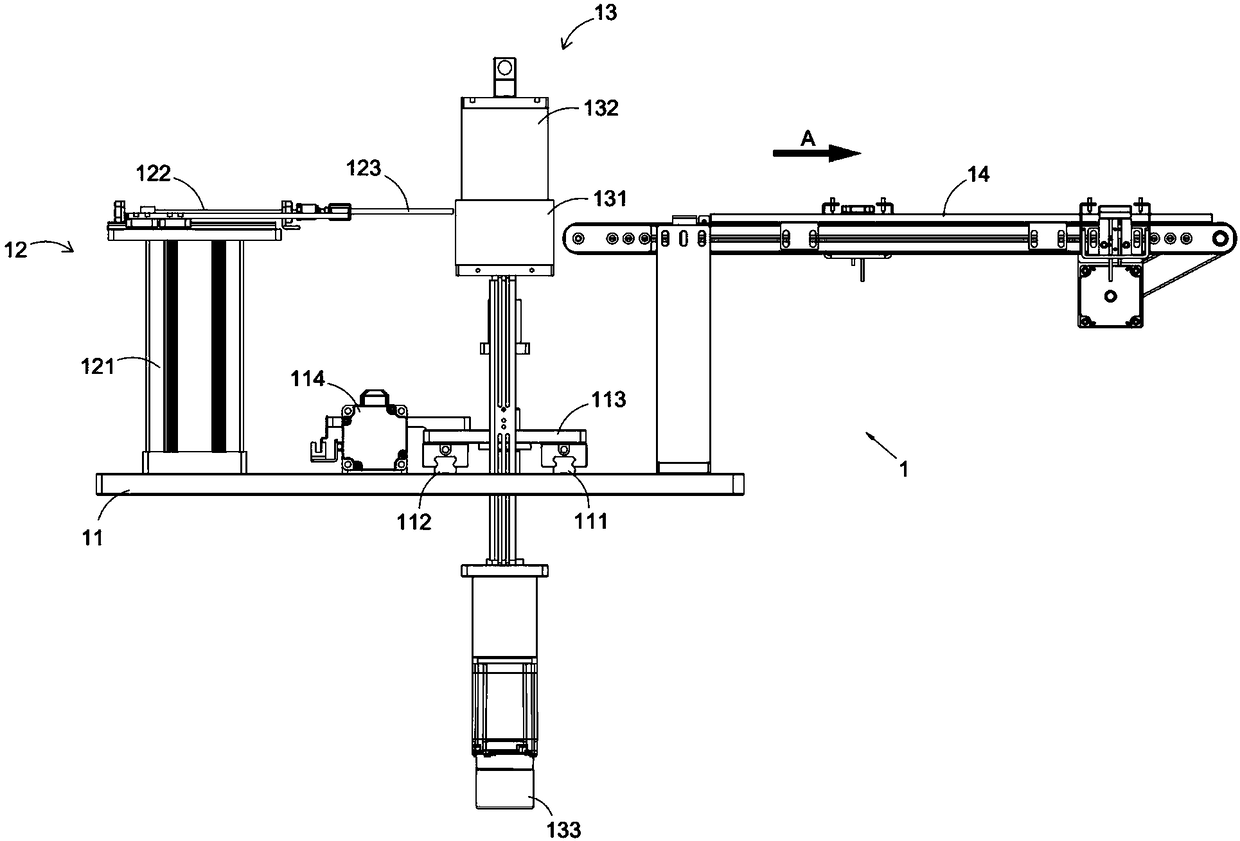

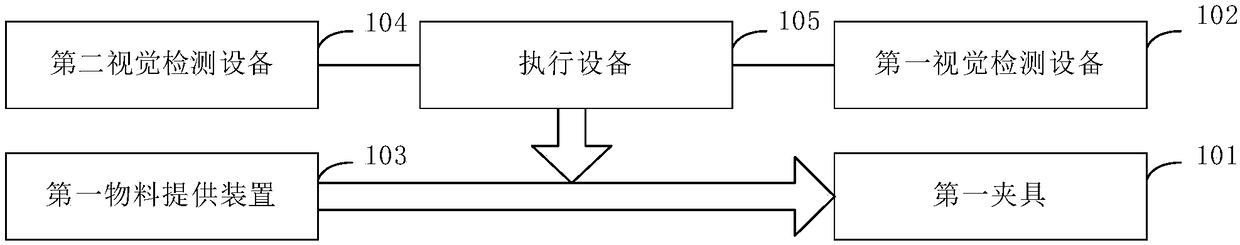

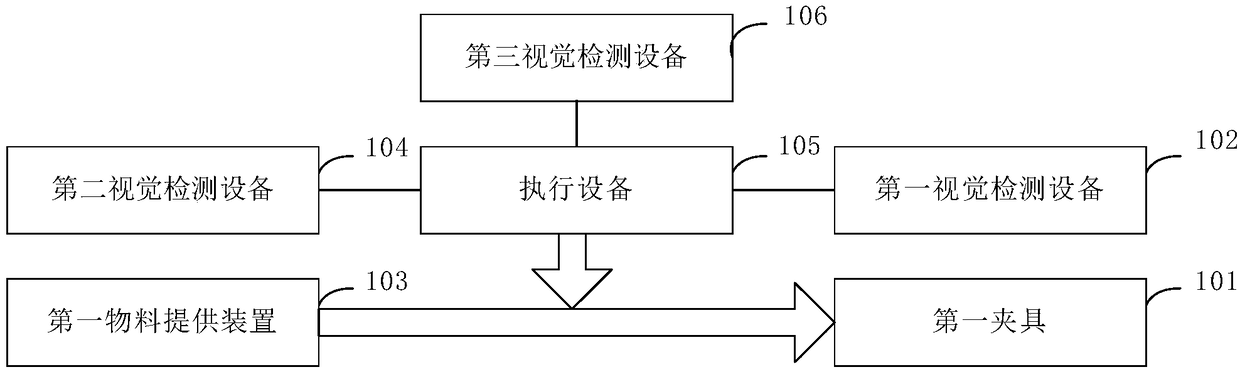

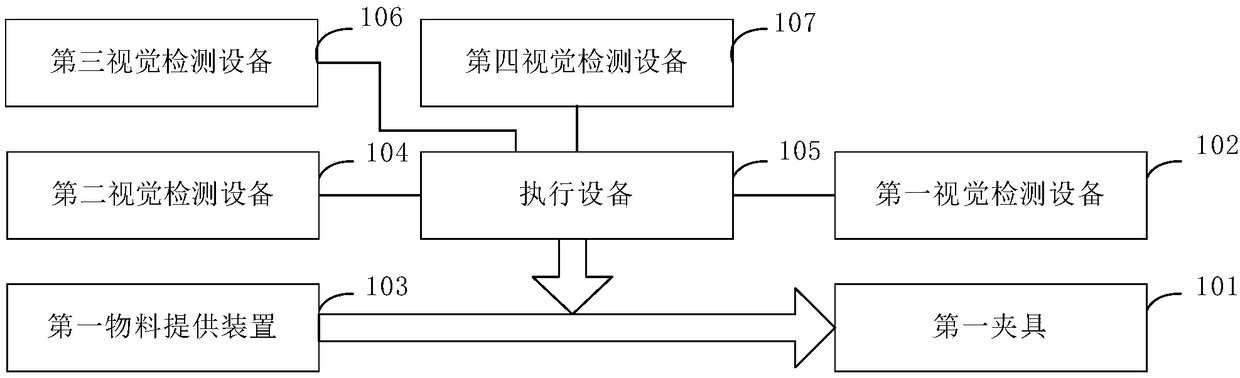

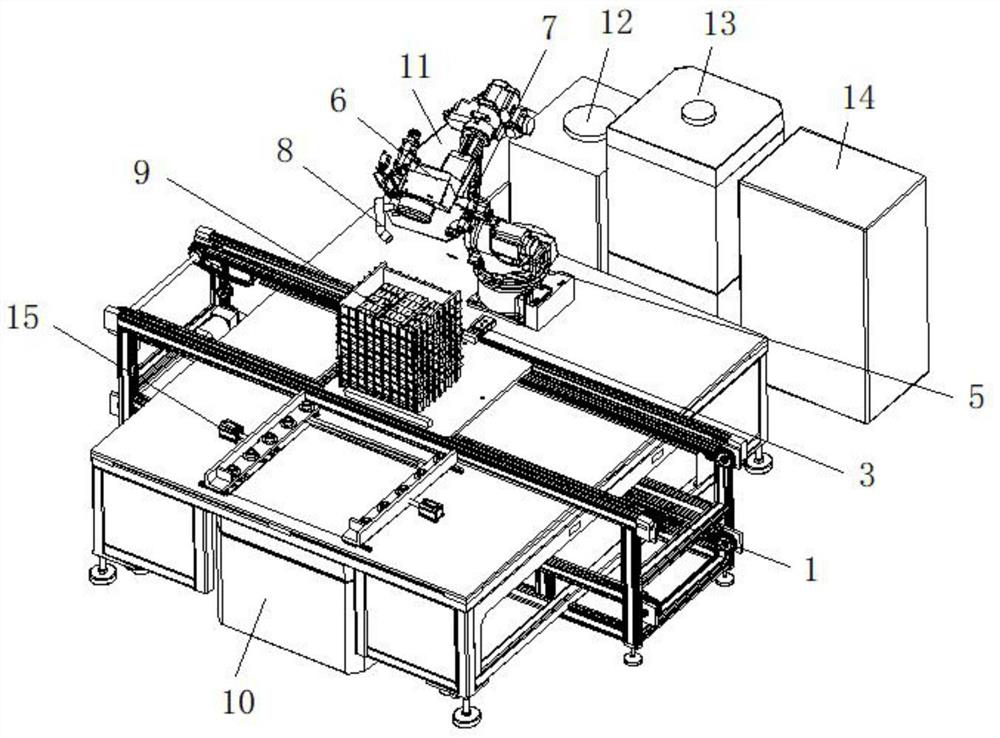

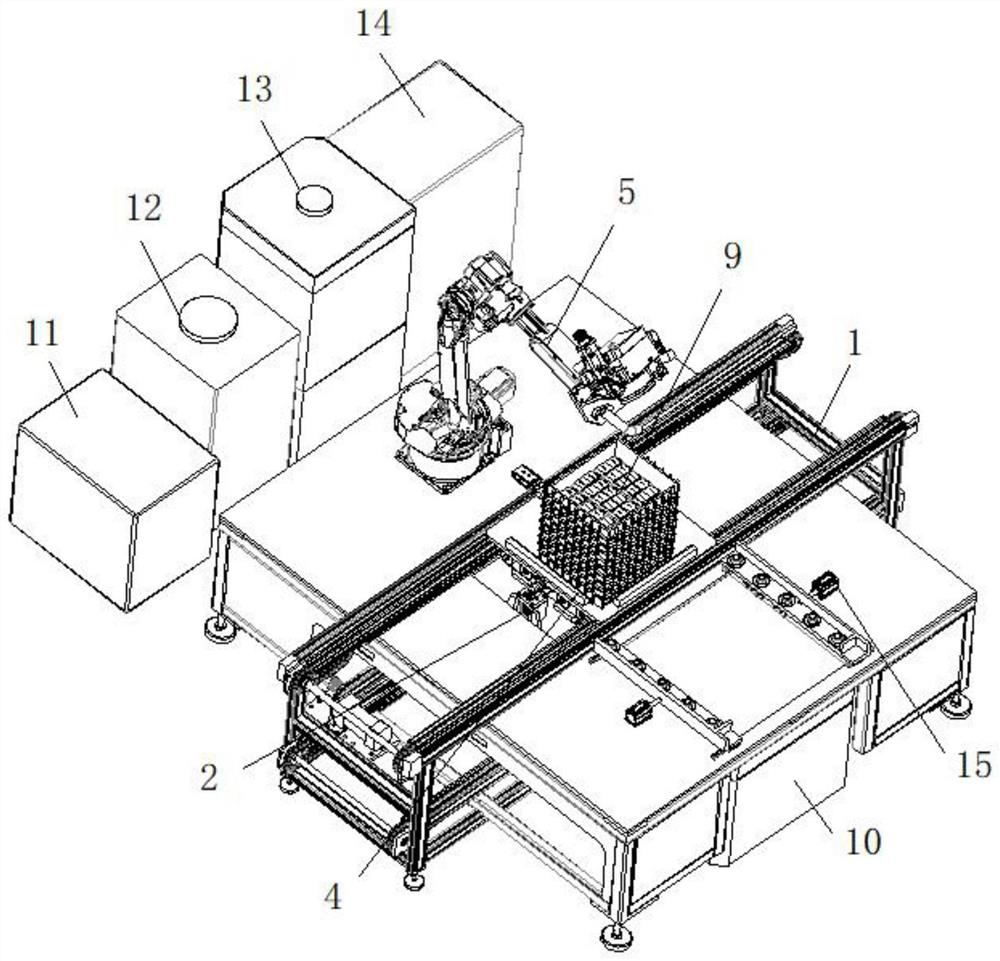

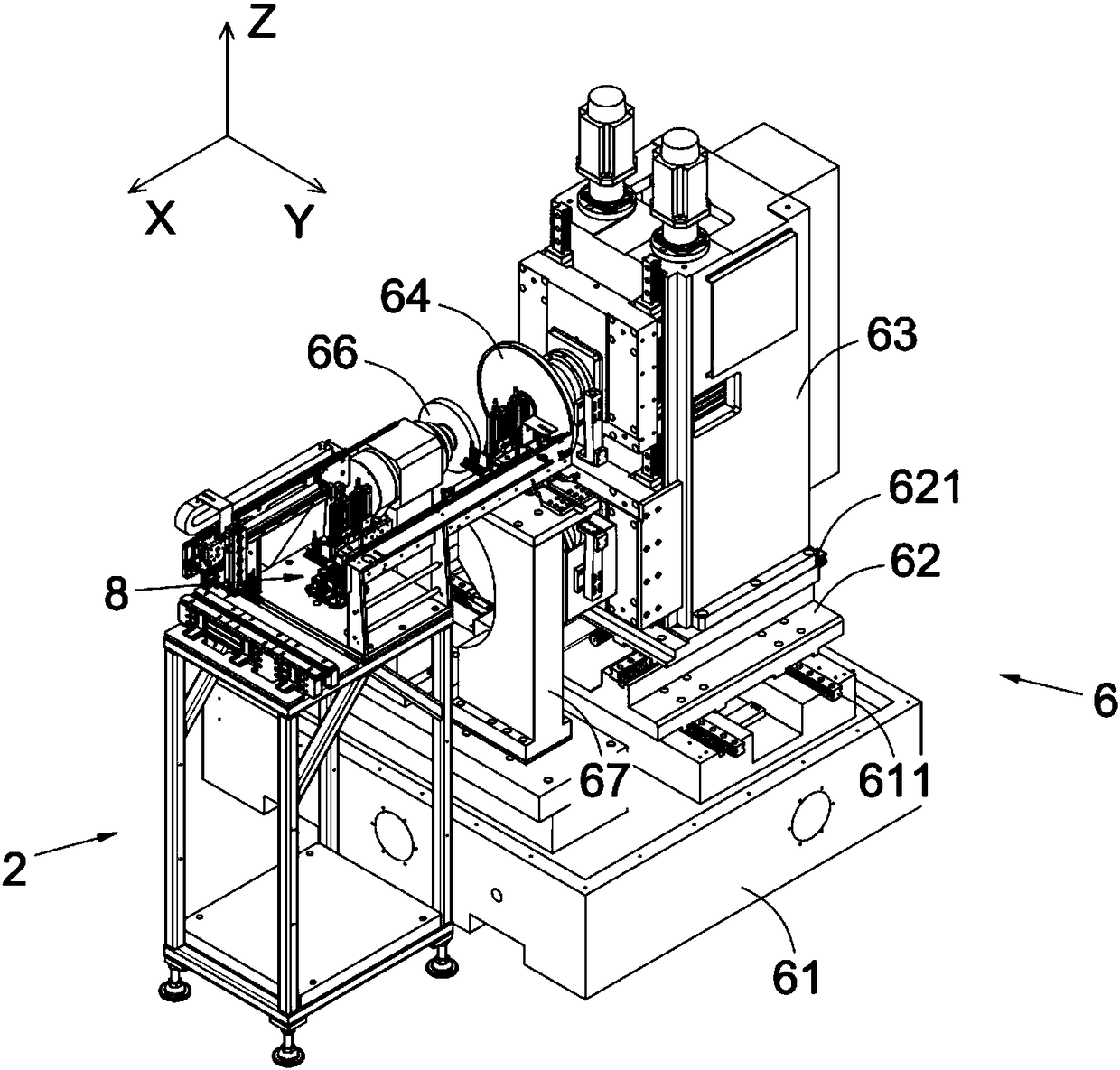

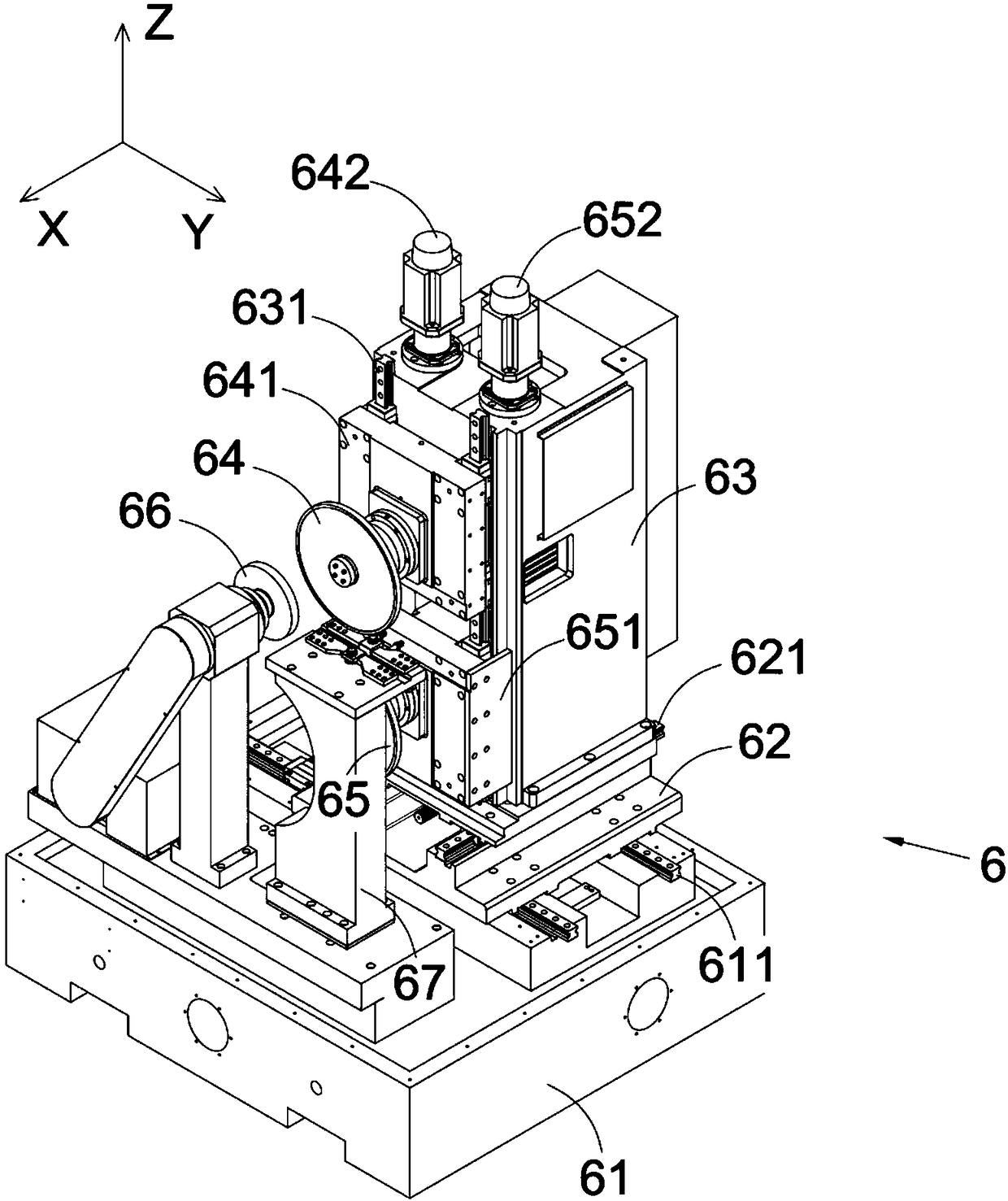

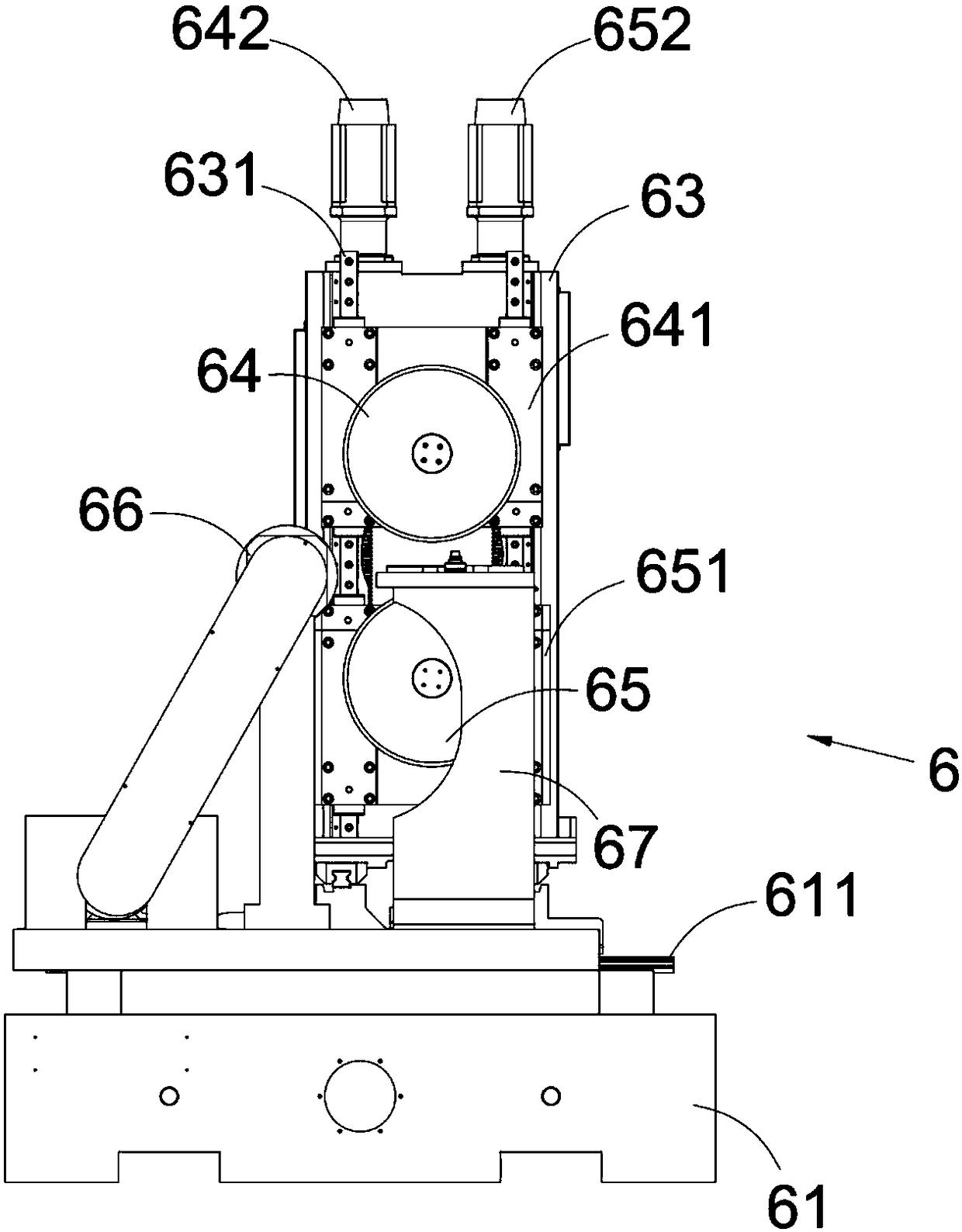

Vision-positioning-based assembly system and assembly method and production line

ActiveCN109500591ARealize automatic matching adjustmentIncrease automation rateAssembly machinesUsing optical meansProduction lineVision inspection

The embodiment of the invention discloses a vision-positioning-based assembly system and assembly method and a production line. The vision-positioning-based assembly system comprises a first fixture,a first vision inspection device, a first material supply device, a second vision inspection device and an execution device, wherein the first fixture is used for clamping and fixing a first assemblyunit; the first vision inspection device is arranged in the position, opposite to first locating holes, of the first fixture clamping and fixing the first assembly unit and used for detecting the first locating holes of the first assembly unit to obtain first position information of the first assembly unit; the first material supply device provides a second assembly unit; the second vision inspection device is used for detecting the second assembly unit provided by the first material supply device to obtain second position information of the second assembly unit; the execution device acquiresthe second assembly unit from the first material supply device according to the second position information and assembling the second assembly unit to the first assembly unit according to the first position information, and a target unit is obtained. The vision-positioning-based assembly system provided by the embodiment of the invention can improve the automatic assembly efficiency.

Owner:智车优行科技(上海)有限公司

Laser cutting flow guide row device for power battery disassembly

InactiveCN112570907AReduces the risk of short circuit firesSolve the problem of manual labor intensityWaste accumulators reclaimingLaser beam welding apparatusPower batteryLaser ranging

The invention relates to the technical field of power battery disassembly, in particular to a laser cutting flow guide row device for power battery disassembly. The laser cutting flow guide row devicecomprises a conveyor, a blocking assembly, a positioning assembly, a transfer assembly, a robot, a laser cutting head, a CCD (Charge Coupled Device) positioning and laser ranging assembly, a dust suction pipe, a battery pack and a laser; the positioning assembly is fixedly arranged on the conveyor; the transferring assembly is fixedly installed in the middle of the conveyor; the blocking assemblyis fixedly installed on the transferring assembly; the robot is fixedly installed in the middle of the rear portion of the conveyor; and the free end of the robot is in transmission connection with the laser cutting head. The purpose of quickly and safely cutting a power battery flow guide row is achieved; the problem of high labor intensity of workers is solved; meanwhile, harm to people is avoided; potential safety hazards are eliminated; the problem of large cuttings during milling is avoided; the risk of short circuit and fire catching of a battery pack can be reduced; the phenomenon of tool sticking is avoided; and the production efficiency is improved.

Owner:深圳市德龙智能高科技有限公司

Automatic feeding and discharging type upper and lower tank grinding device

PendingCN108406539AStable clampingRealize the degree of automationGrinding carriagesAbrasive surface conditioning devicesDischarge efficiencyButt joint

The invention discloses an automatic feeding and discharging type upper and lower tank grinding device. The automatic feeding and discharging type upper and lower tank grinding device comprises an upper and lower tank grinder, a feeding and discharging mechanism in butt joint with the upper and lower tank grinder and a secondary positioning mechanism arranged in the feeding and discharging mechanism, wherein the feeding and discharging mechanism comprises a machine frame and further comprises a taking guide rail and a feeding guide rail which are arranged on the machine frame. The upper and lower tank grinder comprises a fixing seat, a connecting seat slidably connected to the fixing seat, and a grinding disc mounting seat slidably connected to the connecting seat. The automatic feeding and discharging type upper and lower tank grinding device is small in size and compact in structure, has a high automation rate and improves feeding and discharging efficiency; a to-be-ground workpiececan be stably clamped, and the automation degree of workpiece clamping and grinding can be improved; the matching degree of a clamping procedure and a grinding procedure can be improved; and in addition, a grinding disc can be repaired online after abraded, so that grinding precision and grinding efficiency are greatly improved.

Owner:SUZHOU RS TECH

Hot stamping device

ActiveCN106424279AThe process steps are simpleIncrease automation rateShaping toolsQuenching devicesHot stampingHeat losses

The invention discloses a hot stamping device which comprises a die and a heating cover. The die is covered with the heating cover so that the heating cover can heat the die and a blank in the die. According to the hot stamping device, the process of conveying the heated blank into the die can be omitted, and therefore the problems that the blank is oxidized and heat losses are caused can be solved; and furthermore, some steps of a hot stamping forming technology can be omitted, the steps of the hot stamping forming technology can be simple, and the automation rate is high. In addition, the hot stamping device is simple in structure, and cost of equipment needed for hot stamping forming can be reduced.

Owner:BAIC MOTOR CORP LTD

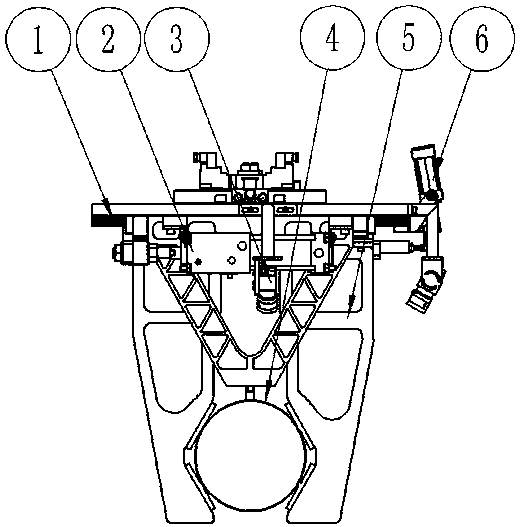

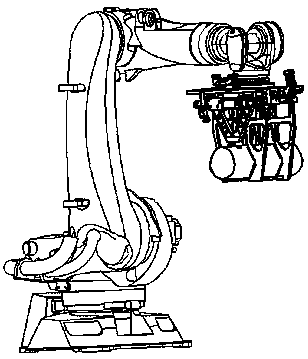

Actuator of binocular vision positioning system

InactiveCN109227577ASolve precise positioningSave time in transitManipulatorControl systemEngineering

The invention discloses an actuator of a binocular vision positioning system, which comprises a binocular vision system and a clamping mechanism, wherein the binocular vision system consists of two cameras and a control system; a clamping mechanism comprises clamping jaws, a linkage mechanism, a clamping cylinder and a linear sliding rail; the linkage mechanism is arranged between the clamping jaws at the two sides, the clamping jaw at one side is connected with the clamping cylinder and retracts and moves along the sliding rail under the driving of the cylinder, the clamping jaw at the otherside is driven to carry out the motion with an opposite direction through the linkage mechanism until the clamping jaws at the two sides are completely attached to a workpiece. The invention has the advantages that: according to the actuator of the binocular vision positioning system, the accurate positioning of the actuator and work piece is better, the transfer time of the work piece is shortened, the universality is strong, the automation rate of production is improved by combining with the use of a control system of a robot, the labor intensity of workers is reduced, the function of humanfactors in the system is reduced, and the production efficiency is improved.

Owner:大连四达高技术发展有限公司

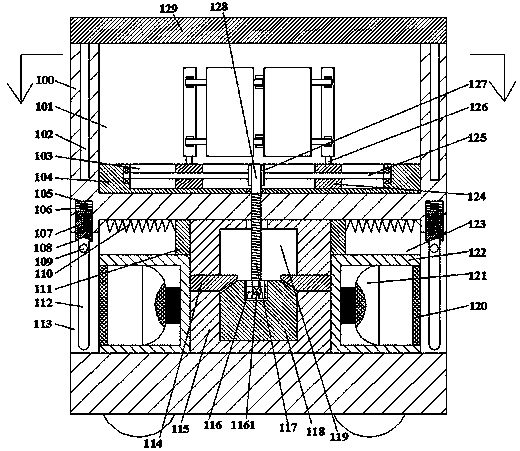

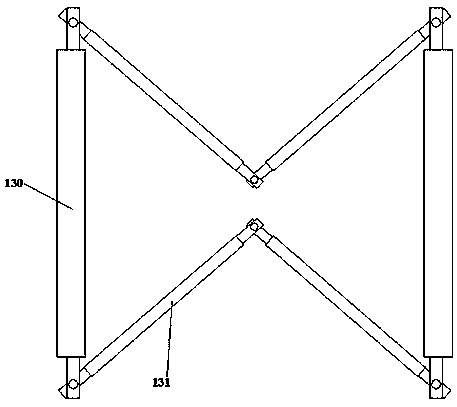

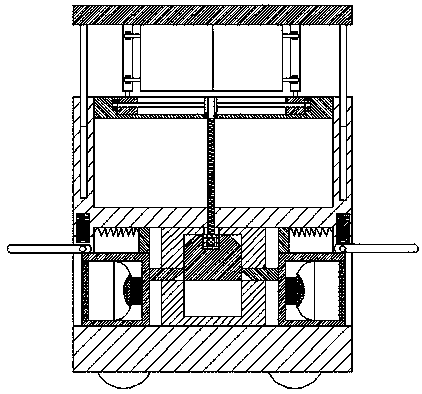

Information security evaluation system

InactiveCN108397663AEasy maintenanceSimple structureStands/trestlesIdentification meansEngineeringEvaluation system

The invention discloses an information security evaluation system. The information security evaluation system comprises a vehicle body as well as a first cavity and a second cavity which are sequentially formed in the vehicle body from top to bottom, wherein the top of the first cavity penetrates through the end surface of the top of the vehicle body and a first slide guide block is connected in the first cavity in a manner of slide fit; a first slide guide groove with an upward opening is formed in the first slide guide block; second slide guide blocks which form left-right symmetry are connected in the first slide guide groove in a manner of slide fit; an adjustment thread rod extending to left and right is connected in each second slide guide block in a manner of thread fit; the tail ends extending to left and right, of the adjustment thread rods, are connected with the left inner wall and the right inner wall of the first slide guide groove in a manner of rotation fit; and a turbine located between the two slide guide wheels is arranged on the adjustment thread rod. The information security evaluation system disclosed by the invention is simple in structure, and convenient to operate, store, move and carry.

Owner:NANAN XINCAN BRAND OPERATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com